Patents

Literature

100 results about "Ion gun" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An Ion Gun typically refers to an instrument that generates a beam of heavy ions with a well defined energy distribution. The ion beam is produced from a plasma that has been confined within a volume. Ions of a particular energy are extracted, accelerated, collimated and/or focused. The ion gun is composed of an ion source, extraction grid structure and a collimation/lensing structure. The plasma can be made up of an inert or reactive gas (e.g. N⁺ and O⁺) or an easily condensable substance (e.g. C⁺ and B⁺). The plasma can be formed from molecules that contain the substance which will form the beam, in which case, these molecules must be fragmented then ionized (e.g. H and CH₄ can together be fragmented and ionized to create a beam for depositing diamond-like carbon films).

Single and multiple operating mode ion sources with atmospheric pressure chemical ionization

ActiveUS20090294660A1Maximize ion source performanceMinimizing chargeIsotope separationMass spectrometersGas phaseCorona discharge

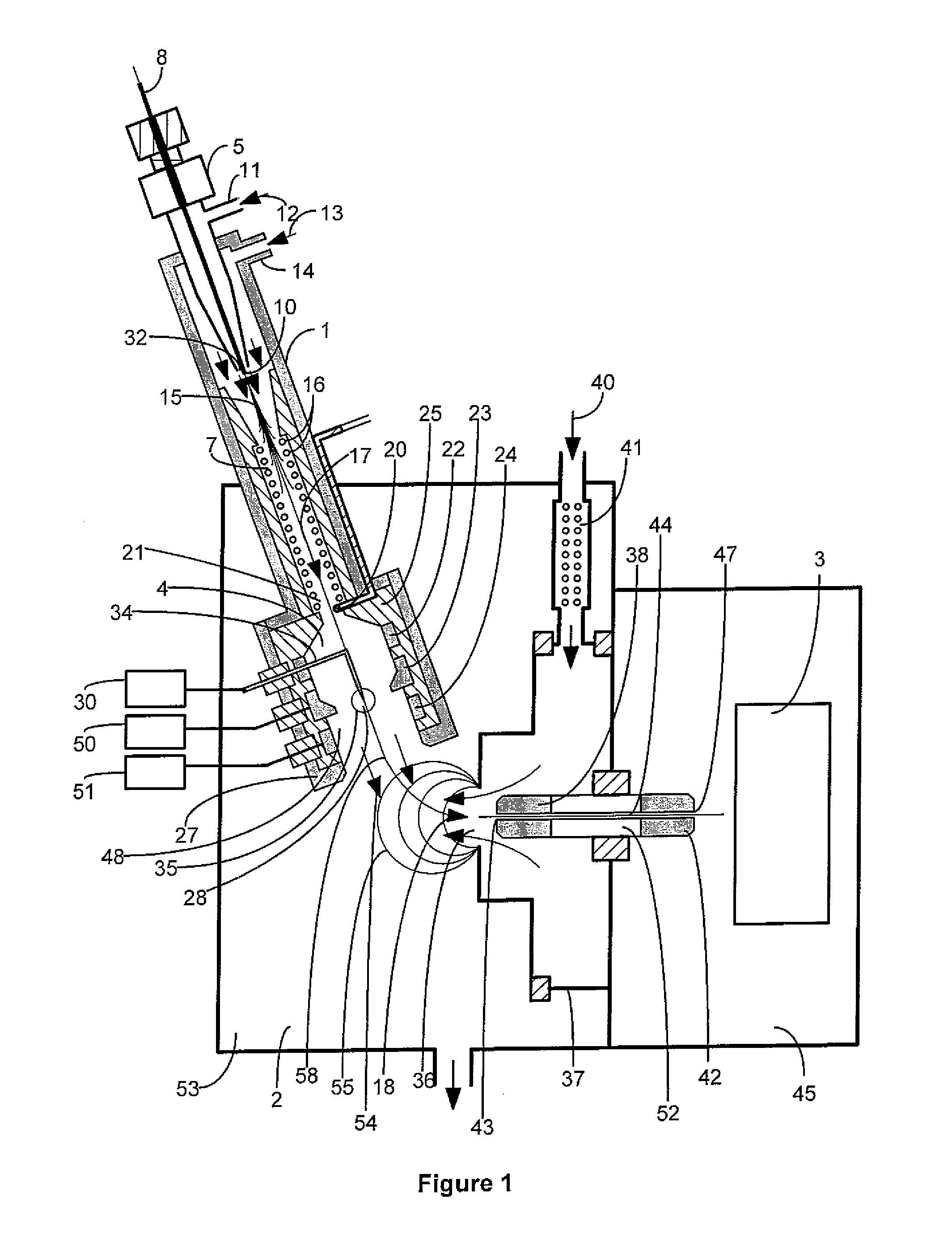

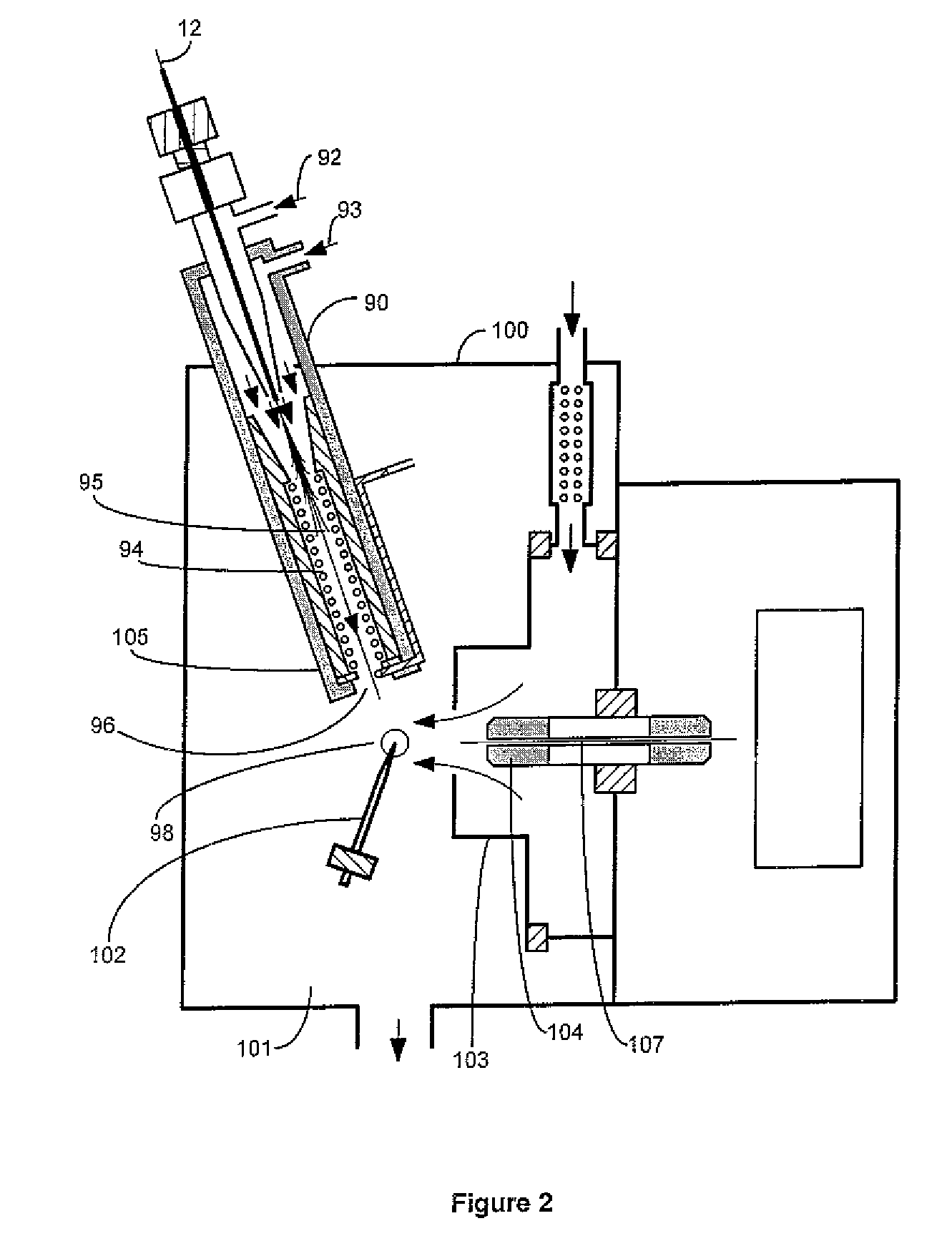

An Atmospheric Pressure Chemical Ionization (APCI) source interfaced to a mass spectrometer is configured with a corona discharge needle positioned inside the APCI inlet probe assembly. Liquid sample flowing into the APCI inlet probe is nebulized and vaporized prior to passing through the corona discharge region all contained in the APCI inlet probe assembly Ions produced in the corona discharge region are focused toward the APCI probe centerline to maximize ion transmission through the APCI probe exit. External electric fields penetrating into the APCI probe exit end opening providing additional centerline focusing of sample ions exiting the APCI probe. The APCI probe is configured to shield the electric field from the corona discharge region while allowing penetration of an external electric field to focus APCI generated ions into an orifice into vacuum for mass to charge analysis. Ions that exit the APCI probe are directed only by external electric fields and gas flow maximizing ion transmission into a mass to charge analyzer. The new APCI probe can be configured to operate as a stand alone APCI source inlet probe, as a reagent ion gun for ionizing samples introduced on solids or liquid sample probes or through gas inlets in a multiple function ion source or as the APCI portion of a combination Electrospray and APCI multiple function ion source. Sample ions and gas phase reagent ions are generated in the APCI probe from liquid or gas inlet species or mixtures of both.

Owner:PERKINELMER U S LLC

Single and multiple operating mode ion sources with atmospheric pressure chemical ionization

ActiveUS7982185B2Minimizes or eliminates analyte ion lossesImprove ionization efficiencyMaterial analysis by optical meansIsotope separationGas phaseCorona discharge

An Atmospheric Pressure Chemical Ionization (APCI) source interfaced to a mass spectrometer is configured with a corona discharge needle positioned inside the APCI inlet probe assembly. Liquid sample flowing into the APCI inlet probe is nebulized and vaporized prior to passing through the corona discharge region all contained in the APCI inlet probe assembly Ions produced in the corona discharge region are focused toward the APCI probe centerline to maximize ion transmission through the APCI probe exit. External electric fields penetrating into the APCI probe exit end opening providing additional centerline focusing of sample ions exiting the APCI probe. The APCI probe is configured to shield the electric field from the corona discharge region while allowing penetration of an external electric field to focus APCI generated ions into an orifice into vacuum for mass to charge analysis. Ions that exit the APCI probe are directed only by external electric fields and gas flow maximizing ion transmission into a mass to charge analyzer. The new APCI probe can be configured to operate as a stand alone APCI source inlet probe, as a reagent ion gun for ionizing samples introduced on solids or liquid sample probes or through gas inlets in a multiple function ion source or as the APCI portion of a combination Electrospray and APCI multiple function ion source. Sample ions and gas phase reagent ions are generated in the APCI probe from liquid or gas inlet species or mixtures of both.

Owner:PERKINELMER U S LLC

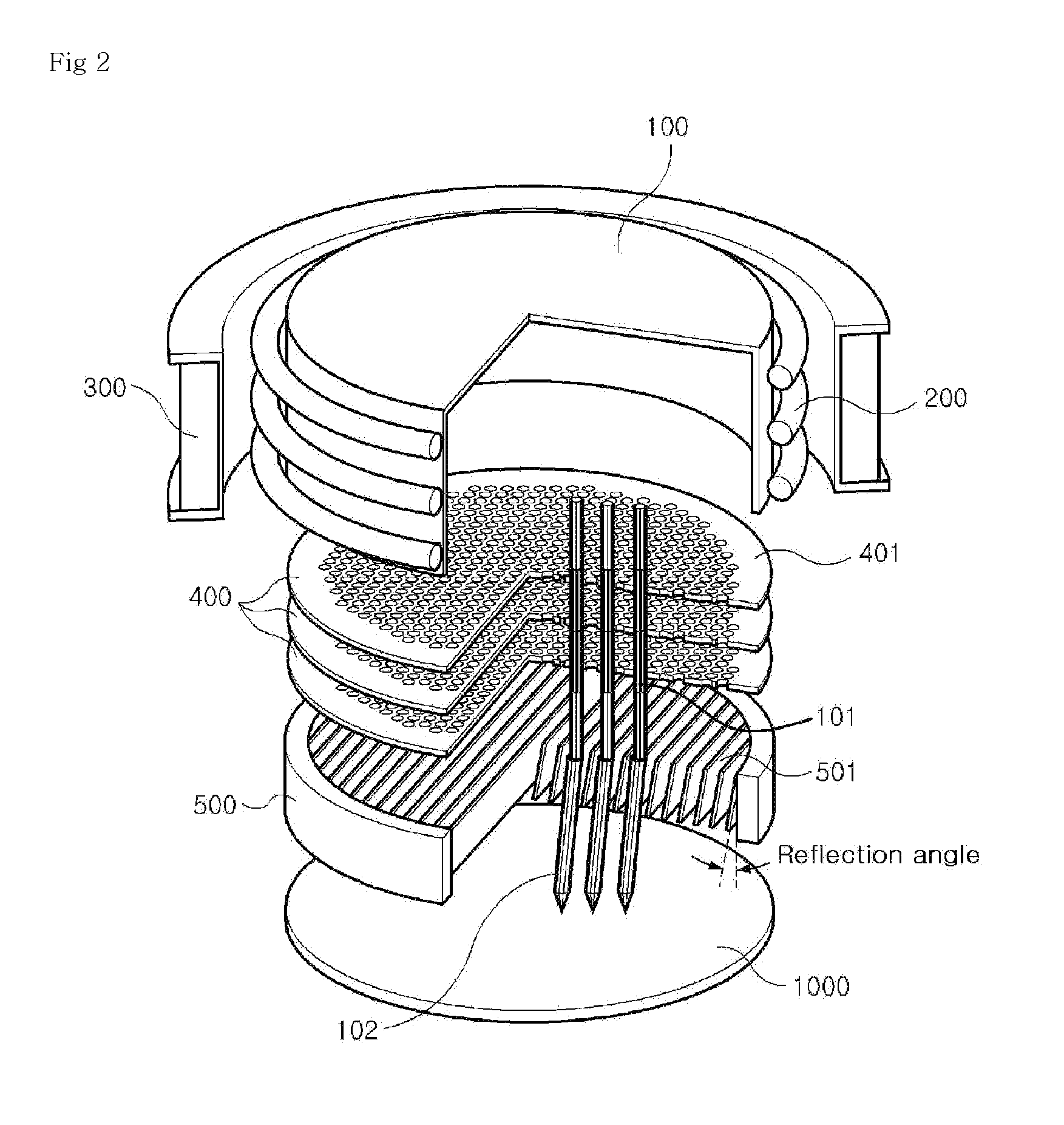

Plasma generating apparatus and method using neutral beam

InactiveUS20070221833A1Broaden the field of applicationPromote generationLaser detailsDecorative surface effectsEngineeringLocal pressure

