Patents

Literature

46 results about "Pit pattern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

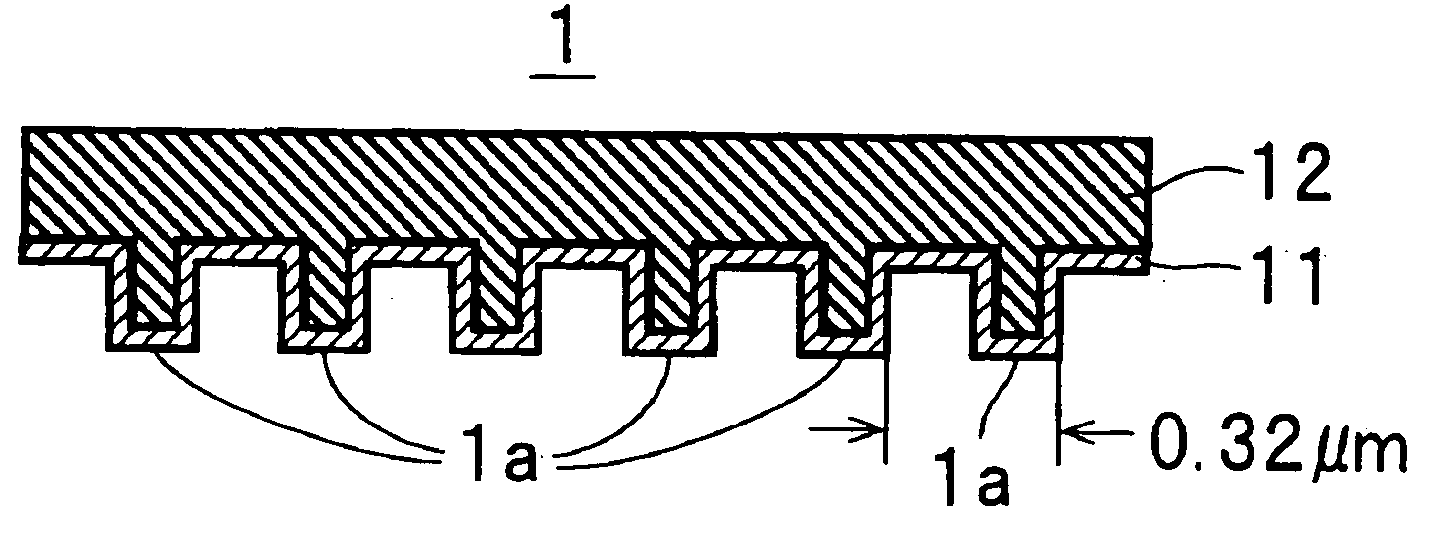

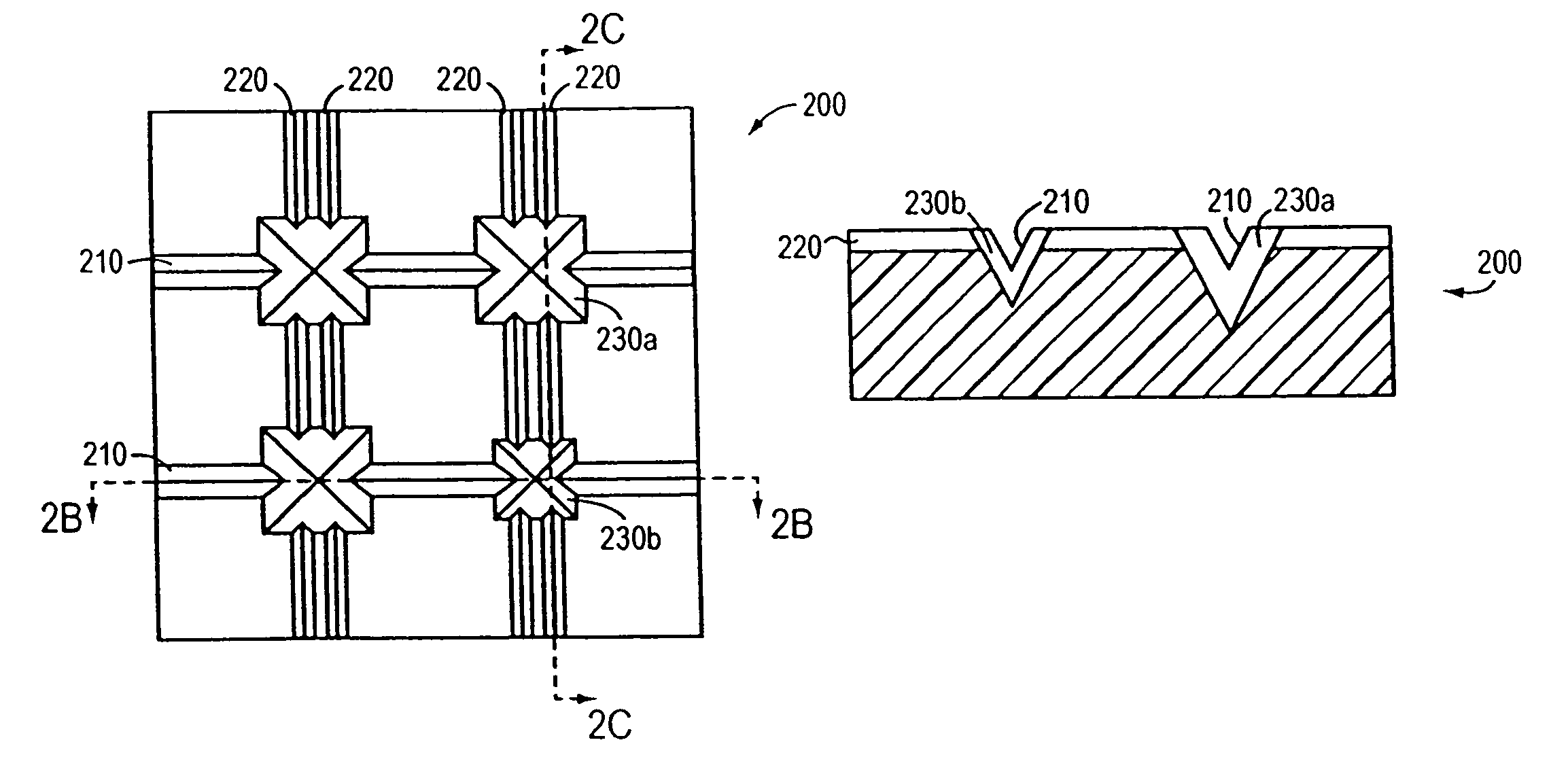

Fabrication of semiconductor devices

InactiveUS7183206B2Avoid the needSemiconductor/solid-state device detailsSolid-state devicesElectrical devicesSemiconductor

