A lithium-ion battery sns hybrid energy storage negative plate and preparation method thereof

A lithium-ion battery and hybrid energy storage technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of low specific capacity of the negative electrode and shedding of active materials, so as to improve the conductivity of the electrode, prevent pulverization and shedding, and buffer The effect of volume change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

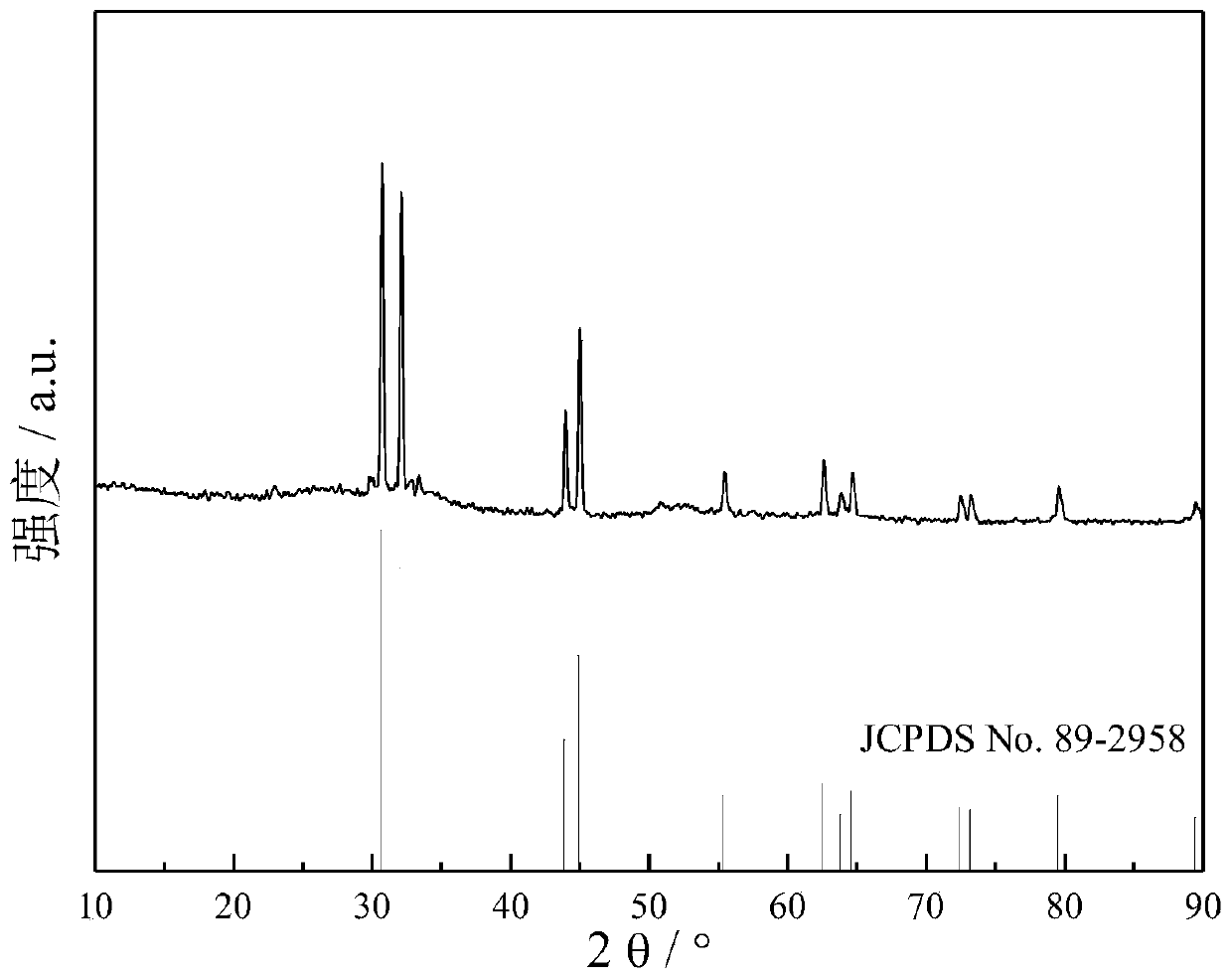

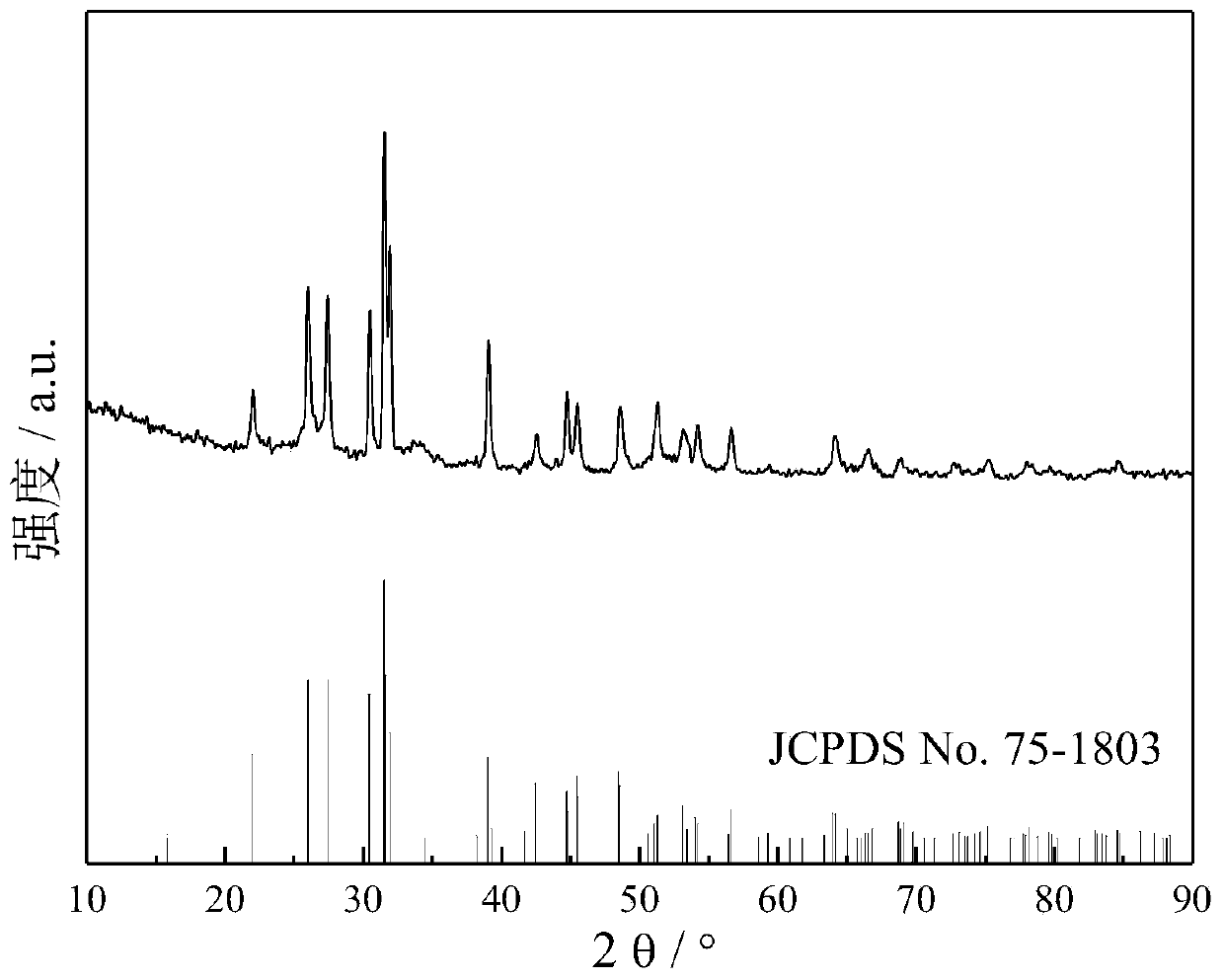

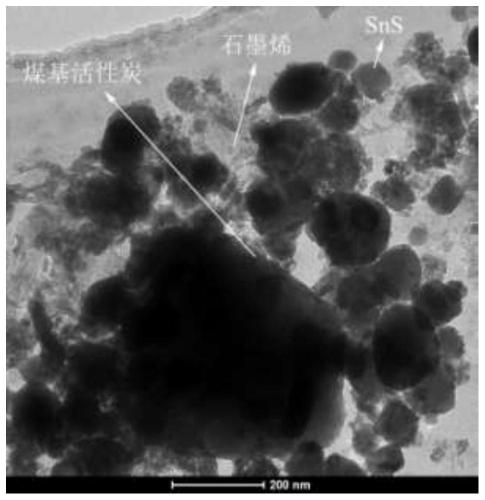

[0038] The preparation method of the SnS-based composite energy storage electrode of the present invention is realized through the following steps:

[0039] Step 1. Weigh 100 parts by weight of SnS / coal-based activated carbon / graphene composite energy storage active material, 7-13 parts of copper-loaded acetylene black, 10-18 parts of 10% by mass N of polyvinylidene fluoride -Methylpyrrolidone solution, 100 to 200 parts of N-methylpyrrolidone, mixed at room temperature to form a negative electrode paste, then evenly coated the negative electrode paste on the copper foil, and then dried at 80°C to obtain a SnS-based composite energy storage electrode ;