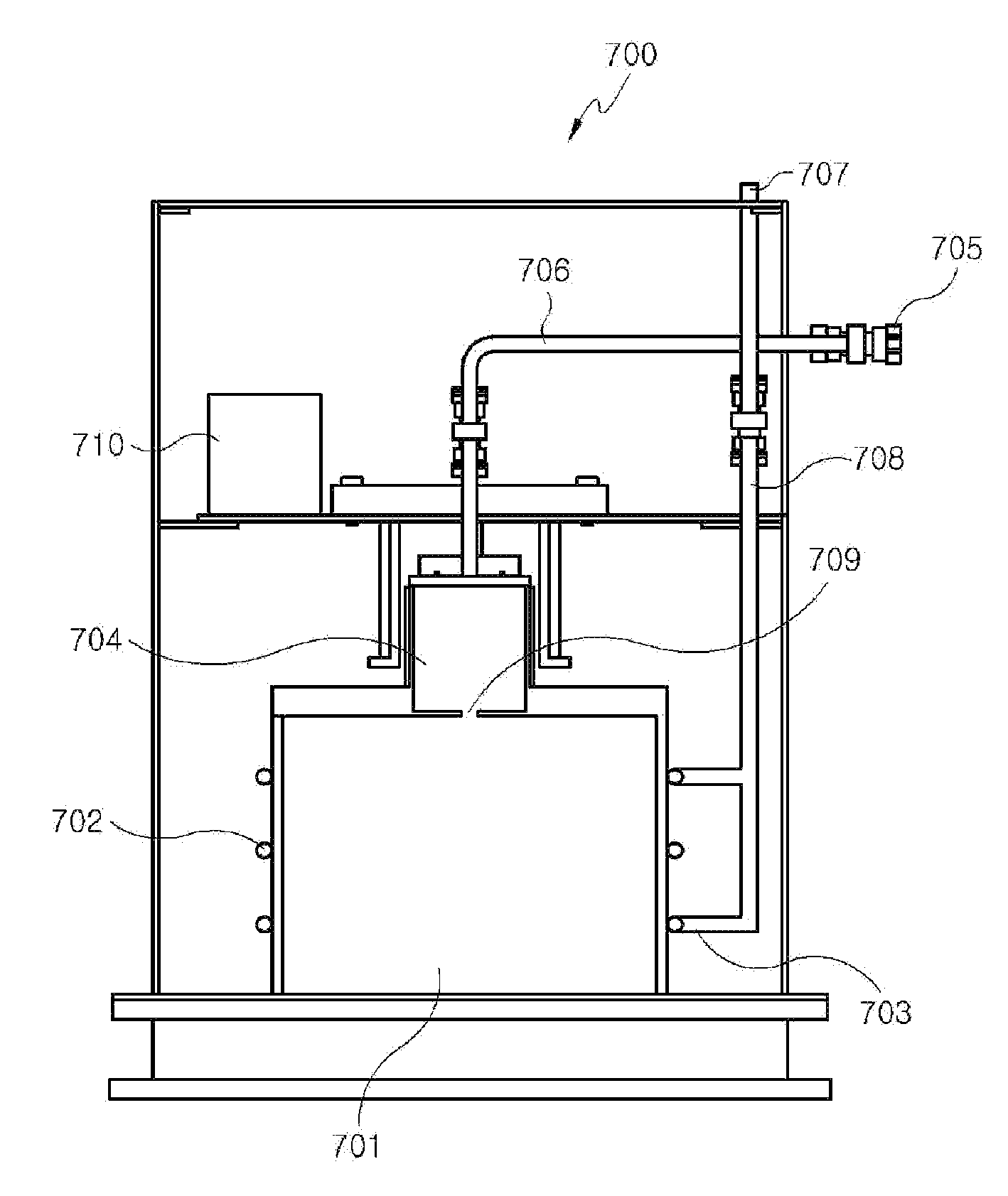

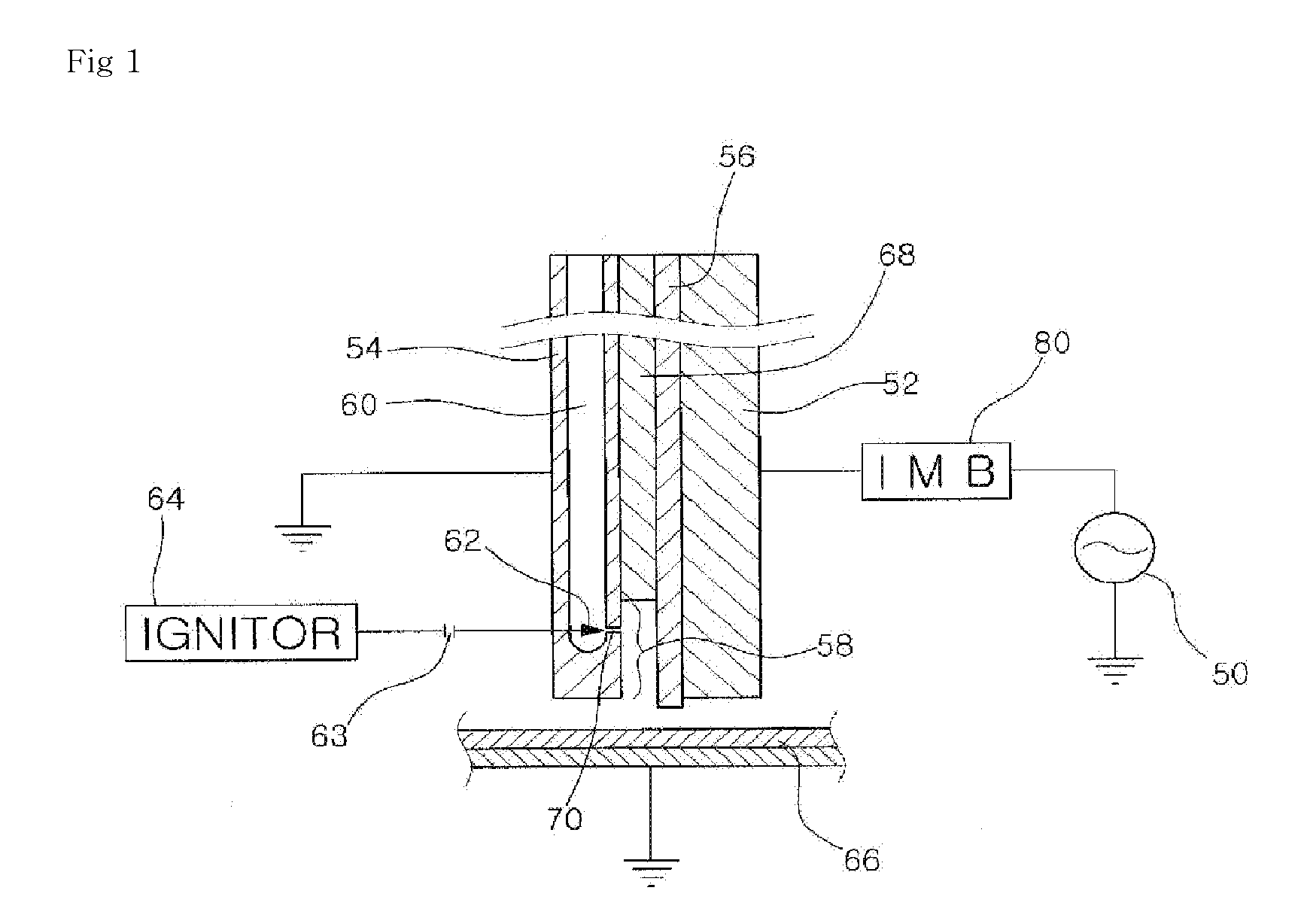

A plasma generating apparatus and method using a neutral beam, capable of readily generating plasma at the same gas flow rate by changing the structure of an ion gun, without a separate ignition device, are provided. The apparatus includes a plasma generating part formed of a quartz cup, a radio frequency (RF) applying antenna disposed at the periphery of the plasma generating part, a cooling water supply part disposed at the periphery of the plasma generating part, and an igniter in direct communication with the plasma generating part, wherein a gas for generating plasma is supplied into the igniter, and the igniter has a higher local pressure than the plasma generating part at the same gas flow rate. The ion gun is also cheaper to manufacture since it does not require a separate power supply.

Owner:SUNGKYUNKWAN UNIVERSITY

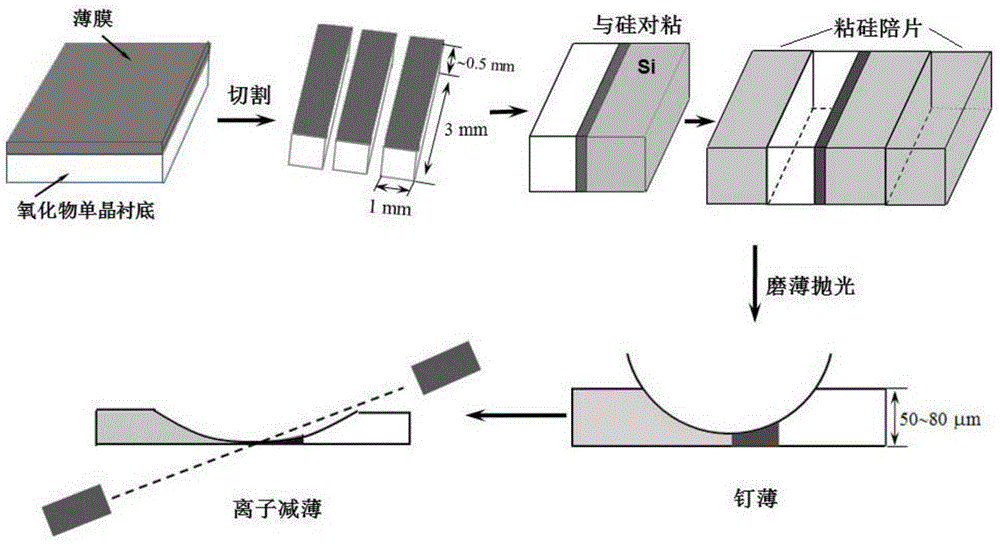

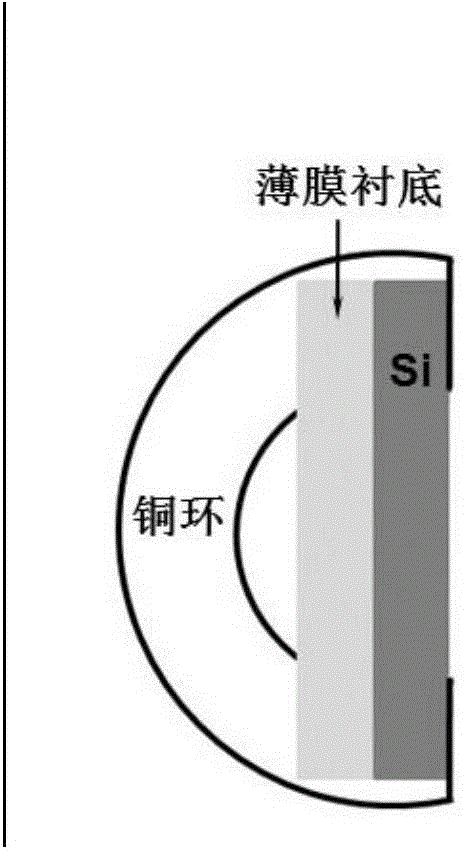

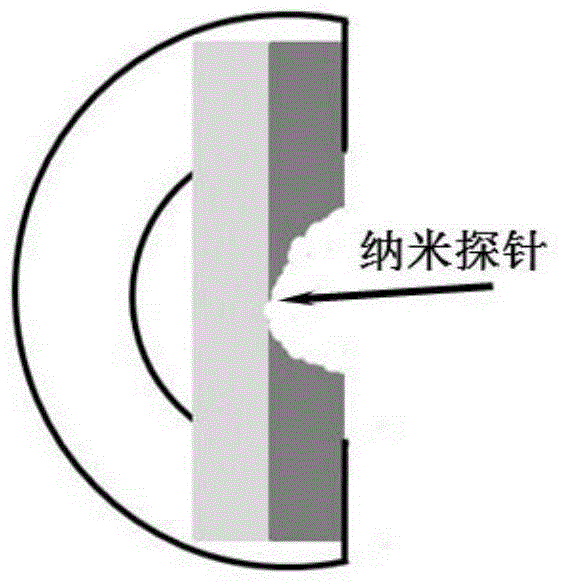

Preparation method of transmission electron microscopy film sample for in-situ application of electric field and stress

ActiveCN104819876AThin area is largeIncrease stressPreparing sample for investigationSingle crystalThinning

The present invention provides a preparation method of a transmission electron microscopy film sample for in-situ application of the electric field and the stress. The preparation method comprises: (1) cutting a film to be detected and a single crystal Si substrate into a strip shape with a size of 3 mm*1 mm*0.5 mm, and adhering the film surface of the film strip and the polishing surface of the Si strip; (2) carrying out mechanical grinding and polishing on both surfaces having the film strip thickness; (3) using a nail thinning instrument to carry out nail thinning; (4) adhering a half copper ring; and (5) selecting an ion thinning instrument to carry out ion thinning, setting the ion gun voltage to 4 kV, setting the angle to 6 DEG, thinning for 20-40 min, changing the angle into 4 DEG, thinning for 15-30 min, and finally polishing for 3 min by adopting the angle of 3 DEG and the voltage of 3 kV so as to obtain the large area perforation on the adhering seam, wherein the large area adhered Si sheet is bombarded, the film is exposed, the electric field and the stress can be applied by using the probe, and the large area thin region suitable for observation by the transmission electron microscopy exists on the edge.