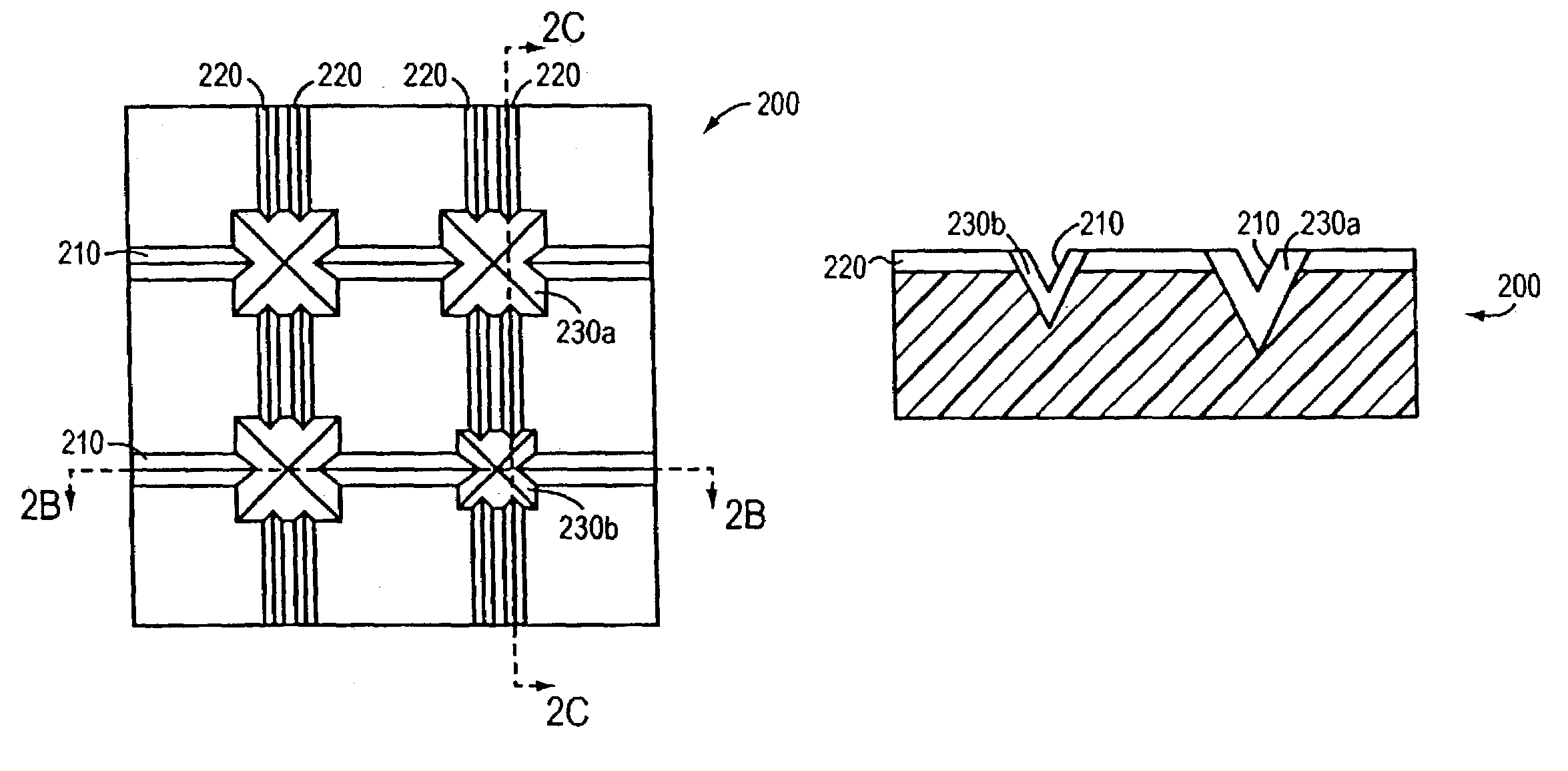

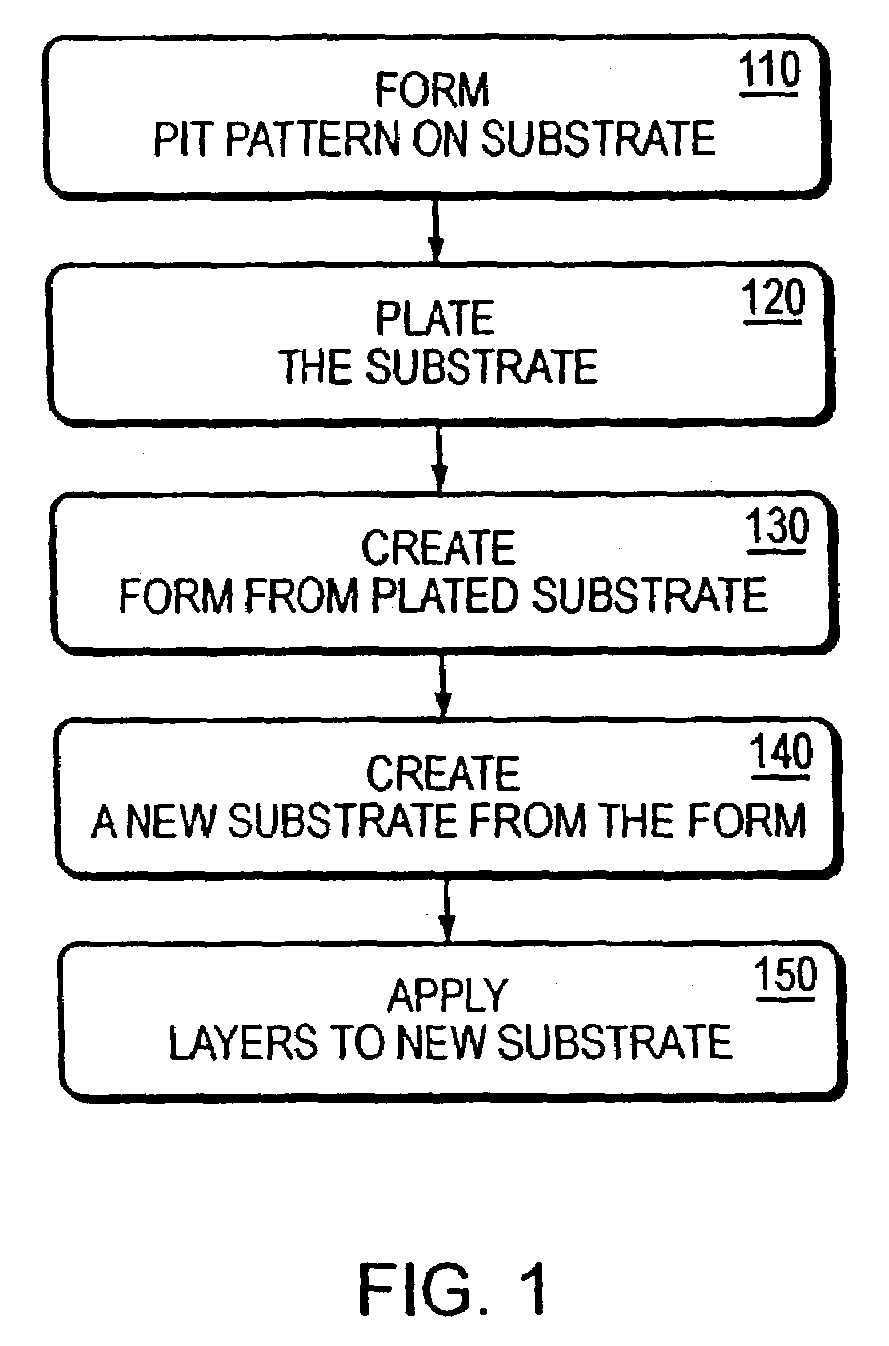

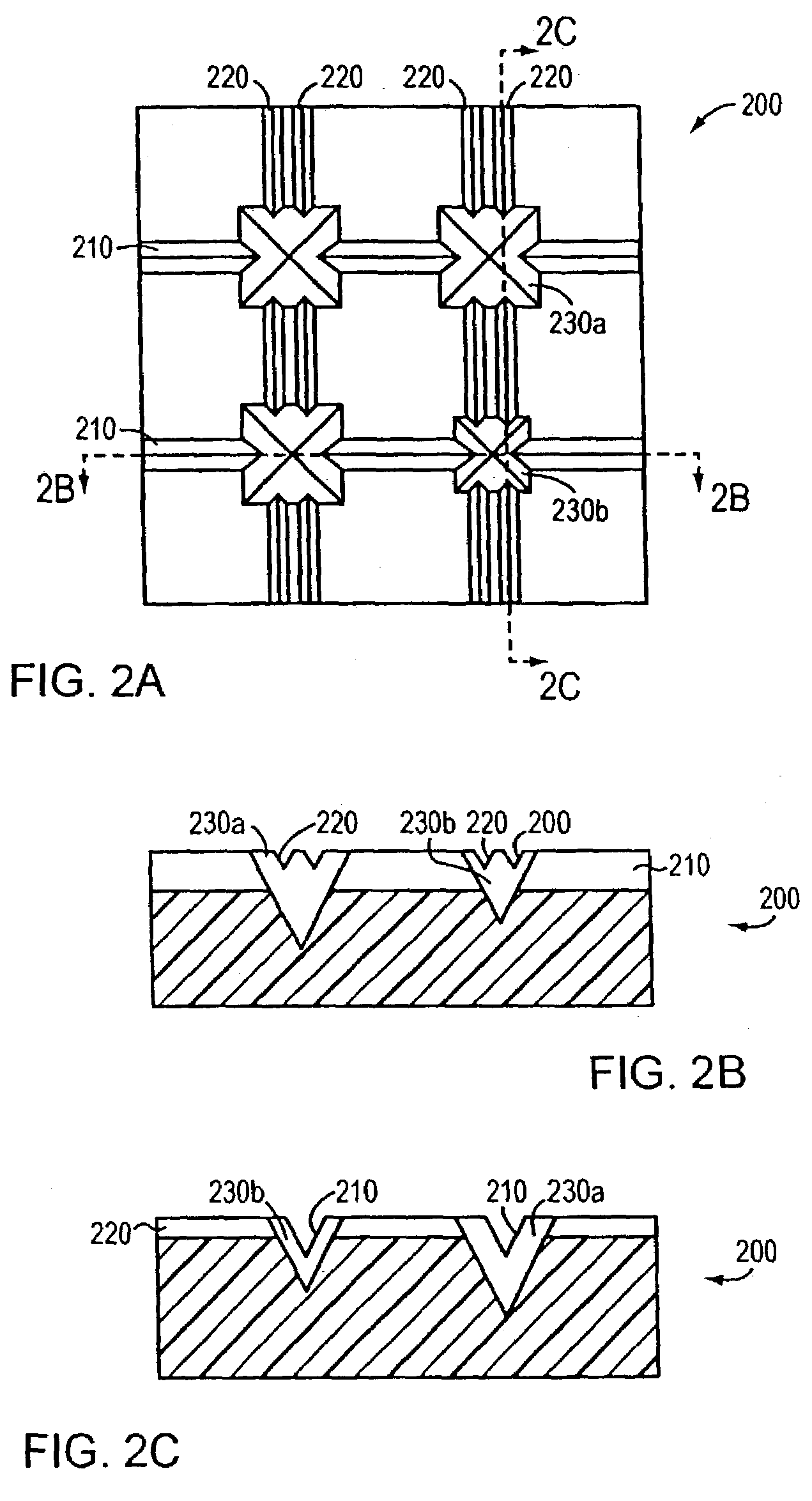

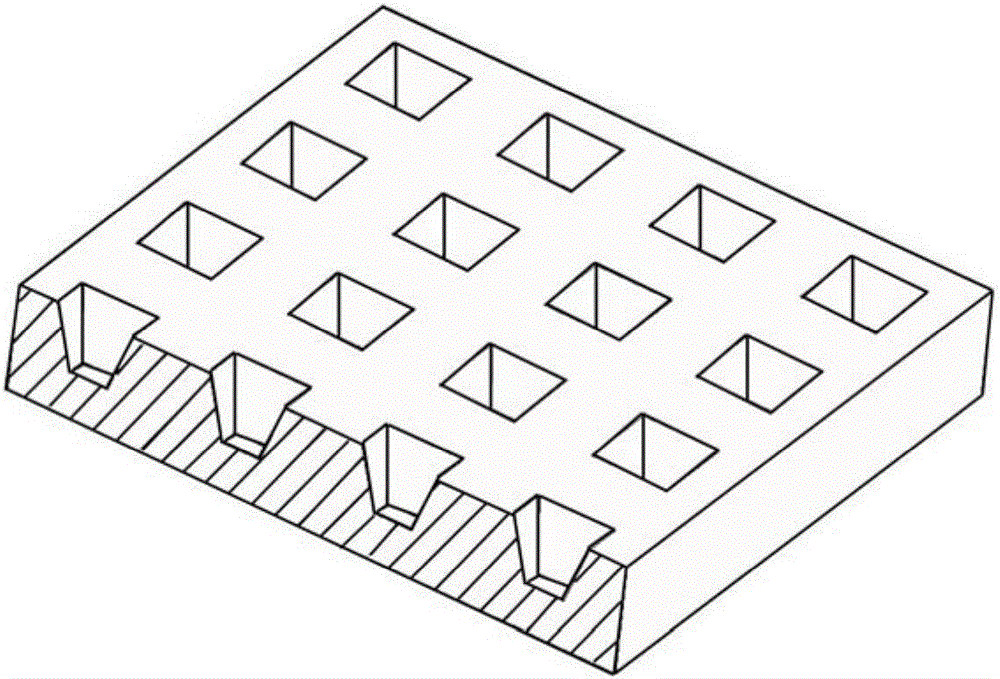

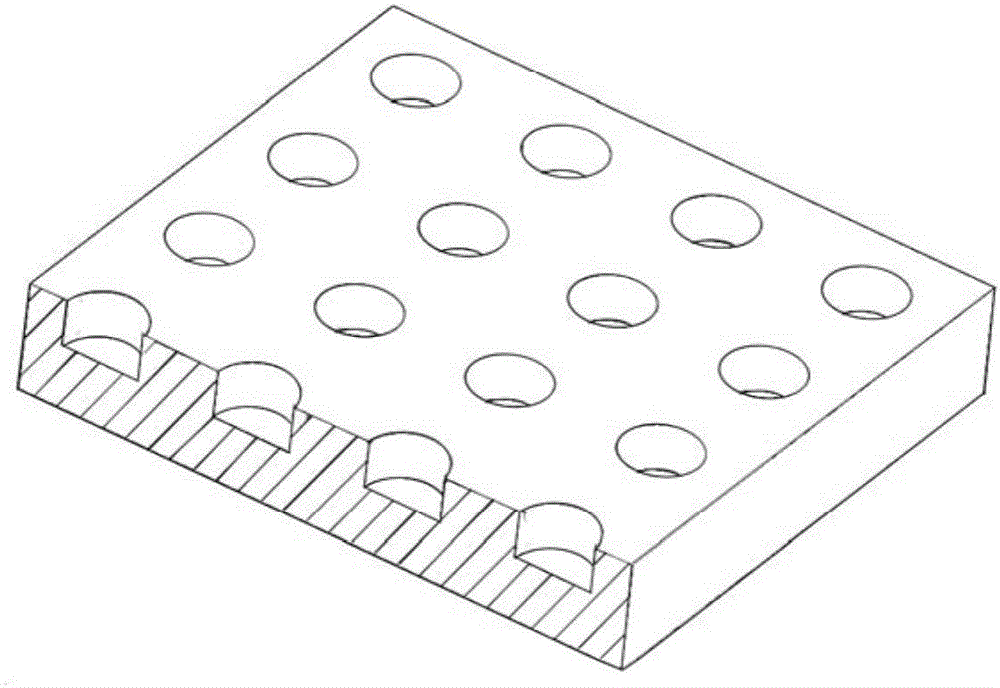

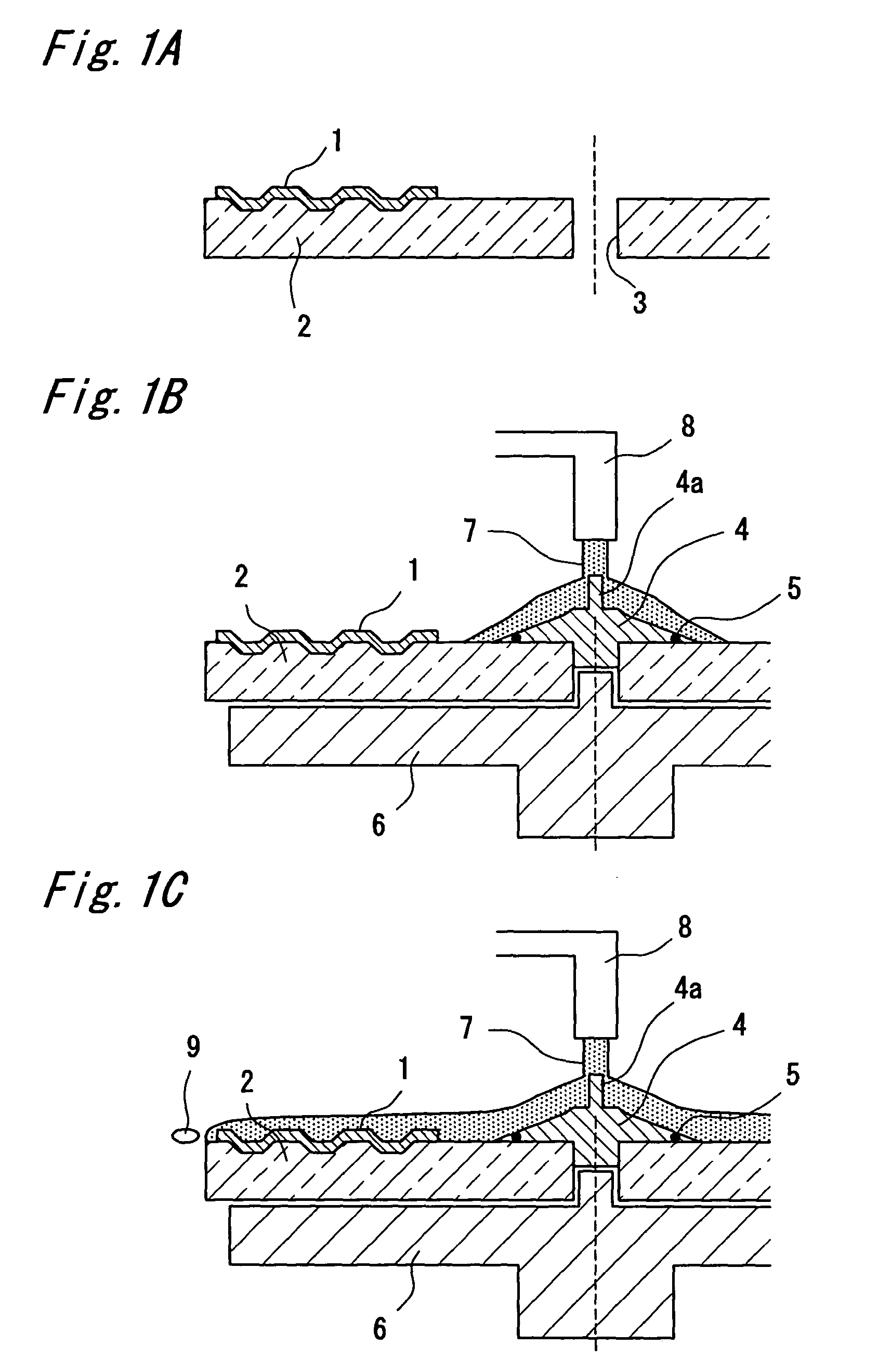

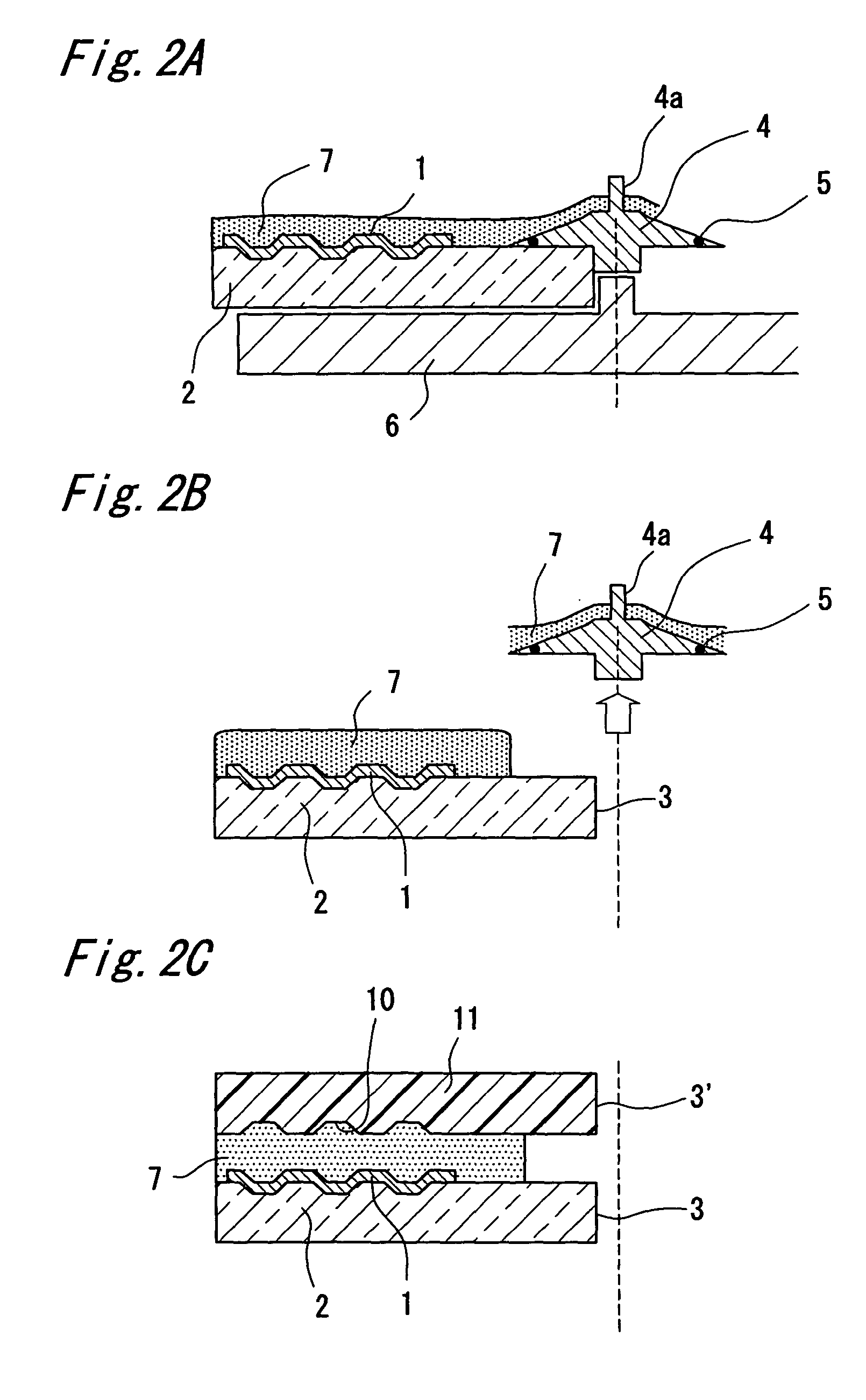

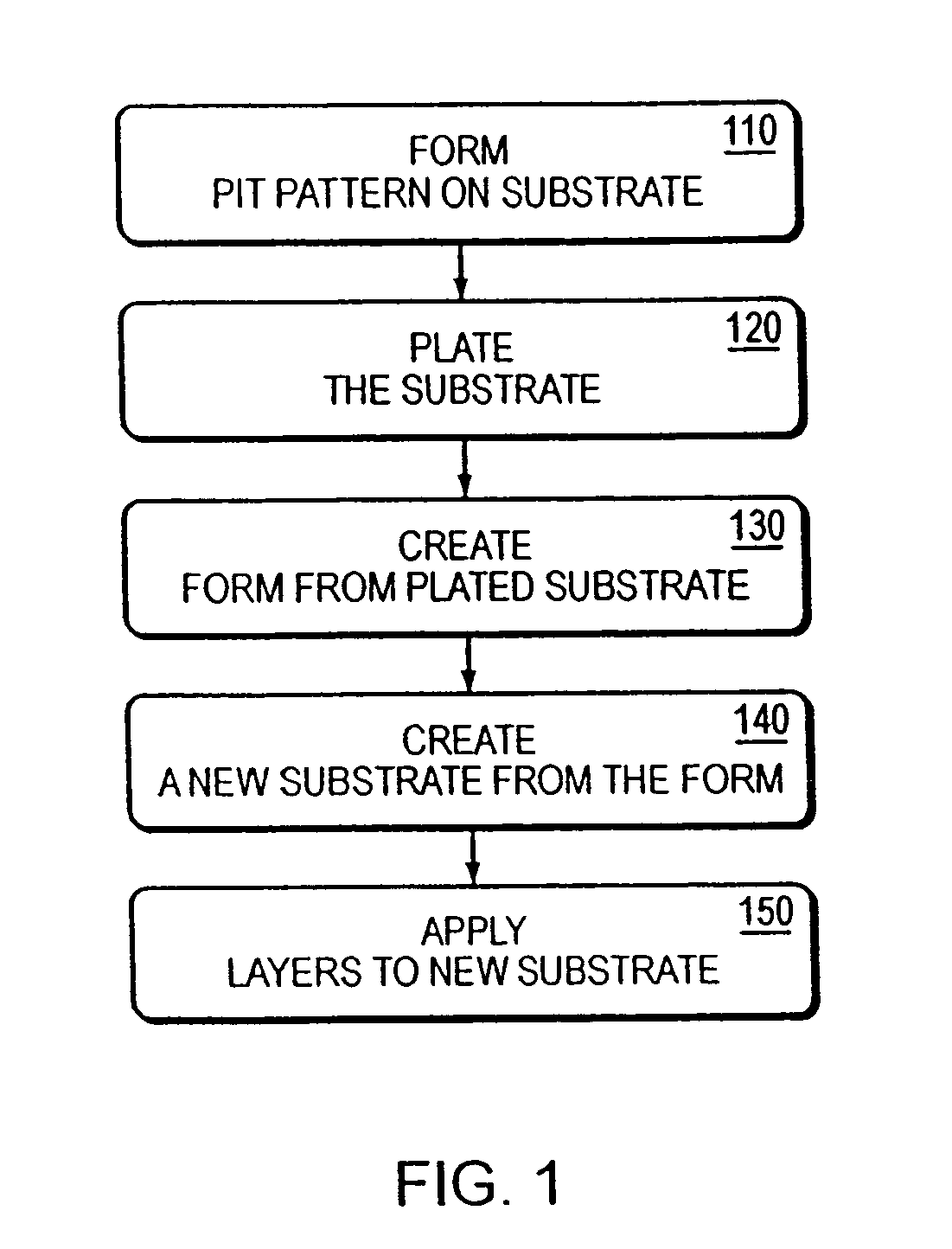

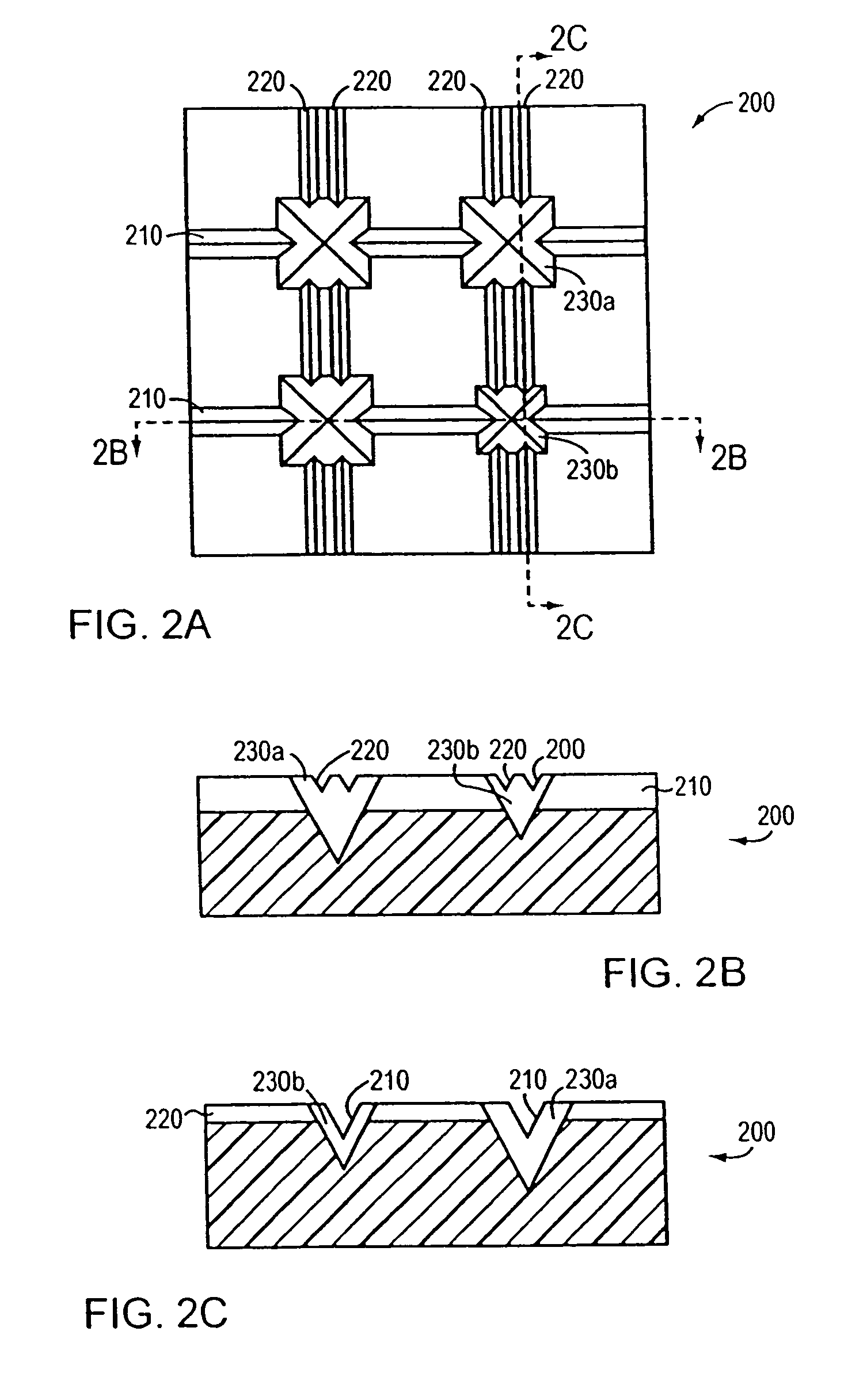

Fabrication of microelectronic devices is accomplished using a substrate having a recessed pattern. In one approach, a master form is used to replicate a substrate having a pit pattern. In another approach, the substrate is produced by etching. A series of stacked layers having desired electrical characteristics is applied to the substrate and planarized in a manner that creates electrical devices and connections therebetween. The microelectronic devices can include a series of row and columns and are used to store data at their intersection.

Owner:WODEN TECH INC

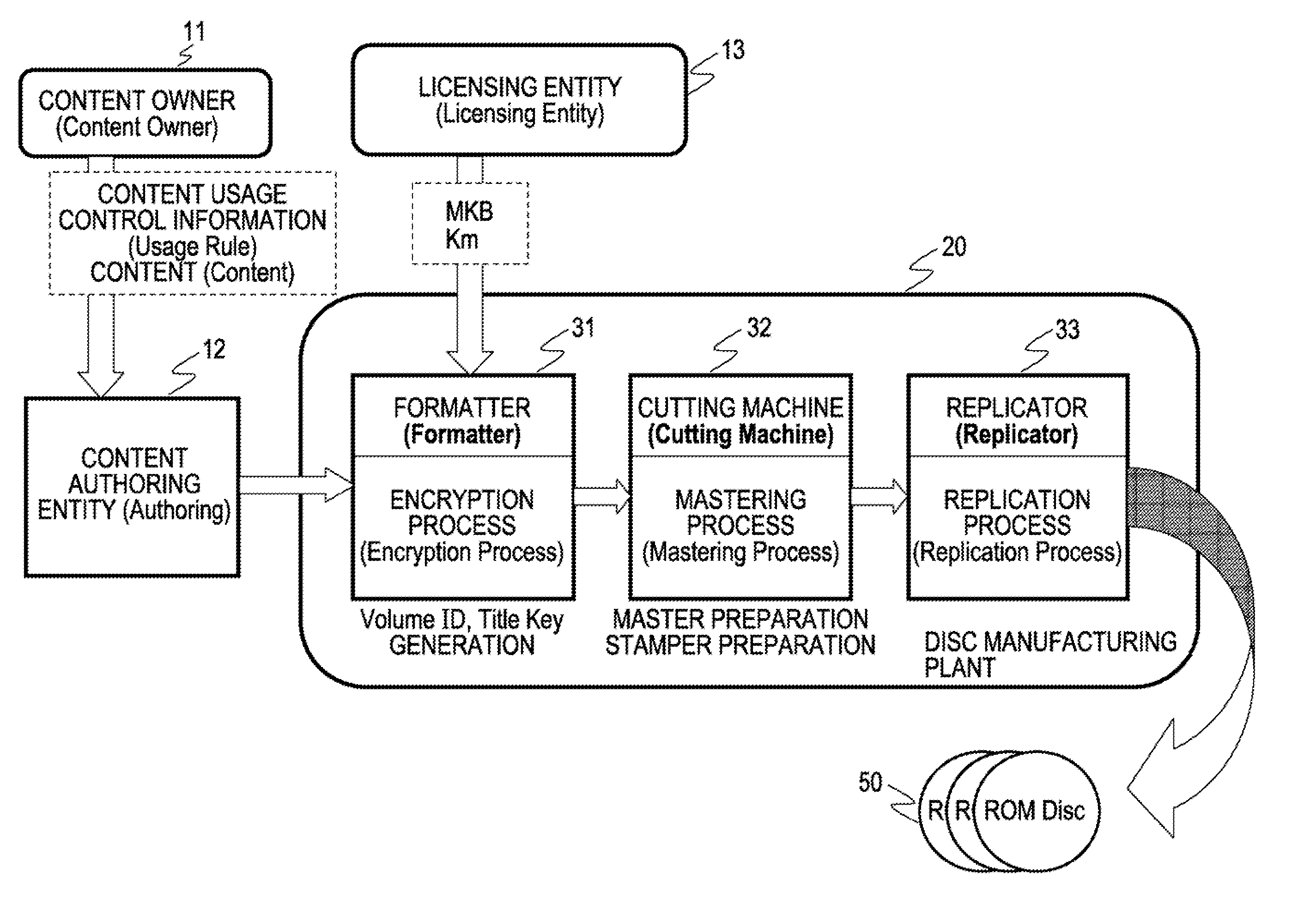

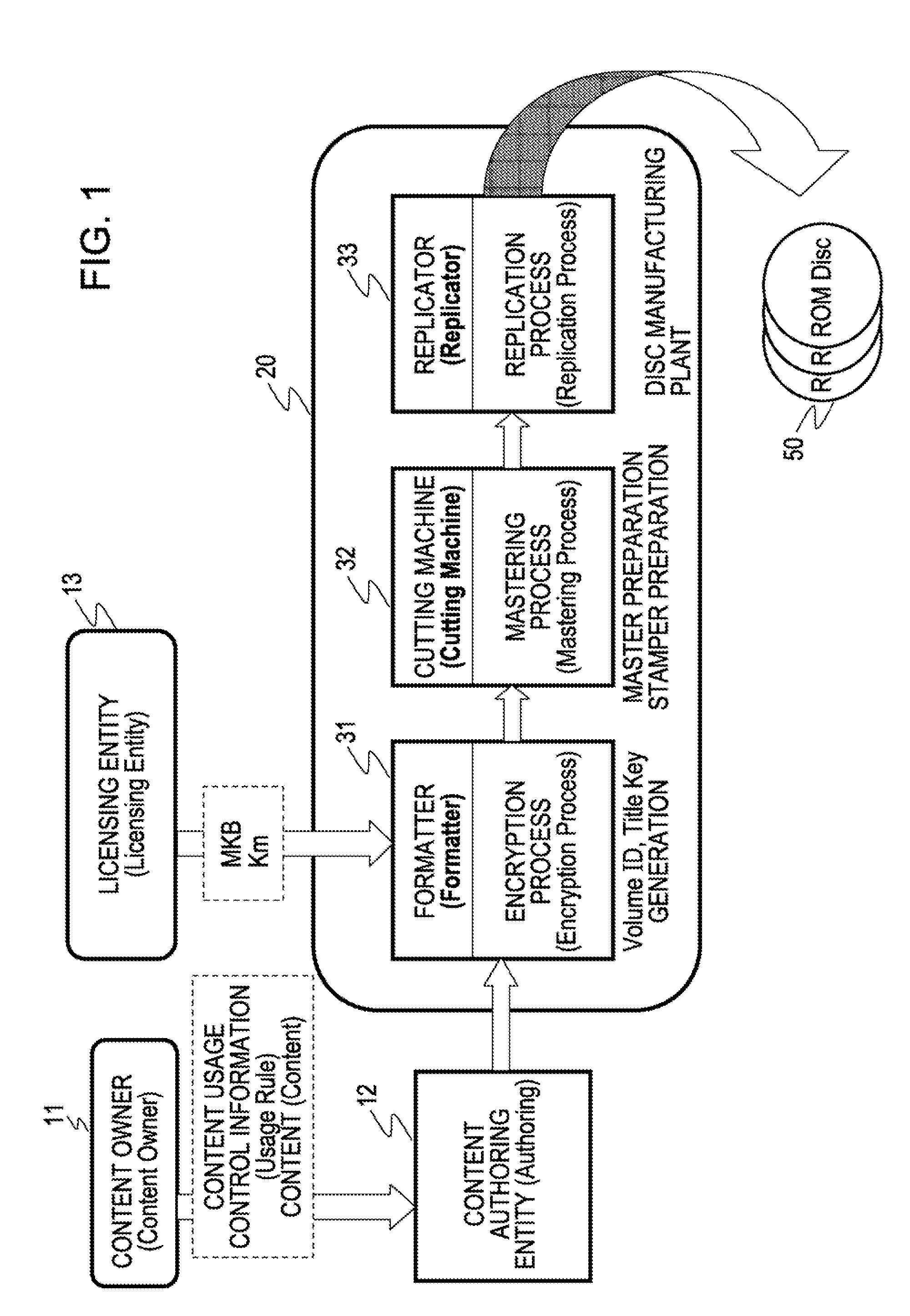

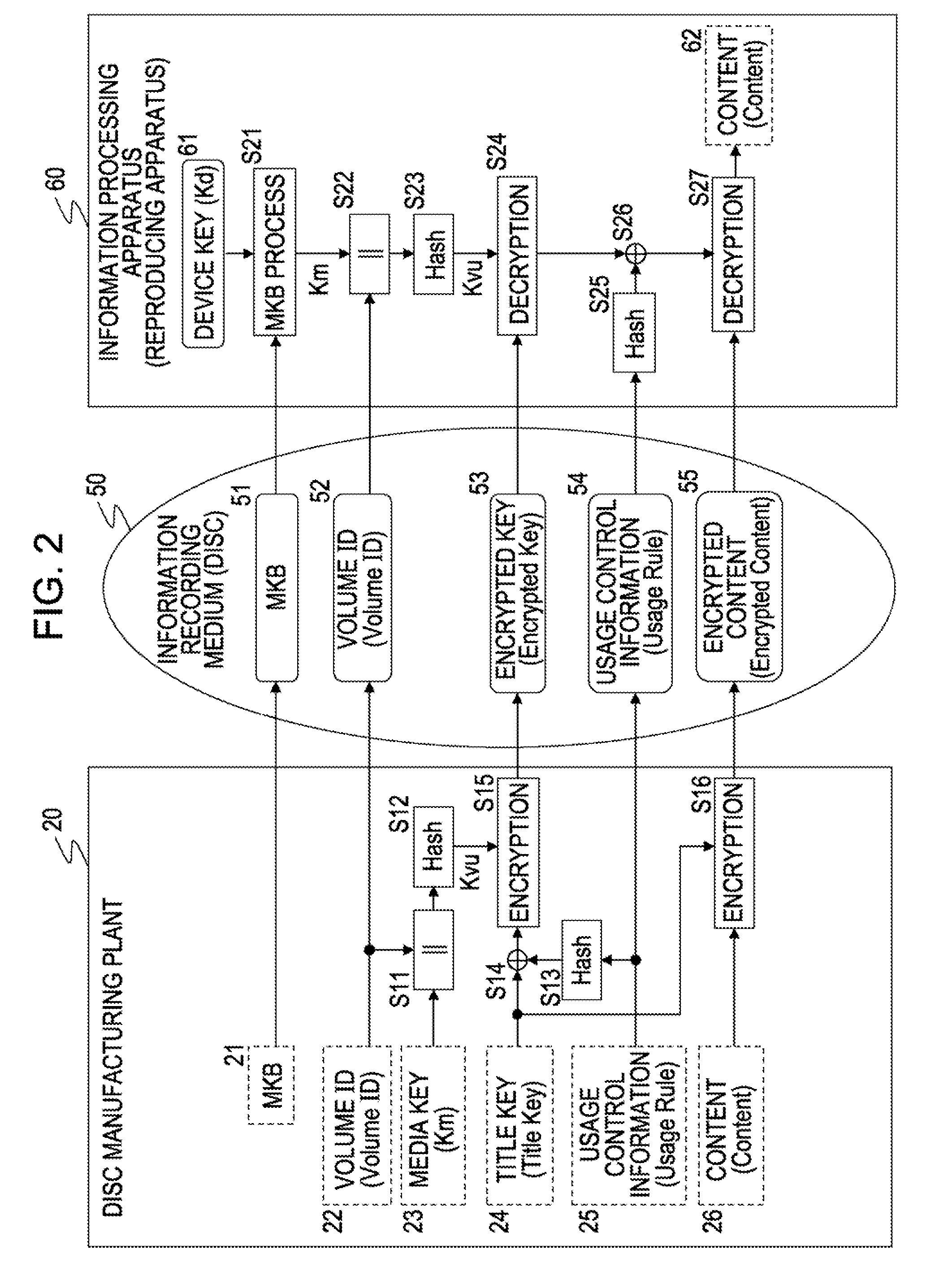

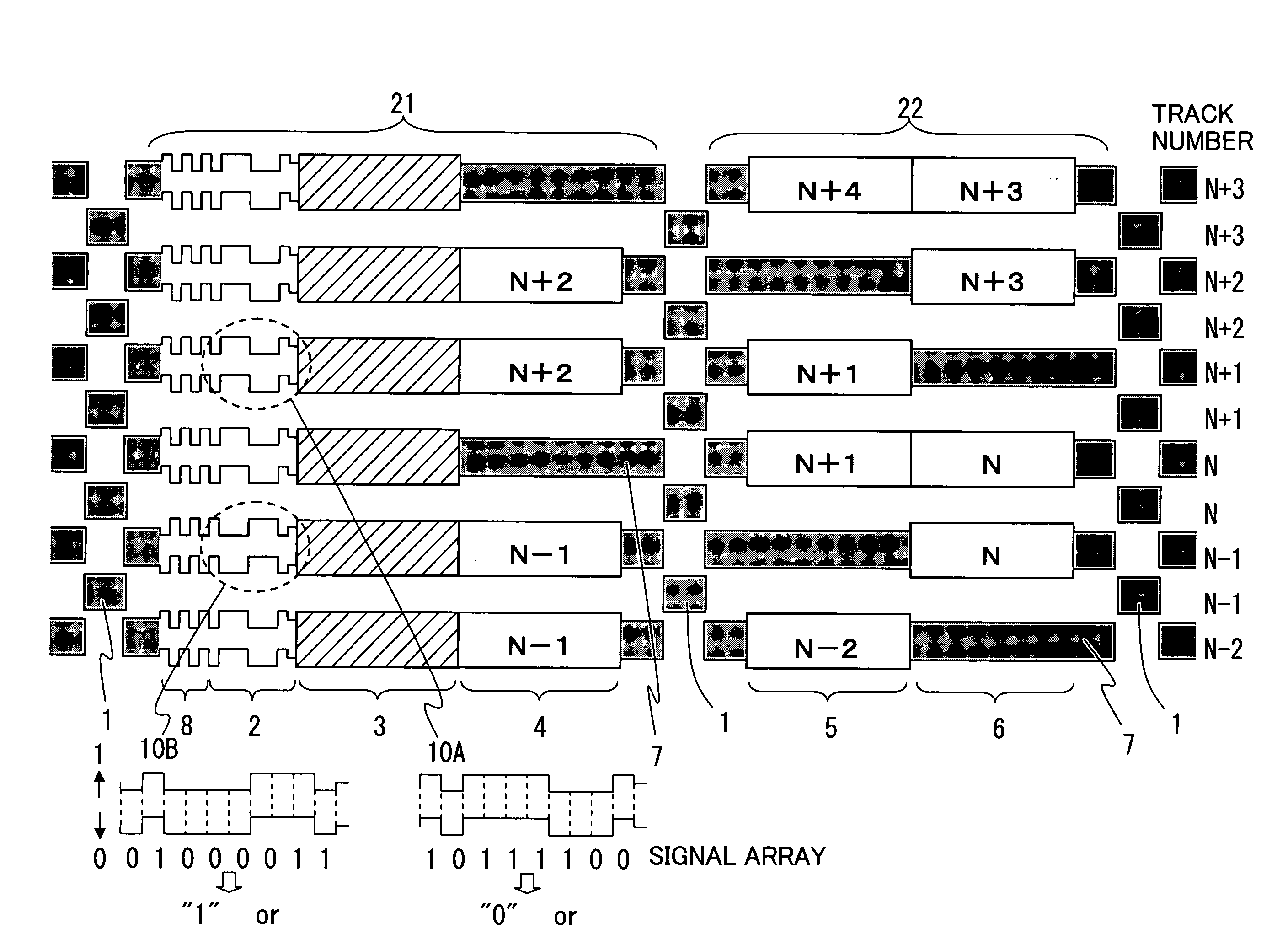

Disc manufacturing method, data recording apparatus, information recording medium, information processing apparatus and method, and computer program

InactiveUS20090238362A1Prevent illegal usePrevent unauthorized reproduction and useDigital data processing detailsRecord information storageInformation processingPublic key certificate

A product mark including a public key certificate issued with respect to an information-recording-medium manufacturing entity or information-recording-medium manufacturing equipment, and an encrypted volume ID calculated by computation based on a product-mark-associated value such as a hash value generated on the basis of the product mark, and a volume ID as an identifier set with respect to a given set of discs to be manufactured, are generated. The product mark and the encrypted volume ID are set as information for generating a key used for decryption of encrypted content, and recorded onto a disc by a reflective-film-removal recording method. Due to this configuration, the product mark and the encrypted volume ID as key generating information cannot be read from a pirated disc produced by physically copying a pit pattern on the basis of a legitimate commercial disc, thereby making it possible to prevent unauthorized reproduction or use of content.

