A kind of multilevel titanium dopamine composite material and its preparation method and application

A technology for titanium dopamine and composite materials, applied in the field of multi-level titanium dopamine composite materials and their preparation, can solve the problems of performance attenuation, poor conductivity, complicated preparation methods, etc., and solves the problems of poor conductivity, which is beneficial to industrial-scale production and preparation process. Simple, efficient and safe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

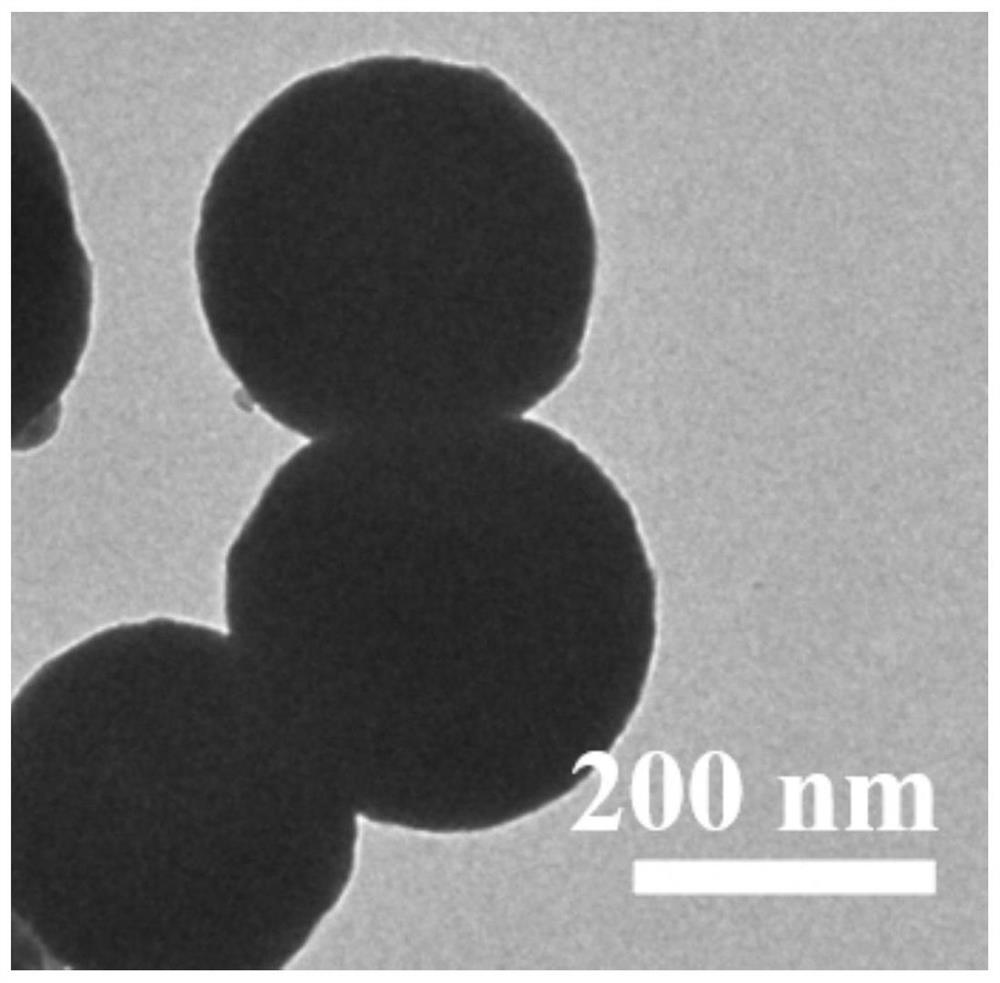

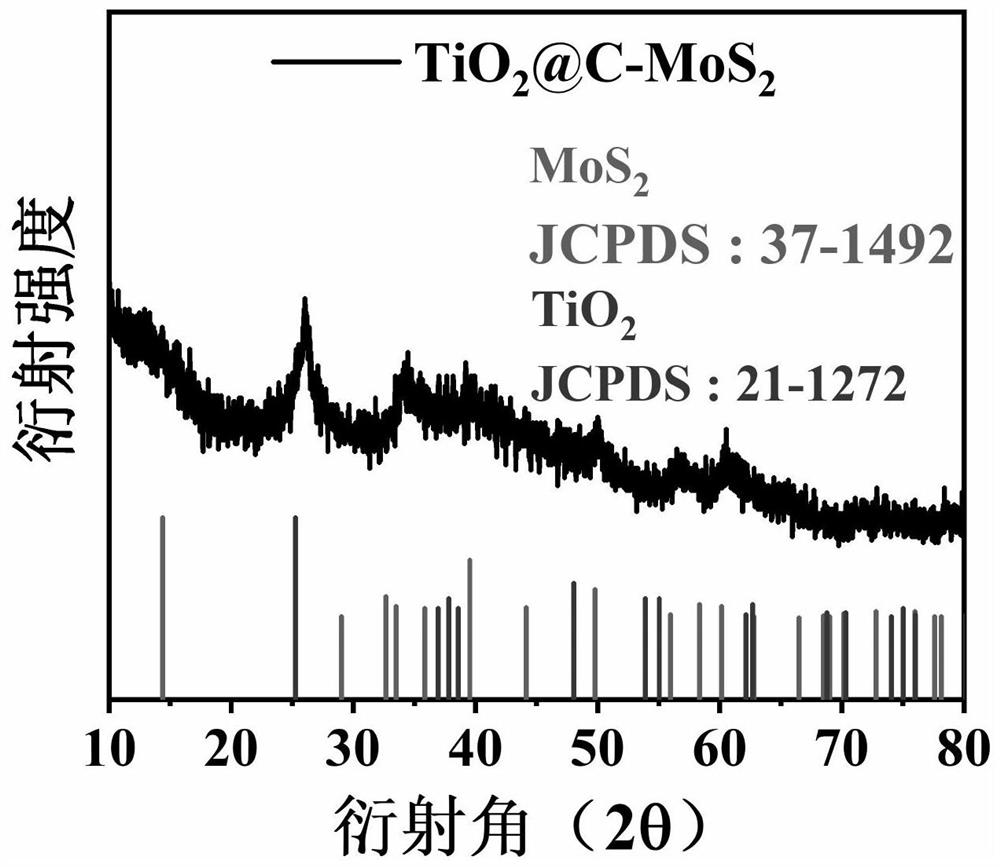

[0039] A preparation method of a multi-level titanium dopamine composite material, comprising the following steps:

[0040] (1) Weigh 20 mg of dopamine and dissolve in 5 mL of deionized water to obtain solution A; 20 mg of titanocene dichloride is dissolved in 8 mL of acetone to obtain solution B; after solution A and solution B are mixed uniformly, 5 mg of ammonium molybdate and 40 mg of tris(hydroxymethyl)aminomethane was continuously stirred for 12 h to obtain an orange turbid liquid;

[0041] (2) centrifugal treatment is carried out subsequently, the centrifugal speed is 8000-10000r.p.m, and the time is 5-7min; then wash with ethanol 1-3 times (acetone can be dissolved in organic solvents such as ethanol, so it will not introduce a variety of solvents), Dry in an oven at 60 °C for 2 h to obtain an orange molybdenum-dopamine composite material.