Owner:HUBEI UNIV

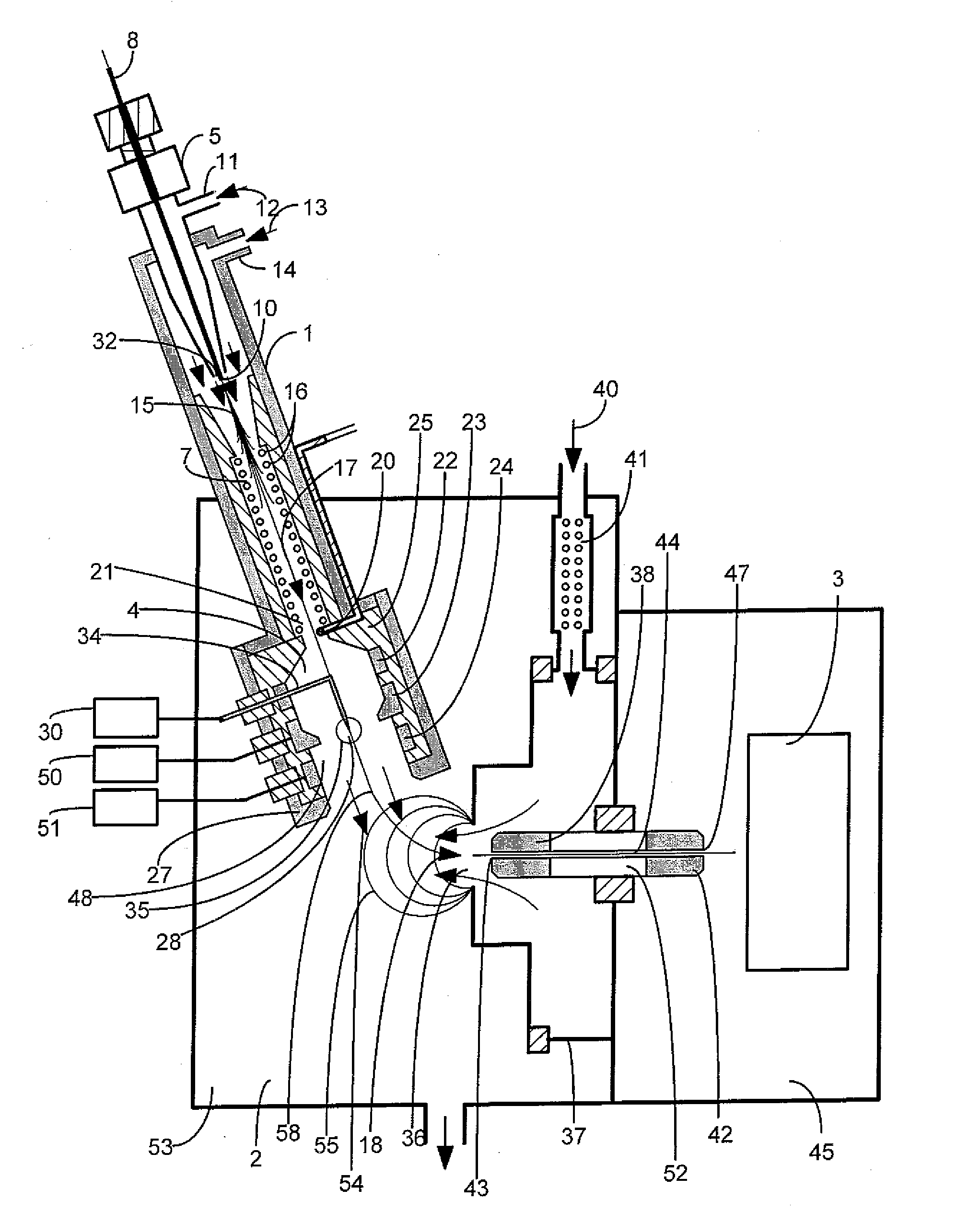

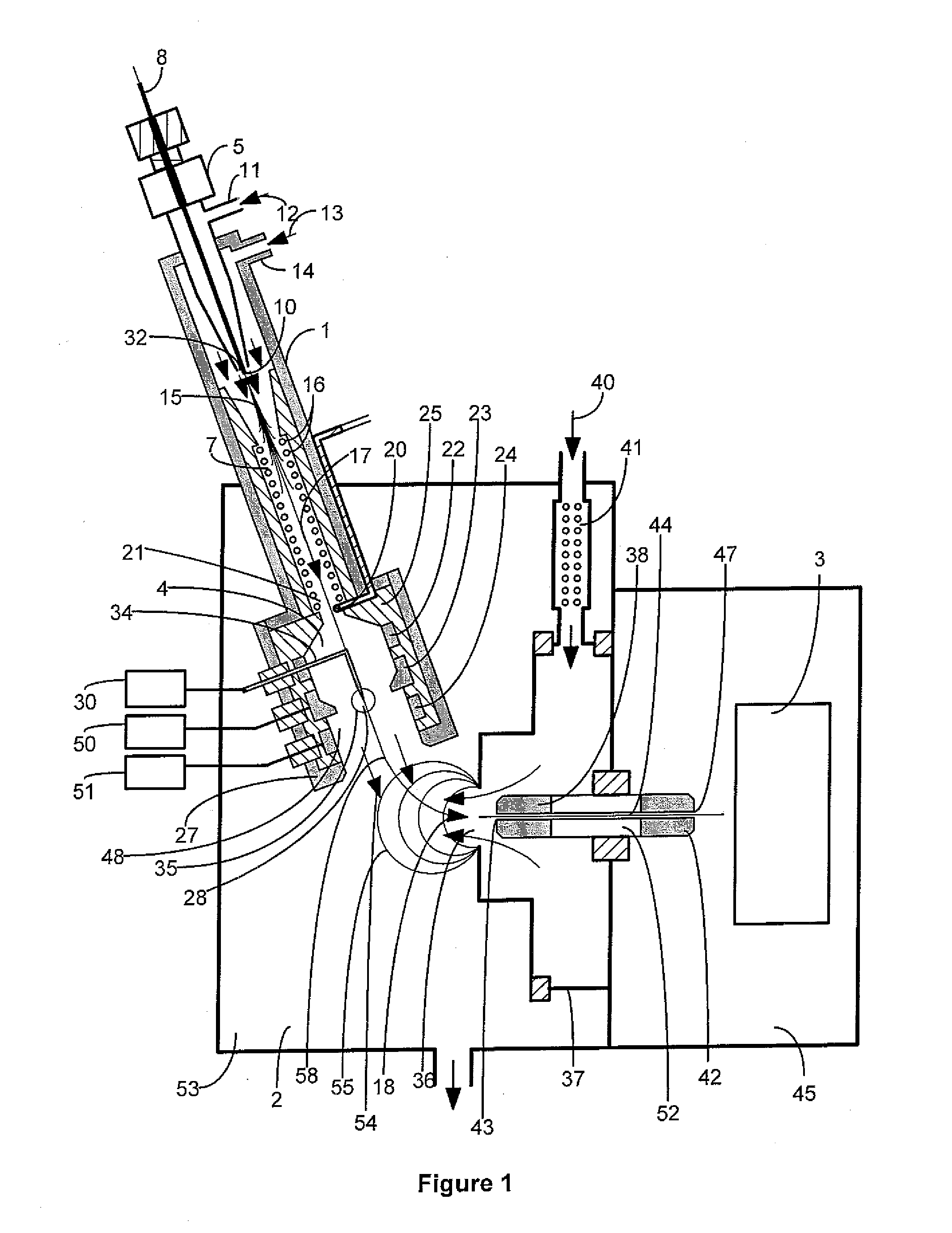

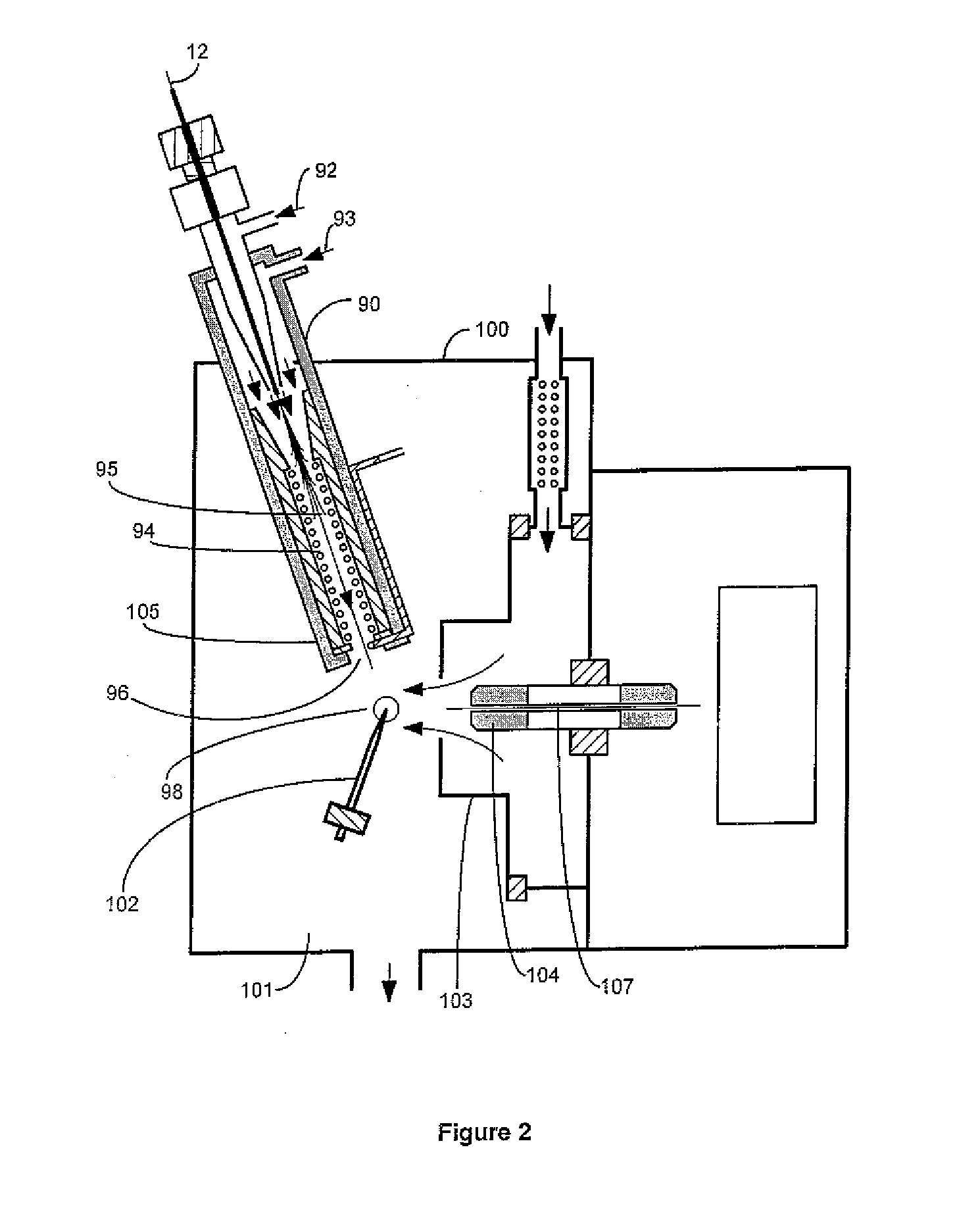

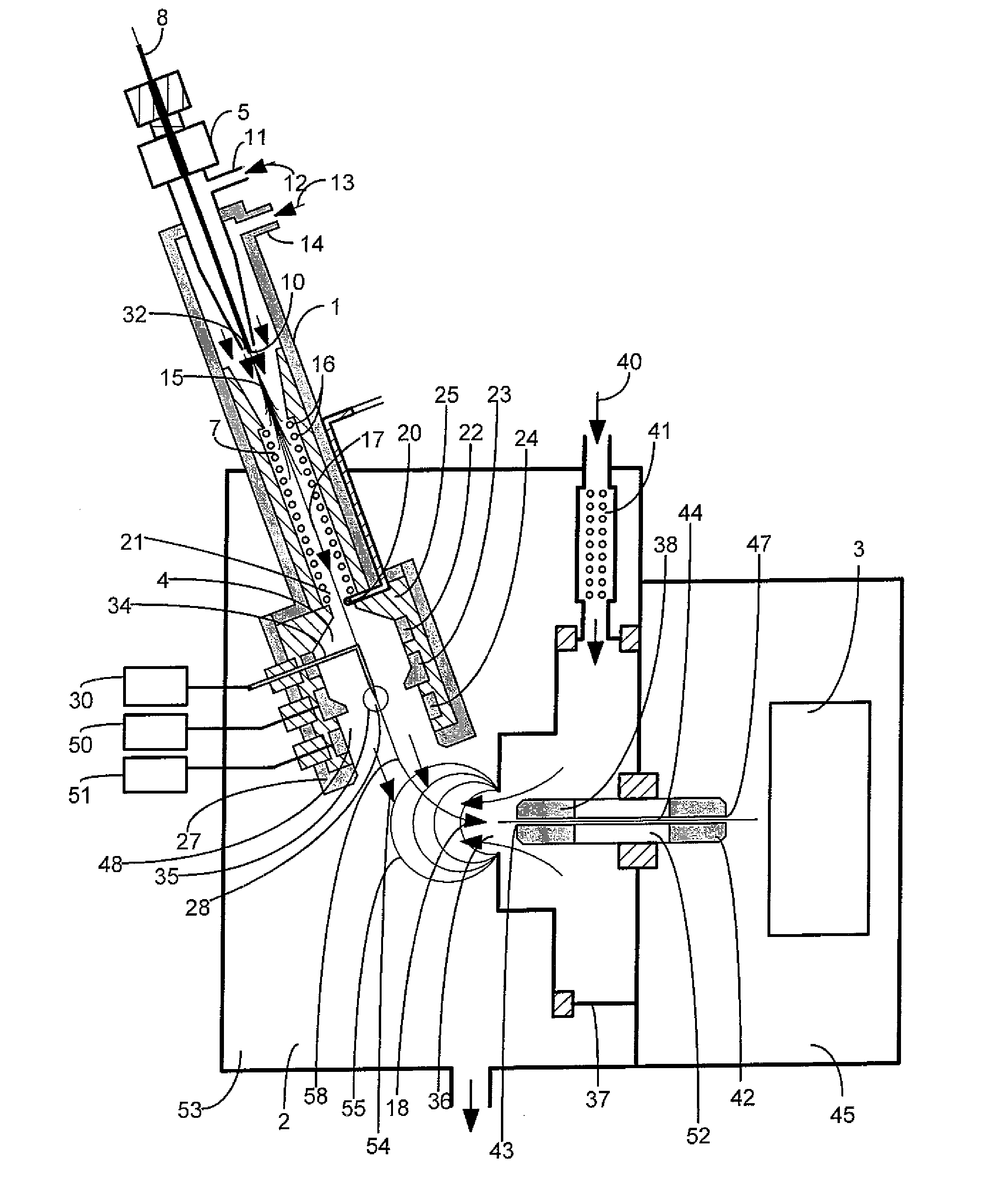

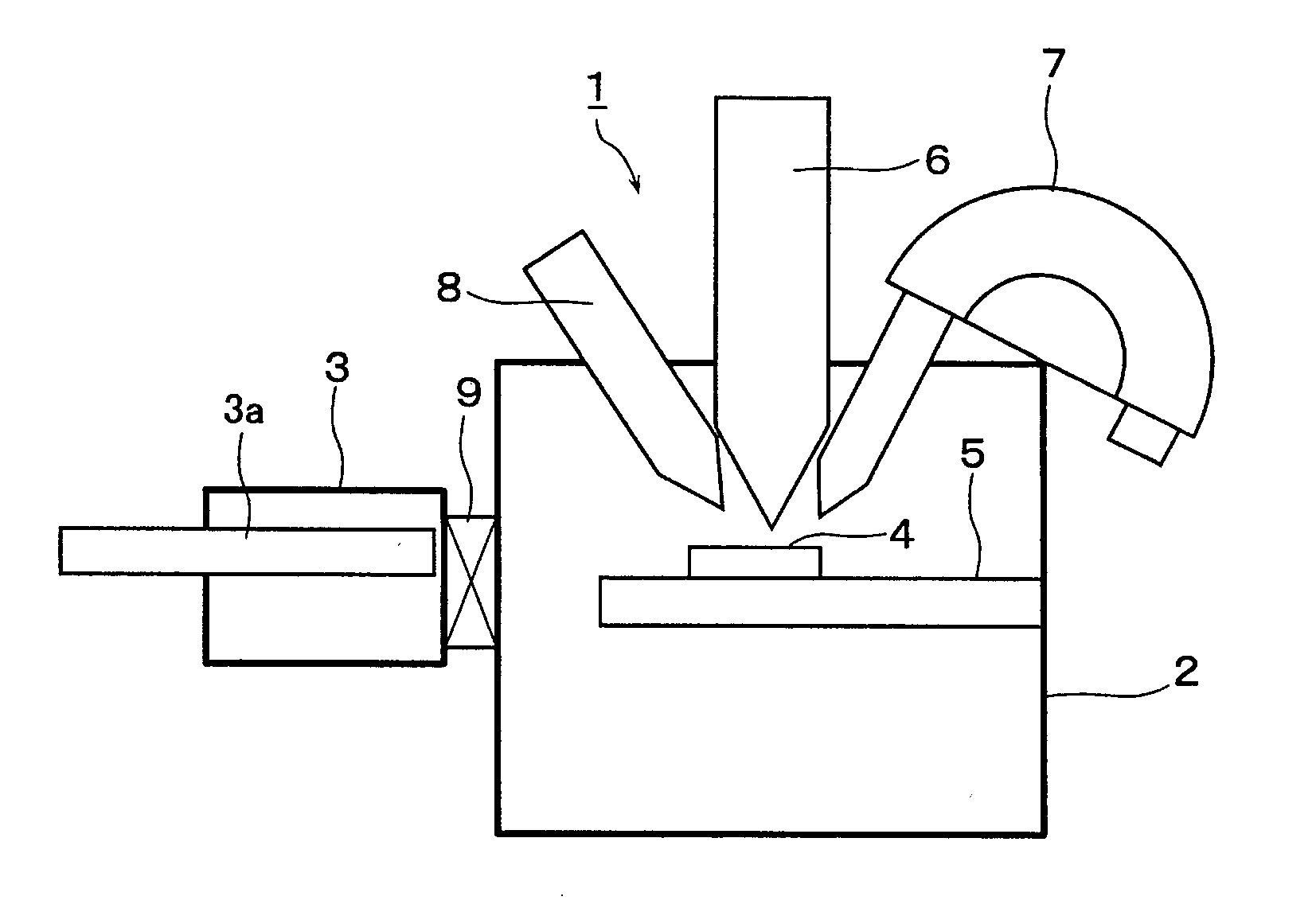

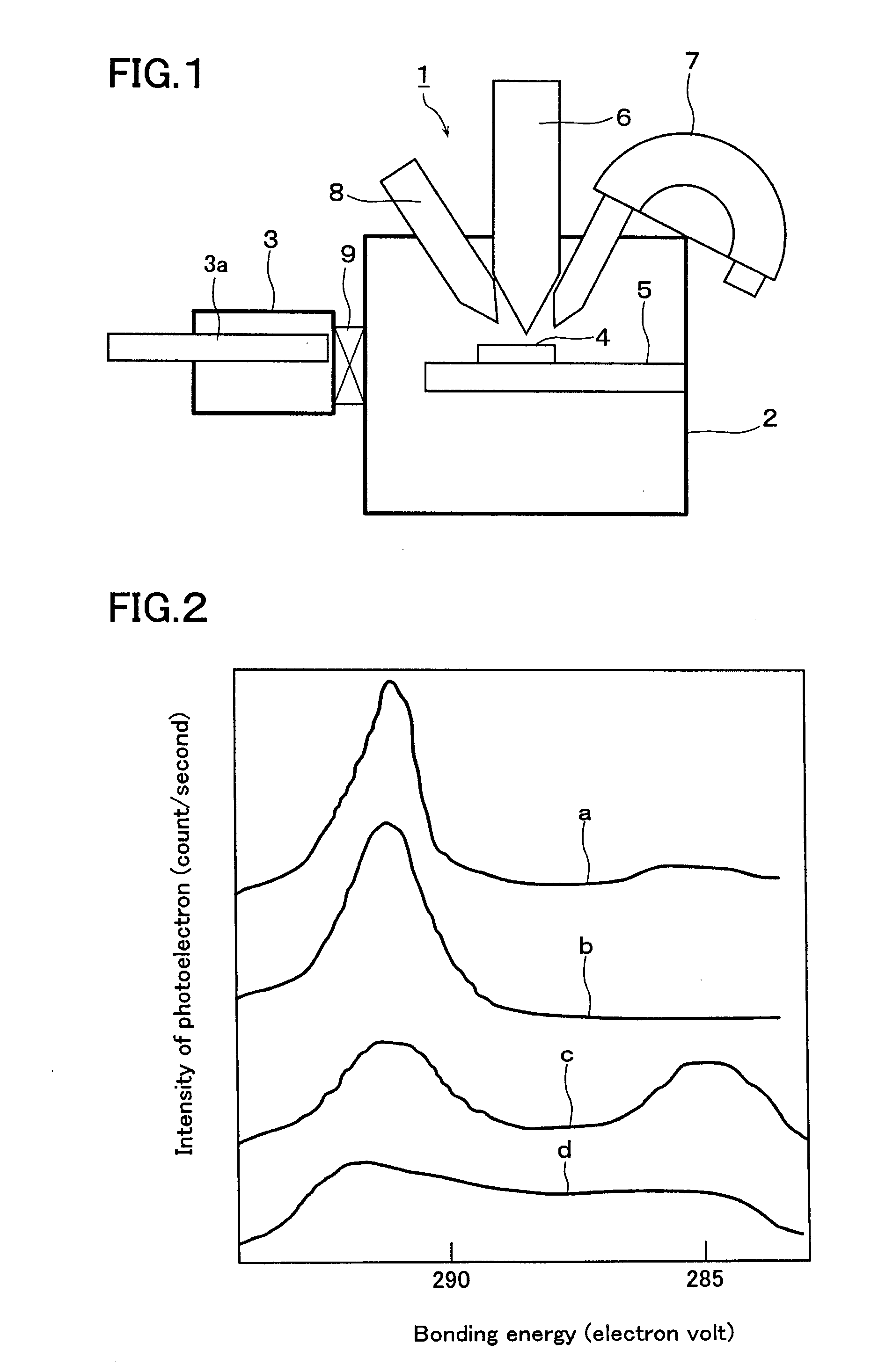

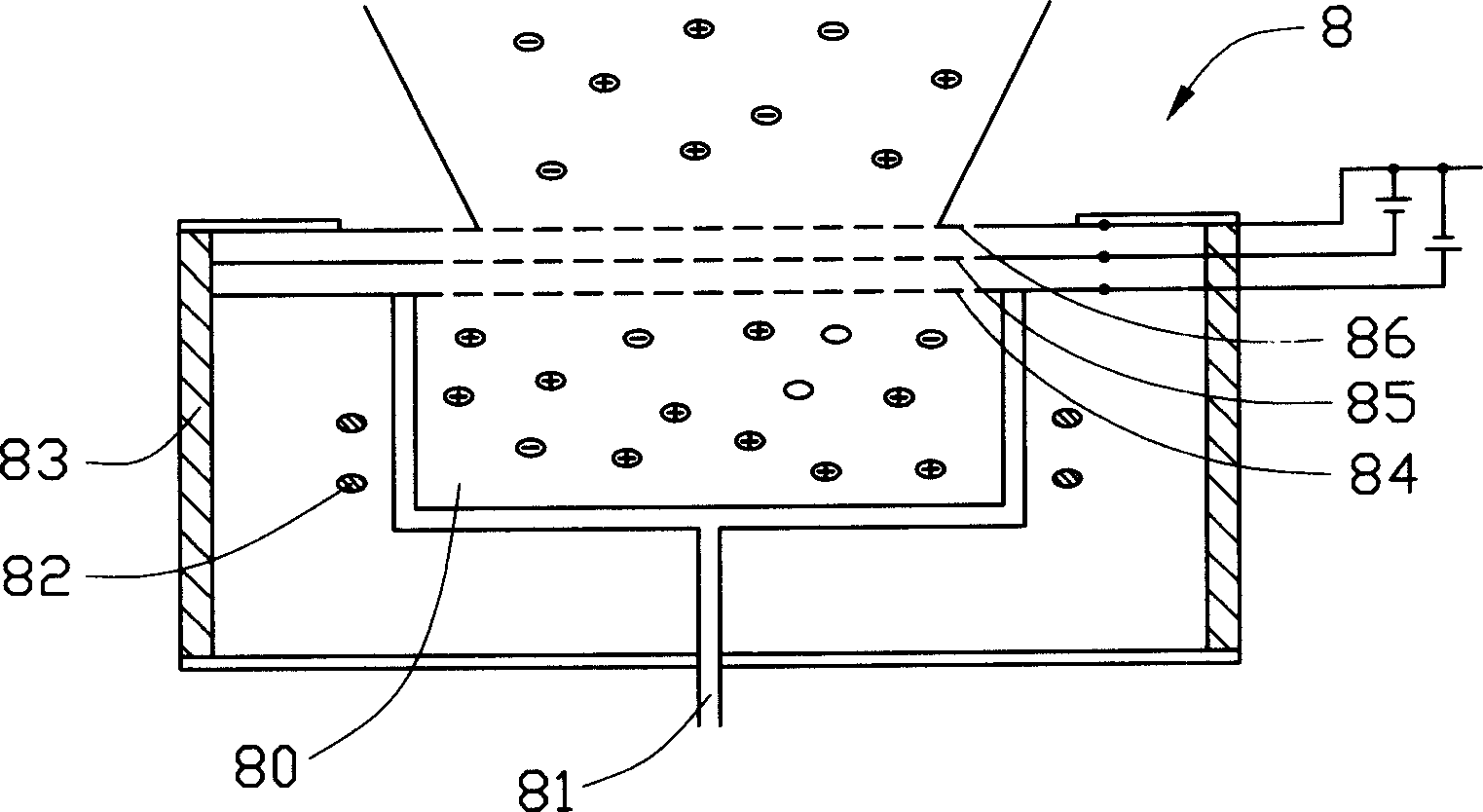

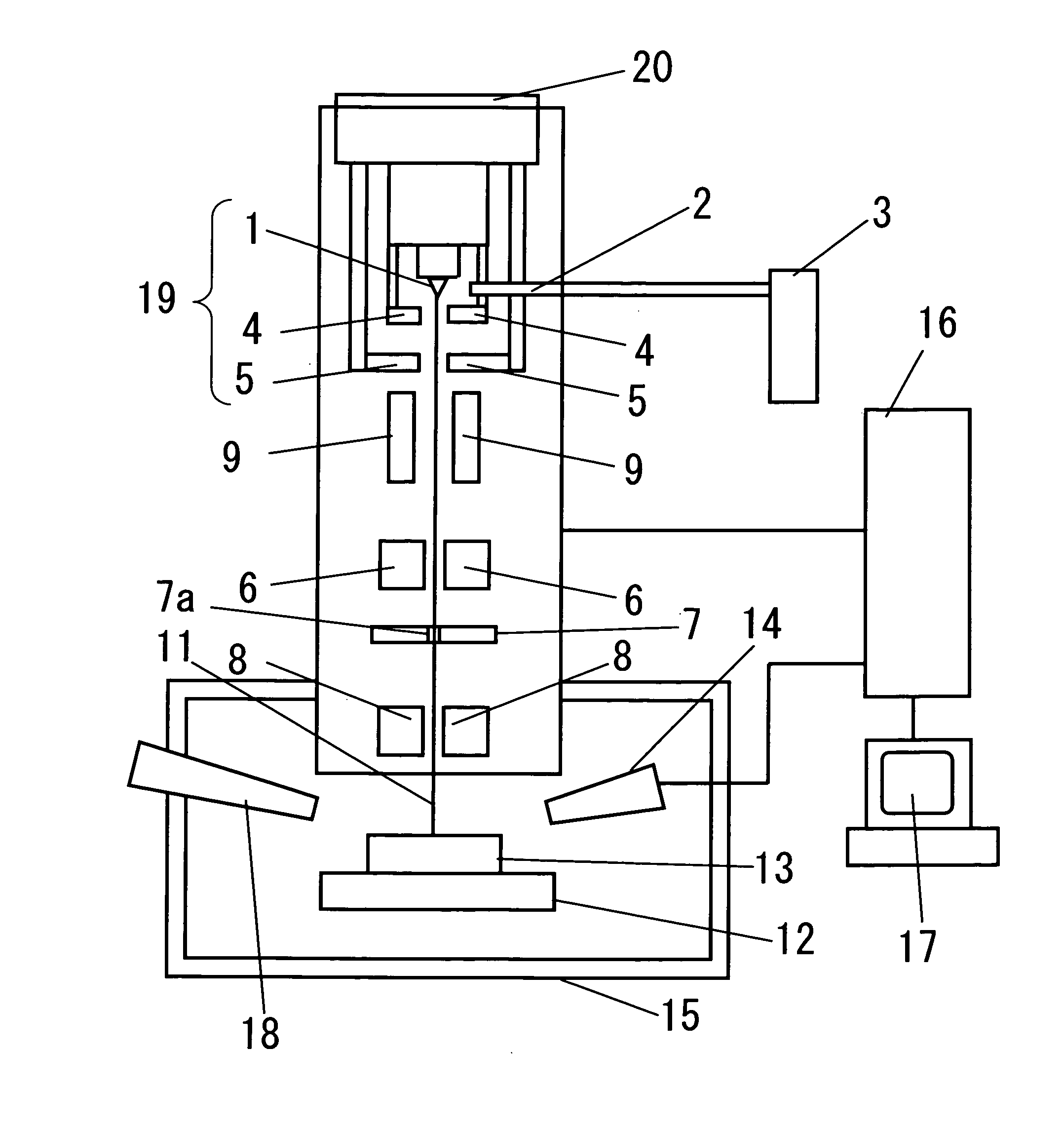

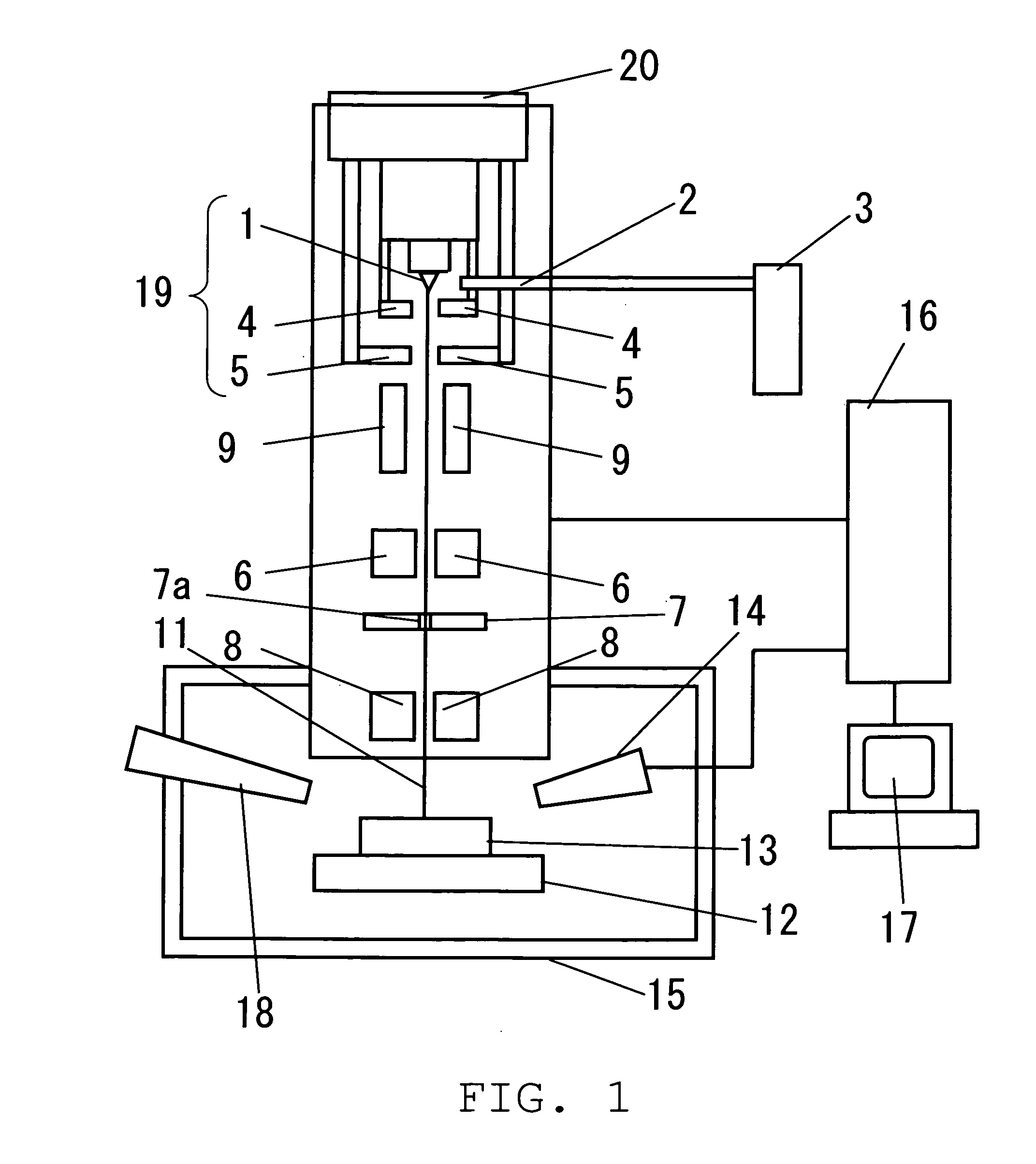

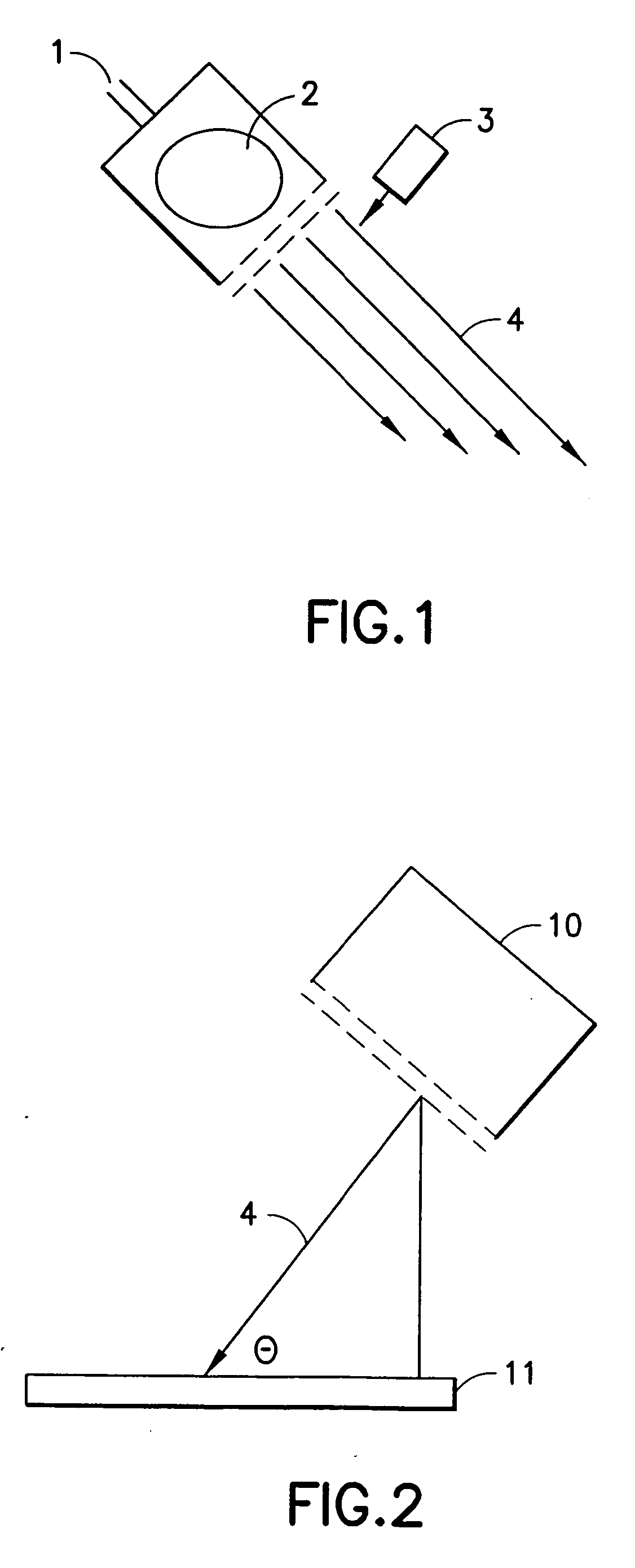

Electron Spectroscopy Analysis Method and Analytical Apparatus

InactiveUS20080042057A1Negligible damageLow costMaterial nanotechnologyPreparing sample for investigationX-rayElectron spectroscopy

[Task] The invention enables uniformly etching a surface of a sample with an improved repeatability, and etching at a low cost without requiring any large-scale equipment.[Means for Solving the Problem] In an electron spectroscopy analytical apparatus (1) for executing an analysis of a composition, a chemical state and the like of a surface of a sample (4) or in a depth direction thereof by irradiating an X-ray to the sample (4) from a high-energy particle irradiating unit (6) within a vacuum chamber (2) under a vacuum atmosphere, and detecting a kinetic energy of electrons emitted from the sample (4) by an electric energy analyzer (7) on the basis of a photoelectric effect, the surface of the sample (4) is ion-etched by irradiating a fullerene ion beam to the surface of the sample (4) from an ion gun (8) before irradiating the high-energy particle to the sample (4).

Owner:ULVAC PHI

Ion source, ion gun, and analysis instrument

ActiveUS20150206732A1Suppressing damage to a acceptable levelLow yieldStability-of-path spectrometersBeam/ray focussing/reflecting arrangementsSpectroscopyMass spectrometry