Owner:SONY CORP

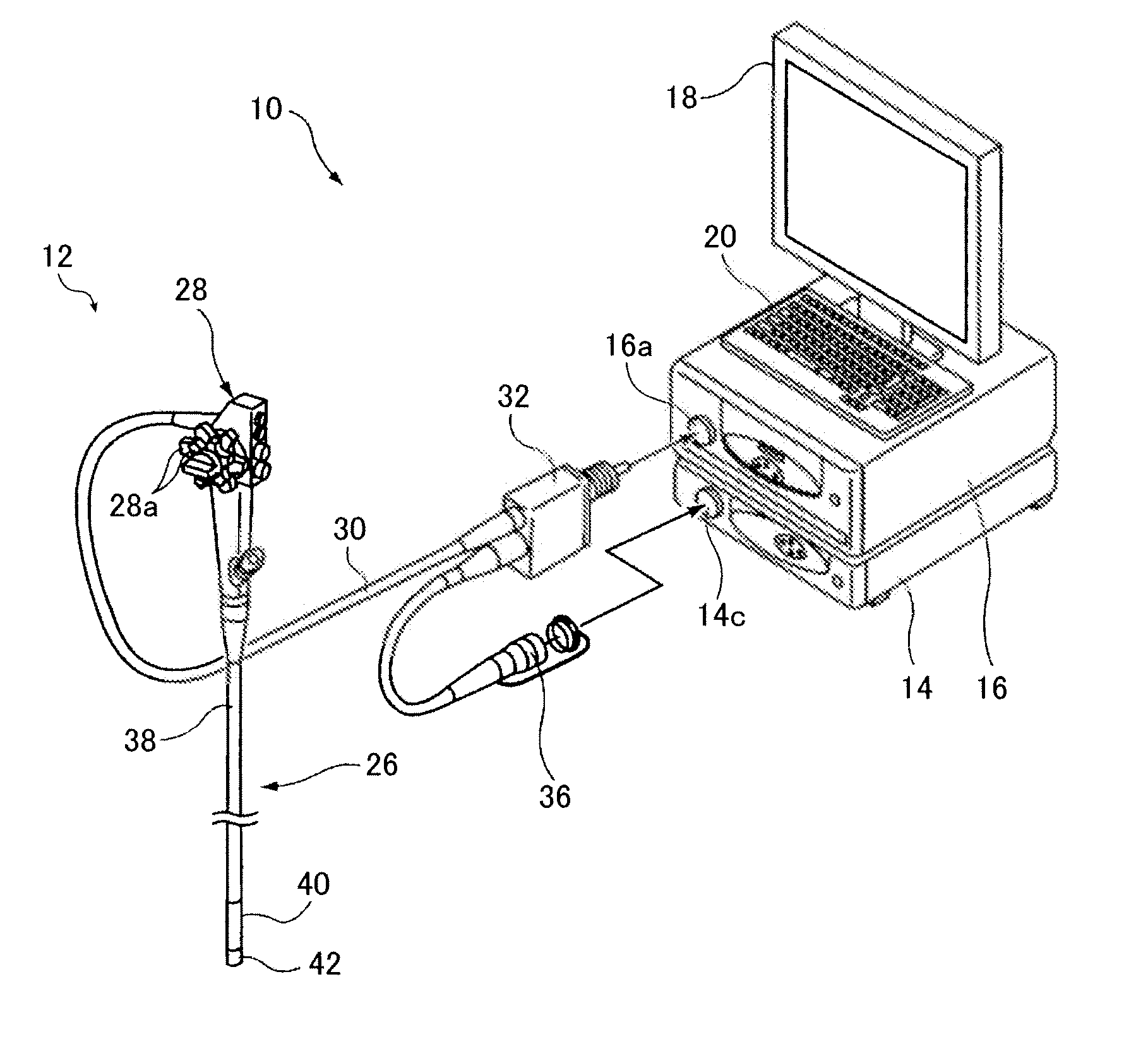

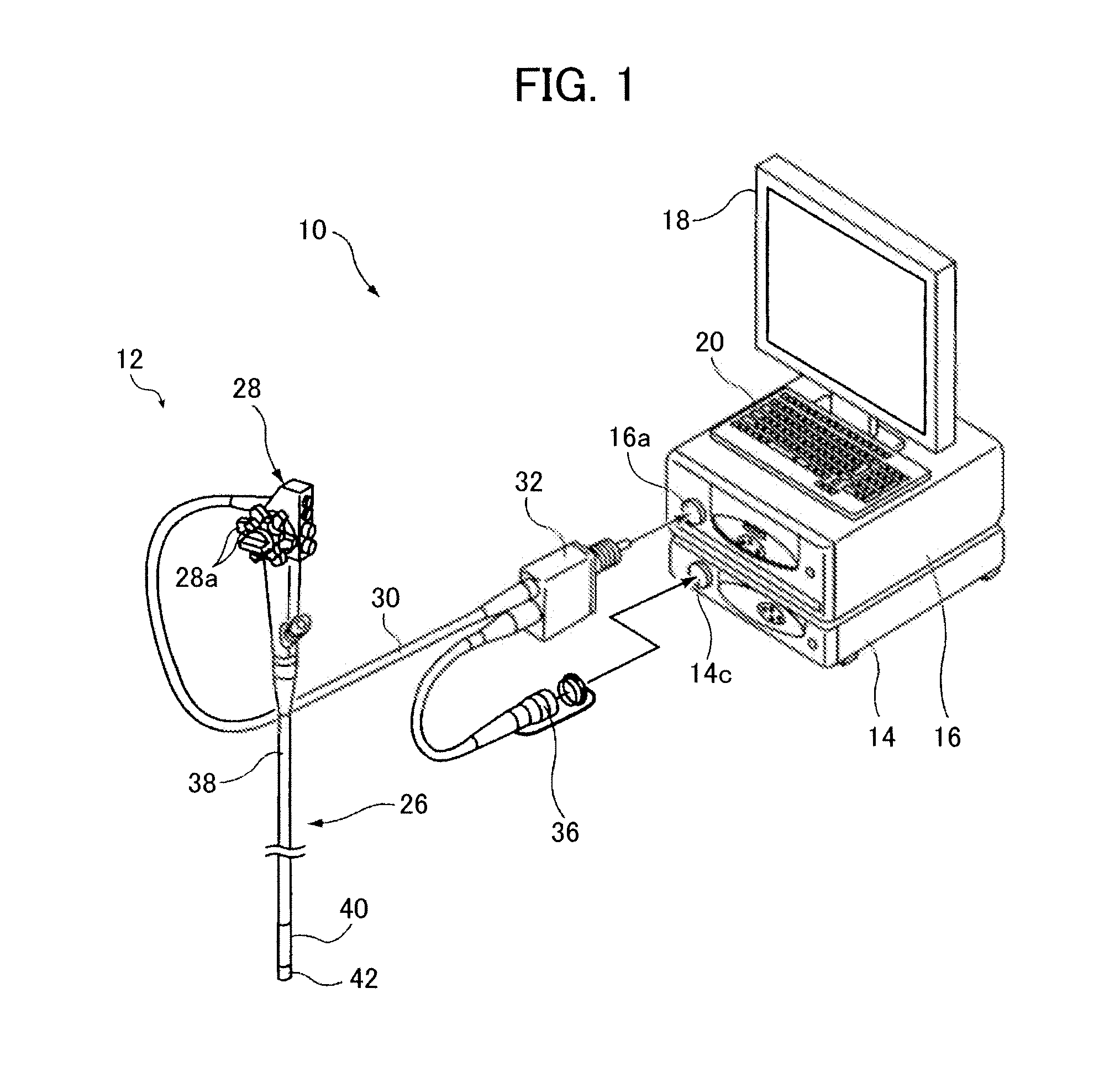

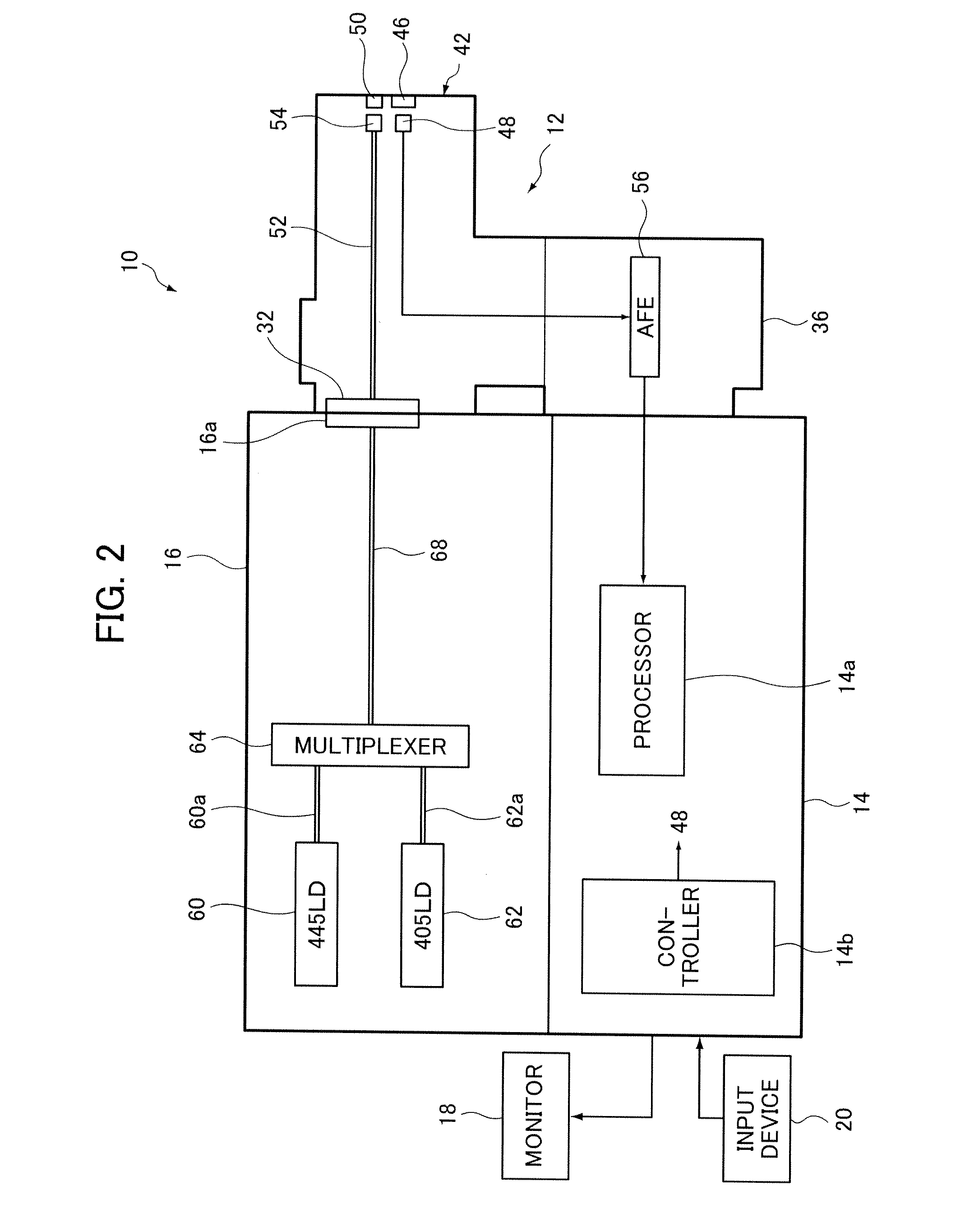

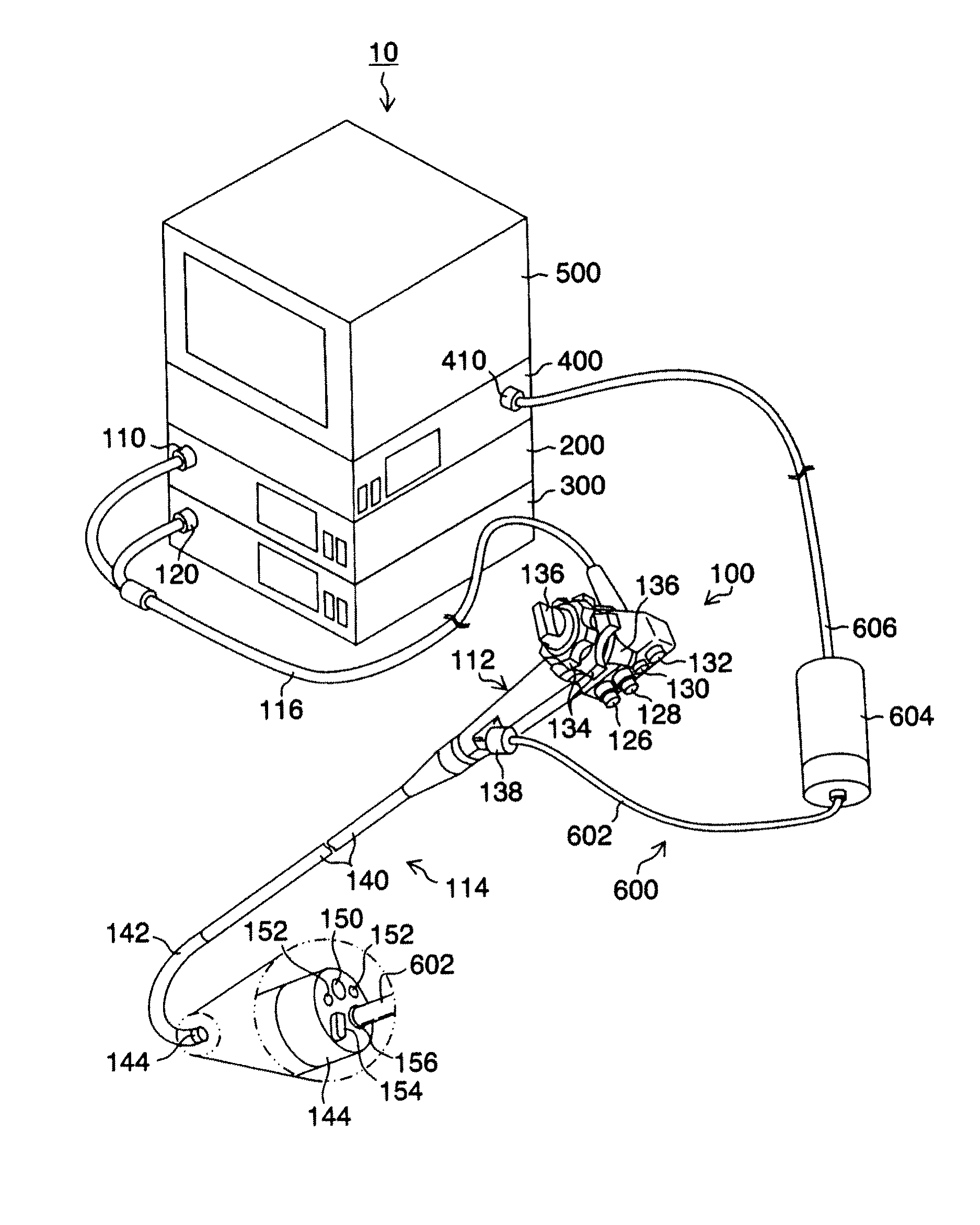

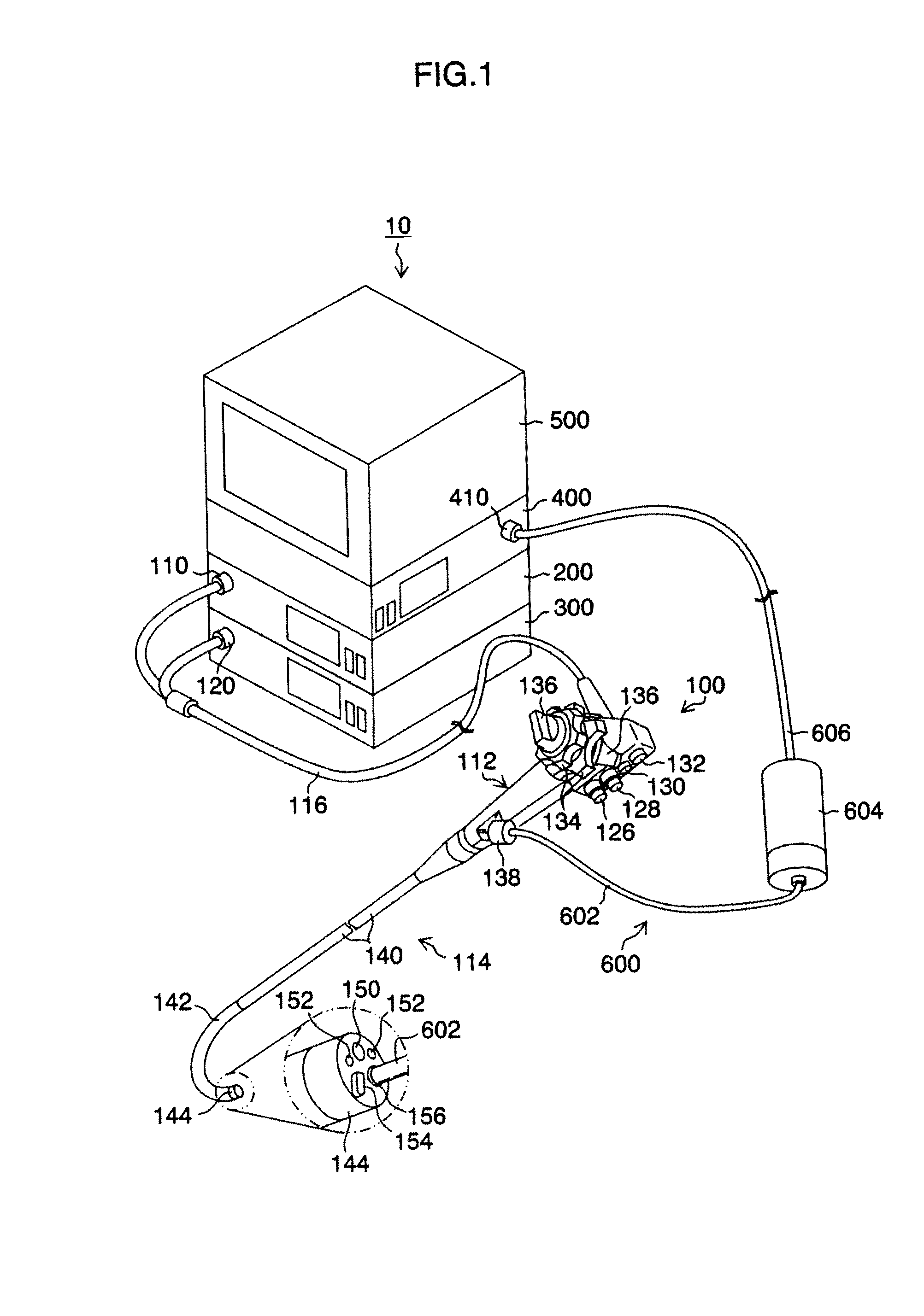

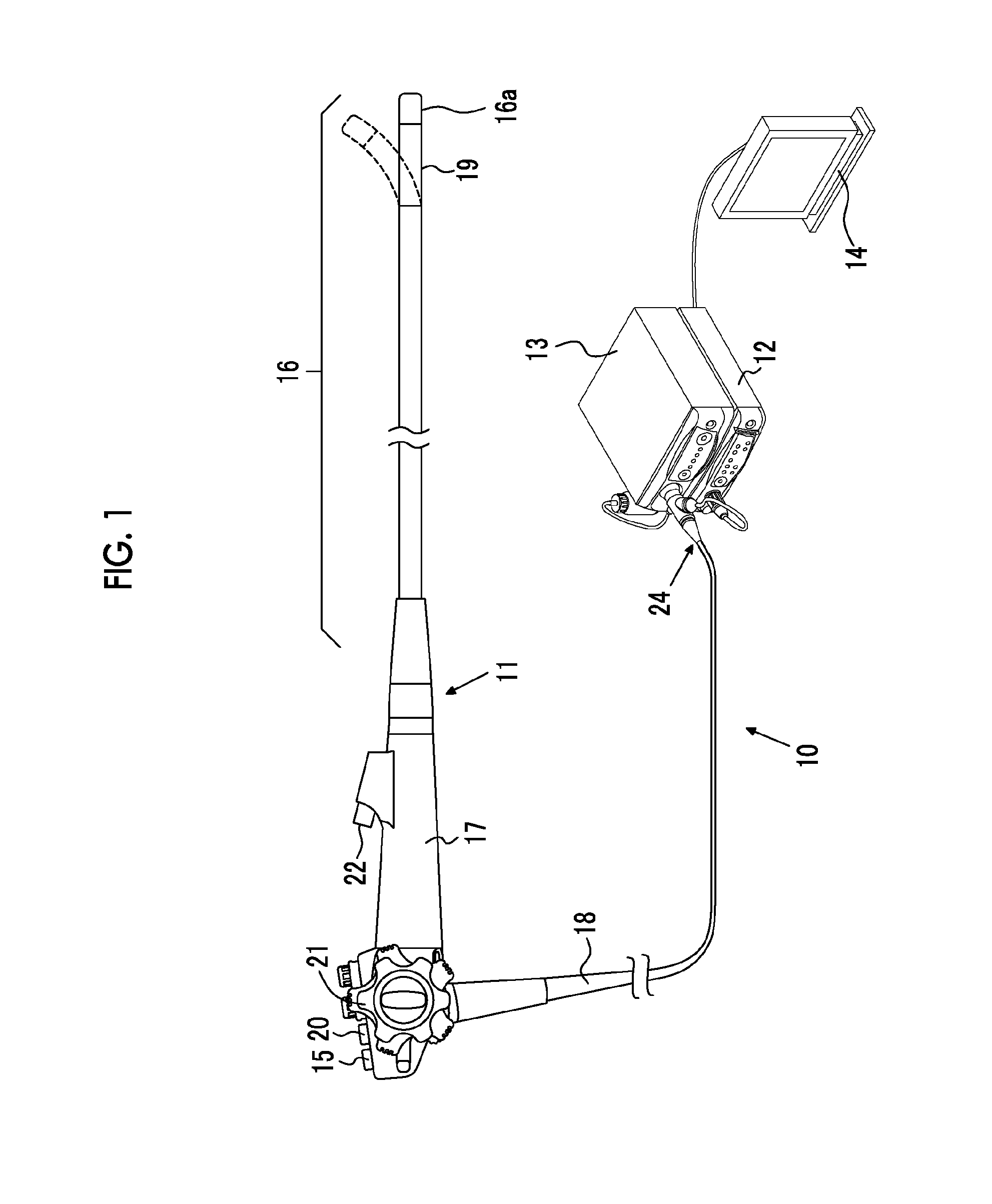

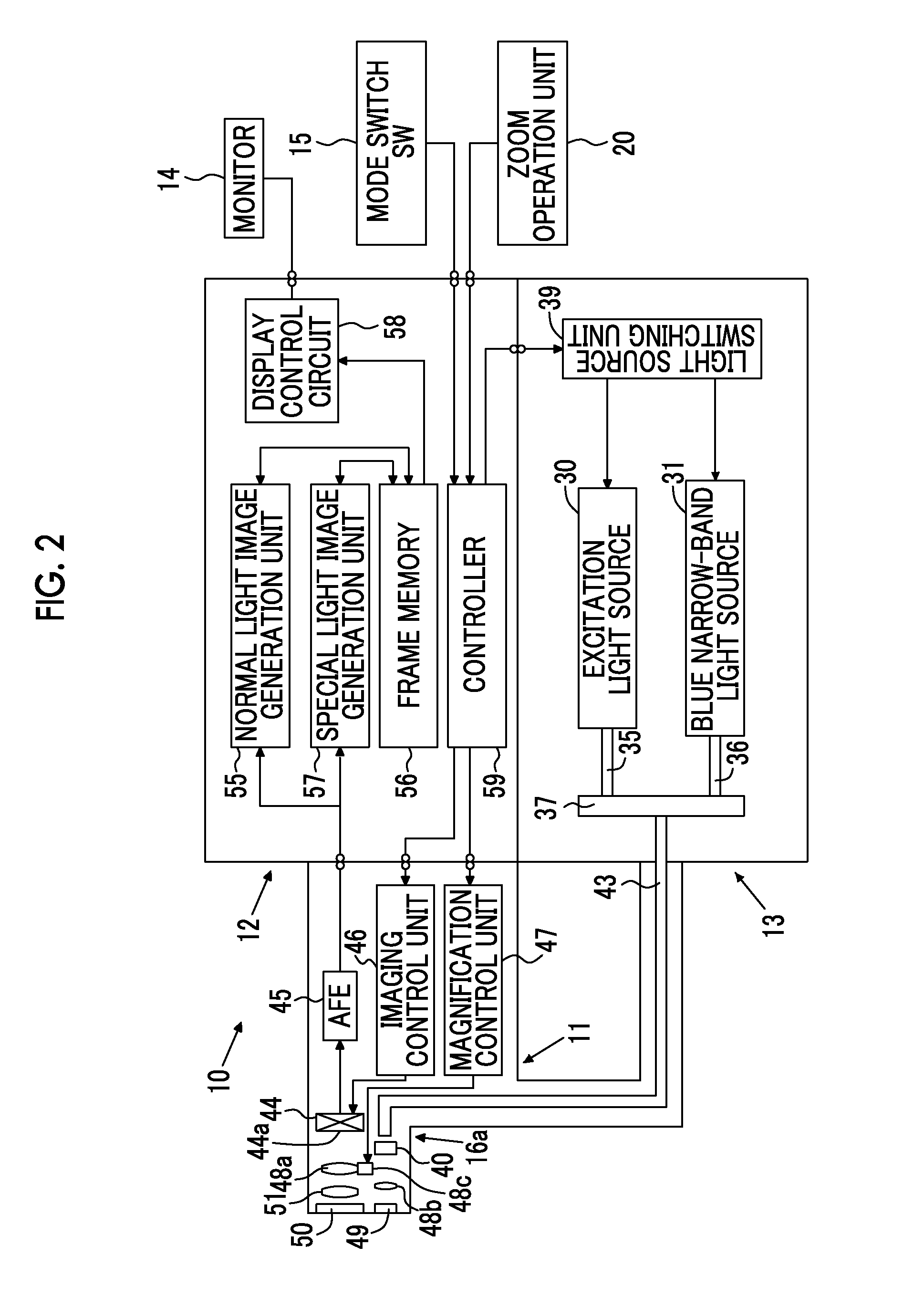

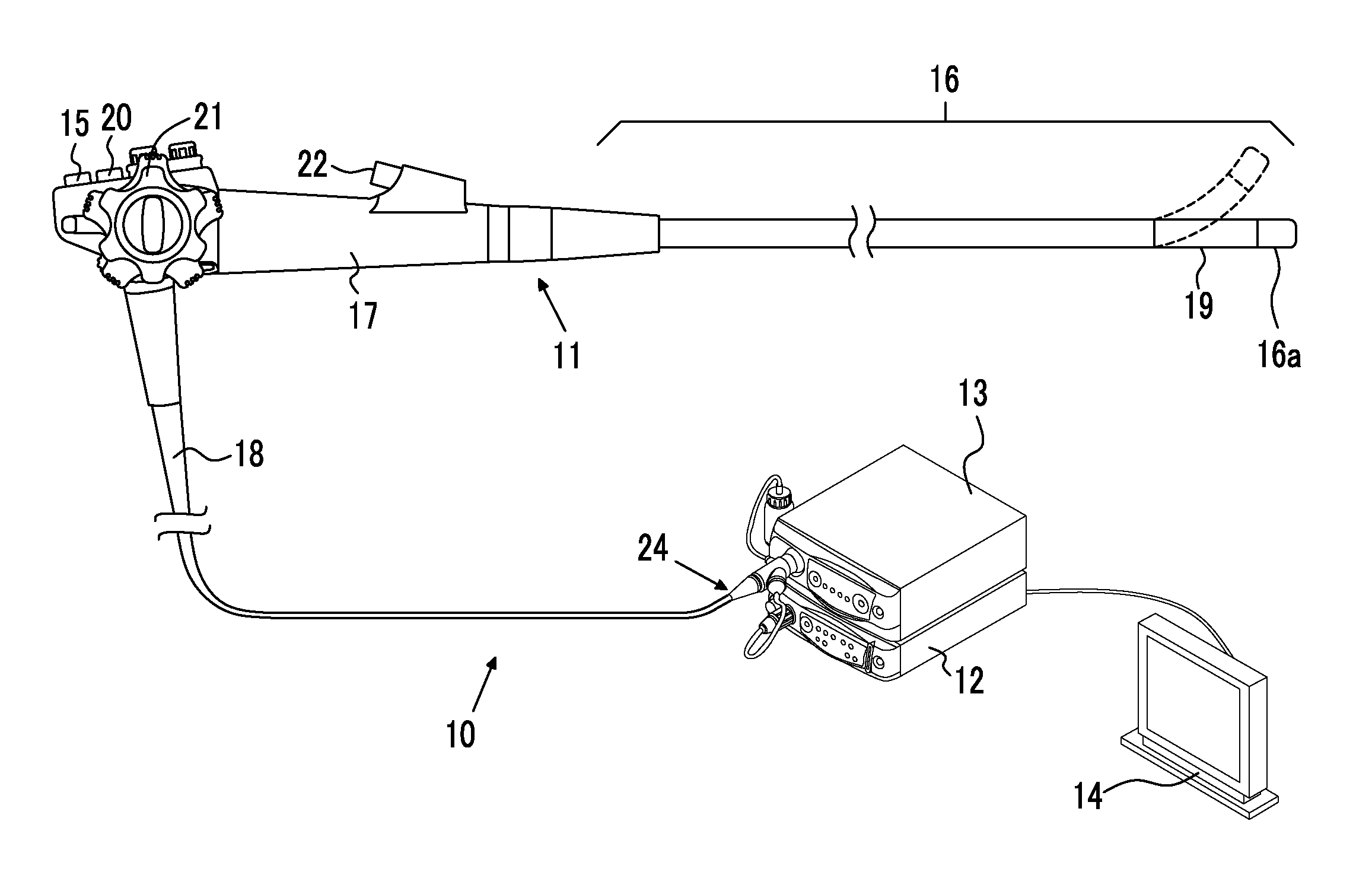

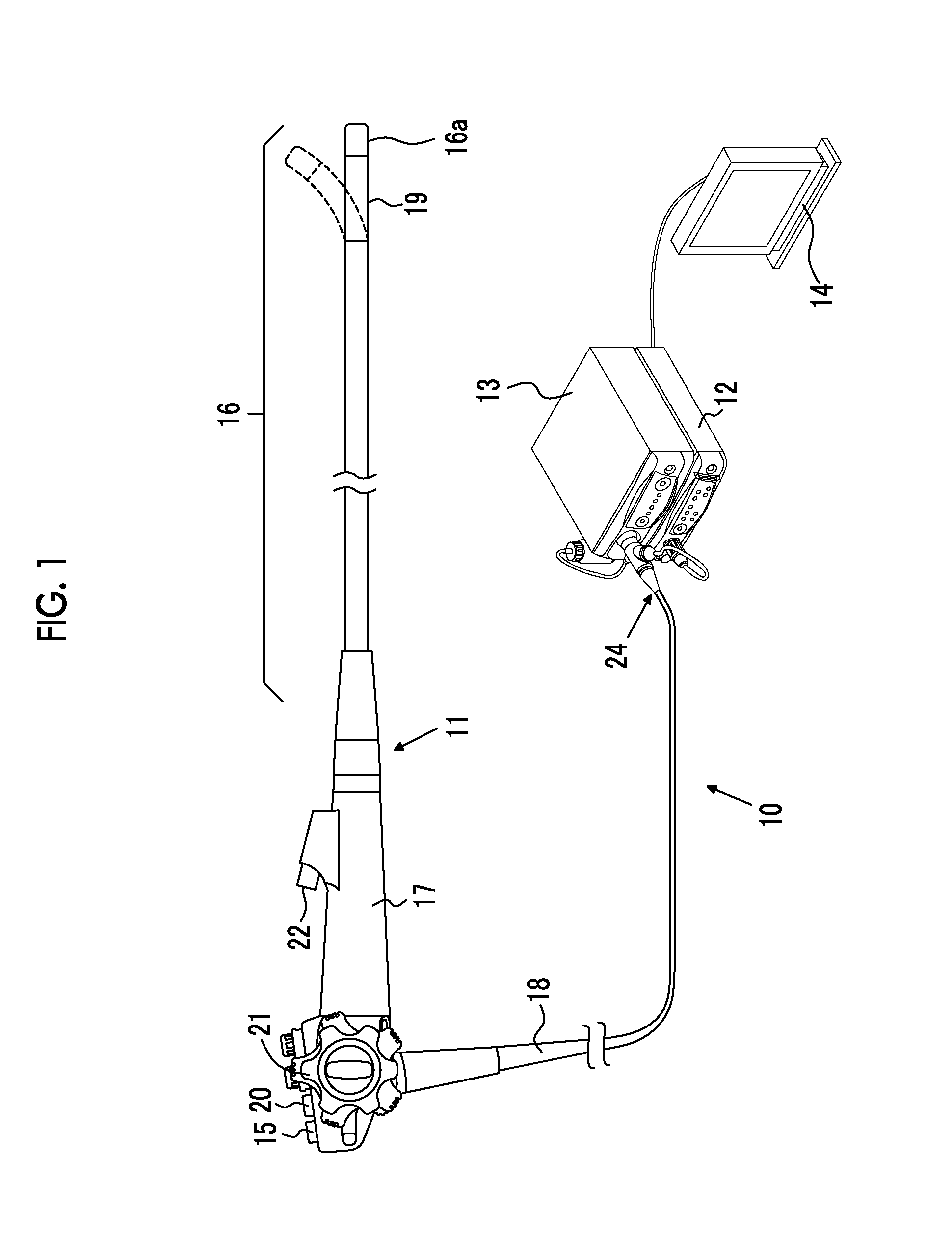

Endoscope system

InactiveUS20120190922A1Accurate diagnosisAccurate observationImage enhancementImage analysisImaging conditionPattern matching