[0040] Step 2, adding dopamine hydrochloride into the solution of oxidized mesophase carbon microspheres, and ultrasonicating for 30-60 minutes; wherein, the ratio of the volume of oxidized mesophase carbon microspheres solution to the mass of dopamine hydrochloride is 99.5-99.9mL:0.1~ 1.0 g, and then evenly coat the solution ...

Embodiment 1

[0052] Example 1: This embodiment is a SnS-based hybrid energy storage negative plate for a lithium ion battery, including a SnS-based composite energy storage electrode and a coated buffer carbon layer. In addition to the SnS / coal-based activated carbon / graphene composite active material, polyvinylidene fluoride and copper-loaded acetylene black are added to the SnS-based composite energy storage electrode. Among them, taking the mass of SnS / coal-based activated carbon / graphene composite material as the base, polyvinylidene fluoride accounts for 7% to 13% of the base, and acetylene black loaded with copper accounts for 10% to 18% of the base. The buffer carbon layer is prepared by ultrasonically mixing the oxidized mesophase carbon microsphere solution and dopamine hydrochloride, directly coating the outer surface of the SnS-based composite energy storage electrode and drying, wherein the volume of the oxidized mesophase carbon microsphere solution and the dopamine The ratio ...

Embodiment 2

[0054] Embodiment 2: The difference between this embodiment and specific example 1 is that the preparation method of the oxidized mesophase carbon microsphere solution is: 1. A three-necked flask is placed in an ice-water bath, and then 15g of concentrated phosphoric acid and 150g of concentrated sulfuric acid are added respectively , then add 6g of mesophase carbon microspheres into a three-necked flask, stir for 20min, then add 25g of potassium dichromate in 4 times, stir for 30min, then place the three-necked flask at 45°C for 2h to obtain viscous thick liquid. 2. Add the viscous liquid in step 1 into distilled water, stir at 90°C for 1.5 hours, then add hydrogen peroxide, stir at room temperature for 30 hours, centrifuge, then wash with dilute hydrochloric acid and distilled water, and centrifuge for 3 to 5 times, then filter The cake was poured into distilled water and sonicated for 2 hours to form a solution of oxidized mesocarbon microspheres.

[0055] The preparation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com