Provided are an ion source, an ion gun, and an analysis instrument, which are capable of performing sputtering without damage to a surface of a sample and improving detection sensitivity in mass spectroscopy. In the ion source, an emission opening to which ionization liquid is supplied is disposed in an electric field formed in vacuum environment by an extracting electrode so that super large droplet cluster ions are generated from the emission opening. When the sample is irradiated with a super large droplet cluster ion beam, the sample surface is subjected to sputtering without damage, so as to remove contamination substances or to expose a new surface of the sample. In mass spectroscopy, detection sensitivity is improved.

Owner:ULVAC PHI INC

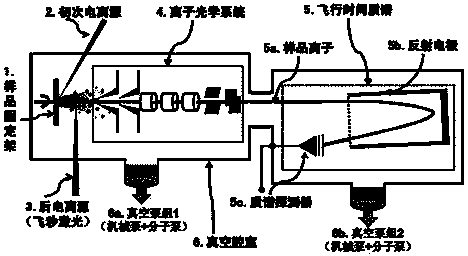

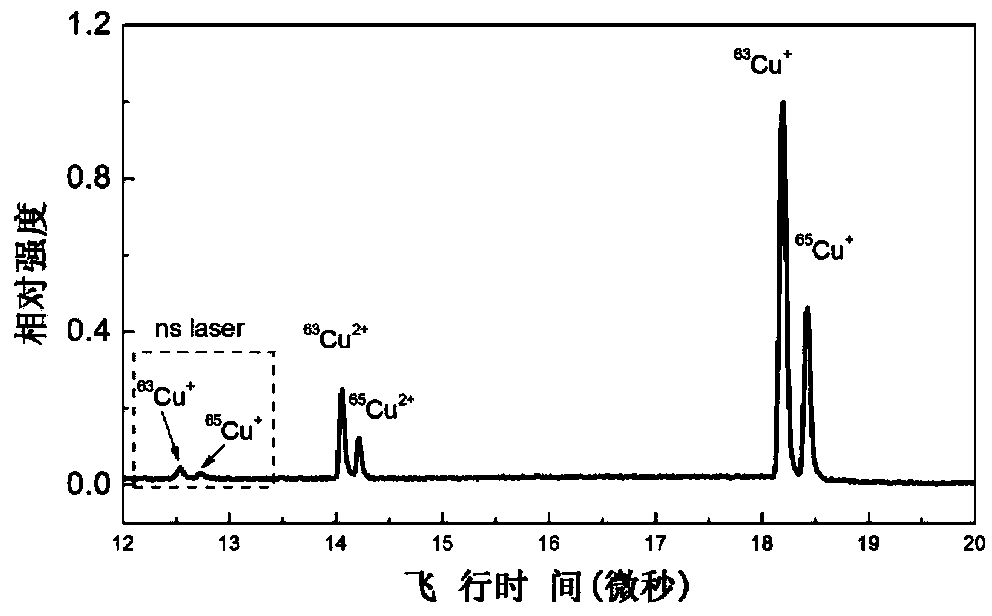

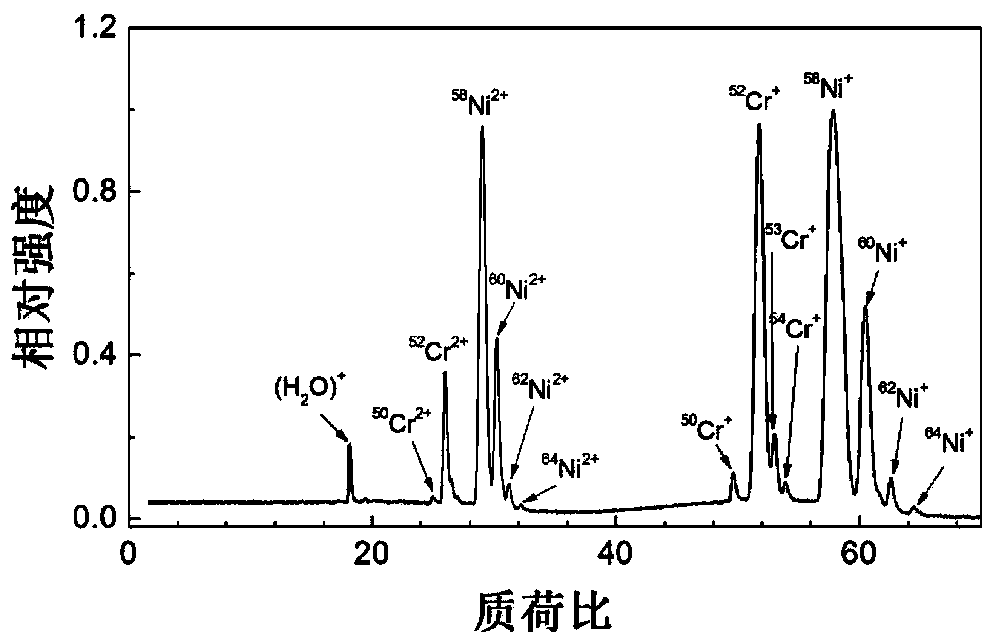

Femtosecond laser post-ionization mass spectrum apparatus

InactiveCN104392887AIncreased peak power densityEfficient use ofSamples introduction/extractionMass spectrometersMass spectrometryVacuum chamber

Disclosed in the invention is a femtosecond laser post-ionization mass spectrum apparatus comprising a vacuum chamber, a sample fixed bracket, a primary ionization source, a post-ionization source, an ion optics system and a flight time mass spectrum unit. An ion gun or laser is used as the primary ionization source to carry out sputtering on the solid surface; and during the primary ionization source sputtering process, a sample ion and a neutral particle can be generated, wherein the neutral-particle-based sputtering part enables the accuracy and the resolution ratio of the analysis result to be limited greatly. According to the invention, the femtosecond laser is used as the post-ionization means of the neutral particle, so that the ionization efficiency of the sample is substantially improved. And the sample ionization component is analyzed by using the flight time mass spectrum way.