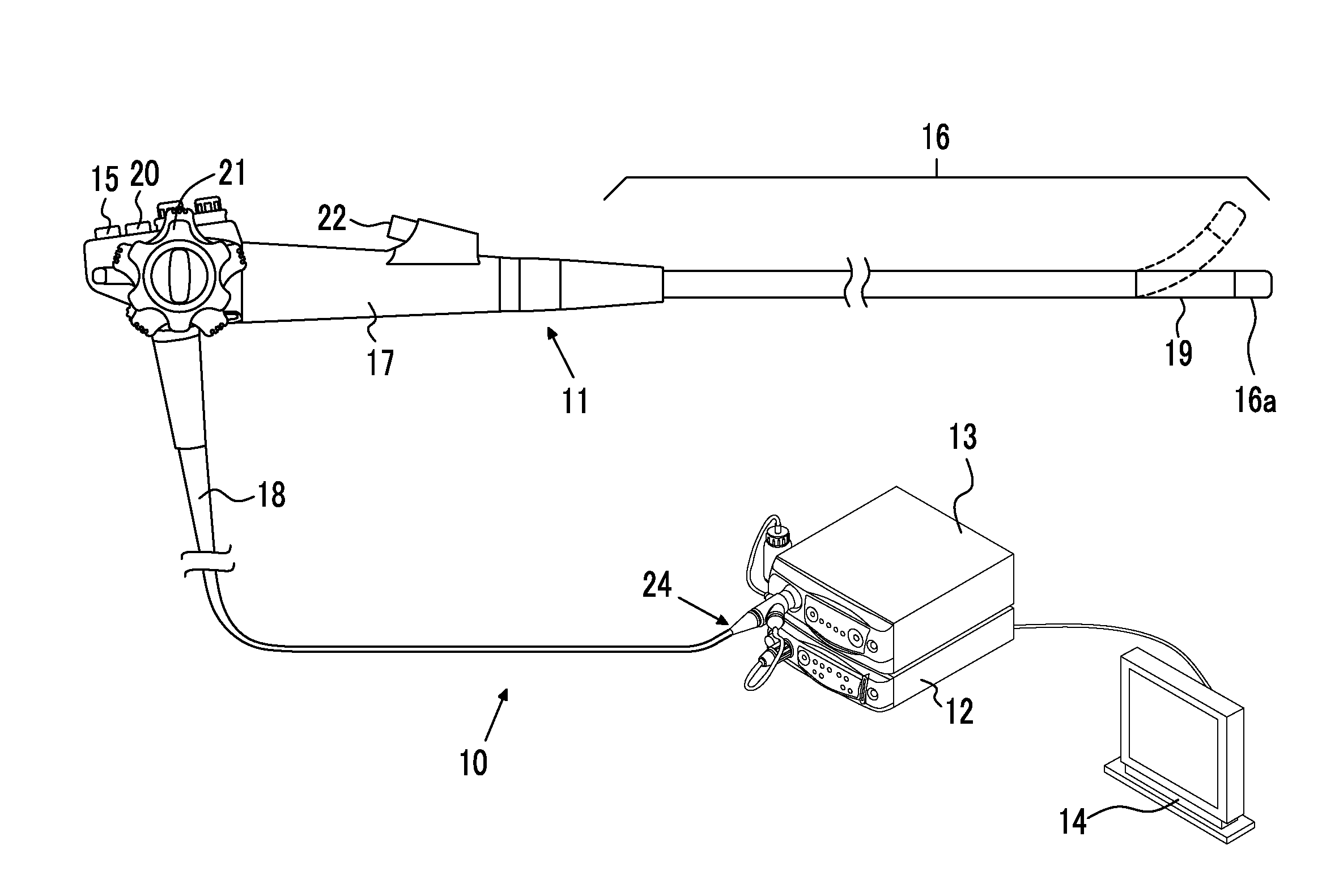

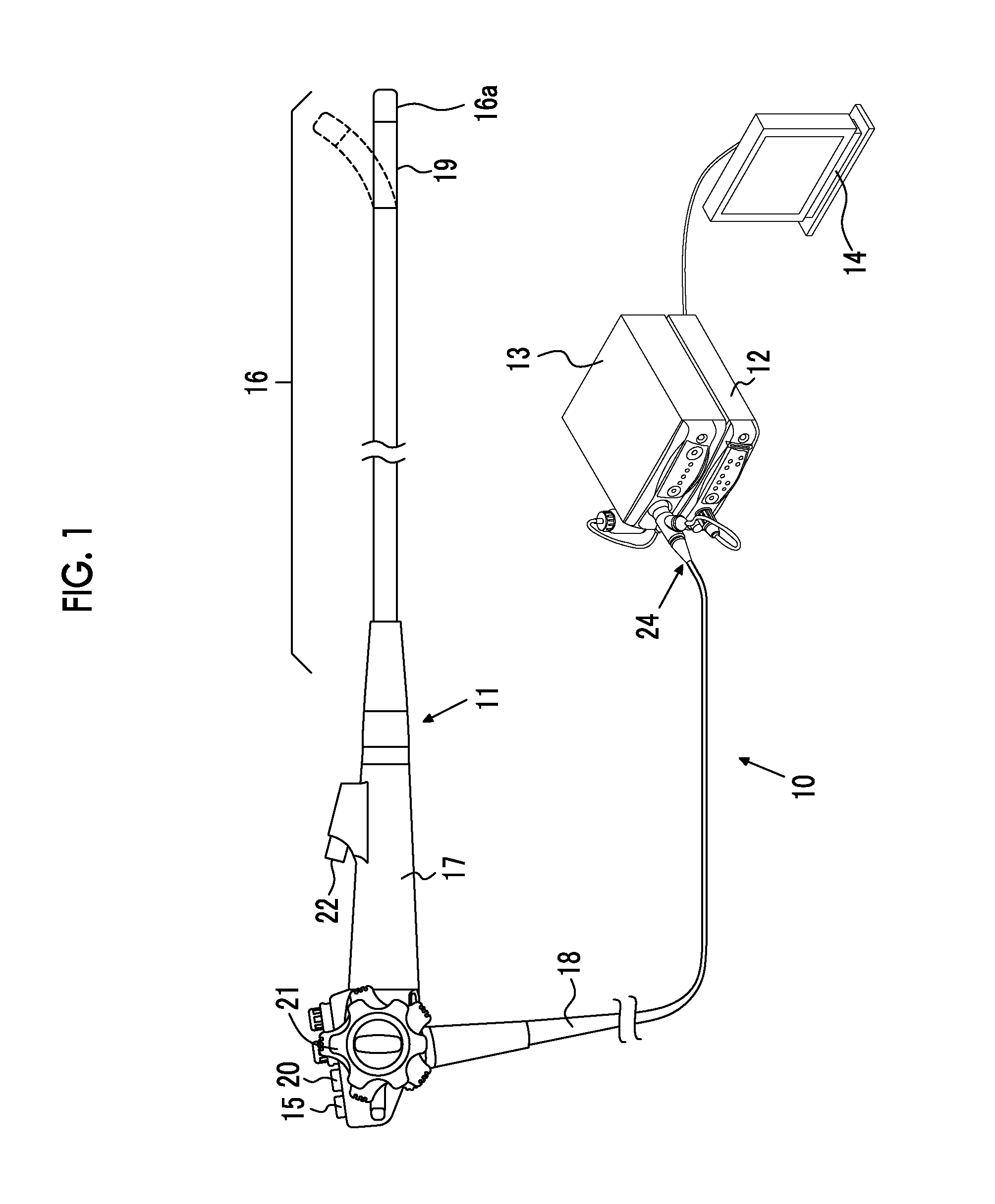

An endoscope system is provided in which blood vessels (pits) are extracted from an image captured by an endoscope to perform pattern matching with vascular patterns (pit patterns) associated with the cancer invasion depth and operations such as enhanced display of blood vessels, suggestion of preferred imaging conditions and display for diagnosis support are performed based on the matching result. The endoscope system enables even a less-experienced doctor to correctly diagnose the cancer invasion depth.

Owner:FUJIFILM CORP

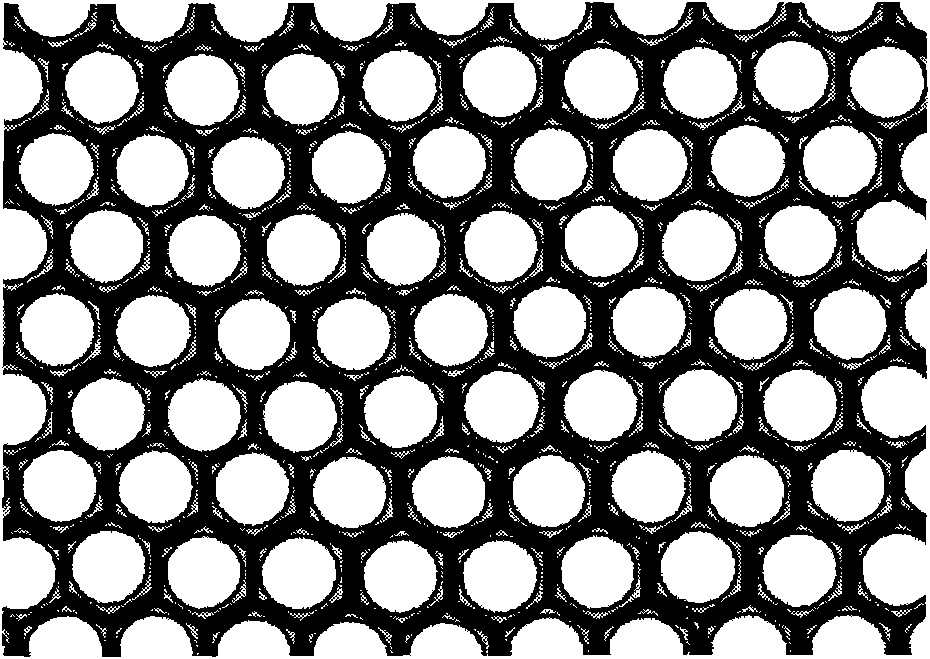

Modulation method for shape morphing of hole of anodic aluminum oxide template

The invention discloses a modulation method for shape morphing of a hole of an anodic aluminum oxide template, which comprises the following steps: I. removing grease and dirt of the surface of annealing-treated or untreated aluminium foil, and then carrying out electrochemical polishing treatment on the aluminium foil for later use; II. forming pit patterns on the surface of the aluminium foil by adopting an electrochemical oxidation method or a hard template mechanical pitting method; and III. carrying out noncontinuous oxidation and chambering on the aluminium foil the surface of which is provided with the pit patterns in an acid electrolyte to form various three-dimensional morphing-type aluminum oxide nanopore array structures by the combination control of electrolyte composition, electrolyte temperature, oxidation voltage, oxidation and chambering frequency and oxidation and chambering time. The modulation method uses existing equipment, has simple implementation and can manufacture various three-dimensional morphing shape-adjustable porous anodic aluminum oxide templates in manner of low cost and big area.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Intaglio printing process for printing decorative pattern

The gravure printing method for printing decorative pattern is characterized by that said method incldues the following steps: gravure plate-making for decorative pattern, using gravure press to print UV printing ink on the card paper, then using UV light to cure, the described pattern is the patterns of pit pattern (imitation metal etch), dioptric pattern, wrinkle, ice flower and corellite pattern, then using chemical etching or electronic plate-making process to make plate and print, also can make composite plate on printing roller. Said invention adopts single-sheet gravure press and web gravure press, the card paper can be gold can paper, silver card paper or card paper with colour, and its printing ink is UV gravure decorative printing ink.

Owner:潘治平 +2

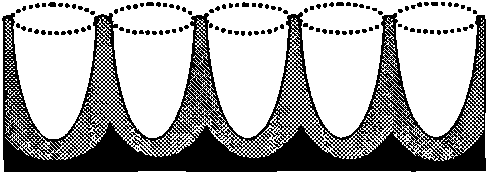

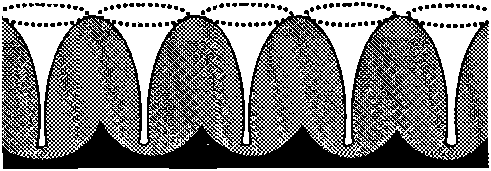

Electrode with pit patterns for secondary battery, and preparation method and application of electrode

ActiveCN106784611ALimit volume changeMaintain stabilityElectrochemical processing of electrodesFuel and secondary cellsLithiumMicrometer

The invention discloses an electrode for a secondary battery. At least one of an upper surface and a lower surface of the electrode is provided with a plurality of pits, the top projection area of each pit is 25 square nanometers to 250000 square micrometers, a depth of each pit is 10 nanometers to 500 micrometers, and a central distance between two adjacent pits is 10 nanometers to 1000 micrometers. When used as a secondary battery electrode, the electrode can effectively limit an electrochemical active metal such as metal lithium in the pits, so that dendritic crystals (for example, lithium dendritic crystals) of the electrochemical active metal can be prevented from appearing on the surface of the electrode, the huge volume deformation of the electrode in an alloy reaction process can be buffered, and the safety performance and cycle life of the metal secondary battery can be improved and prolonged. The invention also provides a preparation method and application of the electrode.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

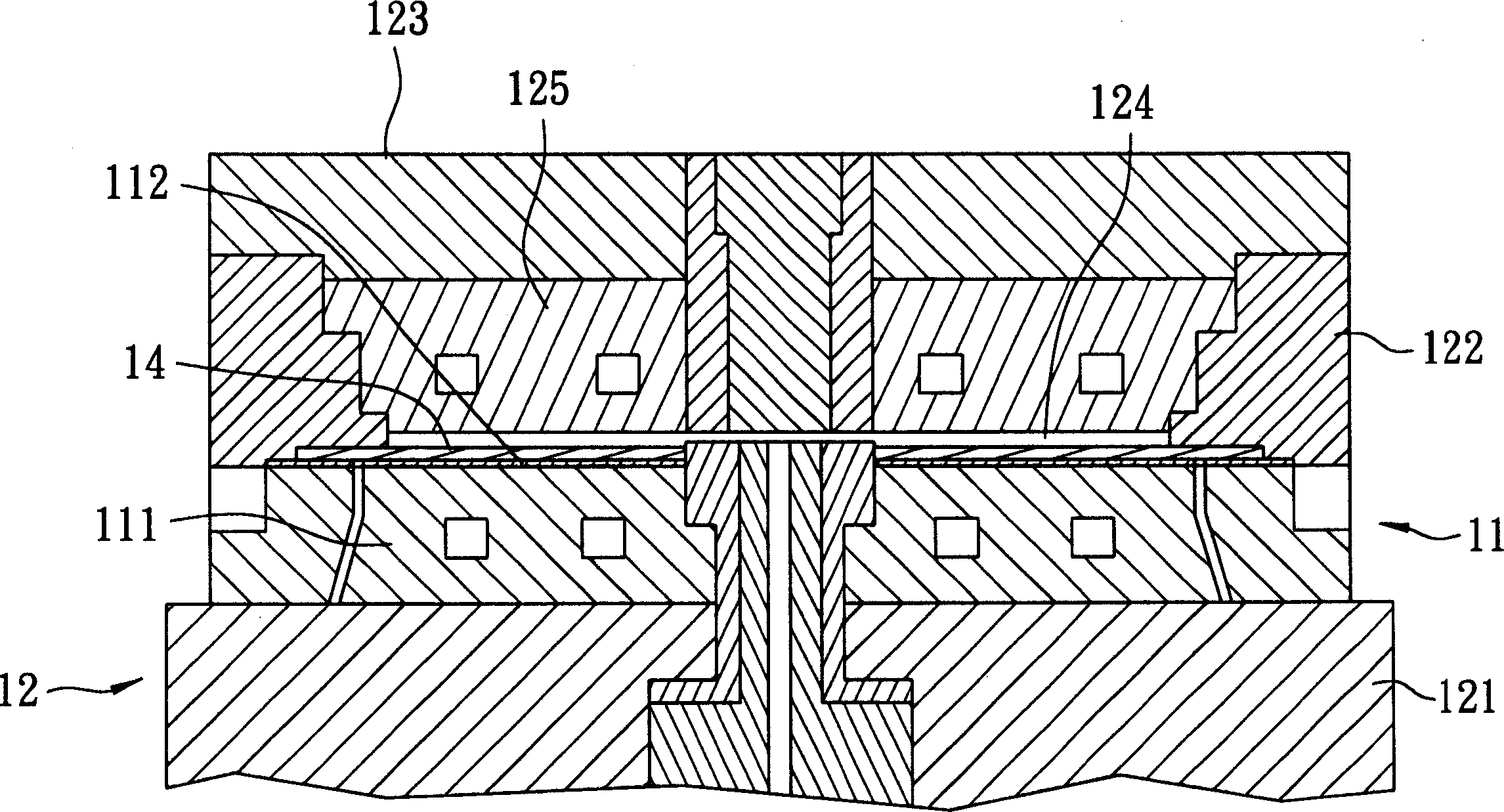

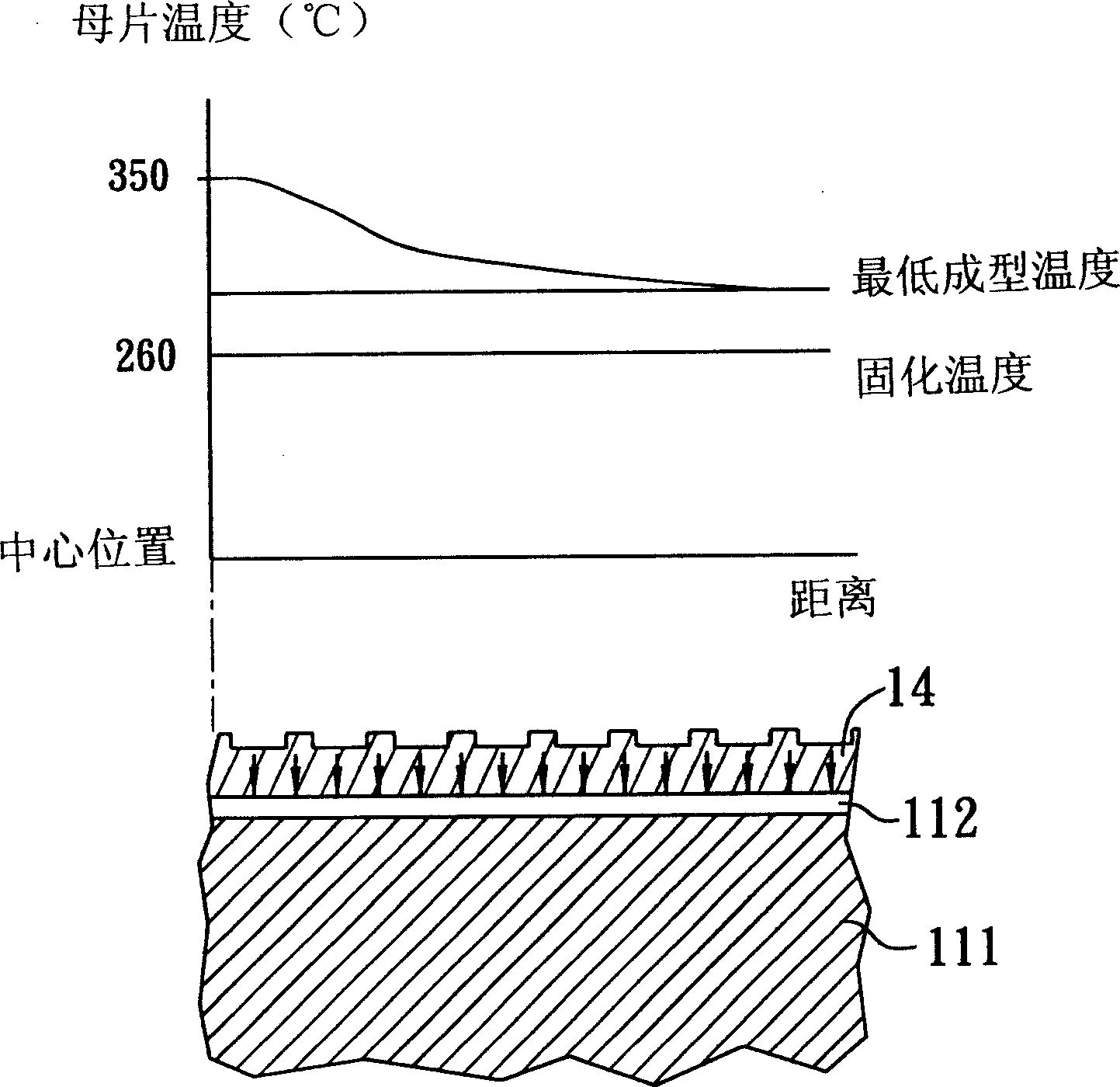

Method for mfg. mould core

A method for preparing the template includes such steps as polishing the top surface of a plate, plating a hard film, and using circular ball to impact on the top surface to form multiple arc pits. A mother film with information pit pattern on its surface can be stuck on said template to decrease the contact area between them and the abrasion. It can also be directly used to form a light conducting plate with high brightness.

Owner:COSMOVAC IND CO LTD

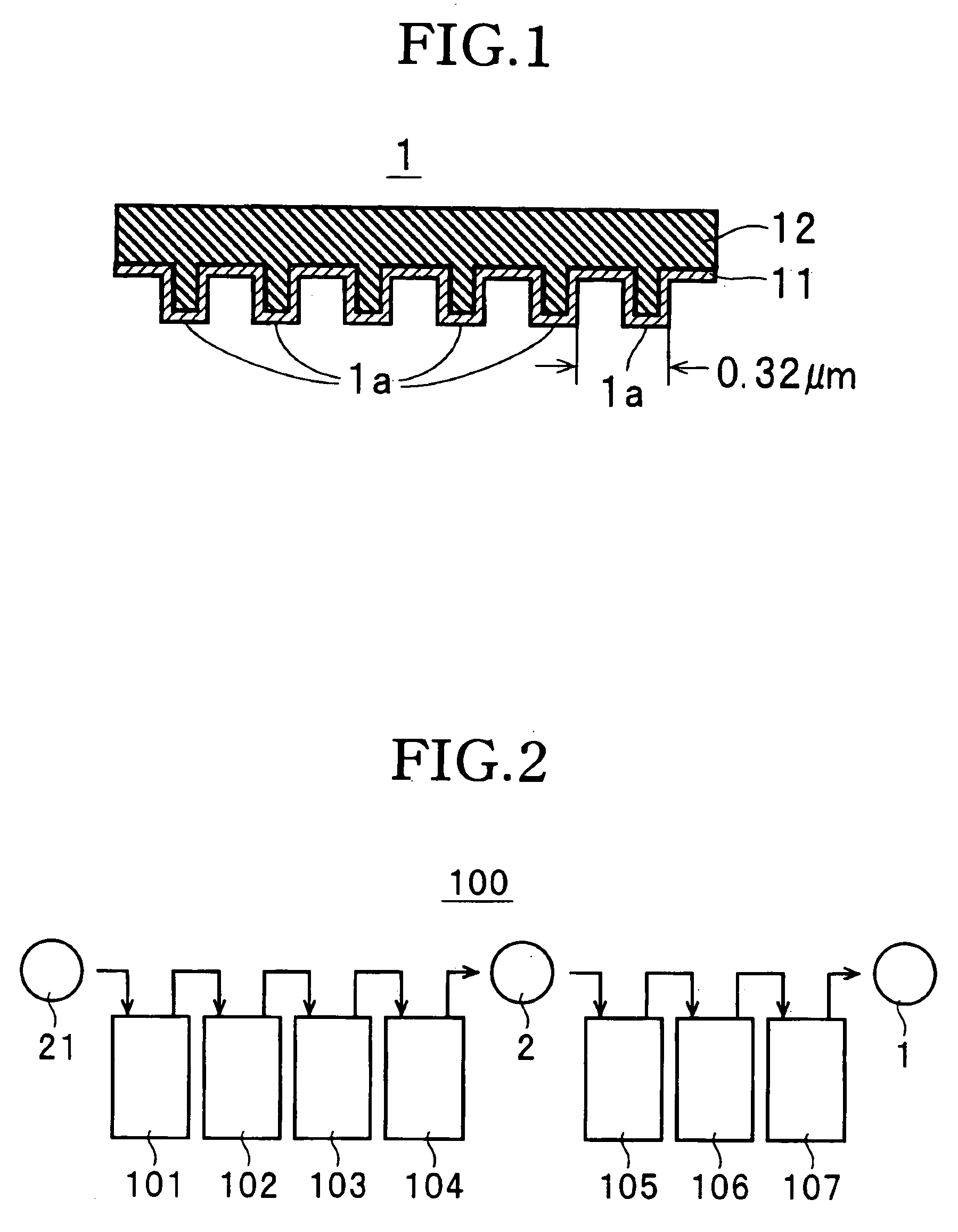

Method for manufacturing a photoresist-coated glass board, method for manufacturing a stamper and method for manufacturing a recording medium

InactiveUS20050064345A1Forming accuratelyReliable formingInformation arrangementRecord information storageLatent imageBenzophenone

A method for manufacturing a photoresist-coated glass board includes steps of forming a resin layer containing a benzophenone system compound on a glass board, forming a photoresist layer on the resin layer, intermittently projecting a laser beam for exposure having a wavelength λ of 100 nm to 300 nm onto the photoresist layer, forming a latent image of a pit pattern so that a half-width l of a shortest pit length is equal to or shorter than 0.65 λ, and developing the photoresist layer in which the latent image is formed to form a pit pattern in the photoresist layer. According to thus constituted method for manufacturing a photoresist-coated glass board, a photoresist-coated glass board can be formed with pits of a pit pattern in a desired manner using a laser beam having a short wavelength.

Owner:TDK CORPARATION

Diagnostic imaging apparatus

InactiveUS20100069747A1Readily visually determineImprove accuracyCatheterCharacter and pattern recognitionLarge intestineDepth direction

A diagnosis apparatus in which a lesion in the large intestine can be diagnosed with high precision by detecting pits is provided. A three-dimensional optical tomographic image is obtained by the configuration of an apparatus using an endoscope and an optical probe, images in X-Y planes perpendicular to the depth direction of a living body tissue are cut out at a plurality of depth positions, based on the three-dimensional tomographic image data, and a pit pattern shape highlighted image is generated from their average image to perform diagnostic support.

Owner:FUJIFILM CORP

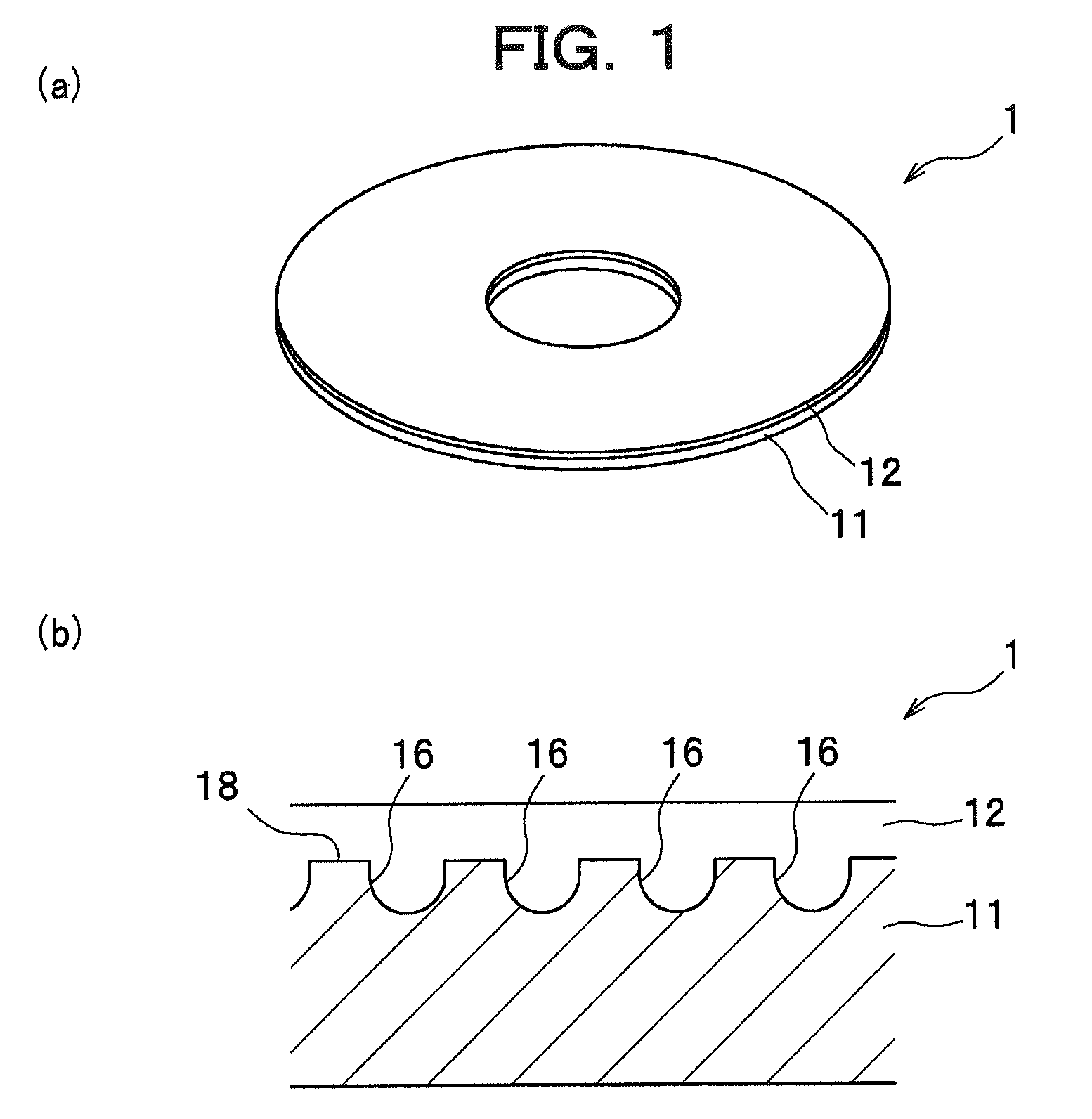

Optical data recording medium and manufacturing method for the same

ActiveUS7195691B2Uniform thicknessHigh thickness accuracyRecord carriersLamination ancillary operationsEngineeringRecording layer

An optical disc manufacturing method suppresses thickness variation in intermediate layers disposed between any two data recording layers to achieve an intermediate layer of uniform thickness. A substrate having a center hole and data recording layer is first prepared. This center hole is then plugged with a capping member and a resin material is dripped from above the center hole while spinning the substrate around its center hole to coat the data recording layer with the resin by a spin coating method. The capping member is then removed. Then, a stamper having a groove or lands and pits on its surface is prepared. The groove or lands and pits side of the stamper is then pressed into the resin material on the substrate, and the resin is then cured to form an intermediate layer. The stamper is then separated from the substrate to leave a data recording layer in the surface of the intermediate layer with a groove or land-and-pit pattern corresponding to the groove or lands and pits in the stamper.