Embodiment 2

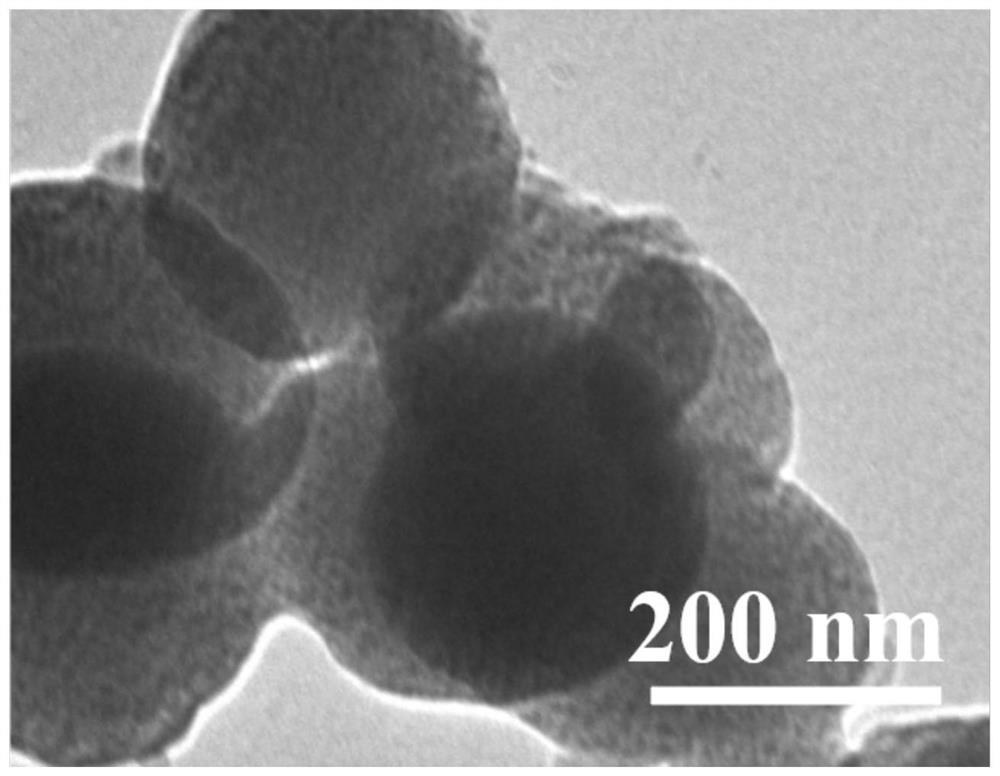

[0043] A preparation method of a multi-stage titanium dopamine composite material, the difference from Embodiment 1 is that a molybdenum source is replaced with a tungsten source, comprising the following steps:

[0044] (1) Weigh 20 mg of dopamine and dissolve in 5 mL of deionized water to obtain solution A; 20 mg of titanocene dichloride is dissolved in 8 mL of acetone to obtain solution B; after solution A and solution B are mixed uniformly, 15 mg of sodium tungstate and 40 mg of tris(hydroxymethyl)aminomethane was continuously stirred for 12 h to obtain a brownish-yellow turbid liquid;

[0045] (2) Carry out centrifugal treatment subsequently, the centrifugal speed is 8000-10000r.p.m, the time is 5-7min, then wash with ethanol 1-3 times (acetone can be dissolved in organic solvents such as ethanol, so a variety of solvents will not be introduced), Then, it was dried in an oven at 60°C for 2 hours to obtain a brown-yellow tungsten-dopamine composite material.

Embodiment 3

[0047] A preparation method of a multi-stage titanium dopamine composite material, the difference from Example 2 is that the tungsten source is replaced by sodium tungstate with phosphotungstic acid, comprising the following steps:

[0048] (1) Weigh 20 mg of dopamine and dissolve in 5 mL of deionized water to obtain solution A; 20 mg of titanocene dichloride is dissolved in 8 mL of acetone to obtain solution B; after solution A and solution B are mixed uniformly, 15 mg of phosphotungstic acid is added, Add 40 mg of tris(hydroxymethyl)aminomethane, and continue stirring for 12h;

[0049] (2) centrifugal treatment is carried out subsequently, the centrifugal speed is 8000-10000r.p.m, and the time is 5-7min; then wash with ethanol 1-3 times (acetone can be dissolved in organic solvents such as ethanol, so it will not introduce a variety of solvents), Then, it was dried in an oven at 60°C for 2 hours to obtain a tungsten-titanium dopamine hybrid material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com