Owner:DALIAN NATIONALITIES UNIVERSITY

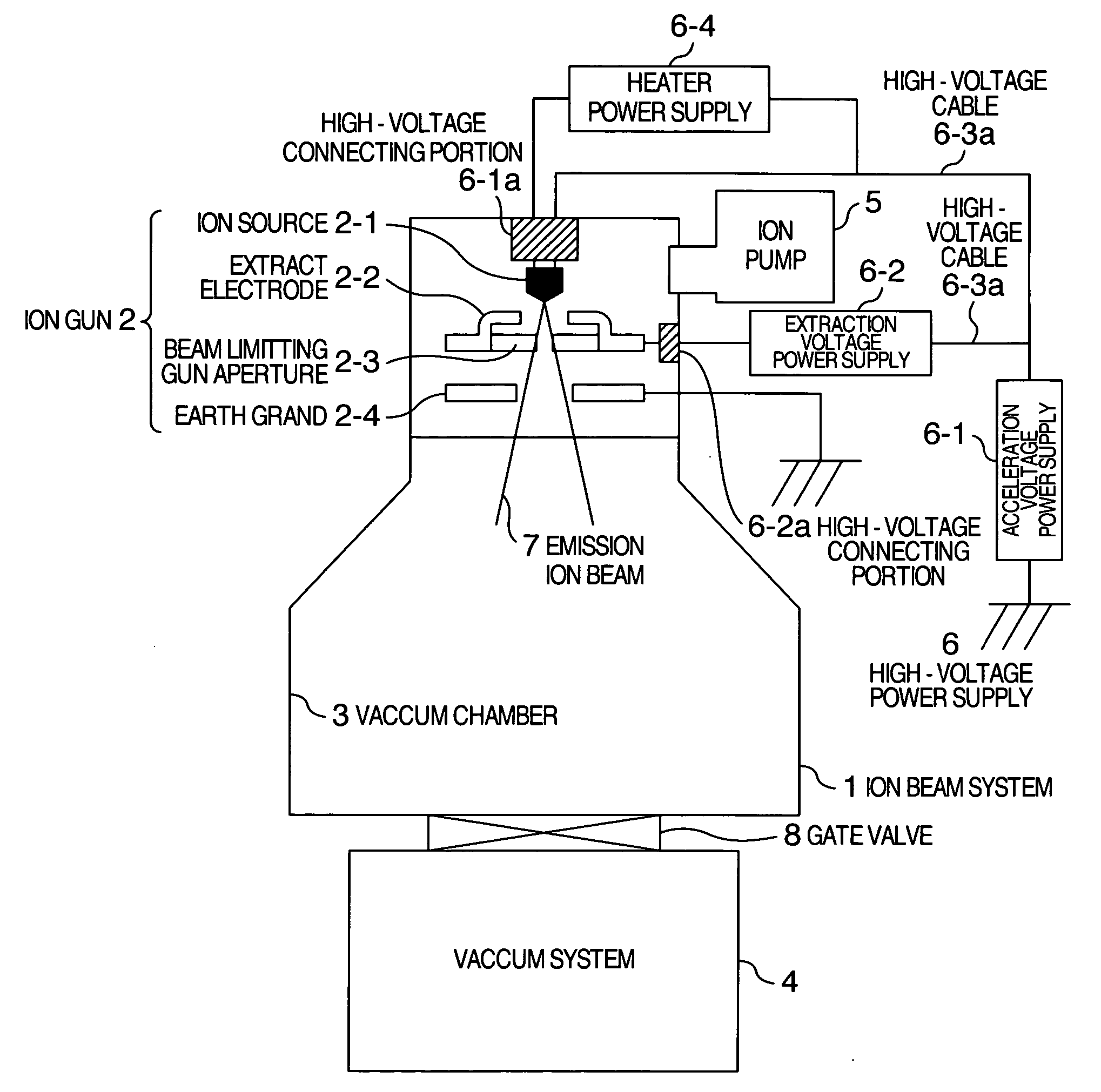

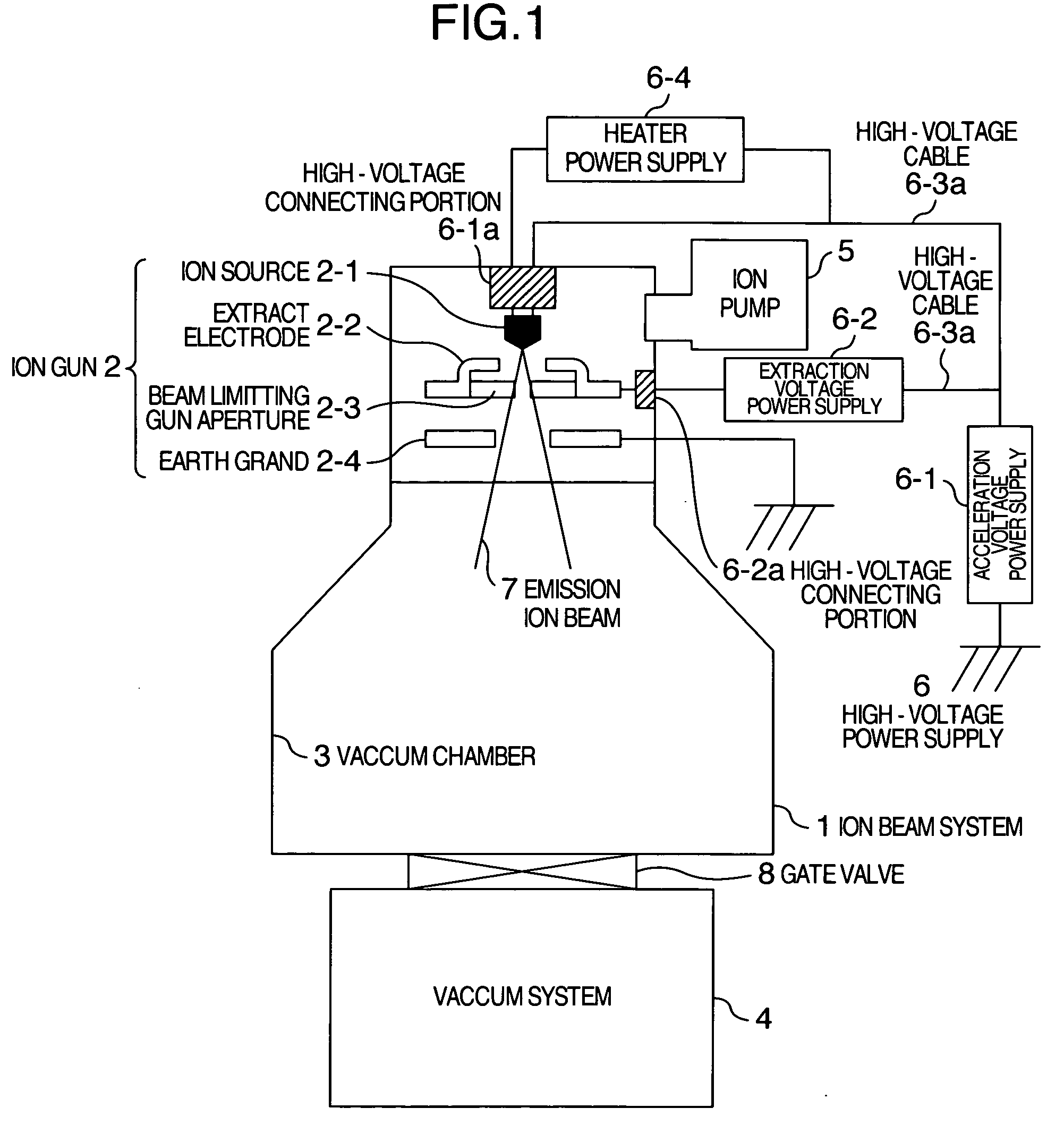

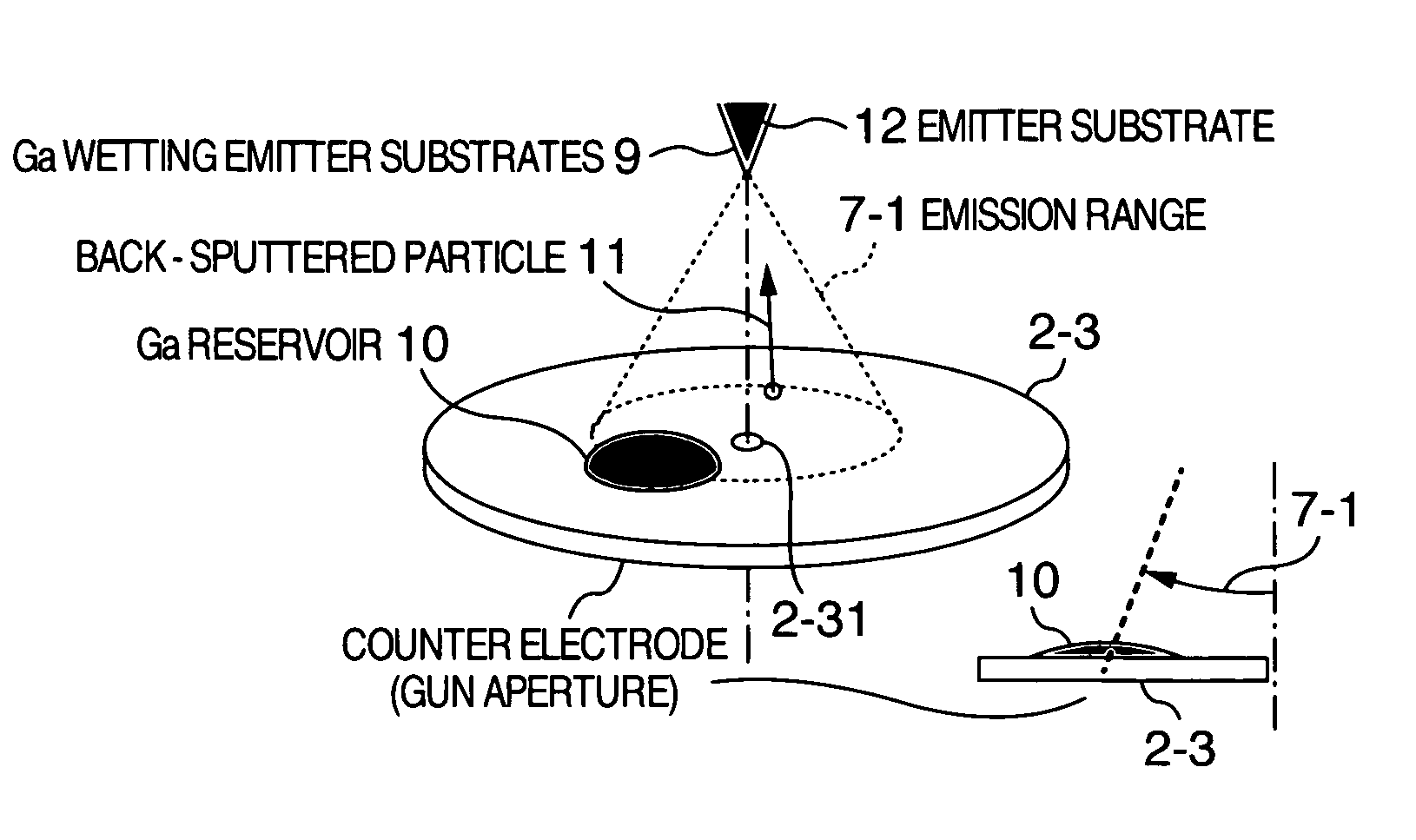

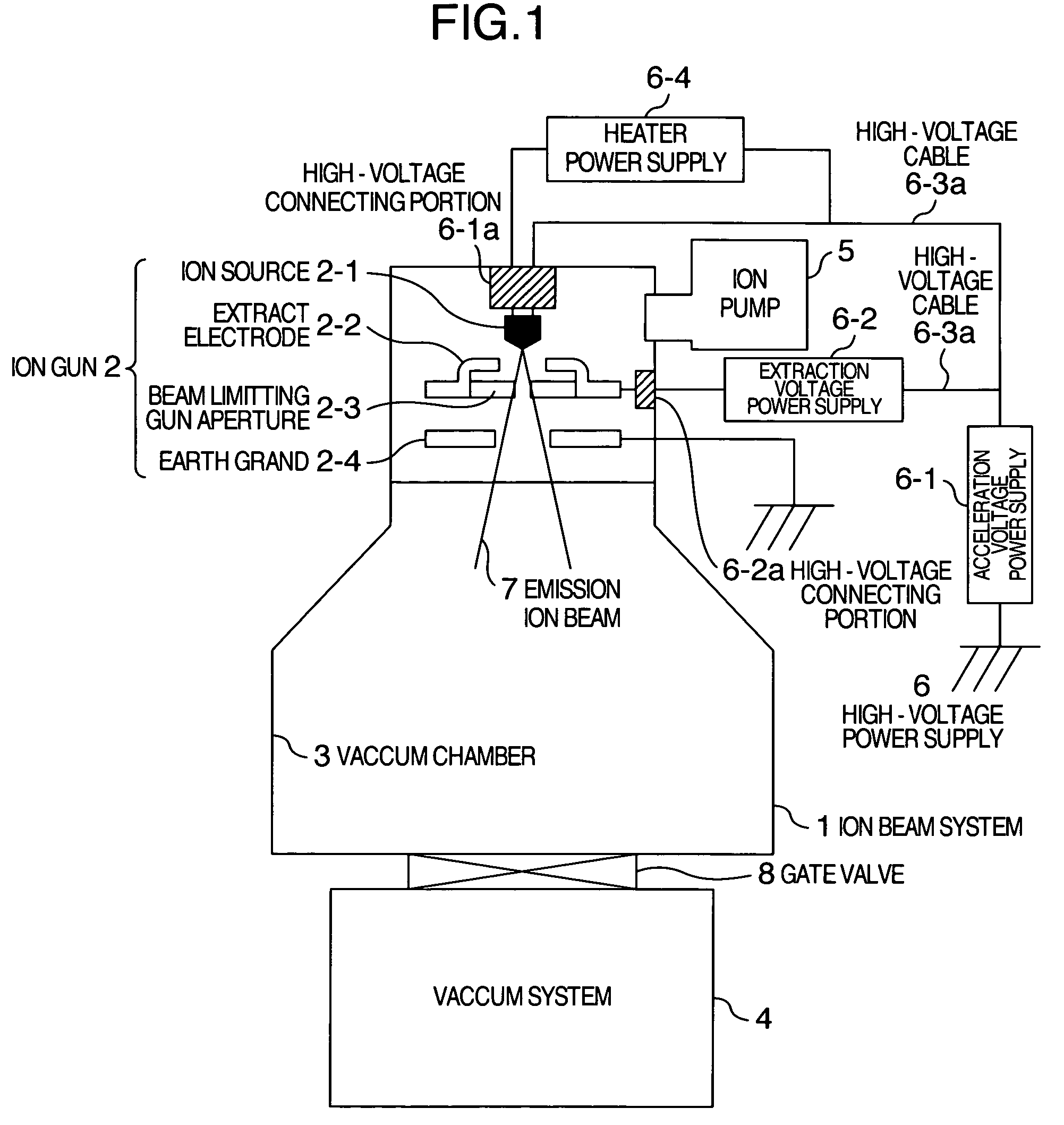

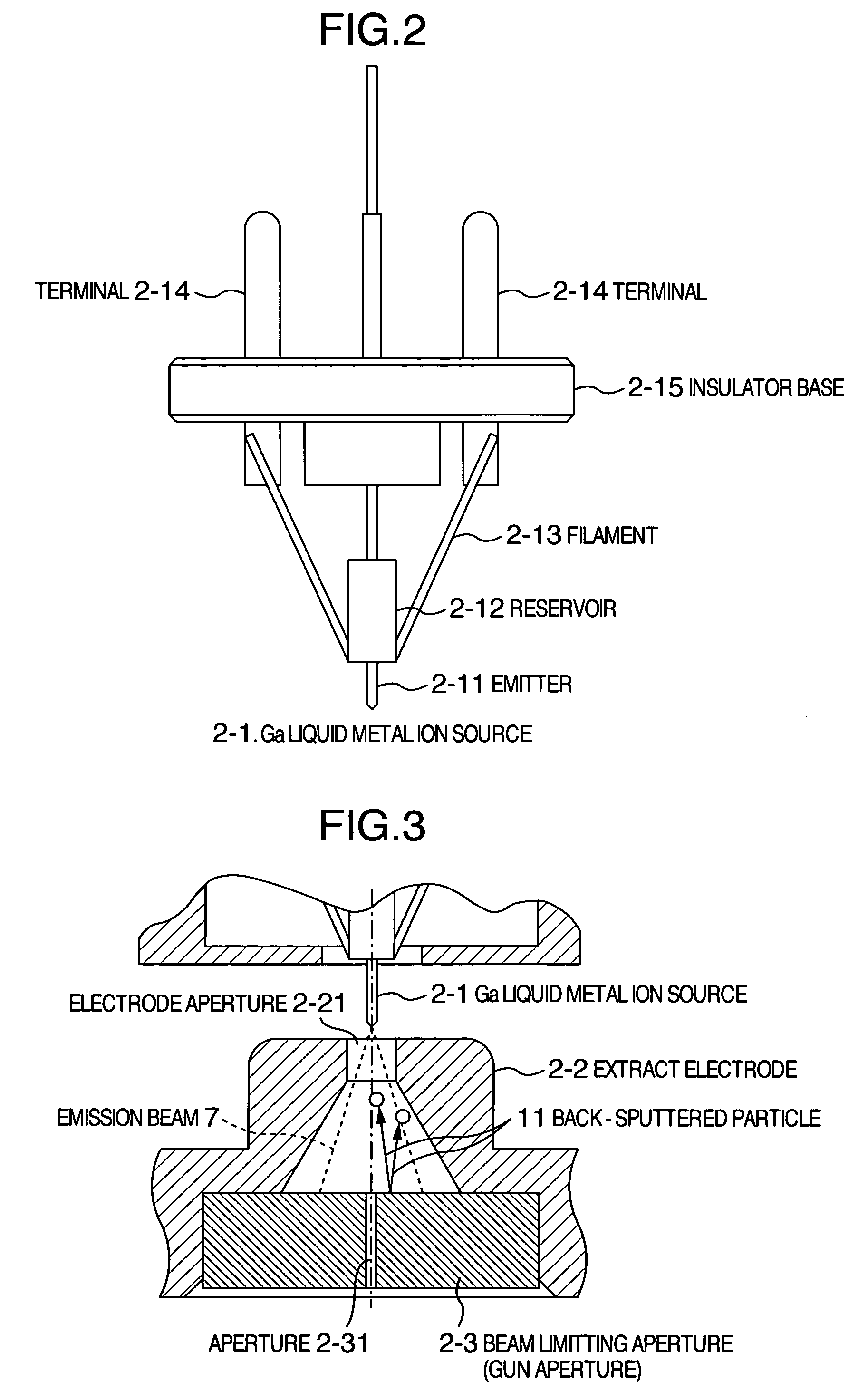

Liquid metal ion gun

InactiveUS20050127304A1Extended service lifeGood reproducibilityMaterial analysis by optical meansIon beam tubesLiquid metal ion sourceLiquid state

An emitter of a Ga liquid metal ion source is constituted to include W12 of a base material and Ga9 of an ion source element covering a surface as construction materials. By making back-sputtered particles become elements (W and Ga) of the Ga liquid metal ion sour source, if back-sputtered particles attach to the Ga liquid metal ion source, contamination which may change physical characteristics of Ga9 does not occur. A W aperture is used as a beam limiting (GUN) aperture to place Ga of approx. 25 mg (of melting point of 30° C.) on a surface of a portion included in a beam emission region (Ga store). When emitting ions to the beam limiting (GUN) aperture, Ga in the emission region melts and diffuses on a surface of the beam emission region of the W aperture.