Owner:PANASONIC CORP

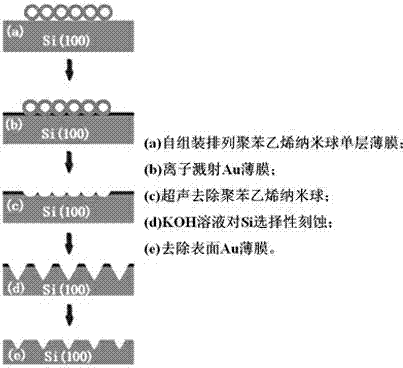

Method for preparing ordered germanium quantum dot on silicon substrate by sputtering

InactiveCN104762593ASolve the disadvantages of disordered distributionLow costMaterial nanotechnologyVacuum evaporation coatingPolystyreneMonolayer

The invention relates to a method for preparing an ordered germanium quantum dot on a silicon substrate by sputtering and belongs to the technical field of semiconductor quantum material. The method comprises the following steps: preparing a two-dimensional ordered hexagonal nano-pit pattern on the surface of the silicon substrate through a polrvinyl benzene nanosphere corrosion technology, growing a silicon buffer layer on the patterned silicon substrate through an ion beam sputtering technology by taking high-purity argon as the working gas under the conditions that the base vacuum degree of a sputtering chamber is less than 3.0*10<-4> Pa, the growth temperature is 400-800 DEG C, the beam voltage is 0.5-1.1 KV and the growth beam is 4-15 mA; and performing self-organized growth to form a single layer ordered germanium quantum dot. The method is a novel method for realizing the volume production of the quantum dot material with low cost, simple process and high production efficiency and provides a good method for researching an efficient quantum dot laser and even a nano-laser.

Owner:YUNNAN UNIV

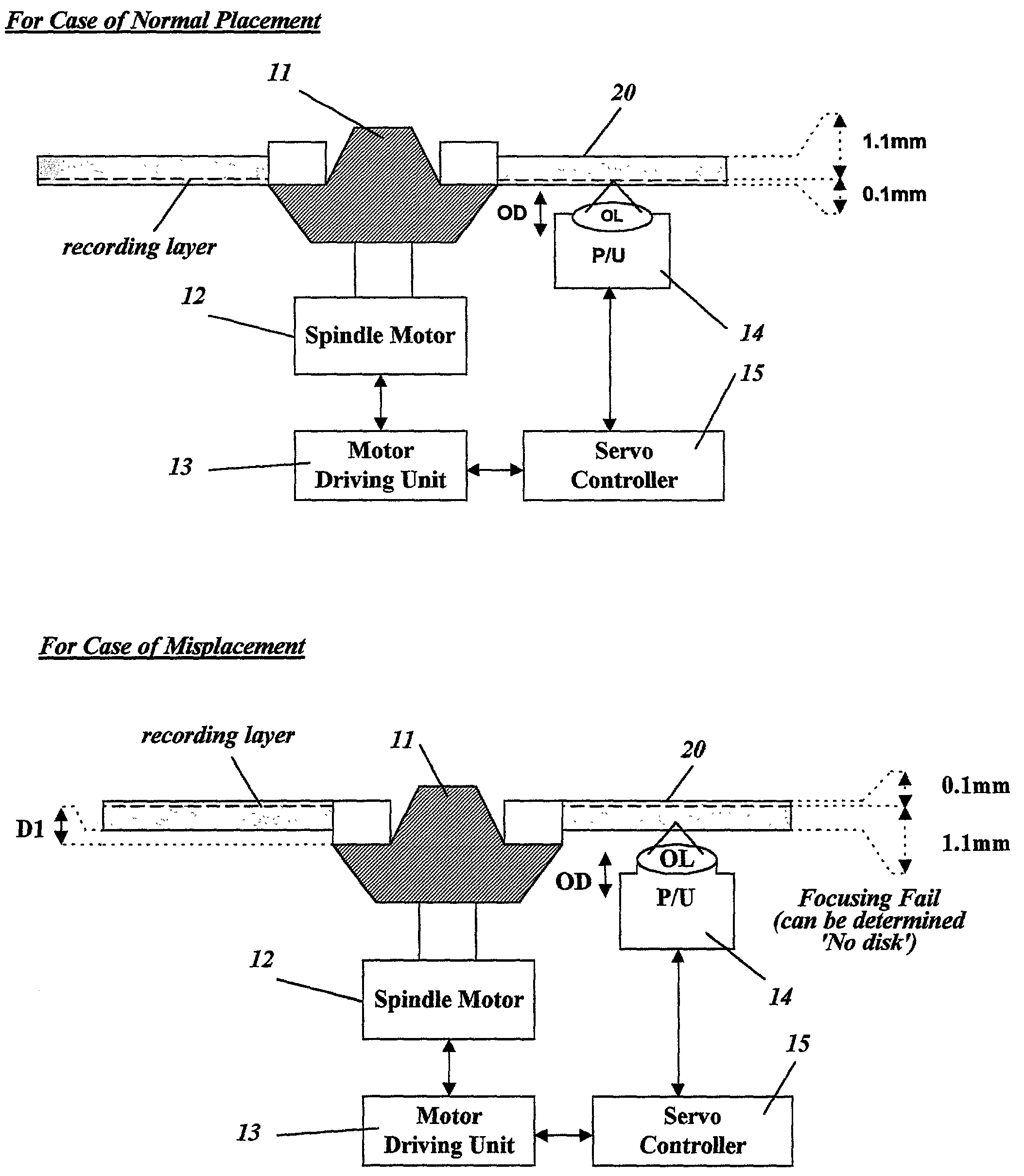

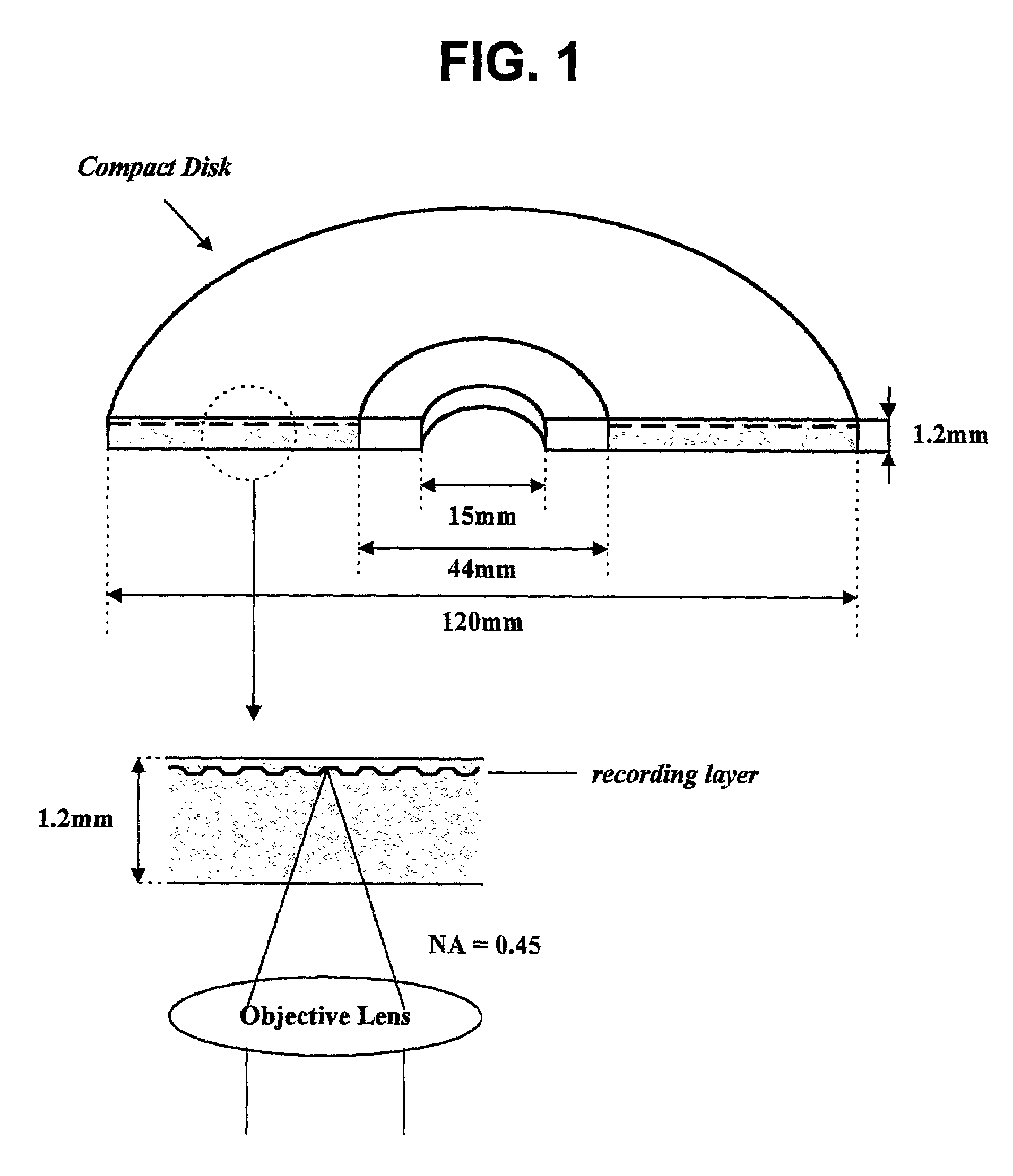

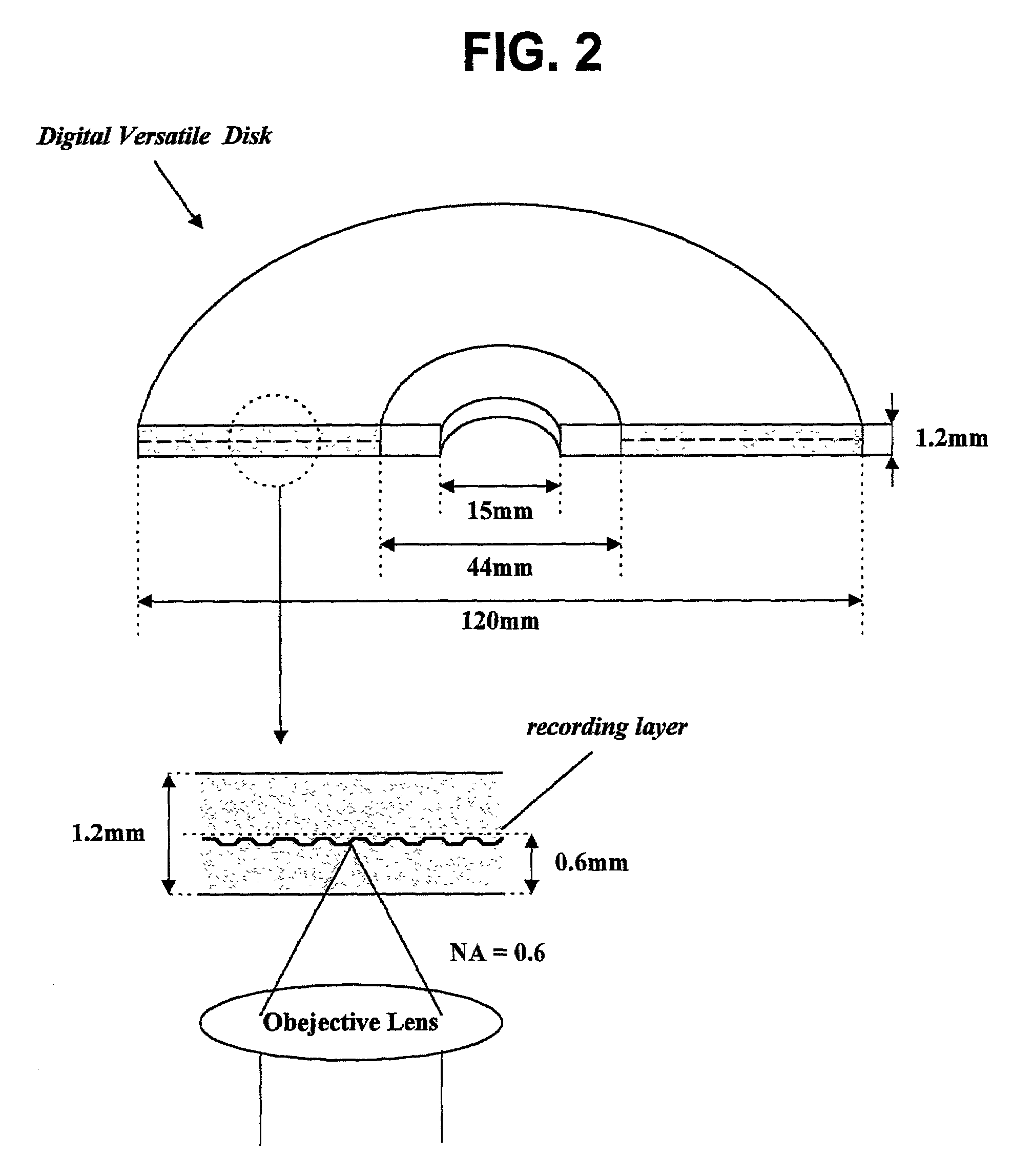

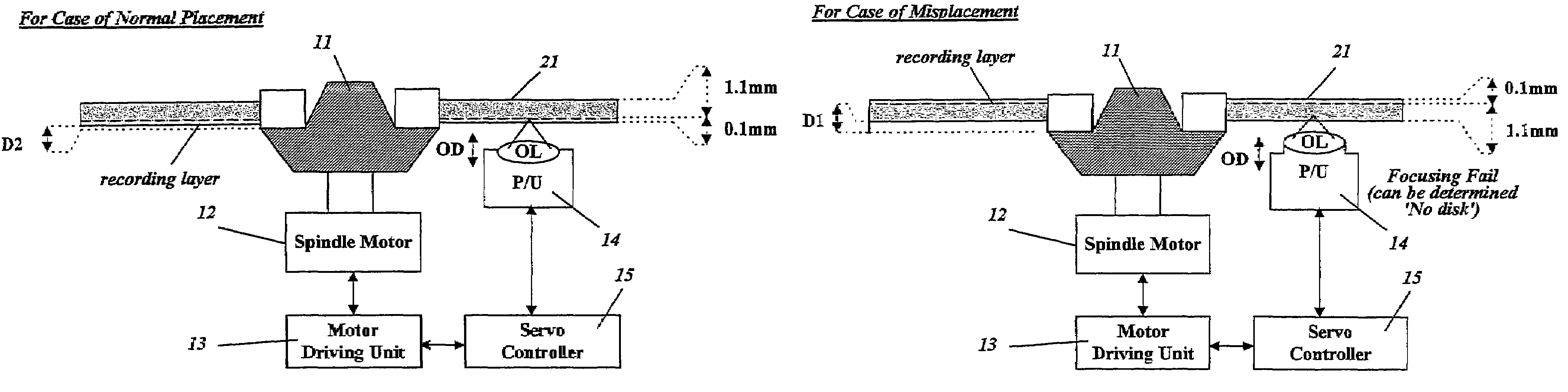

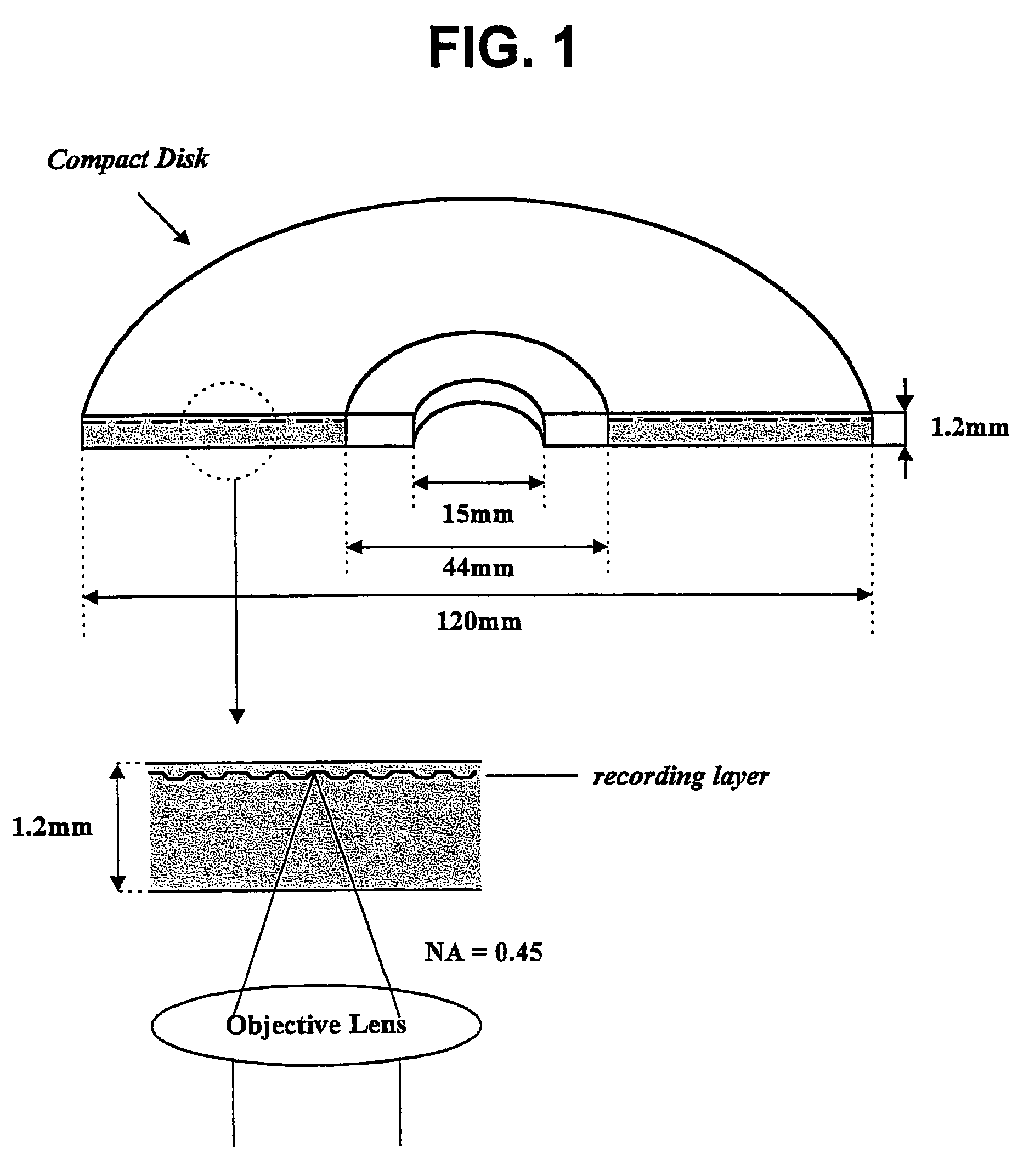

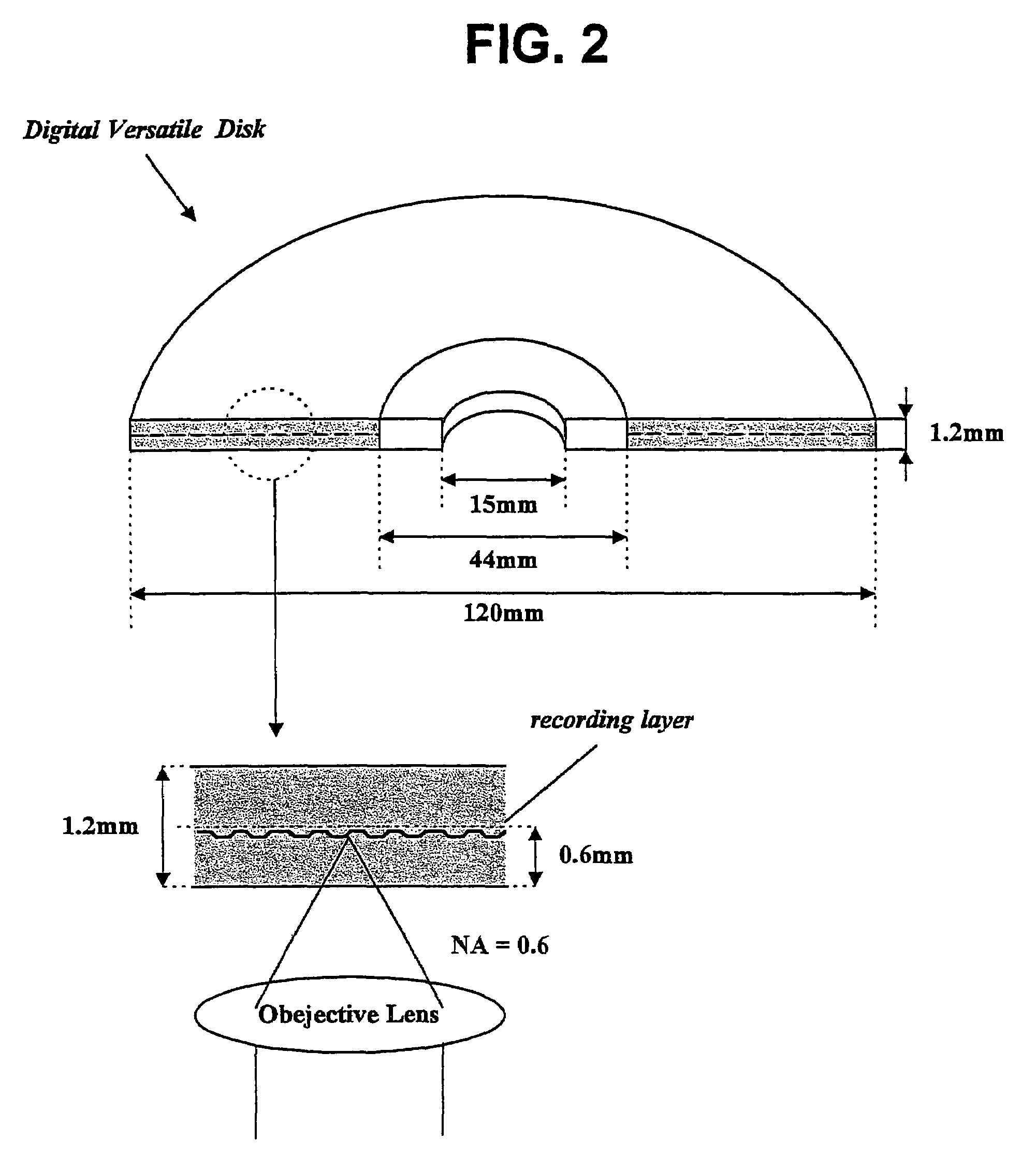

High density disk recording medium and apparatus using the same

InactiveUS7012880B2Enabling detectionMechanical record carriersRecord information storageOptical pickupHigh density

The present invention relates to a high-density disk that is structured to prevent a collision of an optical pickup's objective lens with the high-density disk if the disk is placed upside down in a disk device that is able to record and reproduce signals to / from the high-density disk. A high-density disk recording medium according to the present invention is structured such that, wherein a recording layer having high-density pit patterns is offset from a center plane of disk thickness, both sides of a clamping zone bisected by the center plane have differing thicknesses. One or both sides may protrude from surface of the disk recording medium, or one side of the clamping zone may protrude from the surface while the other side is indented below the surface.

