Method for preparing ordered germanium quantum dot on silicon substrate by sputtering

A technology of silicon substrate and quantum dots, which is applied in the field of semiconductor quantum material preparation, achieves the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

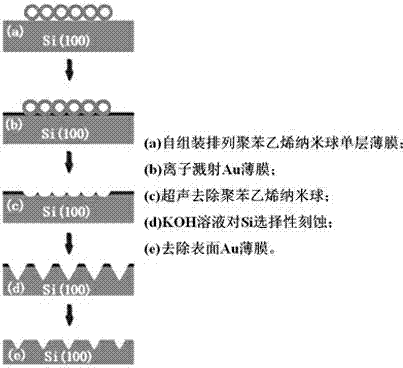

Method used

Image

Examples

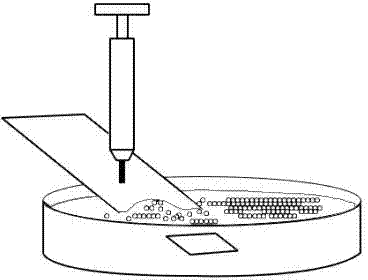

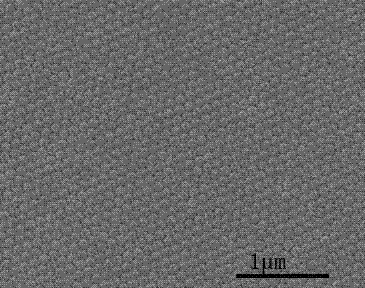

Embodiment 1

[0027] The sputter growth equipment used is FJL560 In the ion beam sputtering chamber of the type ultra-high vacuum multi-target magnetron and ion beam combined sputtering equipment, a Kaufman ion gun is placed in the growth chamber; the target used is 5N (99.999%) high-purity Ge square target and high Pure Si square target, the sputtering gas is 5N (99.999%) high-purity argon gas; the equipment used for sputtering Au is SCD005 ion sputtering instrument, and the target material is 99.99% high-purity Au circular target; the Si substrate used A P-type single-crystal Si wafer with a crystal orientation of (100) is used, polished on one side, and the resistivity is 1 Ω cm to 2 Ω cm; the commercially available polystyrene nanospheres have a mass percentage of 1% and a diameter of 100 nm ; The glass slides purchased are sailboat brand glass slides; the utensils are plastic watch glasses; ultrasonic cleaning uses a commercially available ultrasonic cleaner. Specific steps are as fo...

Embodiment 2

[0040] The equipment and materials used are all the same as in Example 1. The specific steps are:

[0041] 1. Preparation of two-dimensional ordered hexagonal nanopit pattern:

[0042] Same as Example 1.

[0043] 2. Preparation of ordered Ge quantum dots by ion beam sputtering technology:

[0044] A. Use the improved RCA cleaning method to clean the silicon substrate etched by polystyrene nanospheres; after cleaning, dry the silicon substrate with high-purity nitrogen, put it into the ion beam sputtering chamber, and wait for the background vacuum of the sputtering chamber degree less than 3.0×10 -4 Pa, adjust the temperature to 800 °C and keep it for 10 min; then fill the sputtering chamber with argon with a purity of 5N as the working gas, and adjust the pressure to 2.0×10 -2 Pa;

[0045] B. At 800 ℃, the discharge voltage is 75 V, the beam voltage is 0.5 KV, the acceleration voltage is 200 V, the growth beam current is 4 mA, and the sputtering rate is 0.1 ? / s. The b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com