Owner:HITACHI HIGH-TECH CORP

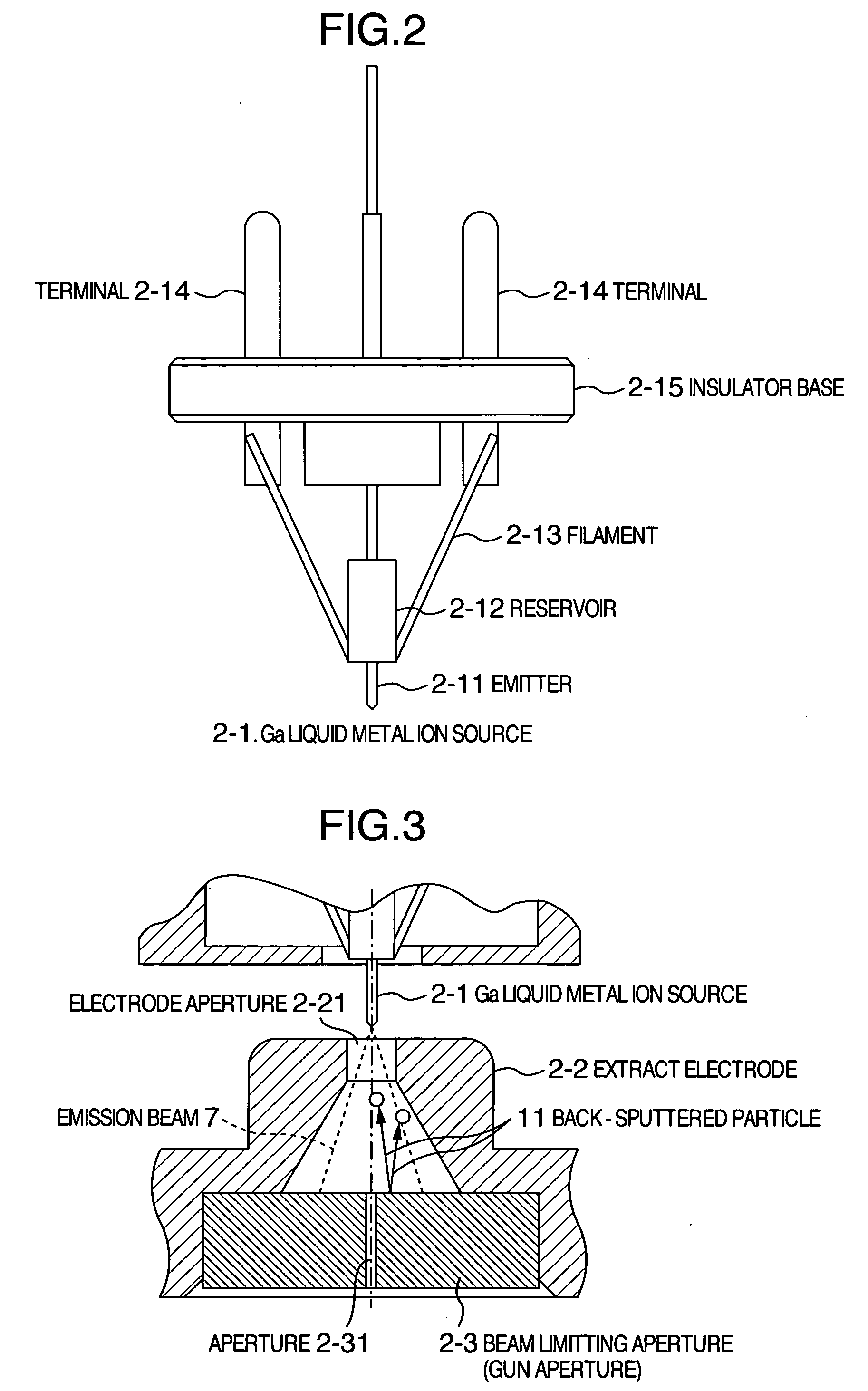

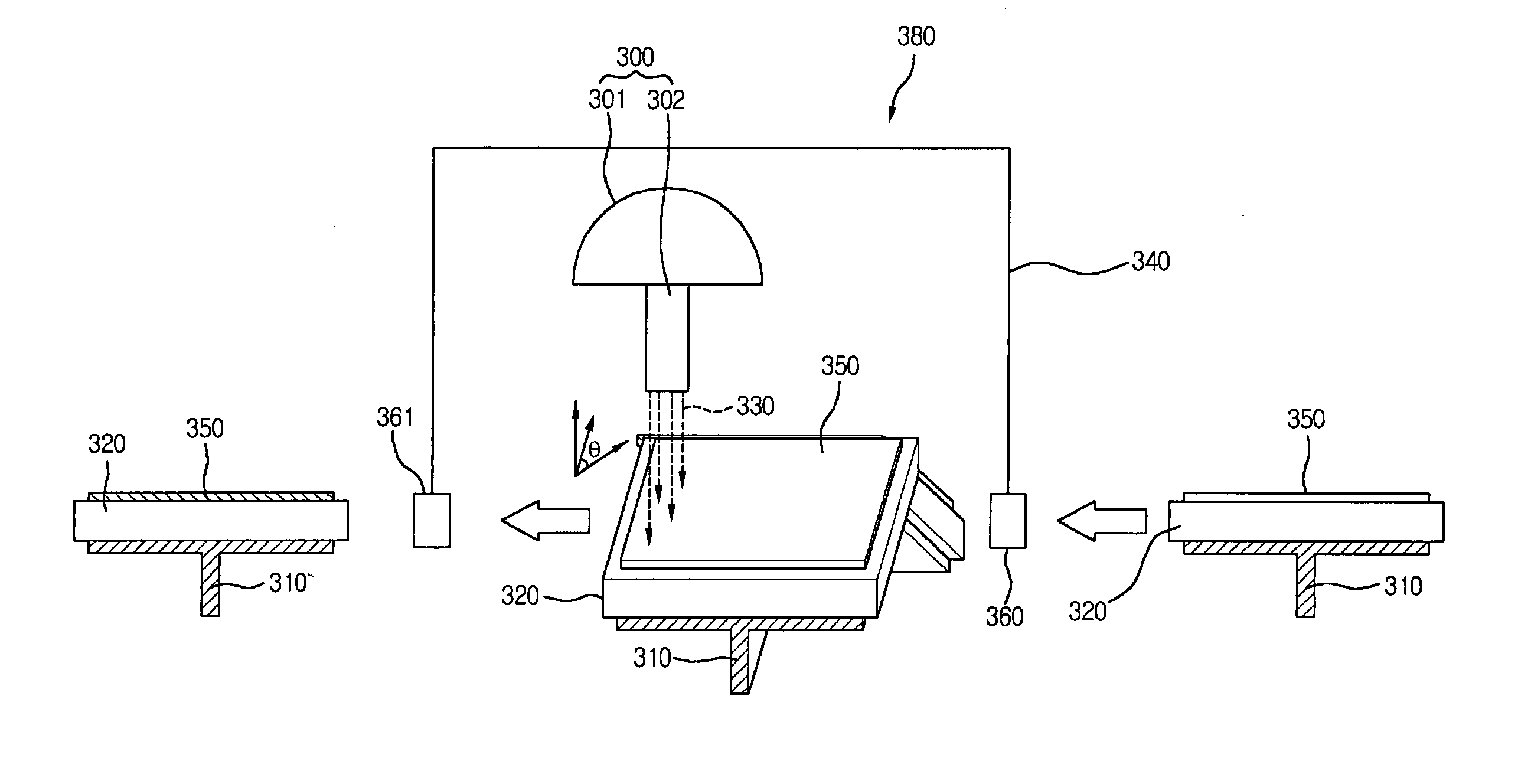

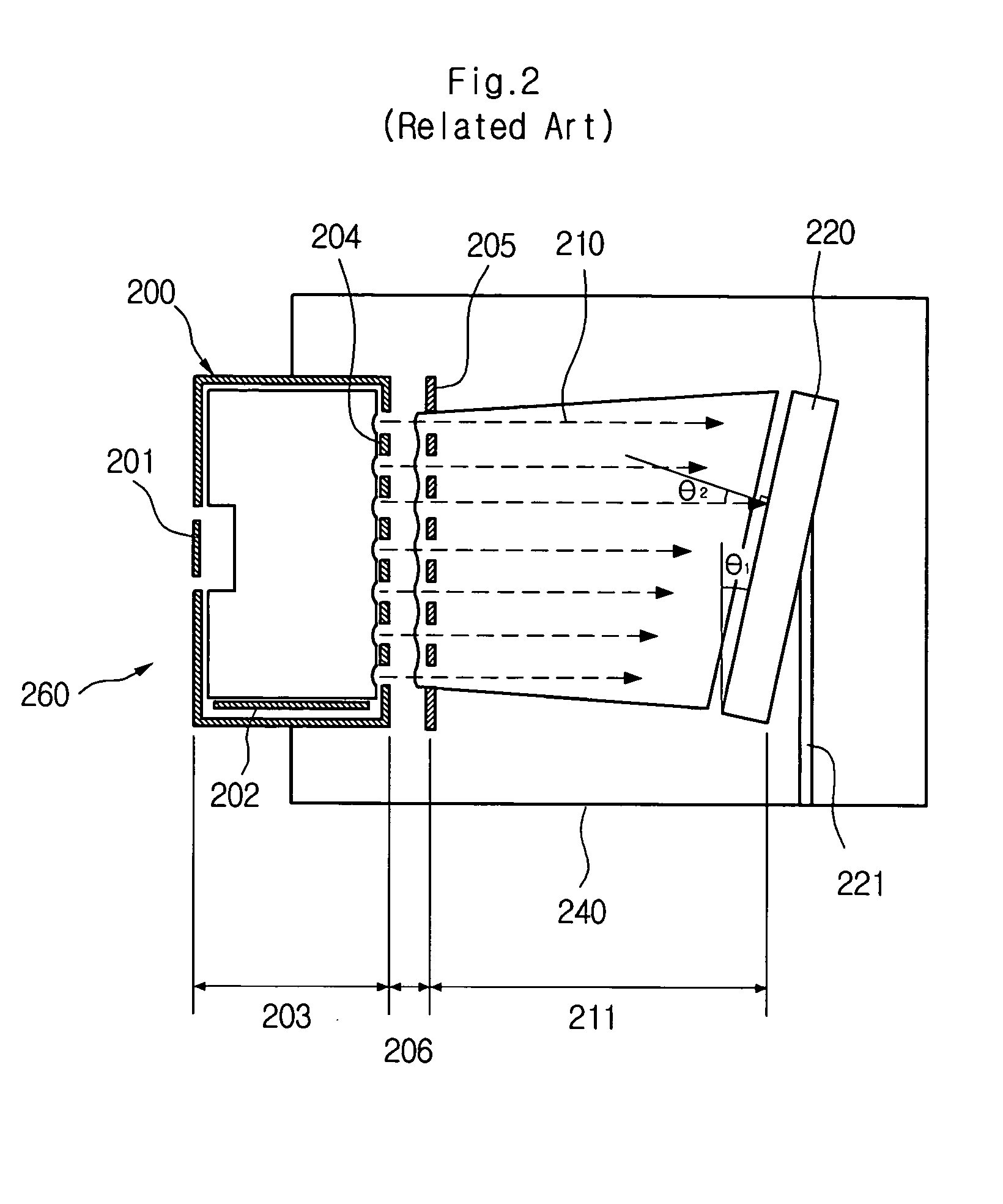

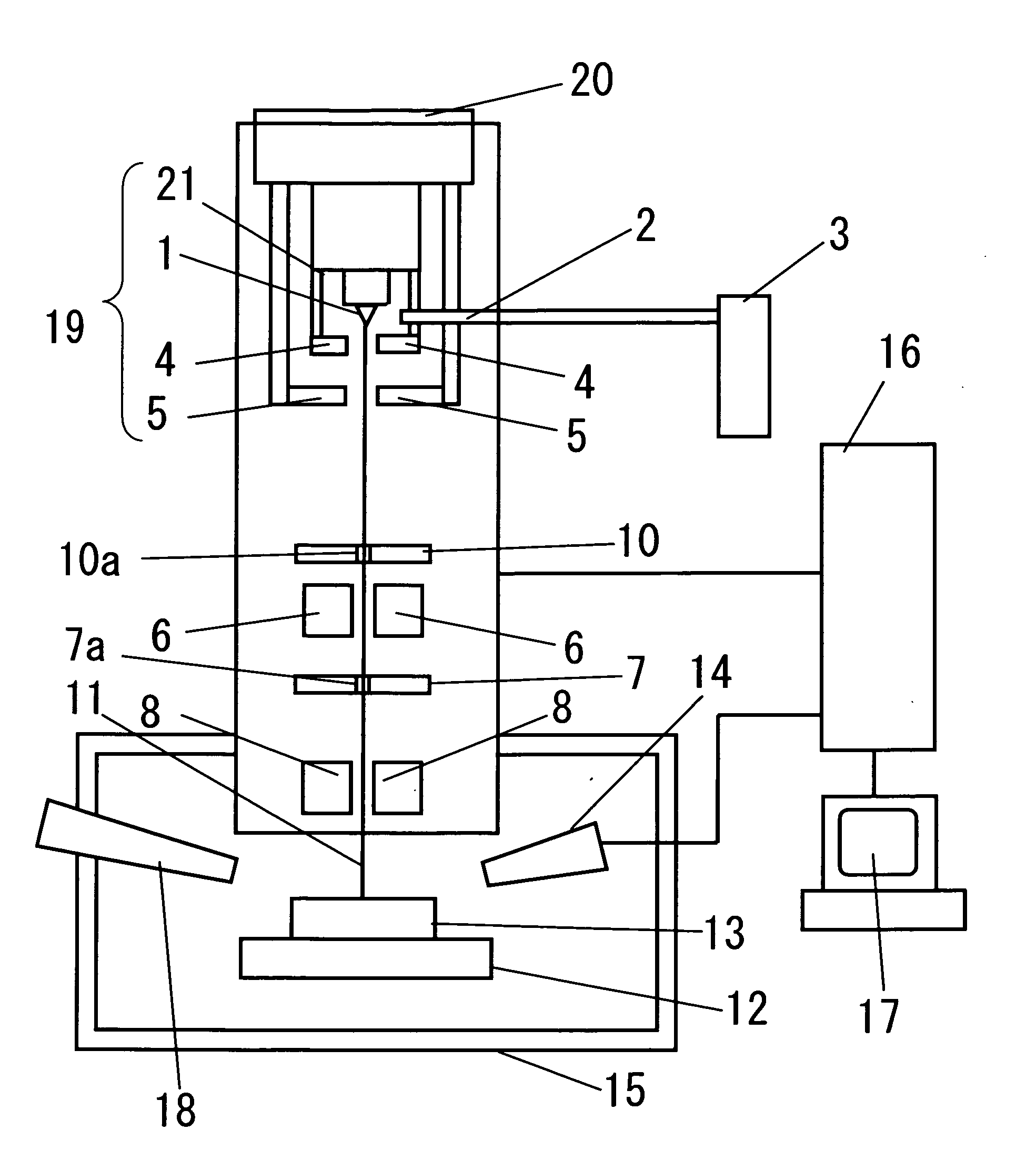

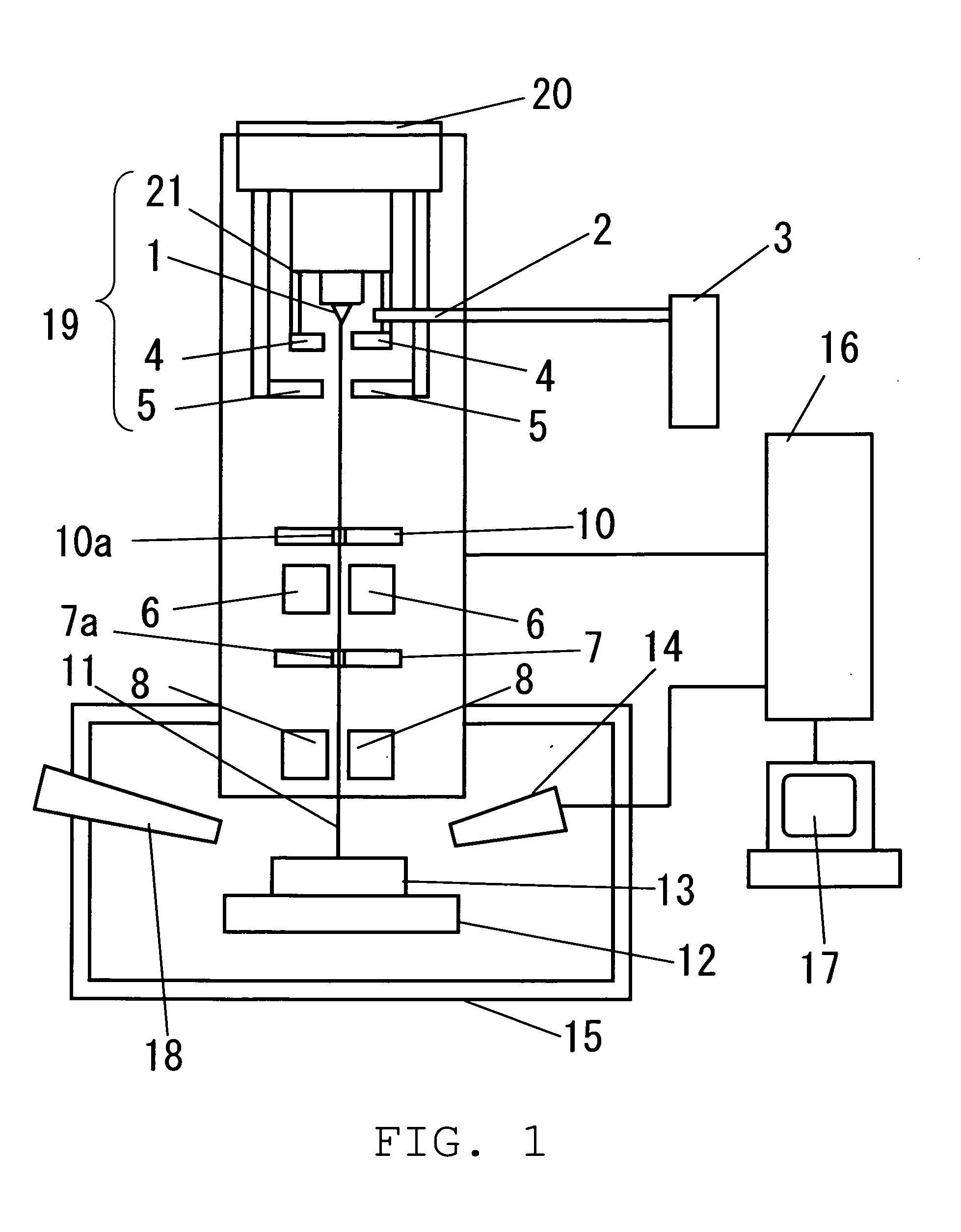

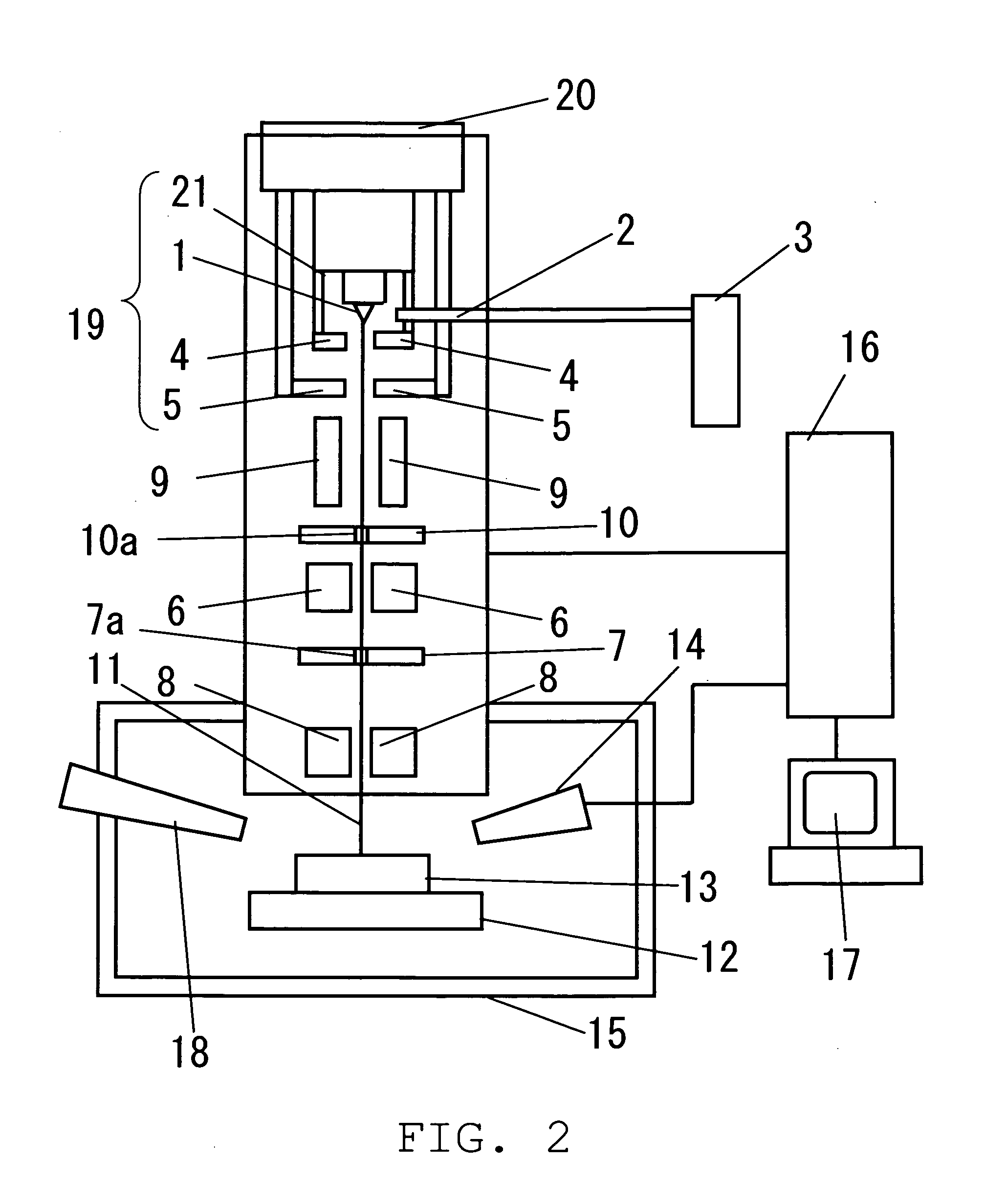

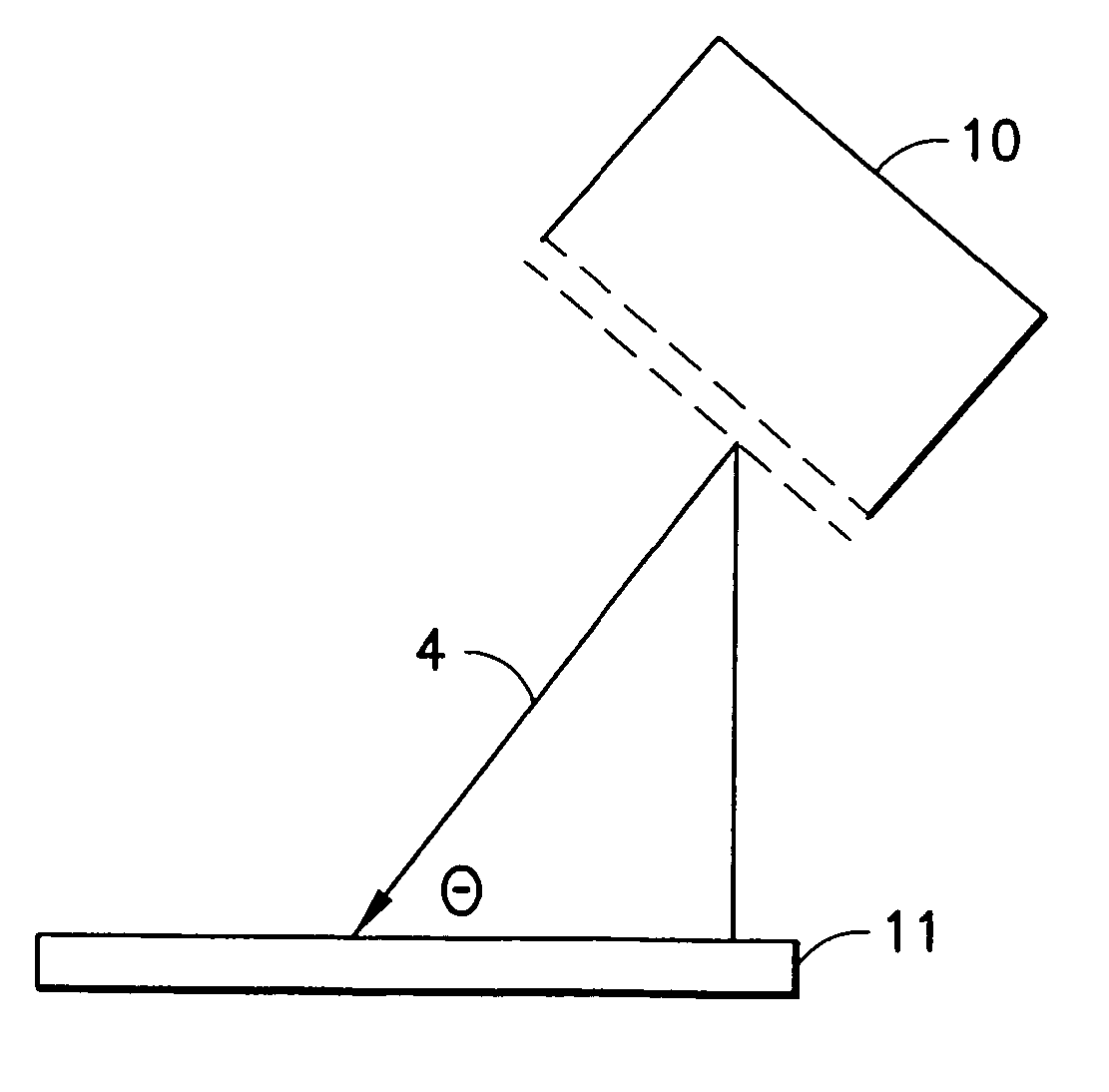

Ion beam irradiation device and operating method thereof

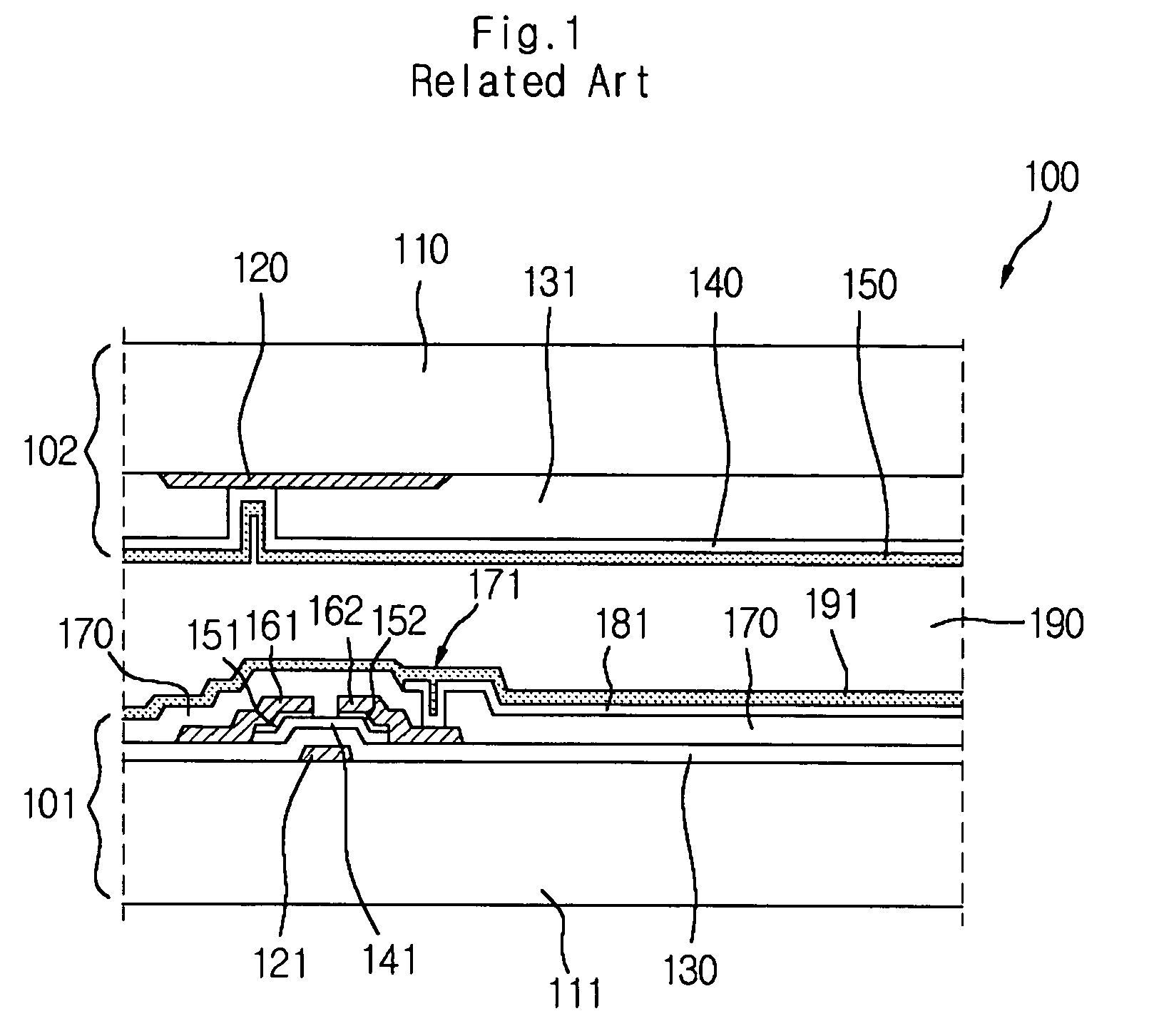

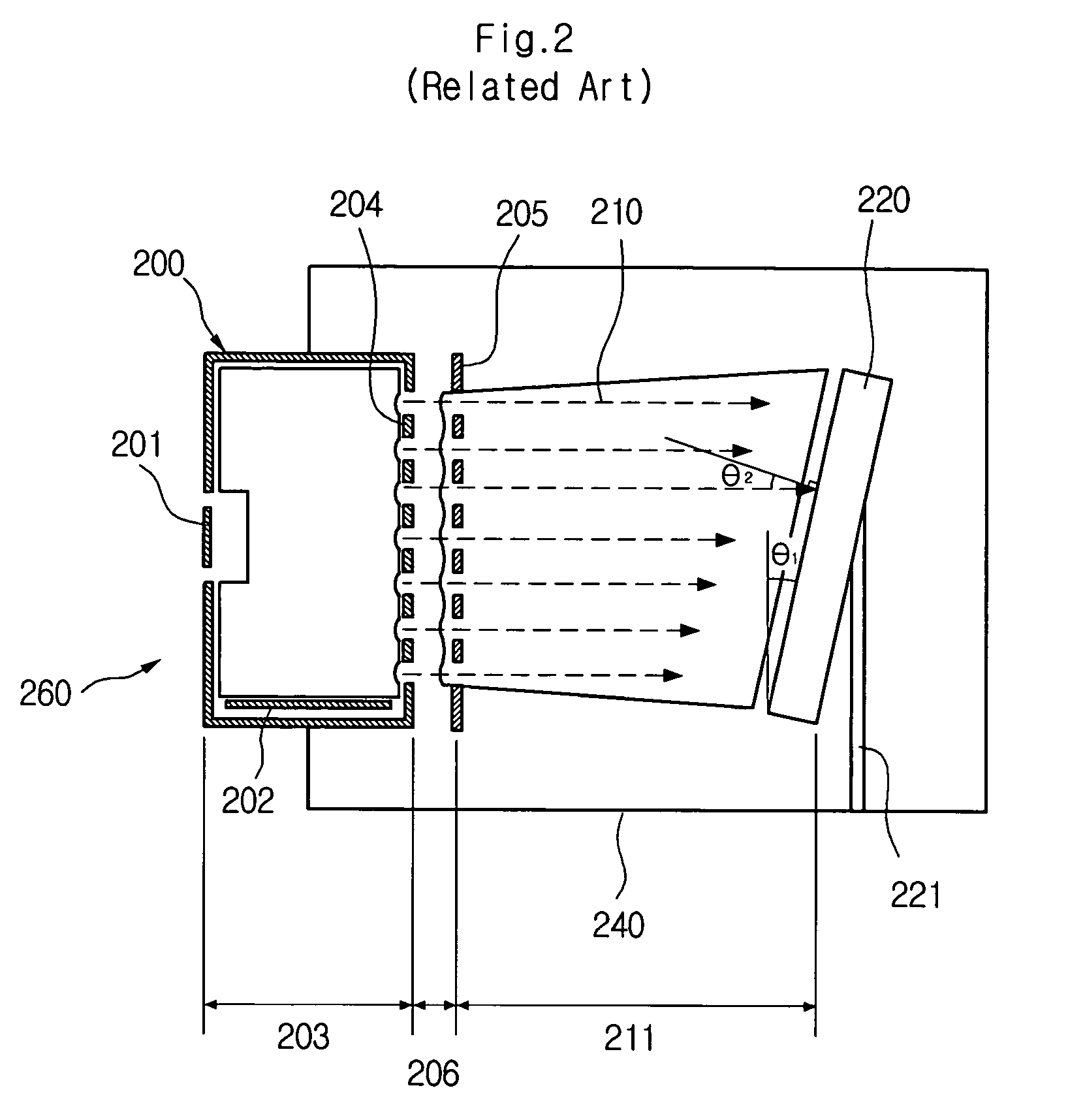

ActiveUS6967340B2Material analysis using wave/particle radiationElectric discharge tubesVacuum chamberSingle pass

An ion beam irradiation device includes a vacuum chamber and a stage on which at least two substrates may be mounted such that each substrate has an inclination angle to a horizontal plane of the vacuum chamber. The stage moves in one direction. An ion gun provided in the vacuum chamber produces ion beams that irradiate the substrates. In a single pass through the vacuum chamber, the alignment layers disposed on multiple substrates may be aligned. The substrates can be aligned such that the ion beam irradiates multiple substrates simultaneously and / or such that the ion beam irradiates the multiple substrates sequentially.

Owner:LG DISPLAY CO LTD

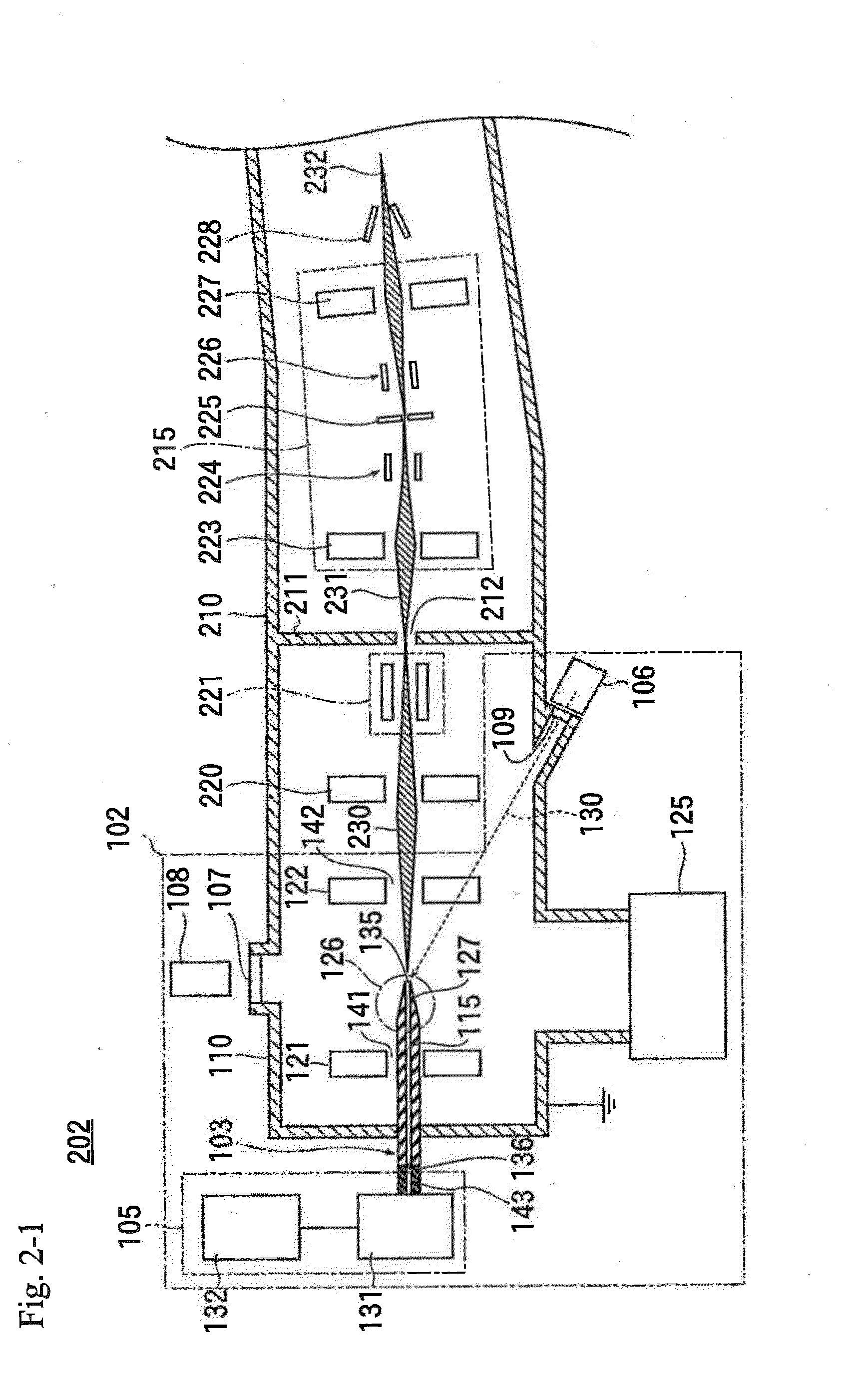

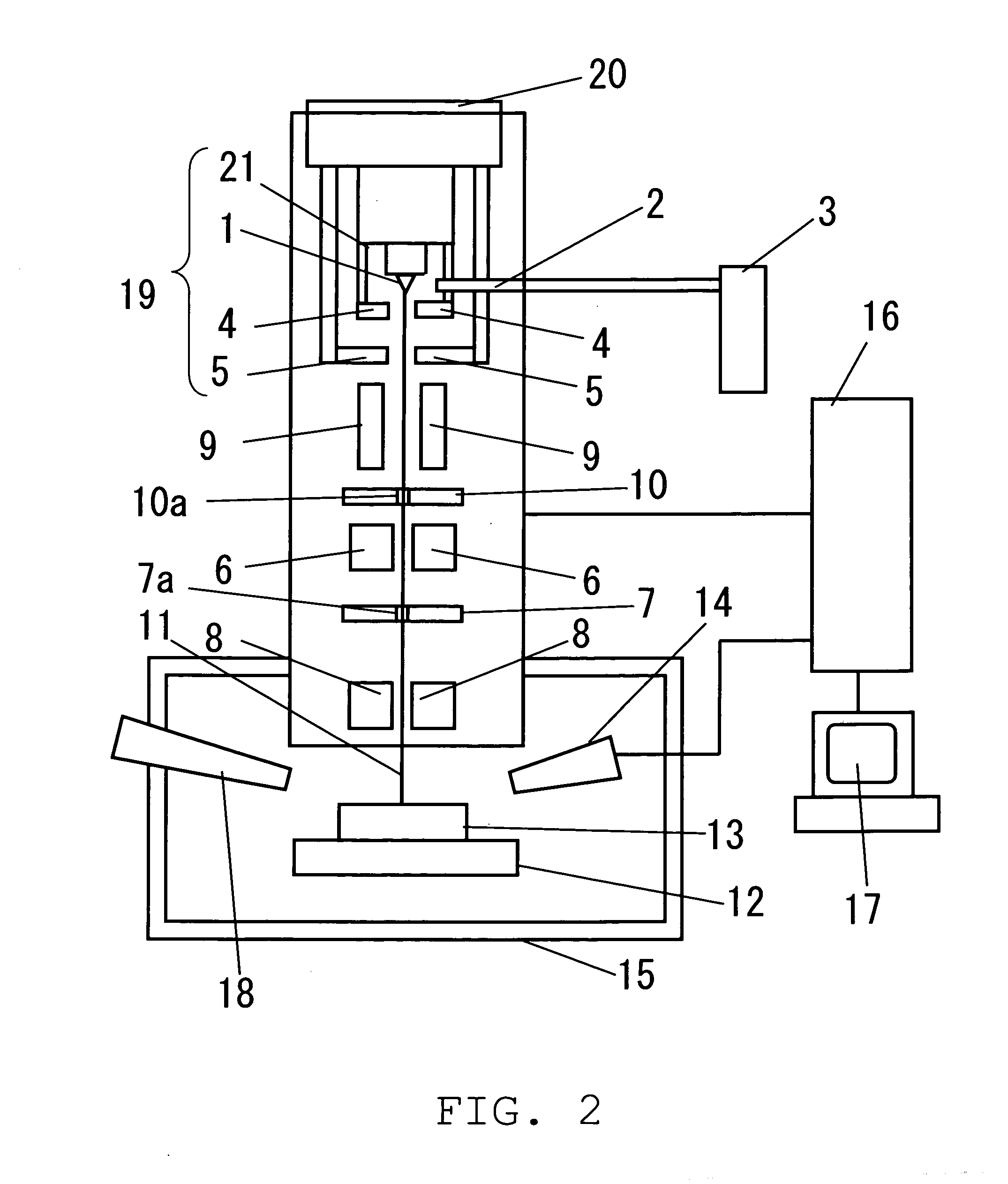

Electron beam-ion beam micro-nanometer process composite system

InactiveCN101301994AClear imagingStable structureNanostructure manufactureElectric discharge tubesImaging qualityScanning electron microscope

The invention discloses an electron beam-ion beam micro and nano machining combination system, wherein the electron beam and the ion beam can be operated simultaneously, and the electron in SEM can be integrated with the positively charged ion to effectively decrease influence on observation and analysis caused by charge accumulation on the surface of sample. The electron beam-ion beam micro and nano machining combination system of the invention comprises a flange, a scan electron microscope, a focused ion beam device, a computer which is a part of the scan electron microscope, wherein the flange is arranged on the bevel of a reaction chamber of the scan electron microscope, and the ion gun of the focused ion beam is arranged in the through hole of the flange. By adopting electron beam and ion beam symmetric device, the design scheme has advantages of stabilized, simple and aesthetic structure, convenient and accurate alignment, defined image and high stabilization of sample stage etc., being beneficial to improvement of the imaging quality of the electron beam.

Owner:BEIHANG UNIV

Liquid metal ion gun

InactiveUS7005651B2Increase distanceImprove performanceMaterial analysis by optical meansIon beam tubesLiquid metal ion sourceLiquid state

Owner:HITACHI HIGH-TECH CORP

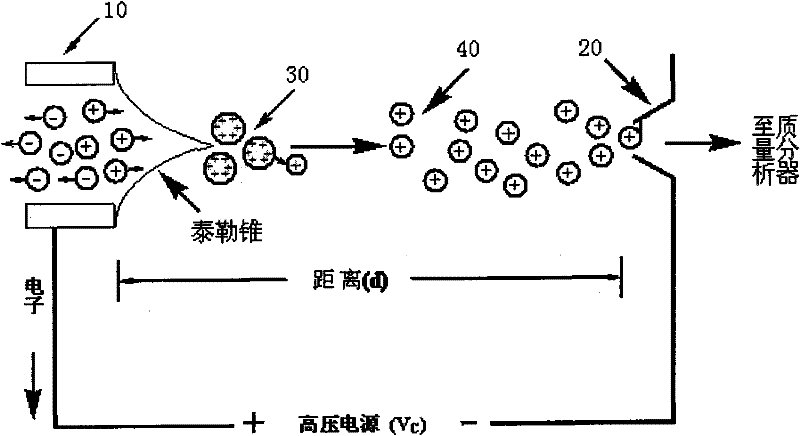

Ion source for time-of-flight mass spectrometers for analyzing gas samples

InactiveUS20030057378A1Easy to integrateCompact and more sensitiveTime-of-flight spectrometersTube electron sourcesTime-of-flight mass spectrometryElectron source