Owner:LG ELECTRONICS INC

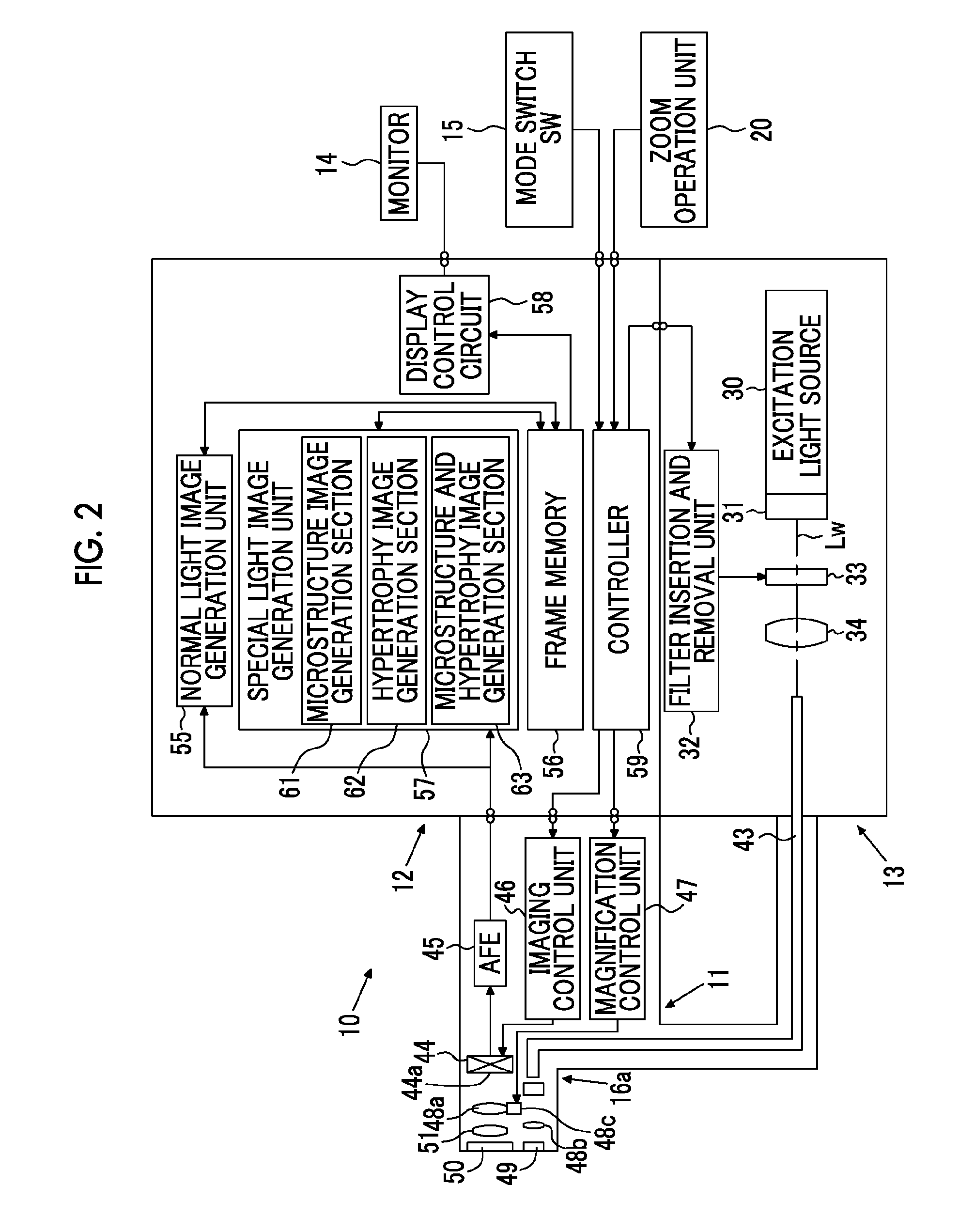

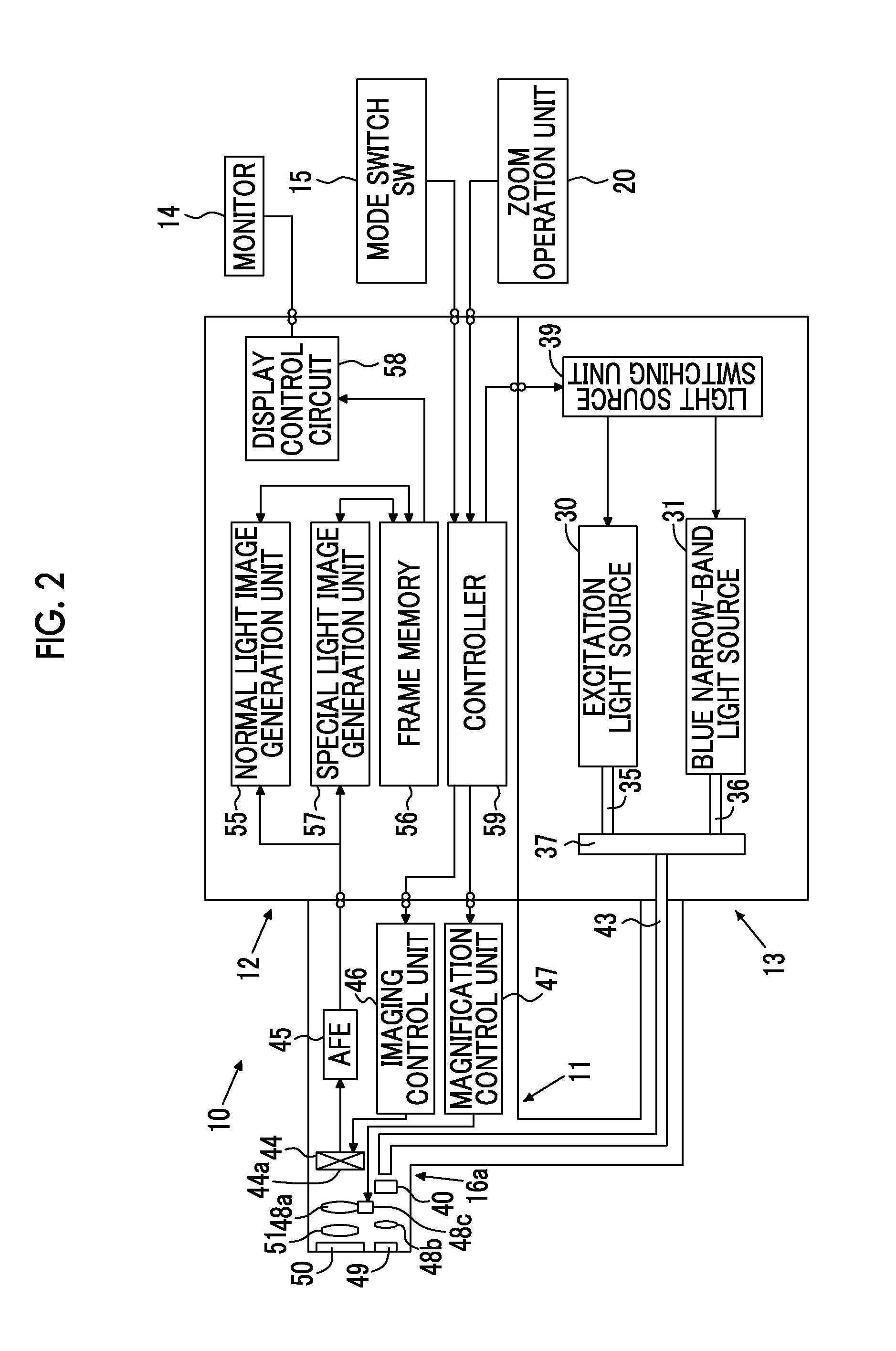

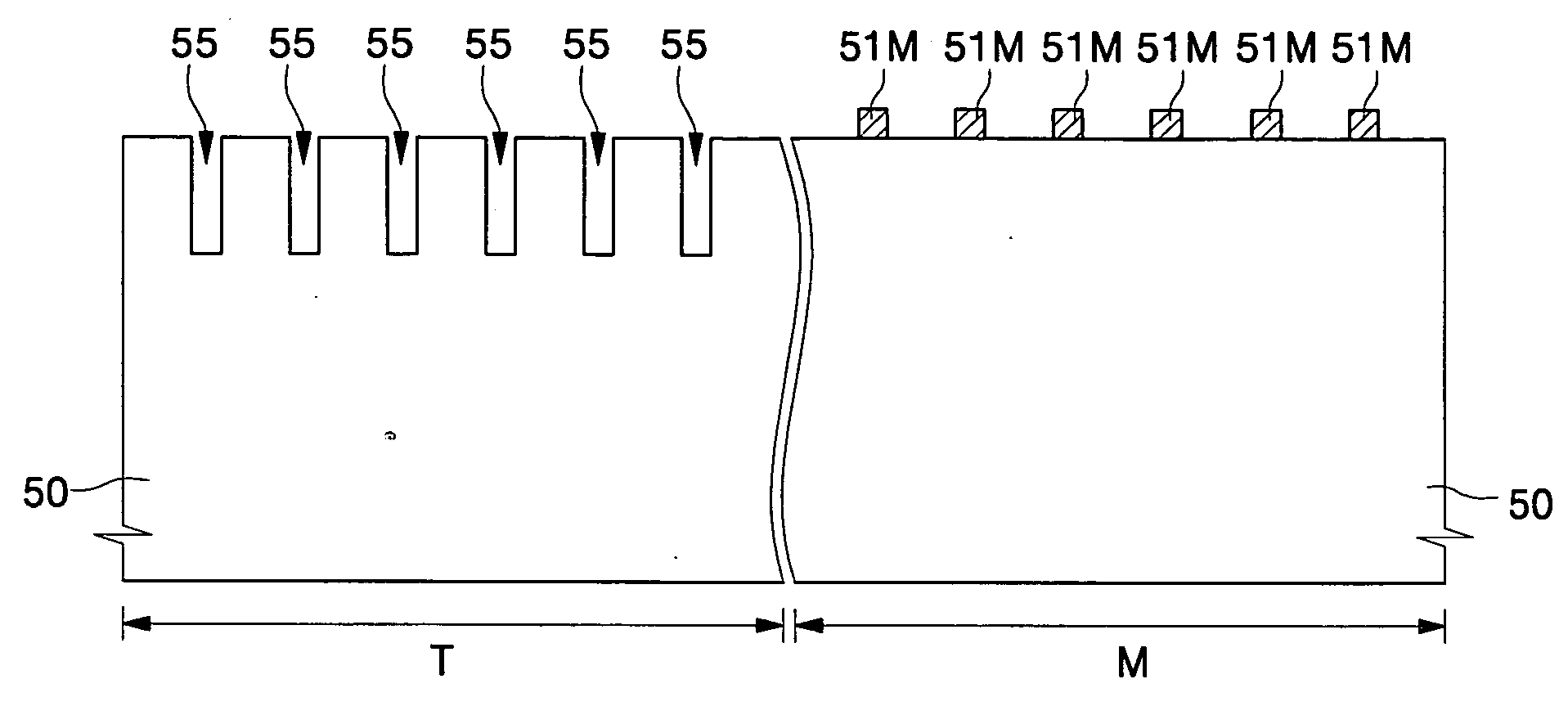

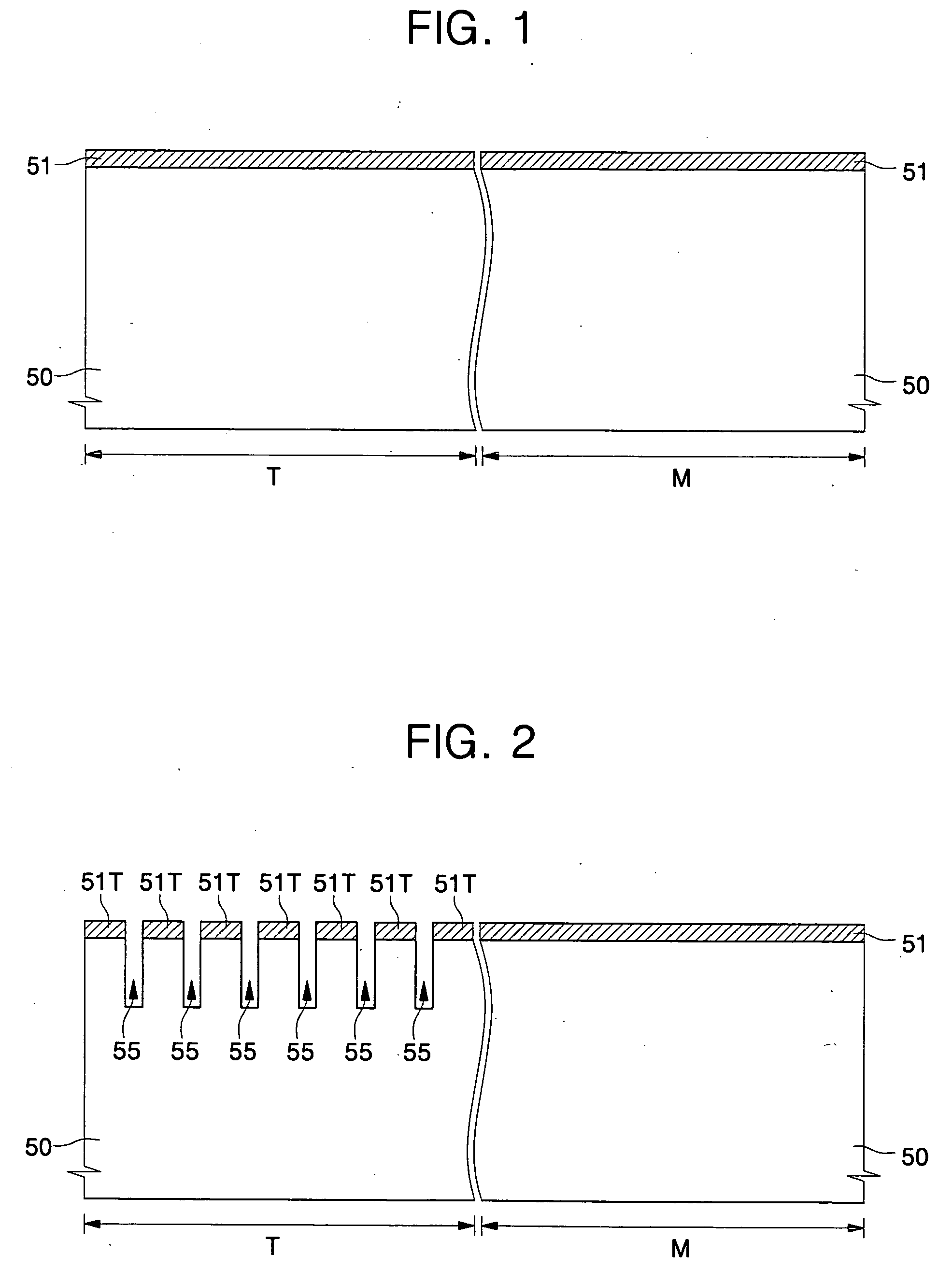

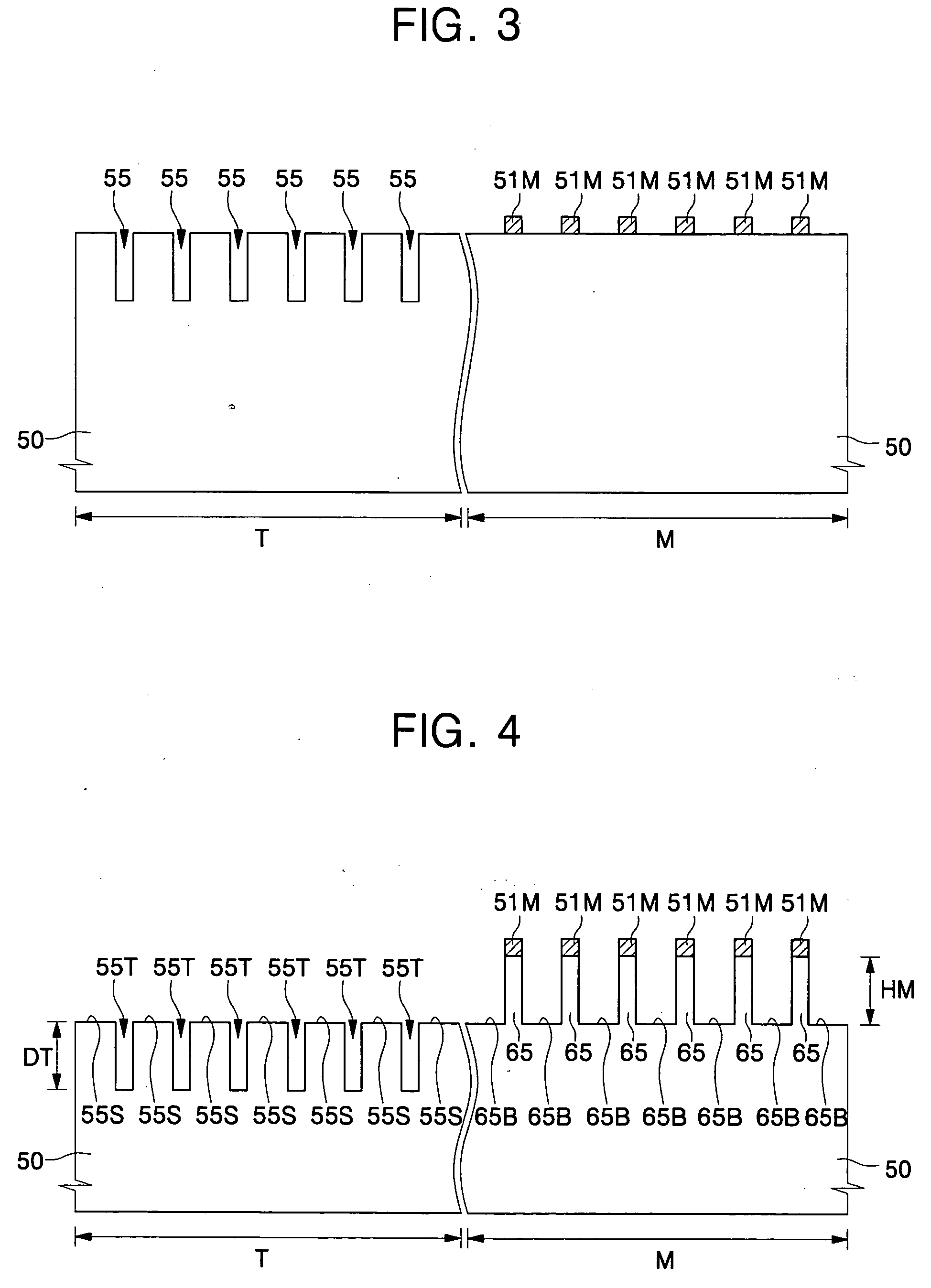

Endoscope system and image generation method

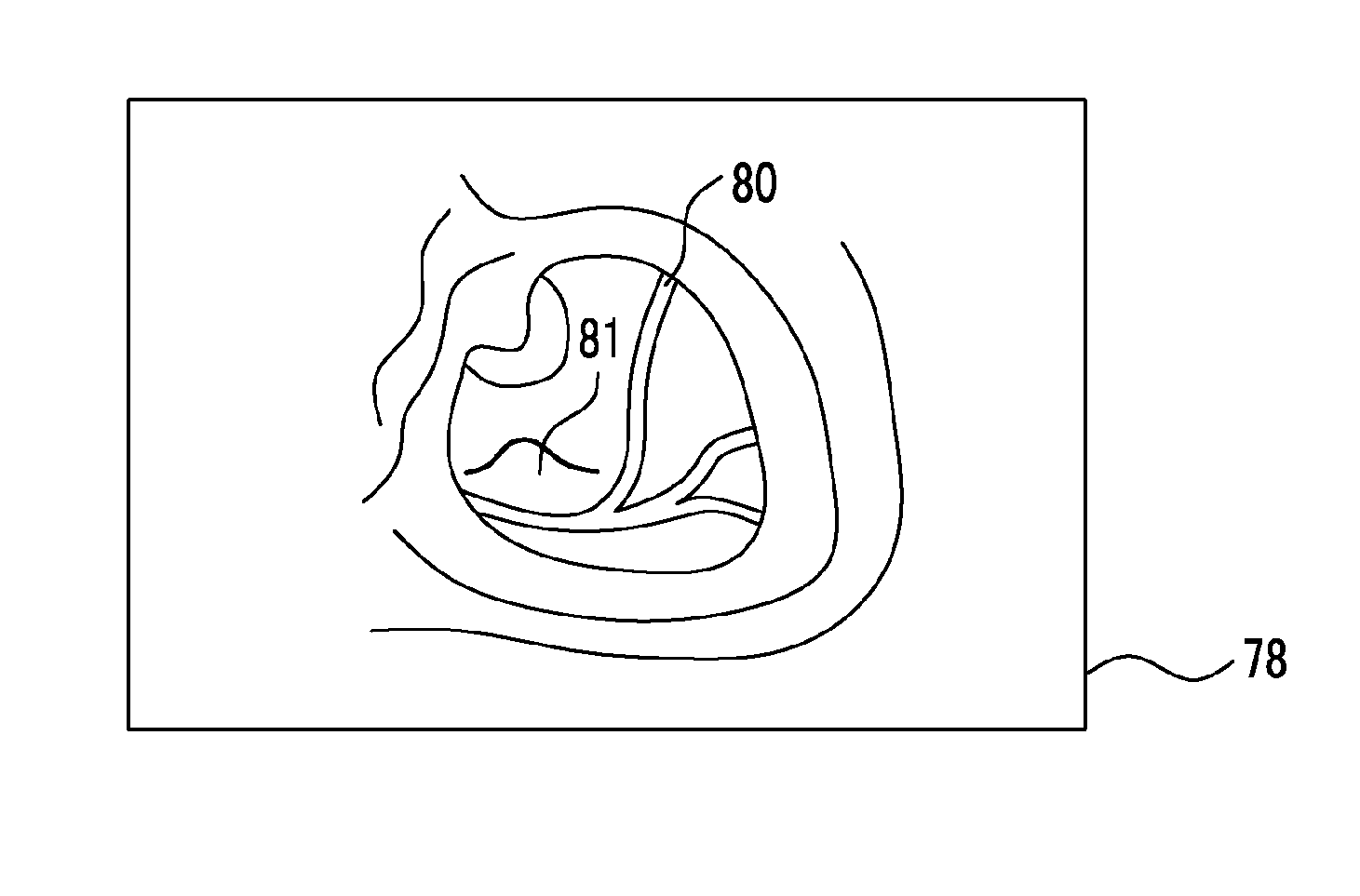

InactiveUS20140221794A1Increase awarenessSuppressing displaySurgeryEndoscopesEccentric hypertrophyHigh absorption

The visibility of irregularities on the body tissue, such as a superficial microstructure or hypertrophy, is improved. Excitation light EL is emitted to a phosphor to excite and emit white light W. High absorption wavelength cut light is generated by removing components in high absorption wavelength bands A1 and A2, in which the absorption coefficient of hemoglobin in the blood is high, from the white light using a high absorption wavelength rejection filter. The subject is illuminated with the high absorption wavelength cut light, and image light of the reflected light is captured by a color CCD. A microstructure image is generated based on a signal Bp output from the B pixel of the CCD. In this microstructure image, the display of superficial microvessels is suppressed. Accordingly, the visibility of superficial microstructures, such as a pit pattern, is relatively improved.

Owner:FUJIFILM CORP

Fabrication of semiconductor devices

InactiveUS7507663B2Avoid the needSemiconductor/solid-state device detailsSolid-state devicesElectrical devicesEngineering

Fabrication of microelectronic devices is accomplished using a substrate having a recessed pattern. In one approach, a master form is used to replicate a substrate having a pit pattern. In another approach, the substrate is produced by etching. A series of stacked layers having desired electrical characteristics is applied to the substrate and planarized in a manner that creates electrical devices and connections therebetween. The microelectronic devices can include a series of row and columns and are used to store data at their intersection.

Owner:WODEN TECH INC

Endoscope system and image generation method

ActiveUS20140221745A1Improve visibilityIncrease awarenessImage enhancementImage analysisEccentric hypertrophyEndoscope

Only irregularities on the body tissue, such as a superficial microstructure or a hypertrophy, are made clear. A blue signal B, a green signal G, and a red signal R are obtained by imaging a subject illuminated with white light W using a color CCD 44. Based on these signals B, G, and R, a brightness signal I ((B+G+R) / 3) showing the average brightness of the subject is generated. A pixel region exceeding the fixed threshold value Th1 of the brightness signal I is extracted as a superficial microstructure P, such as a pit pattern. A superficial microstructure image 70 obtained by extracting the superficial microstructure P is displayed on a monitor 14.

Owner:FUJIFILM CORP

Method for manufacturing titanium-nickel alloy anti-counterfeiting label carried with implicit information

InactiveCN103753139AReach the anti-counterfeiting functionSimple structureStampsStampingMemory effectX-ray

A method for manufacturing a titanium-nickel alloy anti-counterfeiting label carried with implicit information is that pit patterns are pressed on the surface of a titanium-nickel shape memory alloy material having the shape memory effect through a male die with anti-counterfeiting patterns, then the surface of the titanium-nickel shape memory alloy material provided with the pit patterns is subjected to mechanical polishing till pits on the titanium-nickel alloy surface disappear. Therefore, the pattern information implied in the material cannot be seen through naked eyes or microscopes, X-ray and other physical and chemical means by viewing from the appearance, and the anti-counterfeiting purpose is achieved. A titanium-nickel alloy anti-counterfeiting label sheet manufactured by means of the method can display the implicit information when being heated to be higher than Af, an anti-counterfeiting identification function is achieved, and the method is simple and reasonable, and the detection operation is convenient.

Owner:XI AN JIAOTONG UNIV

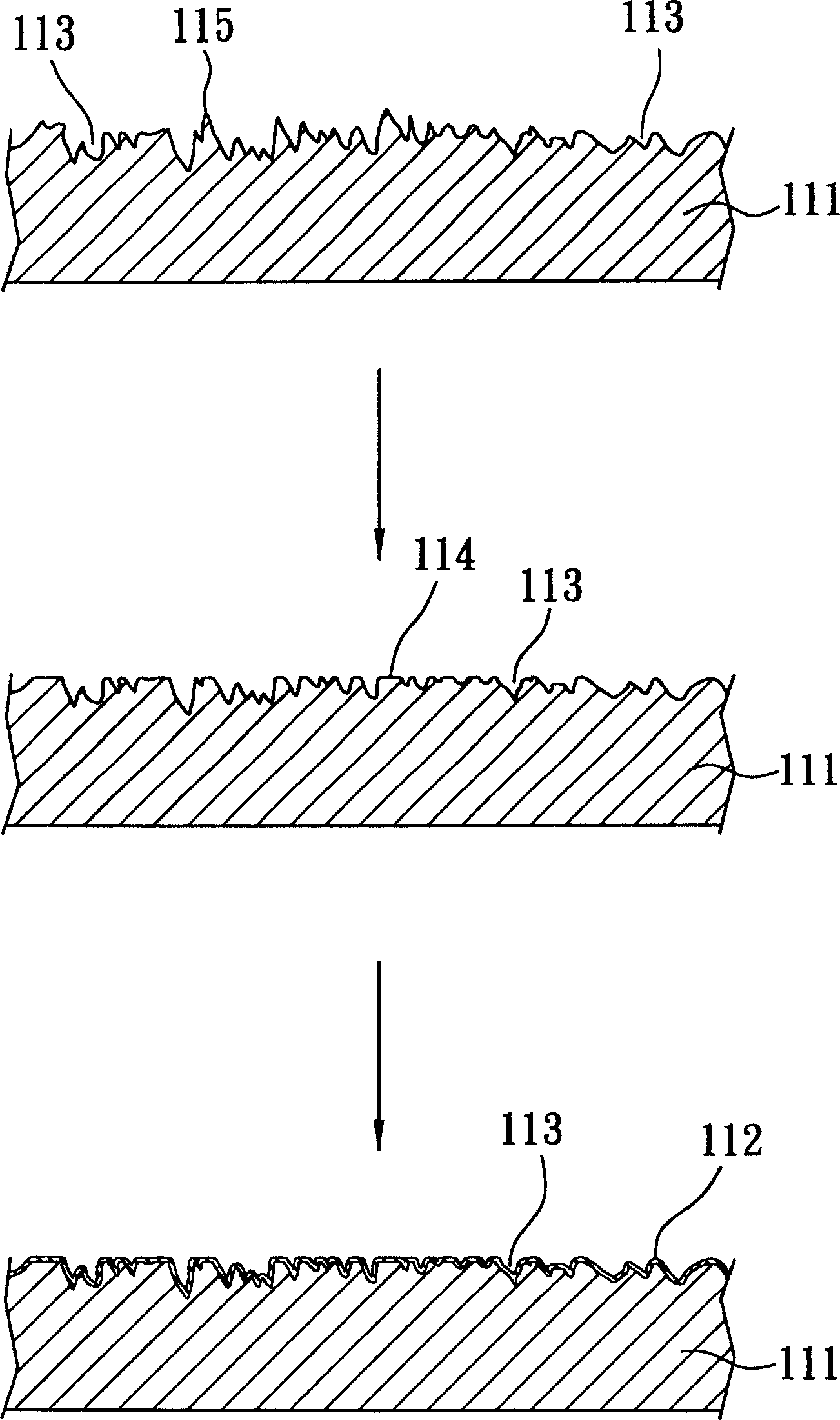

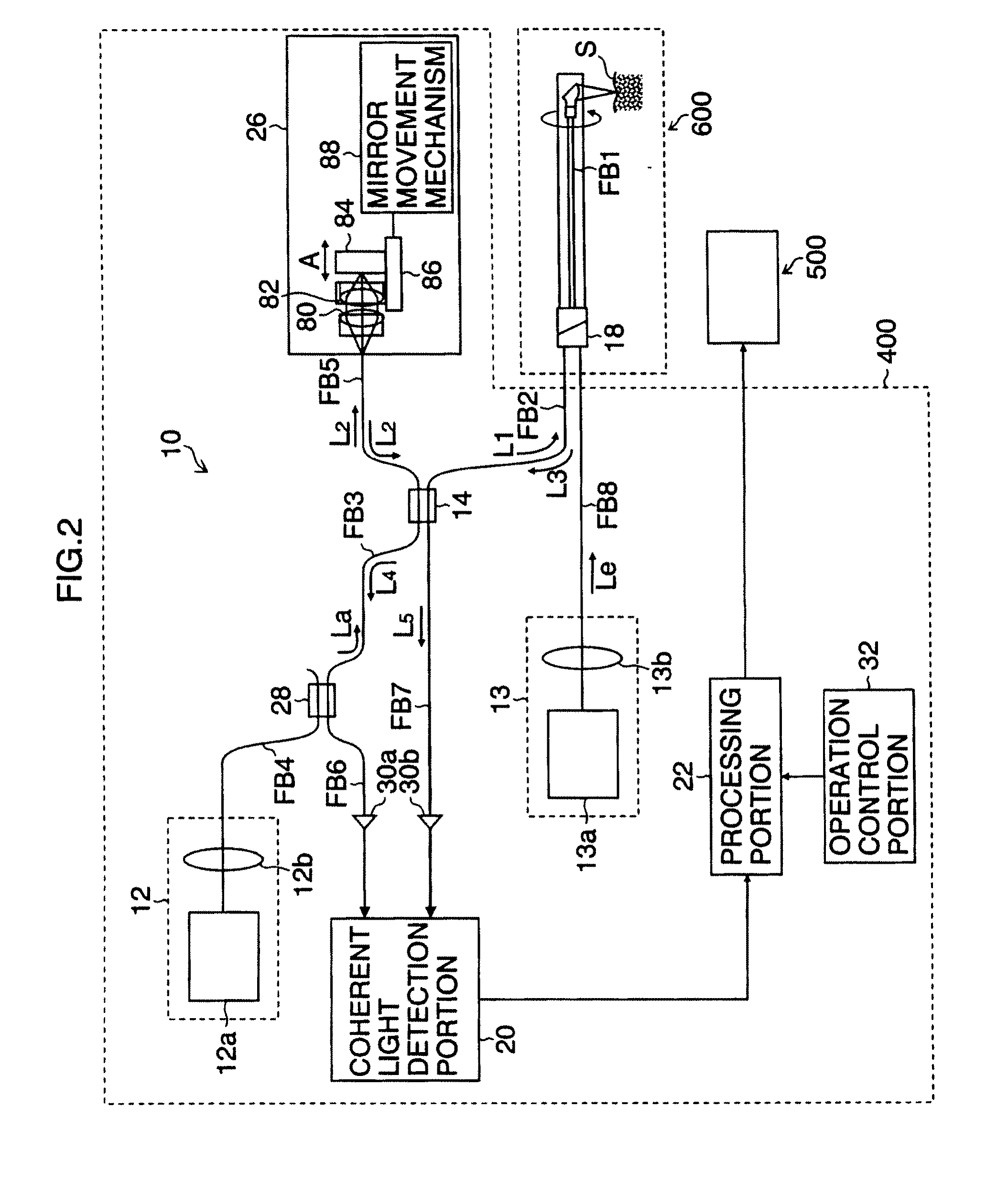

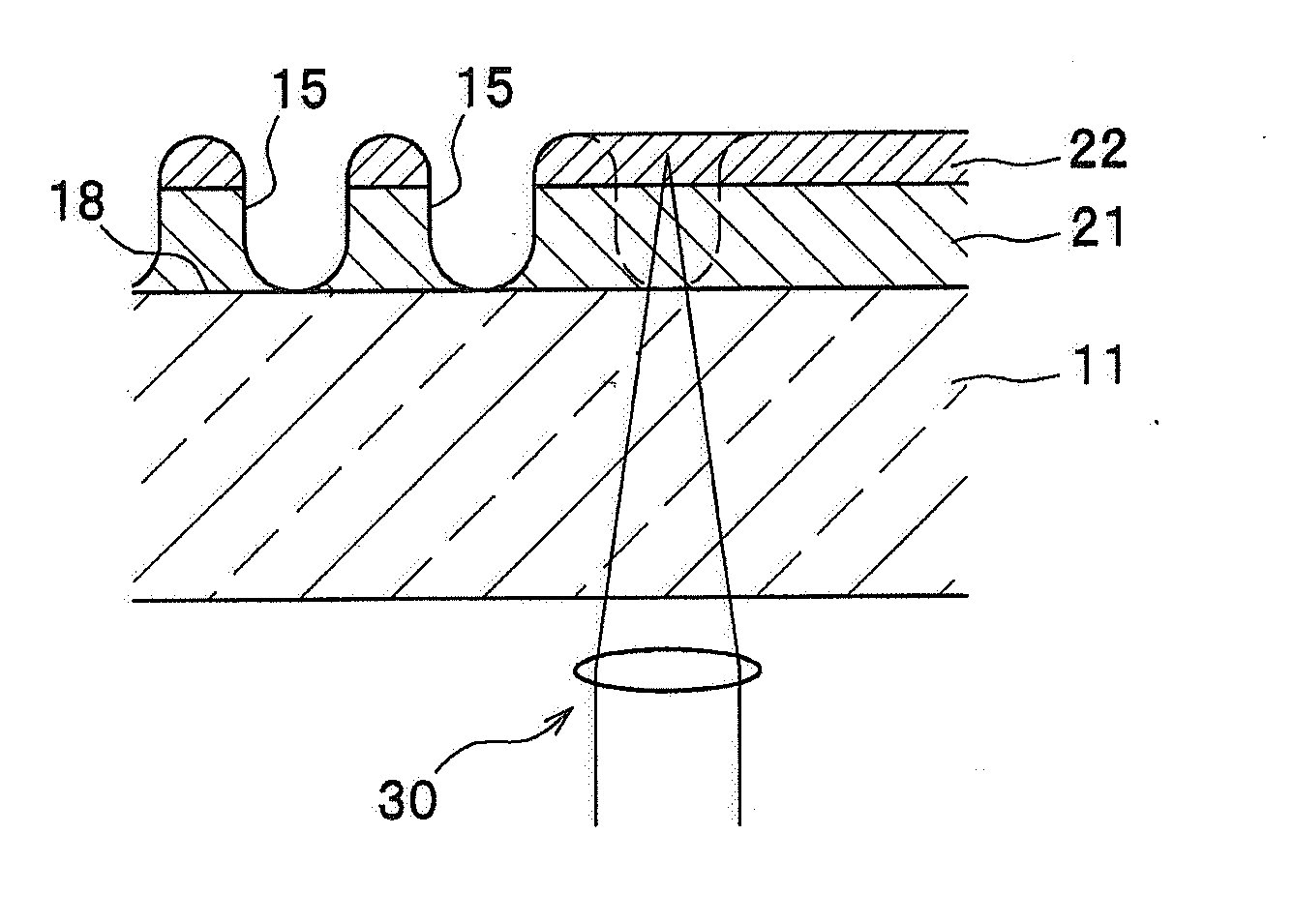

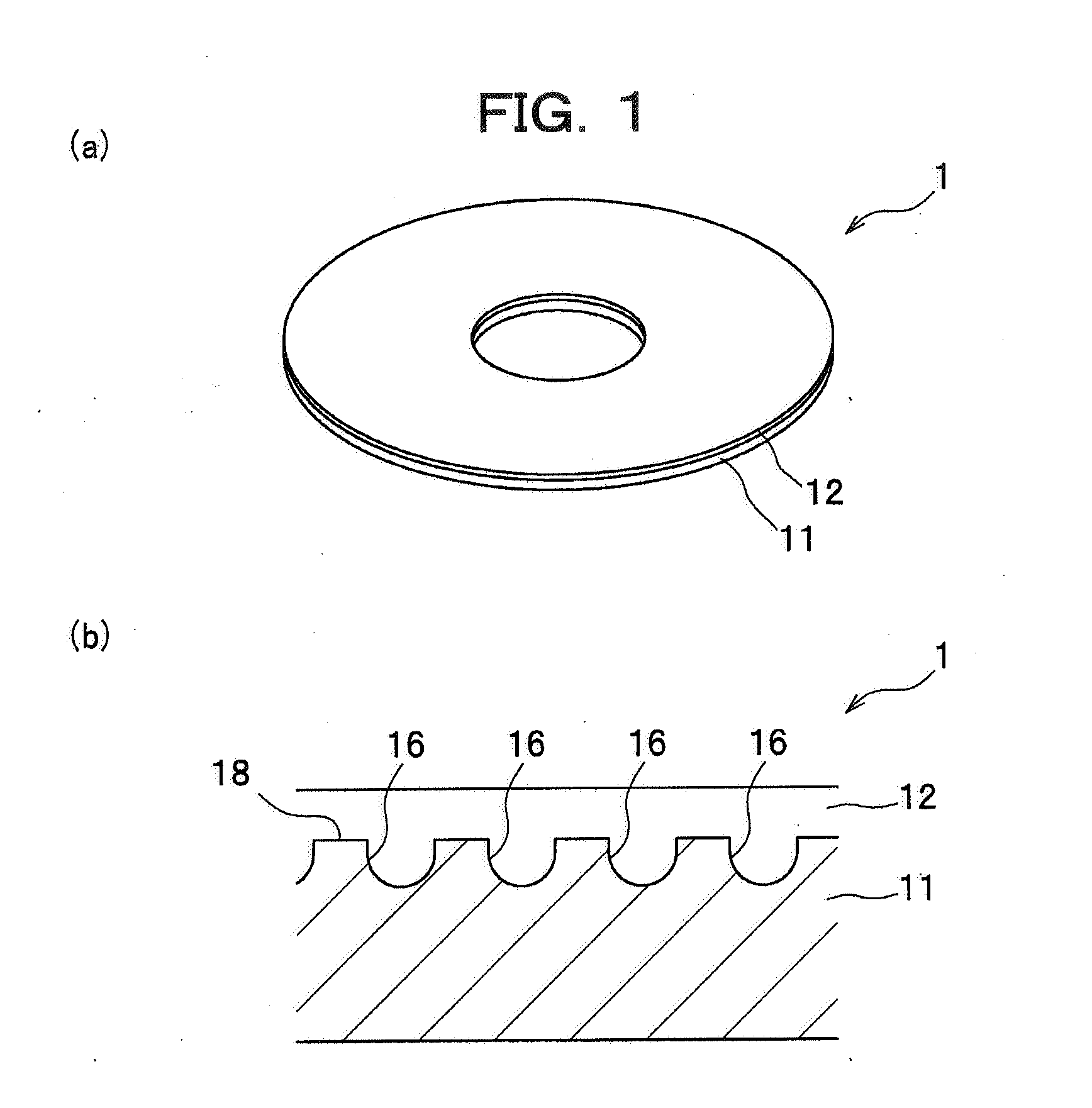

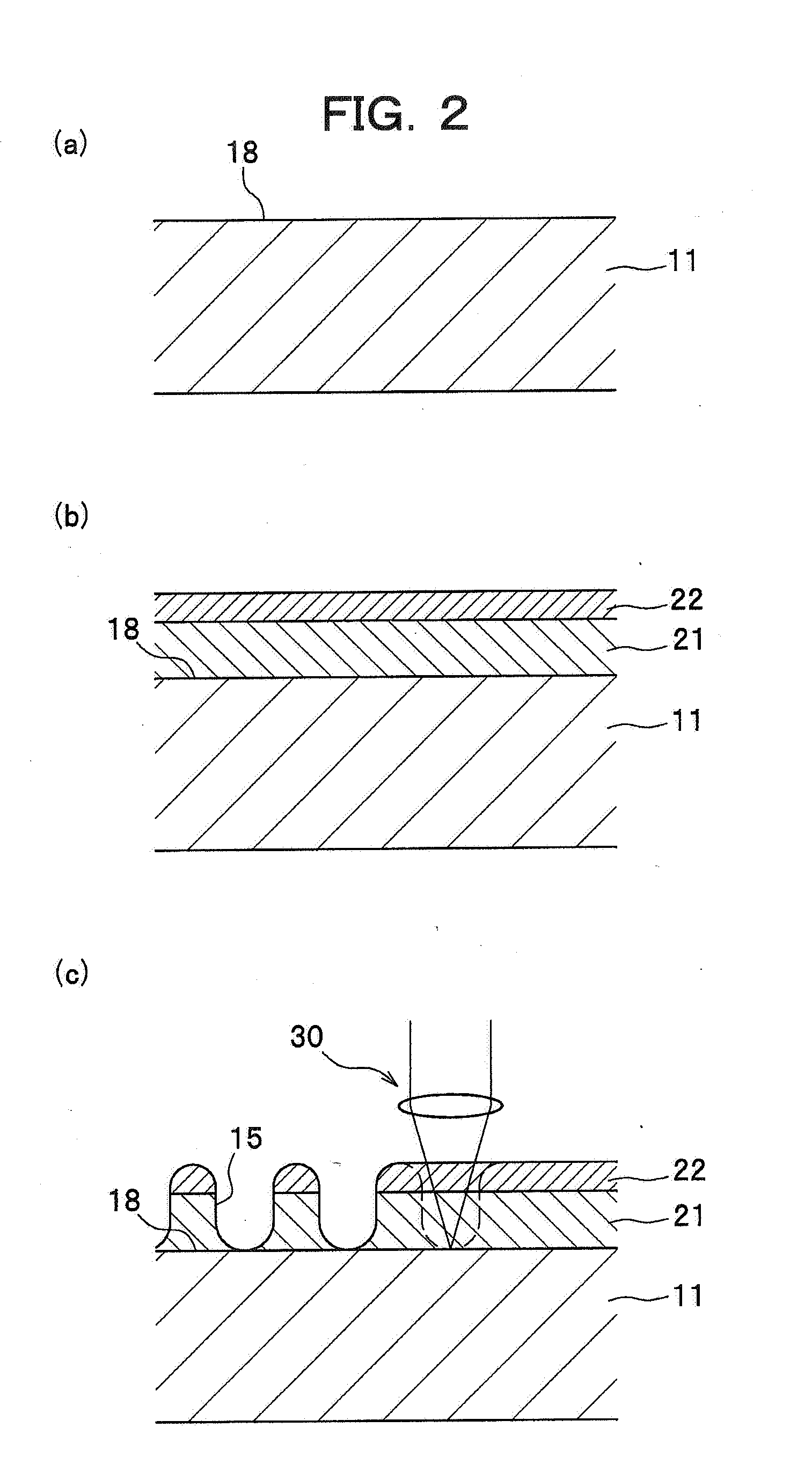

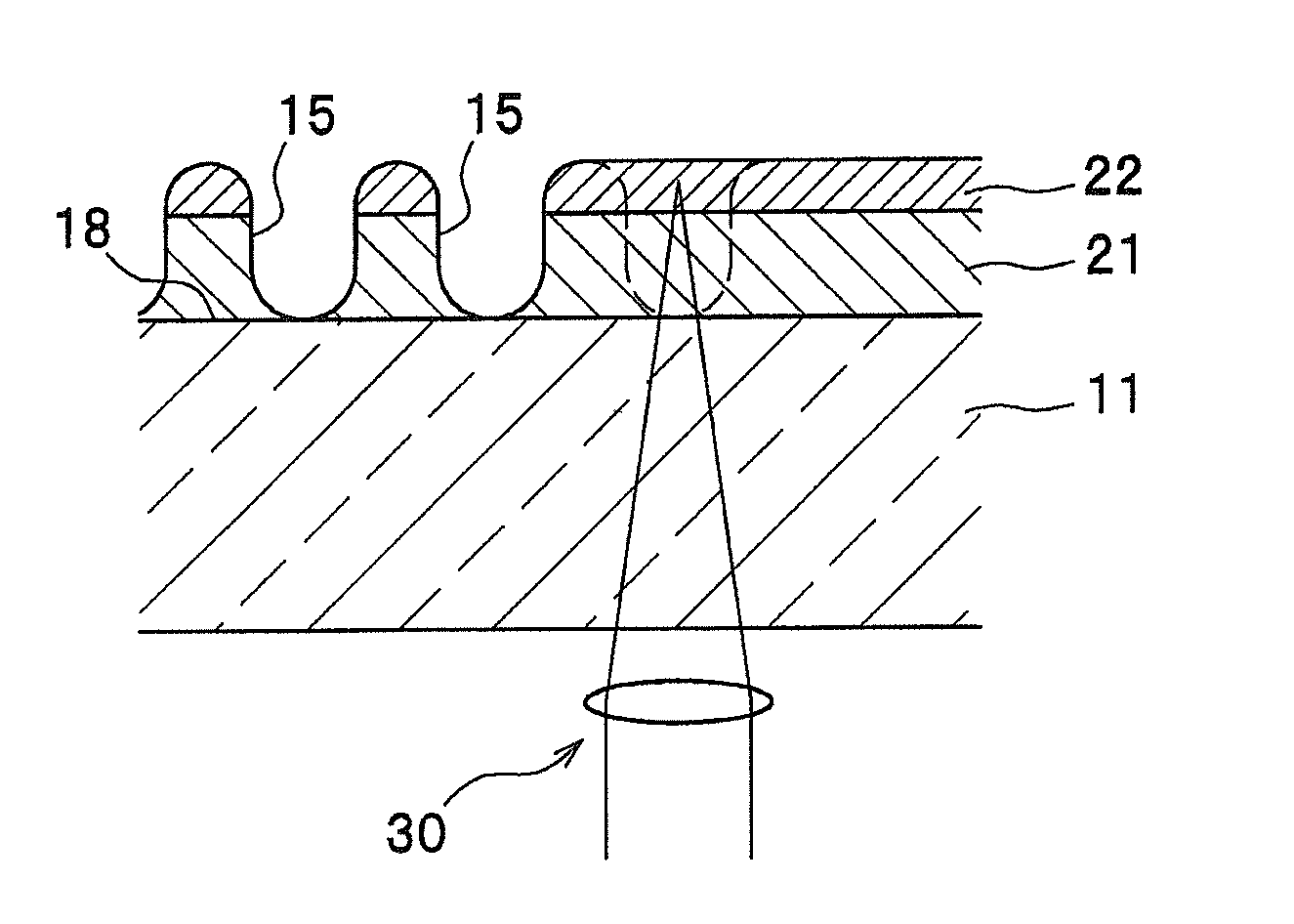

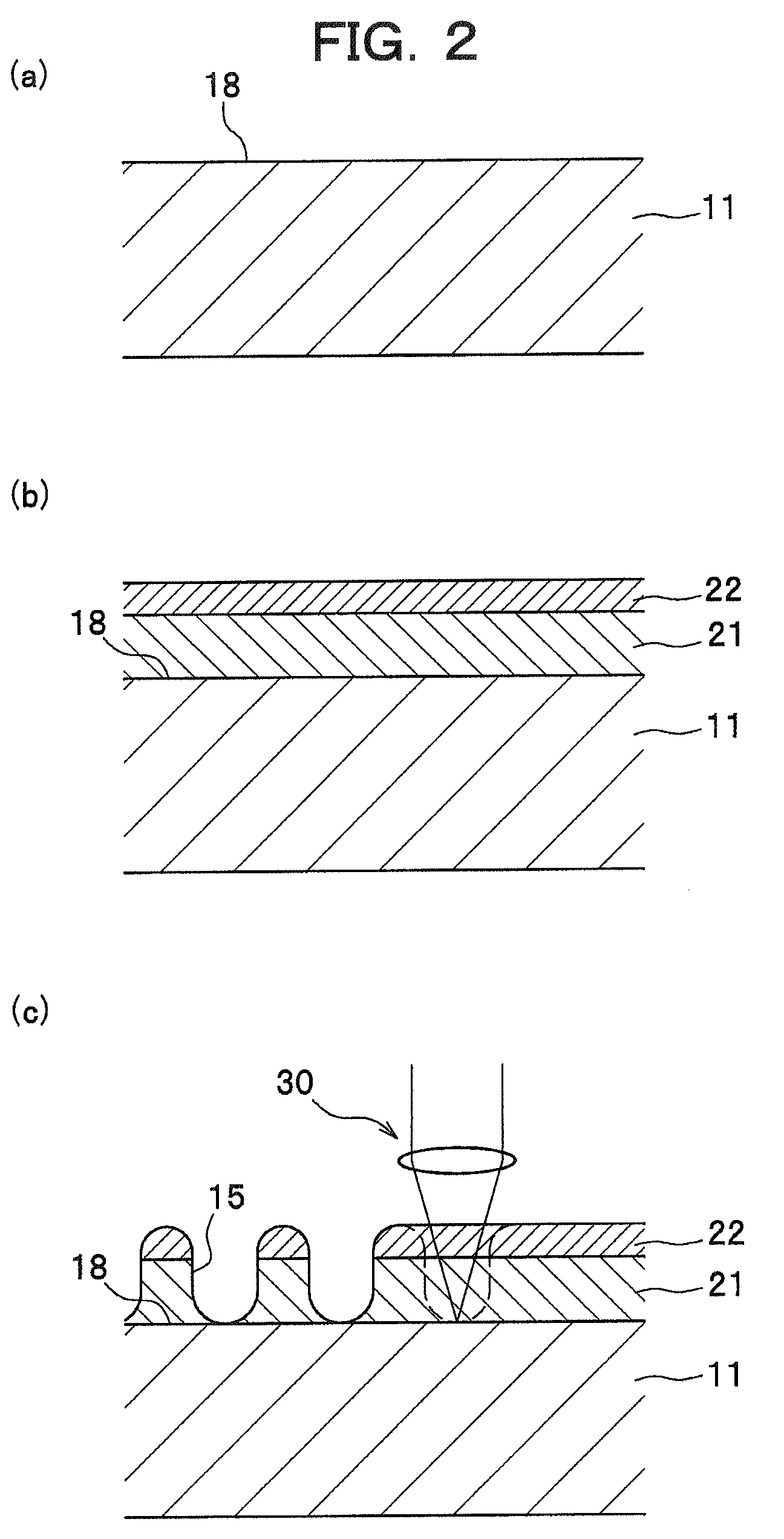

Method for manufacturing medium on which information is recorded in pit pattern

InactiveUS20110222391A1Extended shelf lifeKeep for a long timeLayered productsDecorative surface effectsOptoelectronicsInorganic materials

A method by which depressions and projections (pit pattern) can be formed directly and easily in a substrate made of inorganic material is provided. A method for forming a medium on which information is recorded in a pit pattern comprises the steps of: forming a recording material layer (21) over a substrate (11) made of inorganic material wherein the recording material layer is of a thermally deformable heat mode recording material; forming a plurality of holes 15 by application of condensed light to the recording material layer (21); and forming a plurality of pits (16) in the substrate wherein the plurality of pits corresponding to the plurality of holes (15) are etched by using as a mask the recording material layer (21) in which the plurality of holes are formed.

Owner:FUJIFILM CORP

Endoscope system and image generation method

A blue signal B, a green signal G, and a red signal R are obtained by imagining a subject illuminated with white light W using a color CCD 44. Based on these signals B, G, and R, a normal light image in which a wavelength component of a visible light region is included is generated. Based on the signals B, G, and R, a brightness signal I ((B+G+R) / 3) showing the average brightness of the subject is generated. A pixel region exceeding the fixed threshold value Th1 of the brightness signal I is extracted as a superficial microstructure P, such as a pit pattern. A microstructure enhancement image 72 is generated by combining the normal light image with a superficial microstructure image 70 obtained by extracting the superficial microstructure P. The generated microstructure and blood vessel enhancement image 72 is displayed on a monitor 14.

Owner:FUJIFILM CORP

Method of fabricating chrome-less phase shift mask

InactiveUS20060147819A1Enlarge regionPhotomechanical apparatusSemiconductor/solid-state device manufacturingPhase shiftedEngineering

An embodiment of a method of fabricating a chrome-less phase shift mask includes forming a hard mask film on a surface of a mask body having a trench circuit area and a mesa circuit area. The hard mask film is patterned. The mask body is anisotropically etched using the hard mask pattern as an etching mask to form pre-pitting patterns in the trench circuit area. The hard mask film having the hard mask pattern is again patterned to form a mesa hard mask pattern on the mesa circuit area and to expose a top surface of the trench circuit area. The mask body is anisotropically etched to form phase shift hillock patterns in the mesa circuit area and phase shift pitting patterns in the trench circuit area. Phase shift pitting patterns and phase shift hillock patterns may be formed on a single body.

Owner:SAMSUNG ELECTRONICS CO LTD

Intaglio printing process for printing decorative pattern

The gravure printing method for printing decorative pattern is characterized by that said method incldues the following steps: gravure plate-making for decorative pattern, using gravure press to print UV printing ink on the card paper, then using UV light to cure, the described pattern is the patterns of pit pattern (imitation metal etch), dioptric pattern, wrinkle, ice flower and corellite pattern, then using chemical etching or electronic plate-making process to make plate and print, also can make composite plate on printing roller. Said invention adopts single-sheet gravure press and web gravure press, the card paper can be gold can paper, silver card paper or card paper with colour, and its printing ink is UV gravure decorative printing ink.

Owner:潘治平 +2

Modulation method for shape morphing of hole of anodic aluminum oxide template

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

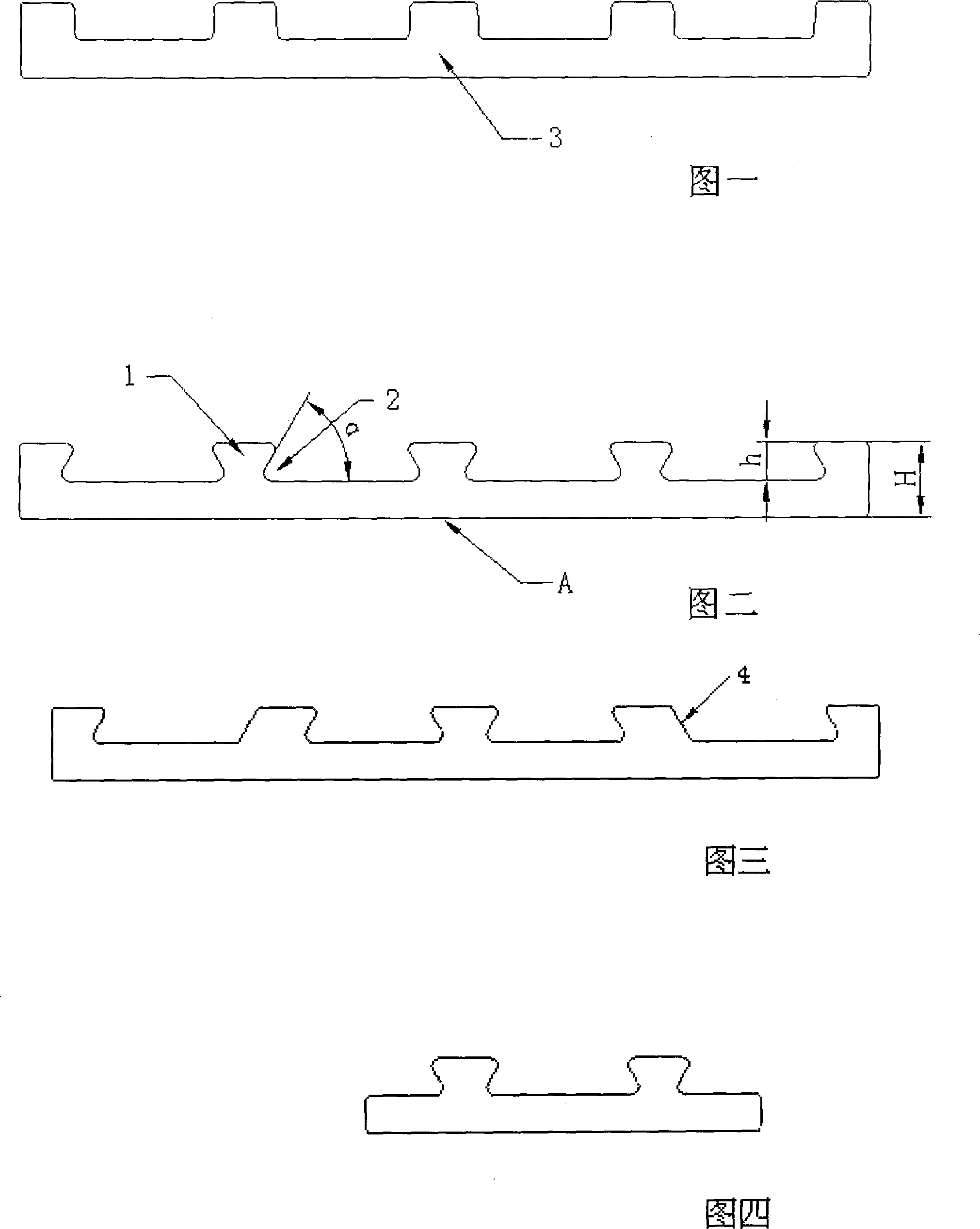

Section-steel tape and manufacturing method

InactiveCN101229783AReduce the cost of steel-aluminum composite manufacturingLow investment costPower railsSteel beltLath

The invention discloses a section steel belt, one side of which is a brush surface A with protruding laths on the back. The invention has more than three pit patterns (2) formed between at least two laths and the back side of the brush surface. The invention is characterized in that the pit patterns (2) are produced firstly by rolling into billets (3) and then being pulled and milled for at least once. The section steel belt of the invention is high in precision and lower in manufacturing cost.

Owner:成都金和工贸有限公司 +1

Method for manufacturing medium on which information is recorded in pit pattern

InactiveUS8323762B2Keep for a long timeWell formedLayered productsPhotomechanical apparatusOptoelectronicsInorganic materials