In accordance with the invention, the ion source of a time-of-flight mass spectrometer includes an electron gun having an electron source and at least one electrode for conditioning the flow of electrons, followed by at least one microchannel wafer for generating a pulsed secondary electron beam containing a greater number of electrons from a pulsed primary electron beam. The secondary electron beam enters a gas ionization area of an ion gun which produces a flow of ions which is then passed through the flight tube in order to be analyzed by an ion detector. This provides a high-performance ion source which is compact, sensitive and easy to integrate.

Owner:ALCATEL LUCENT SAS

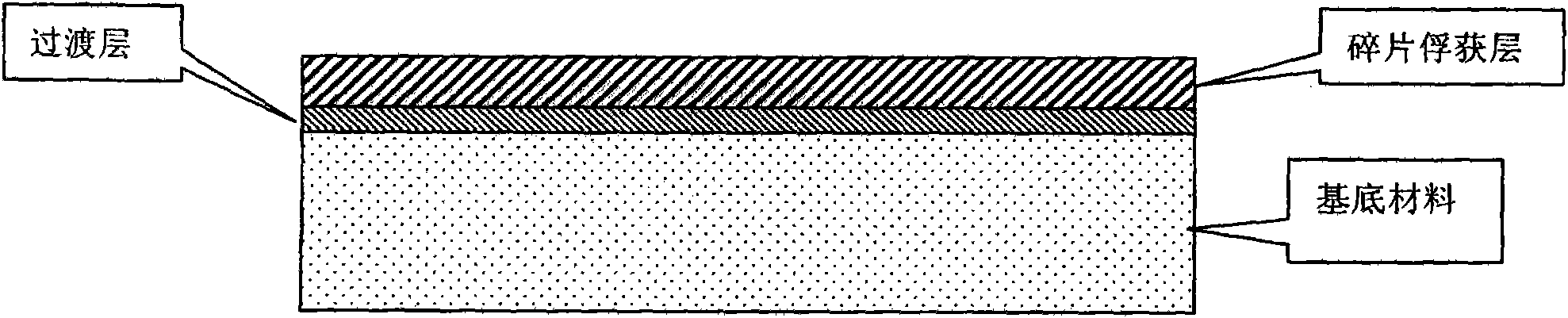

Method for detecting micro space debris

ActiveCN102042820AImplement detectionMaterial analysis by electric/magnetic meansMaterial analysis by measuring secondary emissionX-rayElectron

The invention relates to a method for detecting micro space debris and belongs to the technical field of micro space debris. A detection thin film comprises a debris capturing layer material, a transitional layer material and a base material from top down, wherein the micro space debris layer material is 1to 4 micrometer-thick Au; the base material is 1 to 3-millimeter-thick quartz glass, and the transitional layer material is 50 to 100 nanometer-thick Ir; the detection thin film is carried by the windward side or leeside of spacecraft, and after being exposed in space, the detection thin film is brought back to the ground; ground analysis is performed by secondary ion mass spectroscopic analysis or X-ray photoelectron spectroscopic analysis under ion gun analysis to obtain the correspondence between the data after the analysis of the detection thin film and the related data of the space debris; and thus, the chemical composition of the captured debris is obtained. In the invention, a low-weight power-free detection thin film is used to realize the detection of the space micro debris, and the space debris that can be captured and analyzed by the debris capturing layer is of mg order.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

Ion beam irradiation device and operating method thereof

ActiveUS20050040346A1Material analysis using wave/particle radiationElectric discharge tubesVacuum chamberSingle pass

An ion beam irradiation device includes a vacuum chamber and a stage on which at least two substrates may be mounted such that each substrate has an inclination angle to a horizontal plane of the vacuum chamber. The stage moves in one direction. An ion gun provided in the vacuum chamber produces ion beams that irradiate the substrates. In a single pass through the vacuum chamber, the alignment layers disposed on multiple substrates may be aligned. The substrates can be aligned such that the ion beam irradiates multiple substrates simultaneously and / or such that the ion beam irradiates the multiple substrates sequentially.