Owner:FUJIFILM CORP

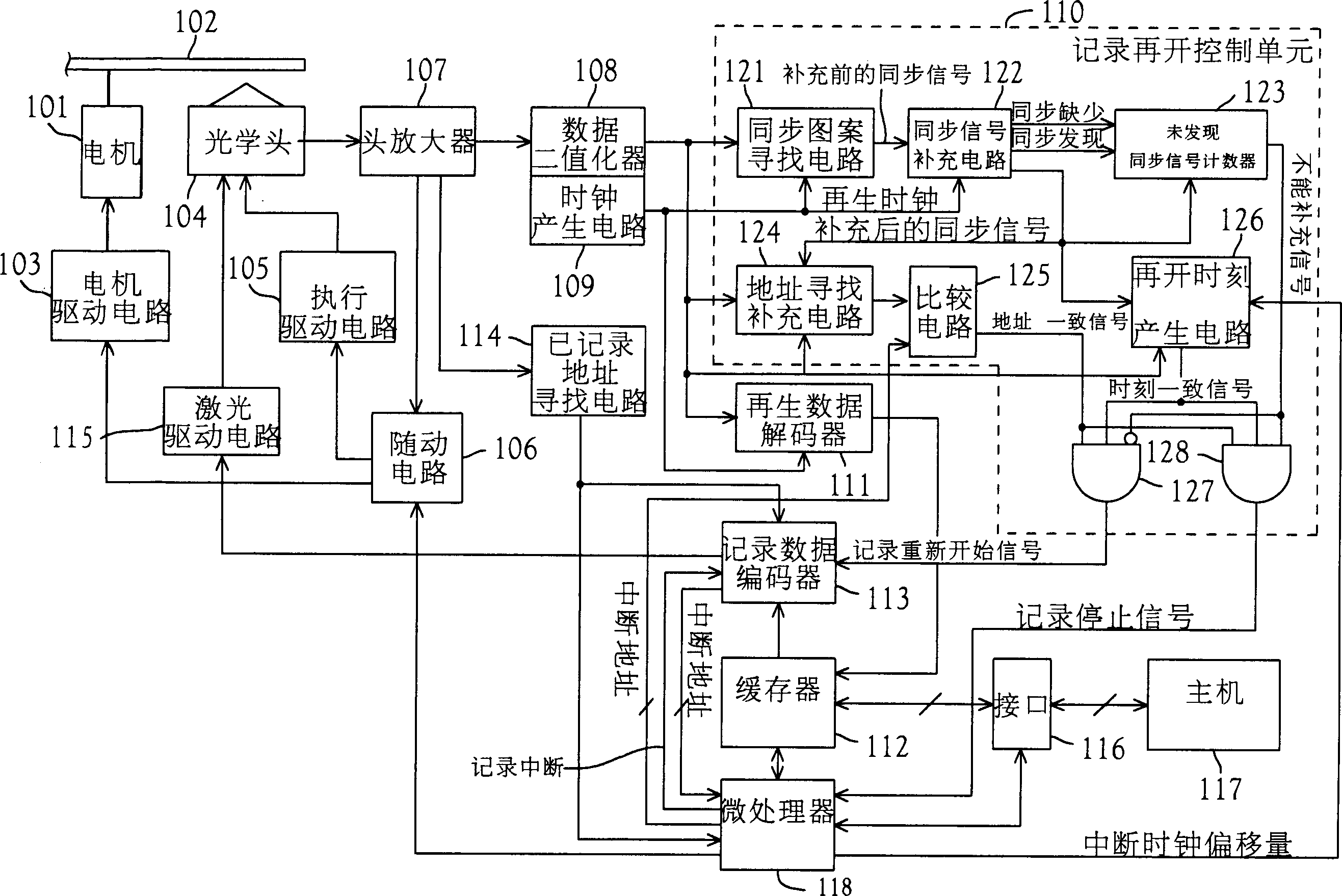

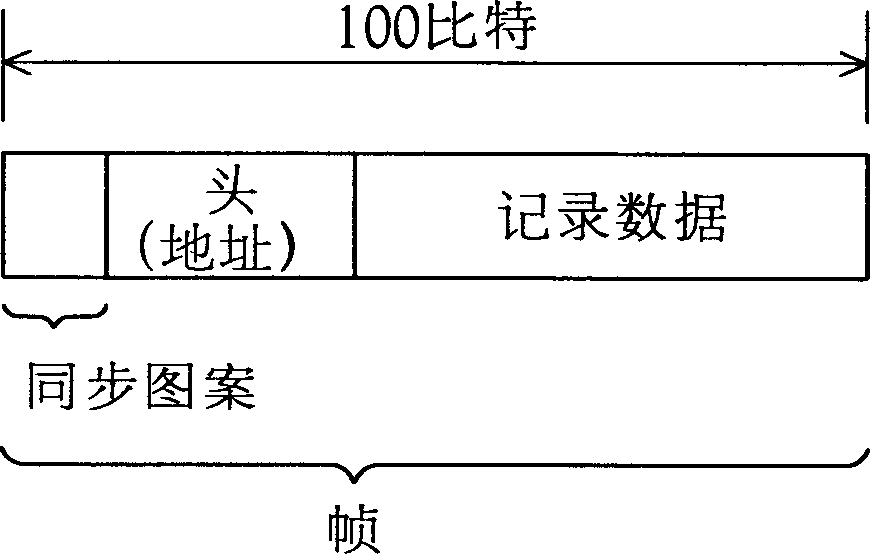

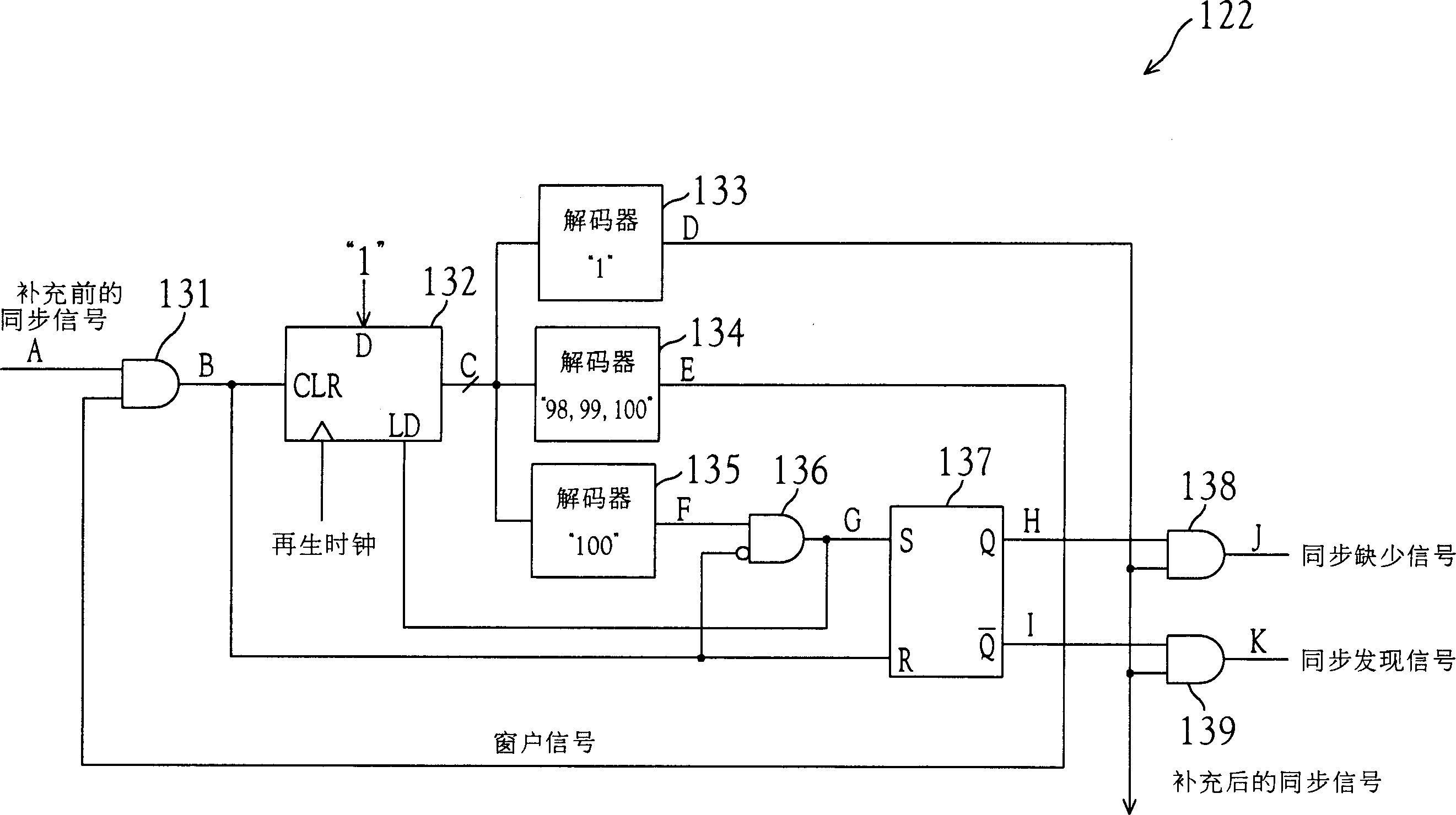

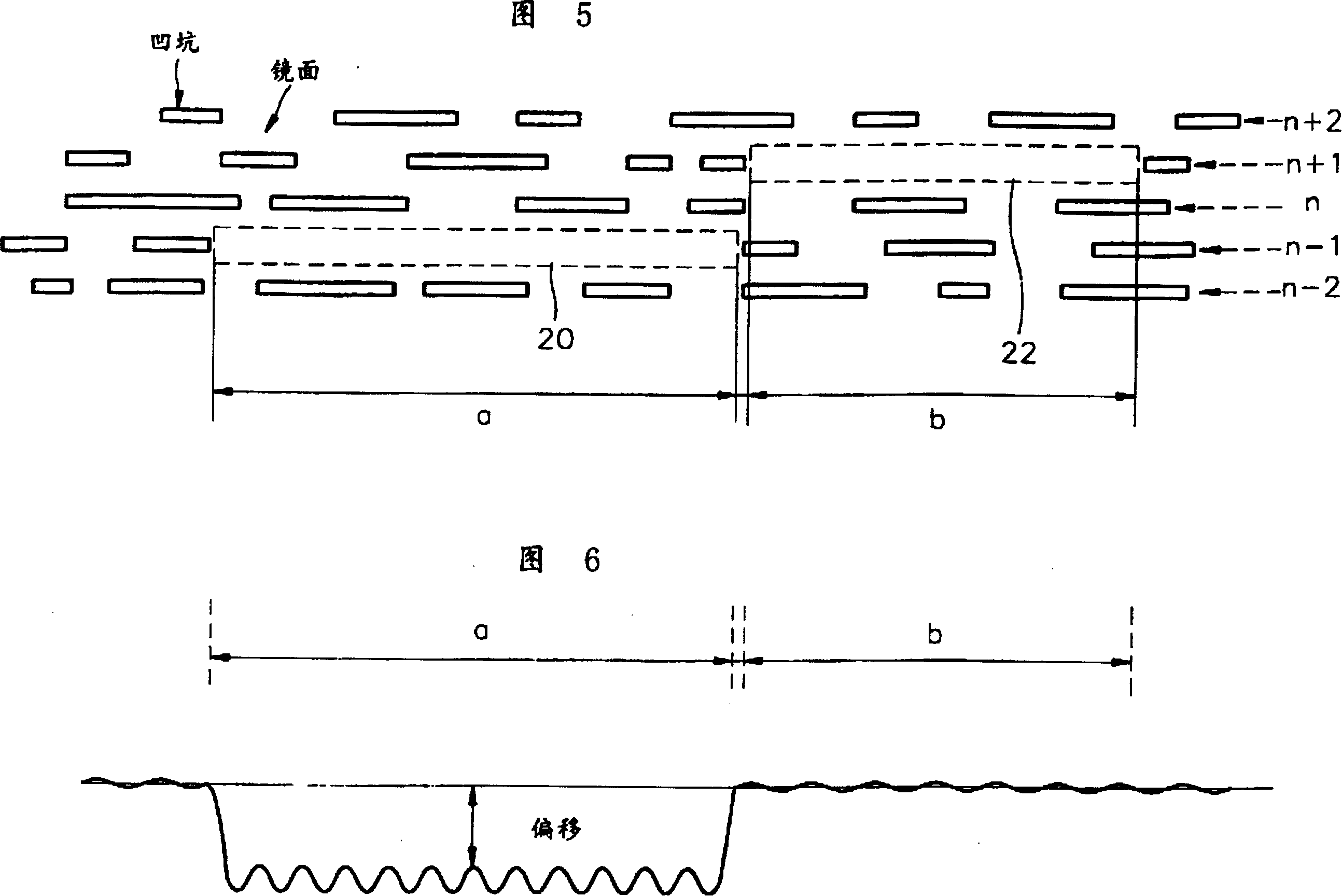

Date recording device, controlling device for data recording device and data recording method

InactiveCN1388529ARecord will not appearRecord information storageDigital signal formattingStart stopPattern detection

A data recording device, in the case where a data recording operation is suspended, even when a synchronization pattern cannot be detected due to a scratch of an optical disk or the like, a position where the last data is recorded is precisely detected so as to resume the recording operation without causing a joint. For this purpose, in resuming the suspended recording operation in the data recording device of this invention, reproducing pattern data corresponding to a pit pattern having been recorded in the optical disk is first reproduced. A synchronization pattern detection circuit detects a synchronization pattern and outputs a pre-complementation synchronization signal. A synchronization signal complementation circuit detects presence of a synchronization signal (synchronization signal pulse) and outputs a detection / loss signal to a synchronization signal non-detection counter. Also, when the synchronization signal is lost, the synchronization signal complementation circuit complements the synchronization signal and outputs a post-complementation synchronization signal to an address detection / complementation circuit and the like. The synchronization signal non-detection counter outputs a non-complementation signal when synchronization signals are continuously lost, so as to stop the resumption of the recording operation.

Owner:PANASONIC CORP

Method for generating meteorite impact pit pattern effect on porcelain stoneware

The invention provides a method for generating meteorite impact pit pattern effect on porcelain stoneware, which comprises the following steps: 1) mixing 1 part by weight of borax, 4-6 parts by weight of argil, 4-6 parts by weight of loess and 8-12 parts by weight water, and grinding into pulp as a cladding glaze; 2) spraying the cladding glaze on a porcelain stoneware blank to form a 0.1-0.3mm glaze; 3) firing the porcelain stoneware blank with the cladding glaze at 600-700 DEG C for 6-8 hours to form a cladding glaze surface; 4) mixing 4-6 parts by weight argil, 4-6 parts by weight of loess, 1-3 parts by weight of quartz, 1 part by weight of fusion cake and 9-13 parts by weight of water, and grinding into glaze pulp as an overglaze; 5) spraying the overglaze on the semi-finished product blank to form a glaze surface which is 0.1-0.3mm thick; and 6) firing the porcelain stoneware blank with the cladding glaze and the overglaze at 1150-1180 DEG C for 13-15 hours, and keeping the temperature for 1-1.5 hours to obtain the porcelain stoneware. The invention adopts a glaze low-temperature granular material method, and the low-temperature material is gasified in the firing process to generate the pattern of different sizes of pits formed by meteorite impacts on a celestial body, so that the porcelain stoneware has strong stereo perception and decorative effect; and the invention overcomes the defects of flat glaze surface and single decorative effect in the porcelain stoneware.

Owner:项云生

High density disk recording medium and apparatus using the same

InactiveUS7515524B2Enabling detectionMechanical record carriersRecord information storageOptical pickupHigh density

The present invention relates to a high-density disk that is structured to prevent a collision of an optical pickup's objective lens with the high-density disk if the disk is placed upside down in a disk device that is able to record and reproduce signals to / from the high-density disk. A high-density disk recording medium according to the present invention is structured such that, wherein a recording layer having high-density pit patterns is offset from a center plane of disk thickness, both sides of a clamping zone bisected by the center plane have differing thicknesses. One or both sides may protrude from surface of the disk recording medium, or one side of the clamping zone may protrude from the surface while the other side is indented below the surface.

Owner:LG ELECTRONICS INC

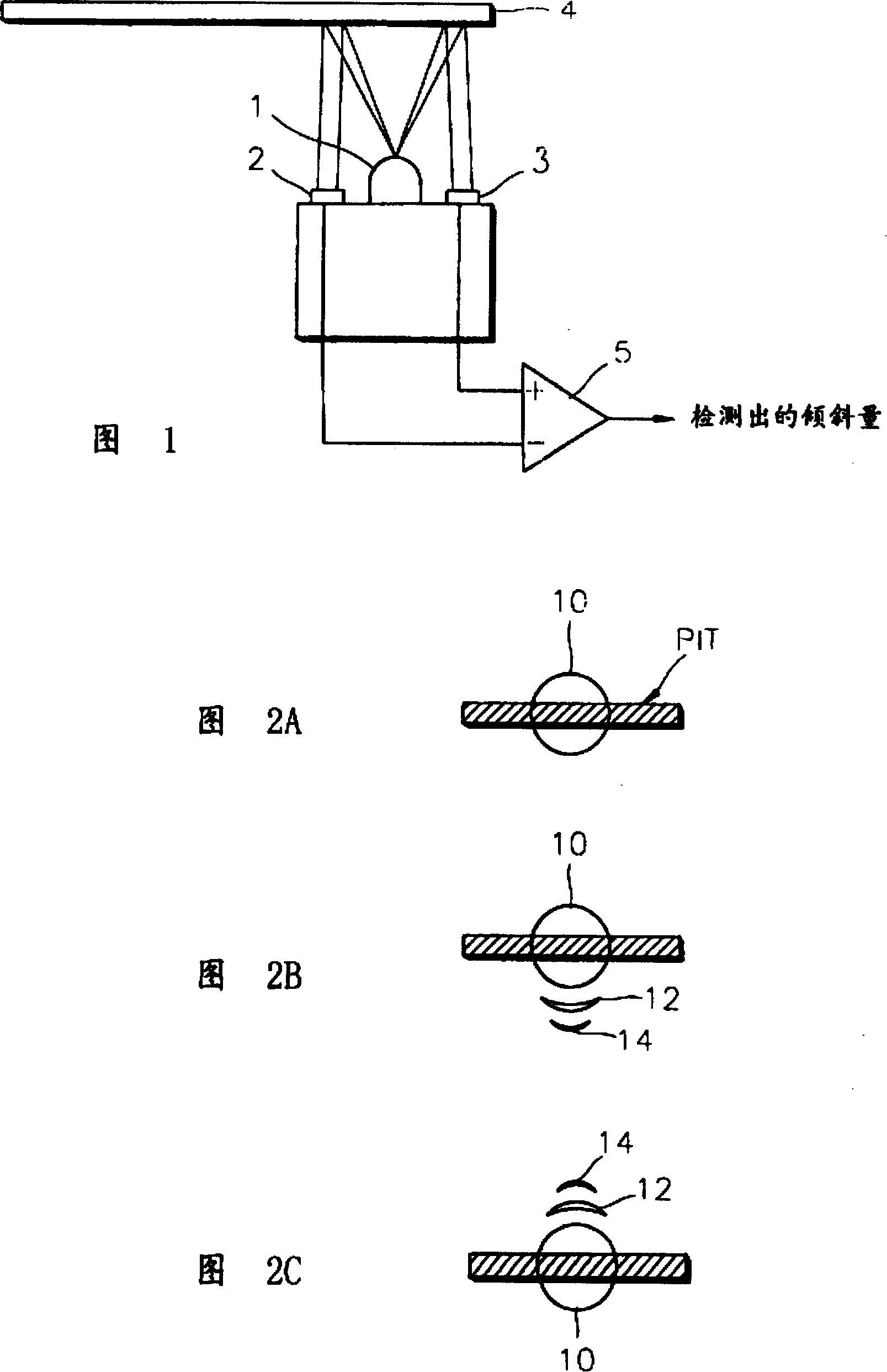

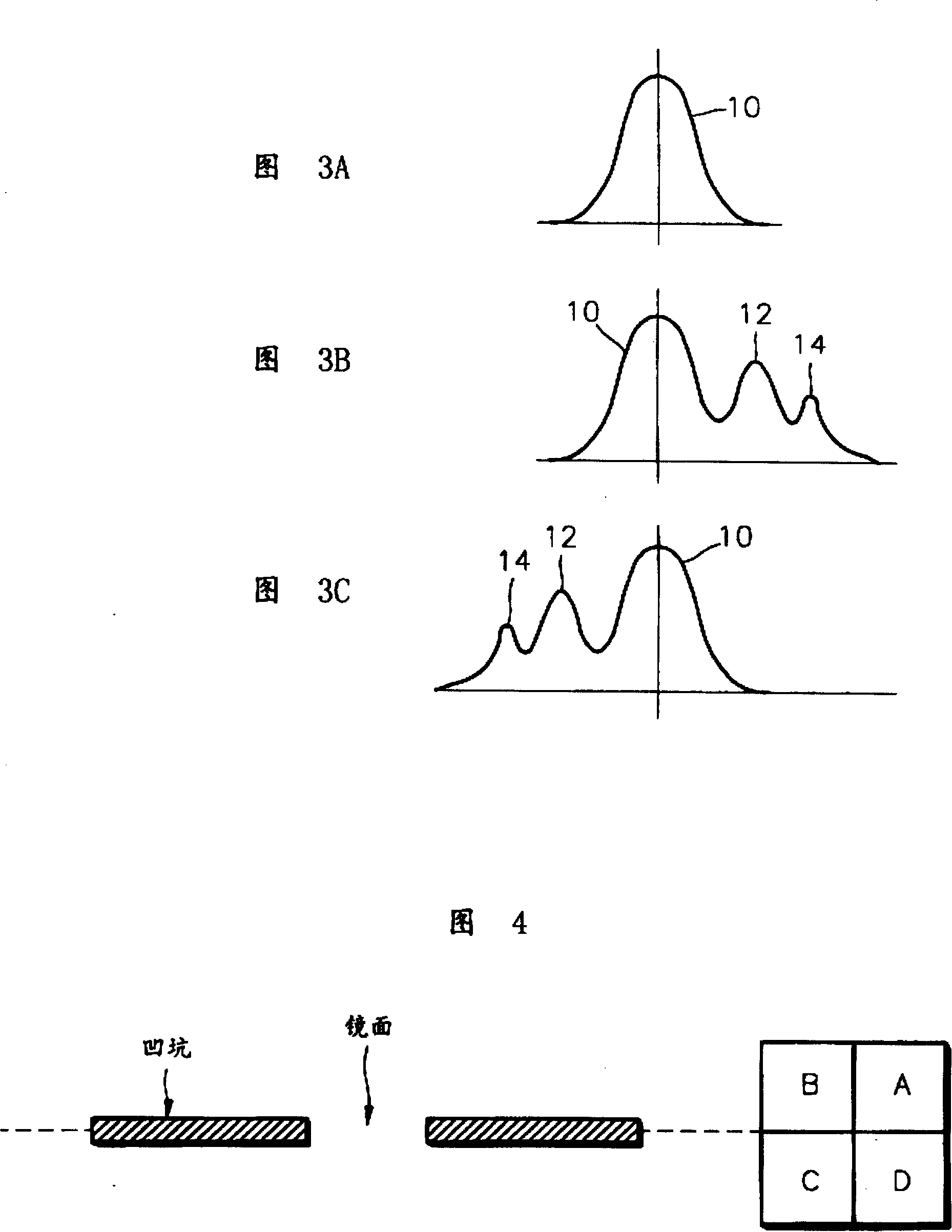

Optical disk having pattern for tilt detection

InactiveCN100375176CRecord information storageDigital signal error detection/correctionPhotodetectorOptical coupler

An optical disk has a pattern for detecting an amount of a tilt of a disk. An optical disk on which a code train having a pit pattern or a mirror pattern is recorded on a concentrically or spirally formed track, wherein a tilt detection pattern having a predetermined code train is recorded at least in a partial area of the disk. Thus, a tilt of a disk can be detected by a common quadrant photodetector without an additional apparatus such as a photo coupler.

Owner:SAMSUNG ELECTRONICS CO LTD

Processing technology for hollowed-out cork cloth

ActiveCN106079824AReduce manufacturing costLow costLaminationLamination apparatusPolyurethane adhesiveEngineering

The invention discloses a processing technology for hollowed-out cork cloth. The hollowed-out cork cloth is prepared from 60 to 75% of natural cork, 15 to 35% of cloth and 1 to 3% of a polyurethane adhesive. According to the processing technology, the natural cork is made into a block or circular shape through die coining and then cut into a thin cork sheet with a cutter; the pitted cloth is spread on a working table, then the cork sheet is laid on the pitted cloth, and coining is carried out so as to allow the cork sheet to be totally bonded with the cloth; the bonded material is turned over with the cork sheet at bottom and the cloth at top, then the cloth is glued, and the whole surface of the cloth is subjected to laminating; bonding cloth is laid immediately after laminating; after fusion between the bonding cloth and glue, the cloth is separated from the bonding cloth through tearing; and in the process of separation, the bonding cloth is bonded with cork peel located in a pitted pattern and brought away the cork peel located in the pitted pattern, and rest cork peel is bonded with the pattern, so the cork cloth with holes is obtained.

Owner:简默强

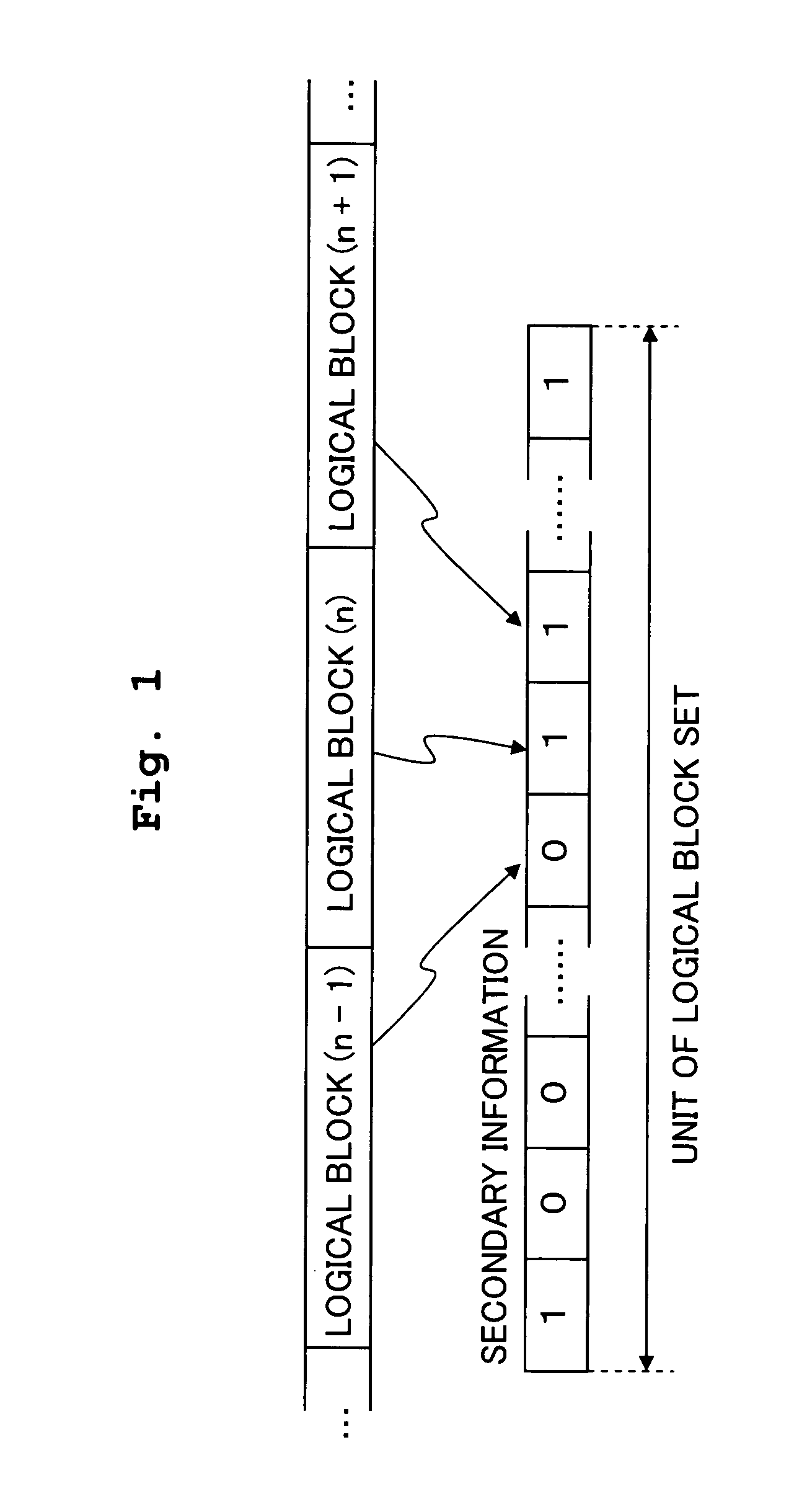

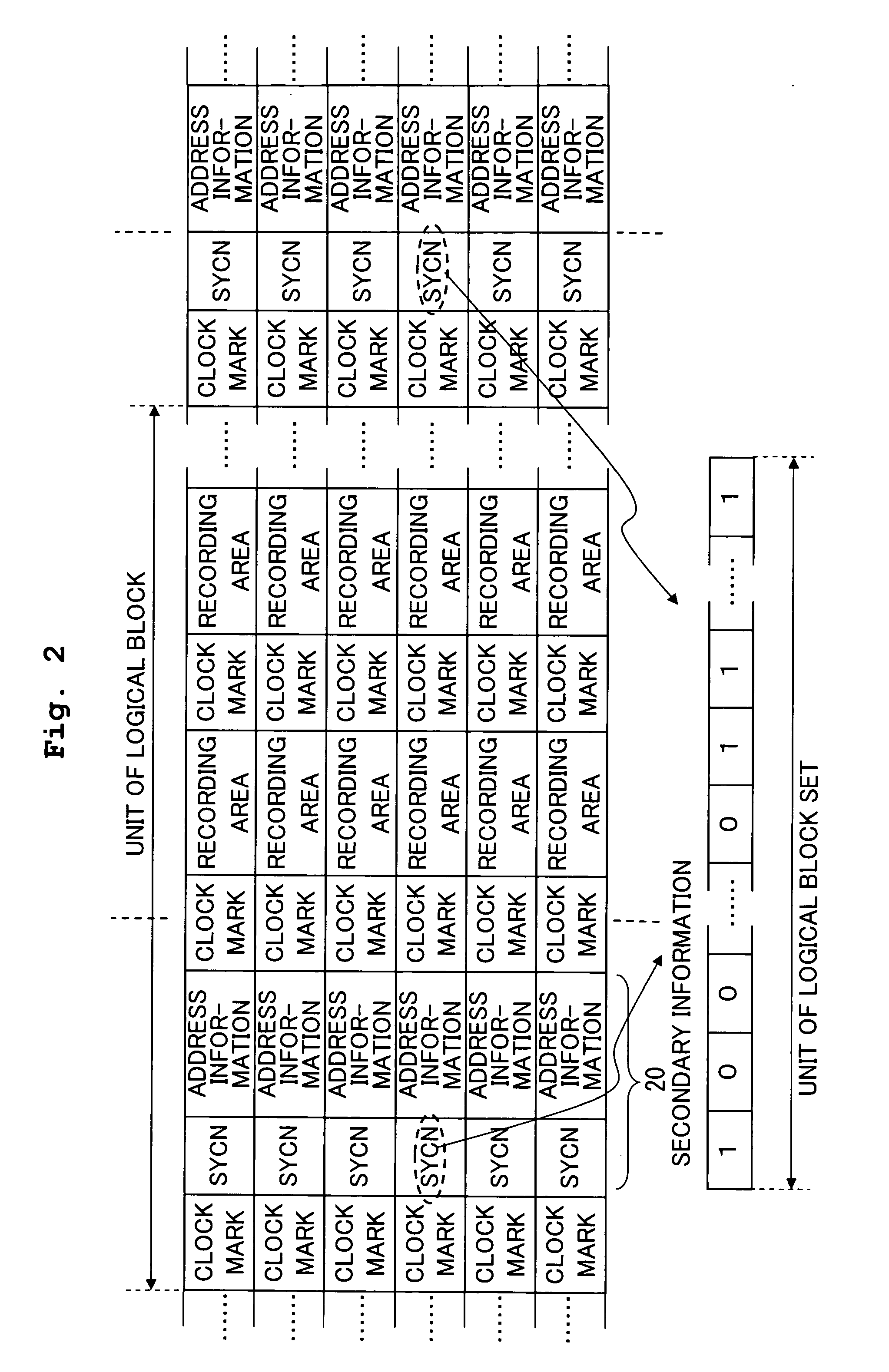

Information recording medium, driving apparatus for the same and method for recording secondary information of information recording medium

InactiveUS20060044999A1Improve reliabilityImprove securityDisc-shaped record carriersElectronic editing digitised analogue information signalsComputer hardwareA domain

An information-recording medium is provided, which comprises a logical block recorded with secondary information and including an address information area, wherein the secondary information is recorded by inverting the phase of a fixed pattern including, for example, a synchronization signal or a resynchronization signal recorded in the logical block. Those used as the pattern for recording the secondary information are fixed patterns including, for example, a wobble pattern, a pit pattern, a recording pattern, and a domain pattern. Therefore, no trouble arises in the reproducing operation of a medium-driving apparatus.

Owner:HITACHT MAXELL LTD

A kind of hollow-out cork cloth processing technology

ActiveCN106079824BReduce manufacturing costLow costLaminationLamination apparatusPolyurethane adhesiveEngineering

The invention discloses a processing technology for hollowed-out cork cloth. The hollowed-out cork cloth is prepared from 60 to 75% of natural cork, 15 to 35% of cloth and 1 to 3% of a polyurethane adhesive. According to the processing technology, the natural cork is made into a block or circular shape through die coining and then cut into a thin cork sheet with a cutter; the pitted cloth is spread on a working table, then the cork sheet is laid on the pitted cloth, and coining is carried out so as to allow the cork sheet to be totally bonded with the cloth; the bonded material is turned over with the cork sheet at bottom and the cloth at top, then the cloth is glued, and the whole surface of the cloth is subjected to laminating; bonding cloth is laid immediately after laminating; after fusion between the bonding cloth and glue, the cloth is separated from the bonding cloth through tearing; and in the process of separation, the bonding cloth is bonded with cork peel located in a pitted pattern and brought away the cork peel located in the pitted pattern, and rest cork peel is bonded with the pattern, so the cork cloth with holes is obtained.

Owner:简默强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com