Owner:LG DISPLAY CO LTD

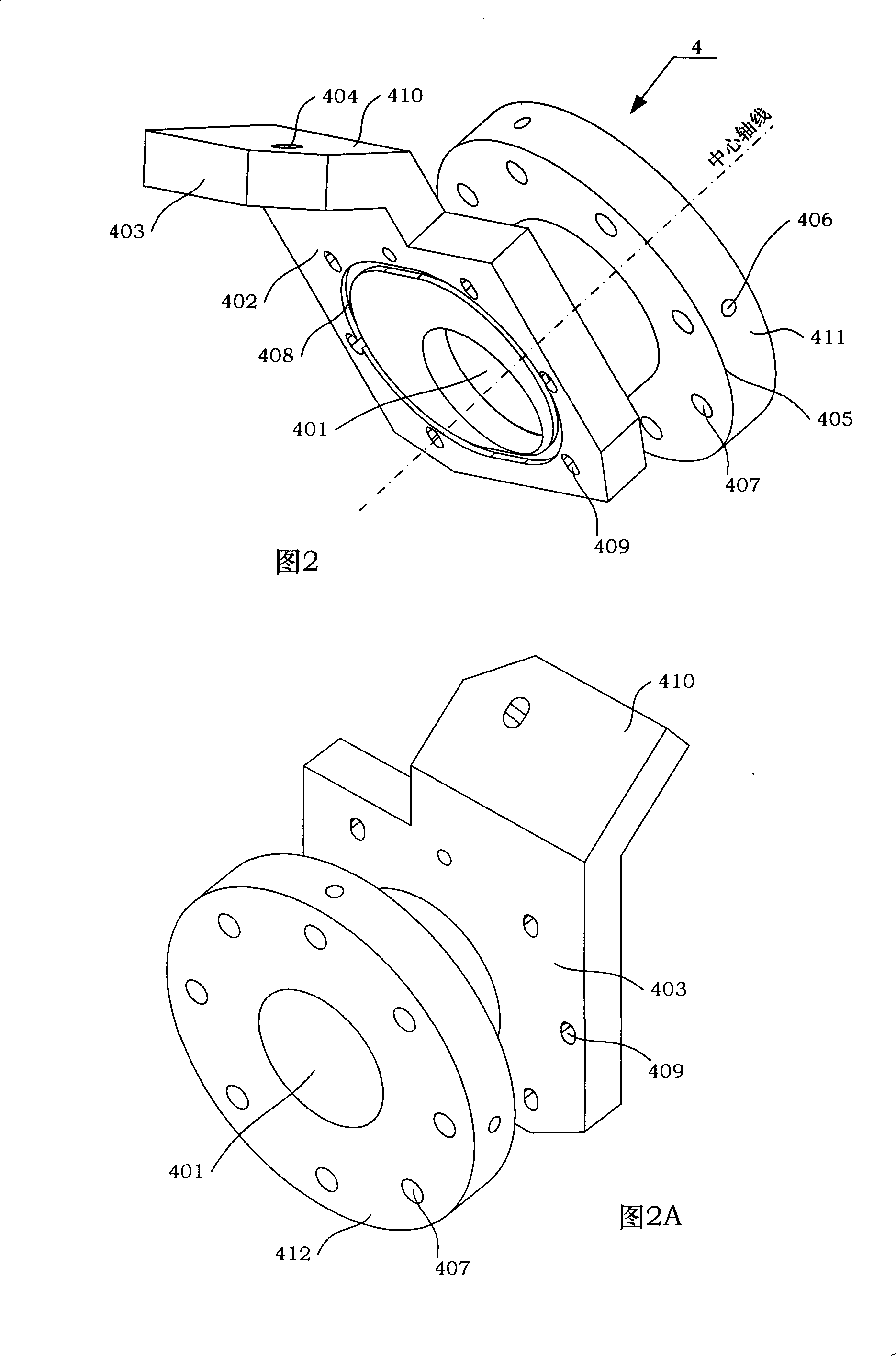

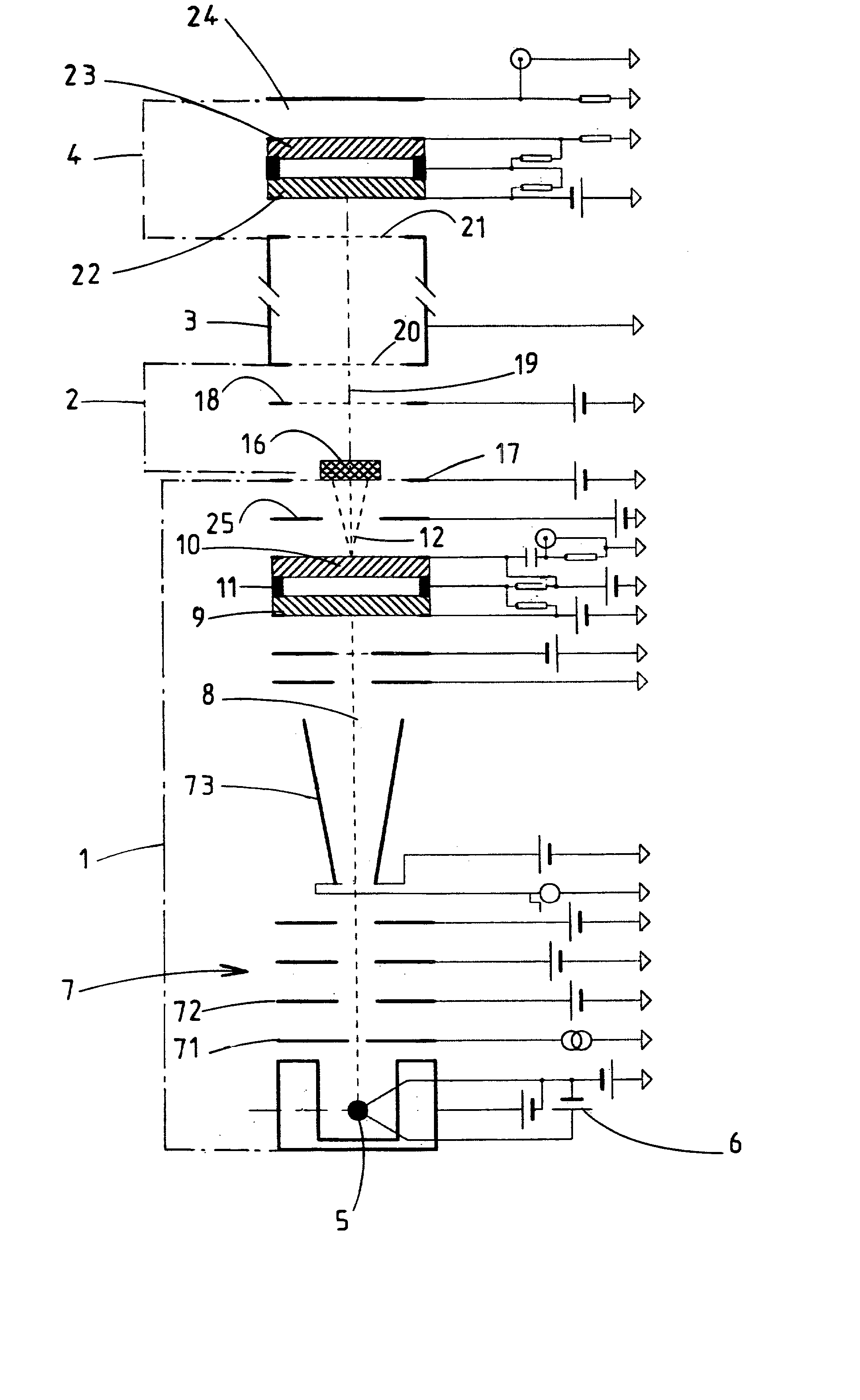

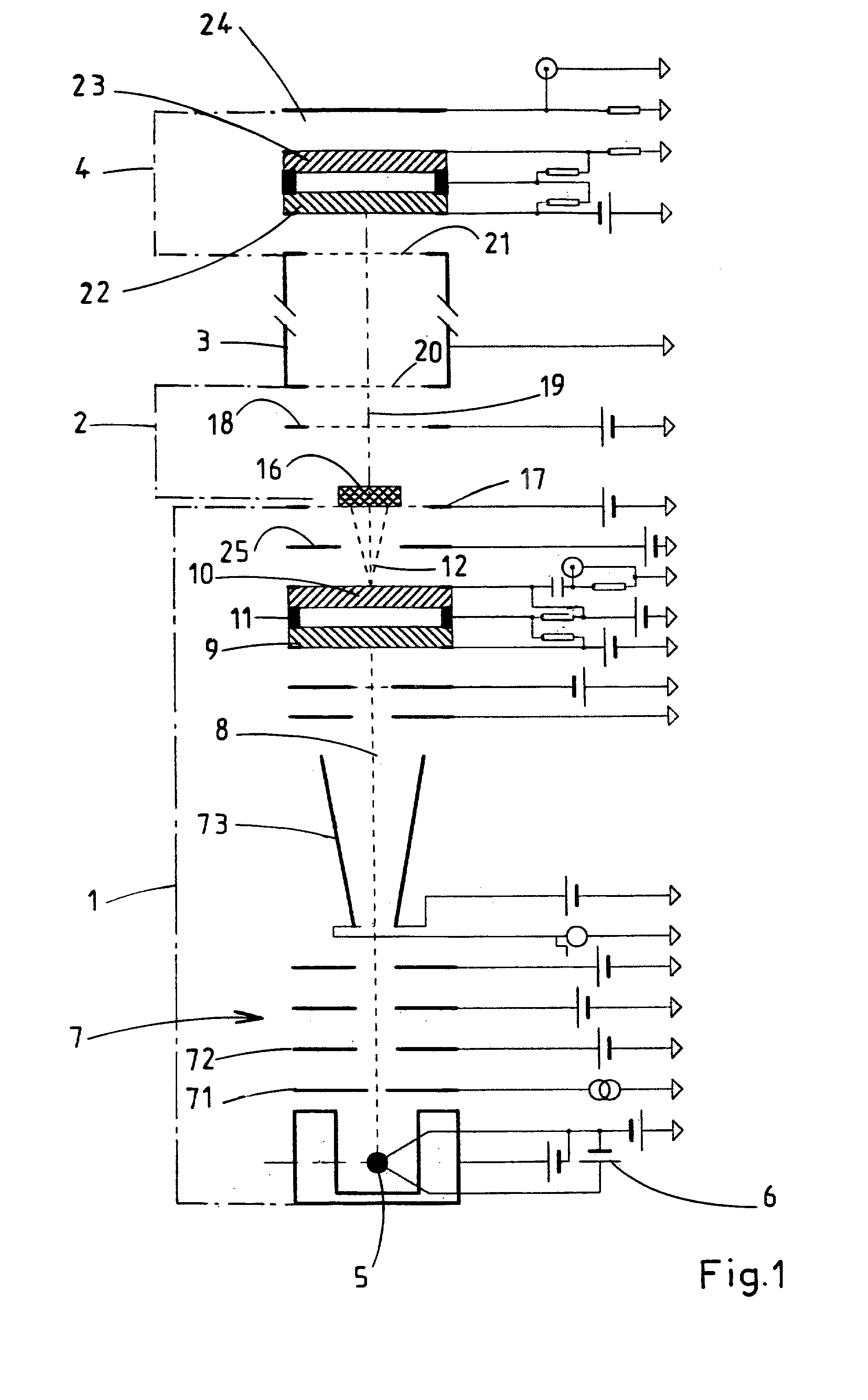

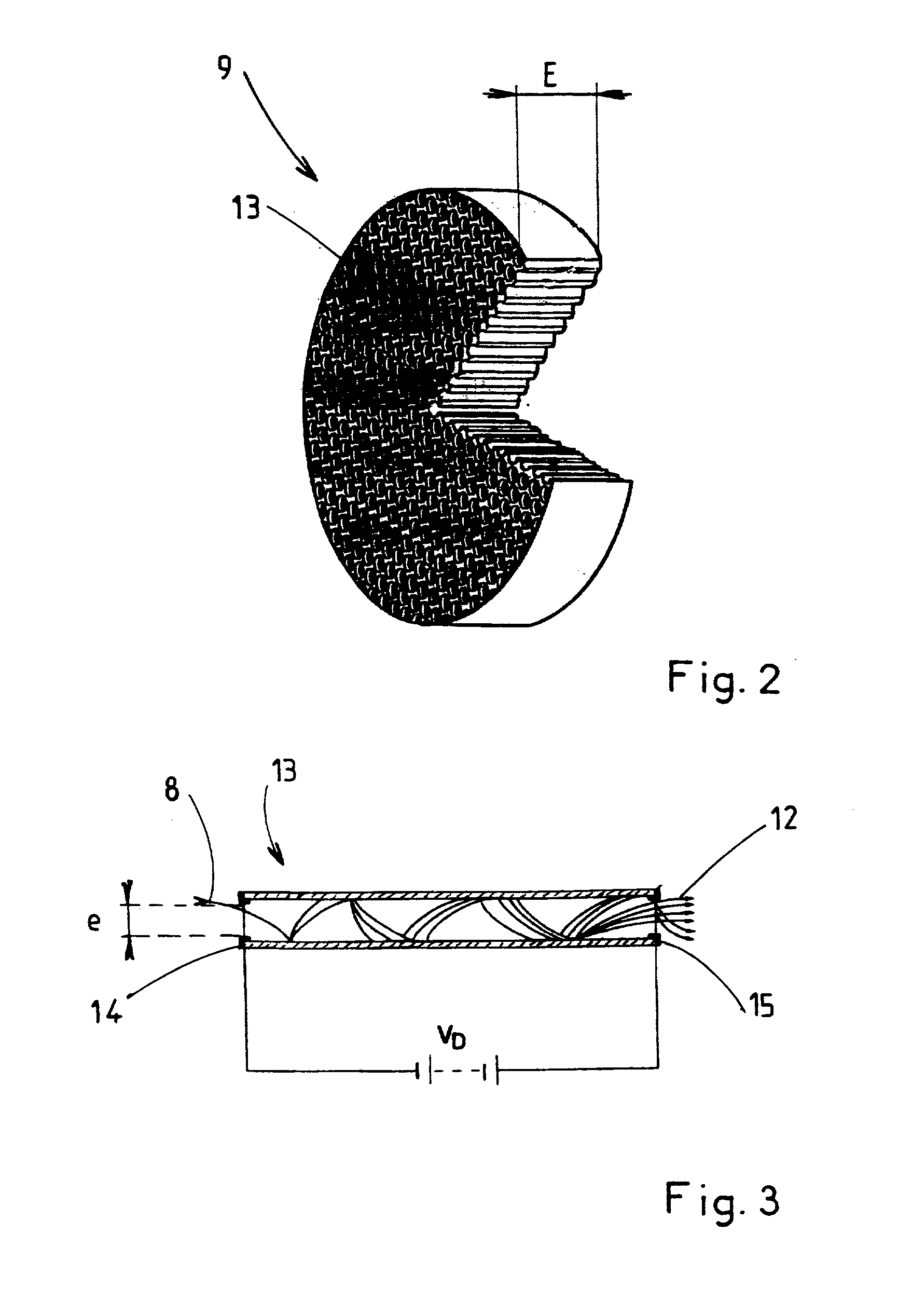

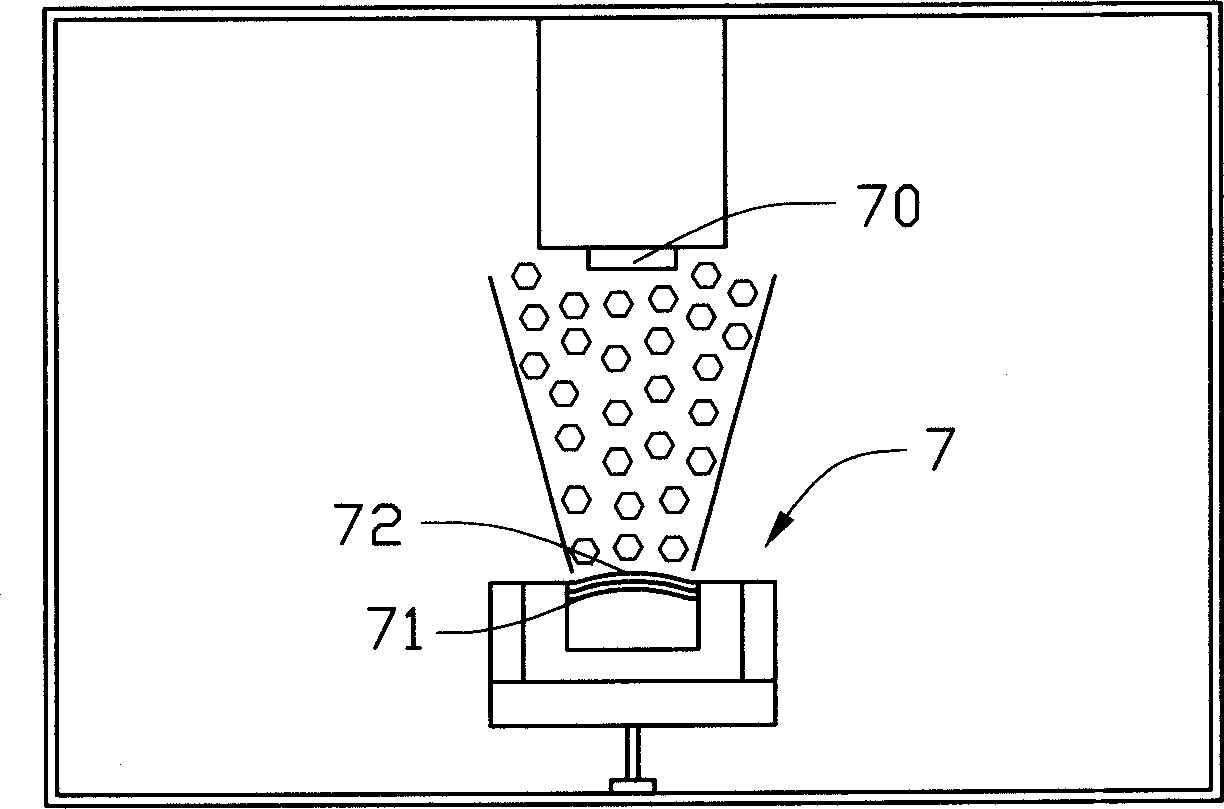

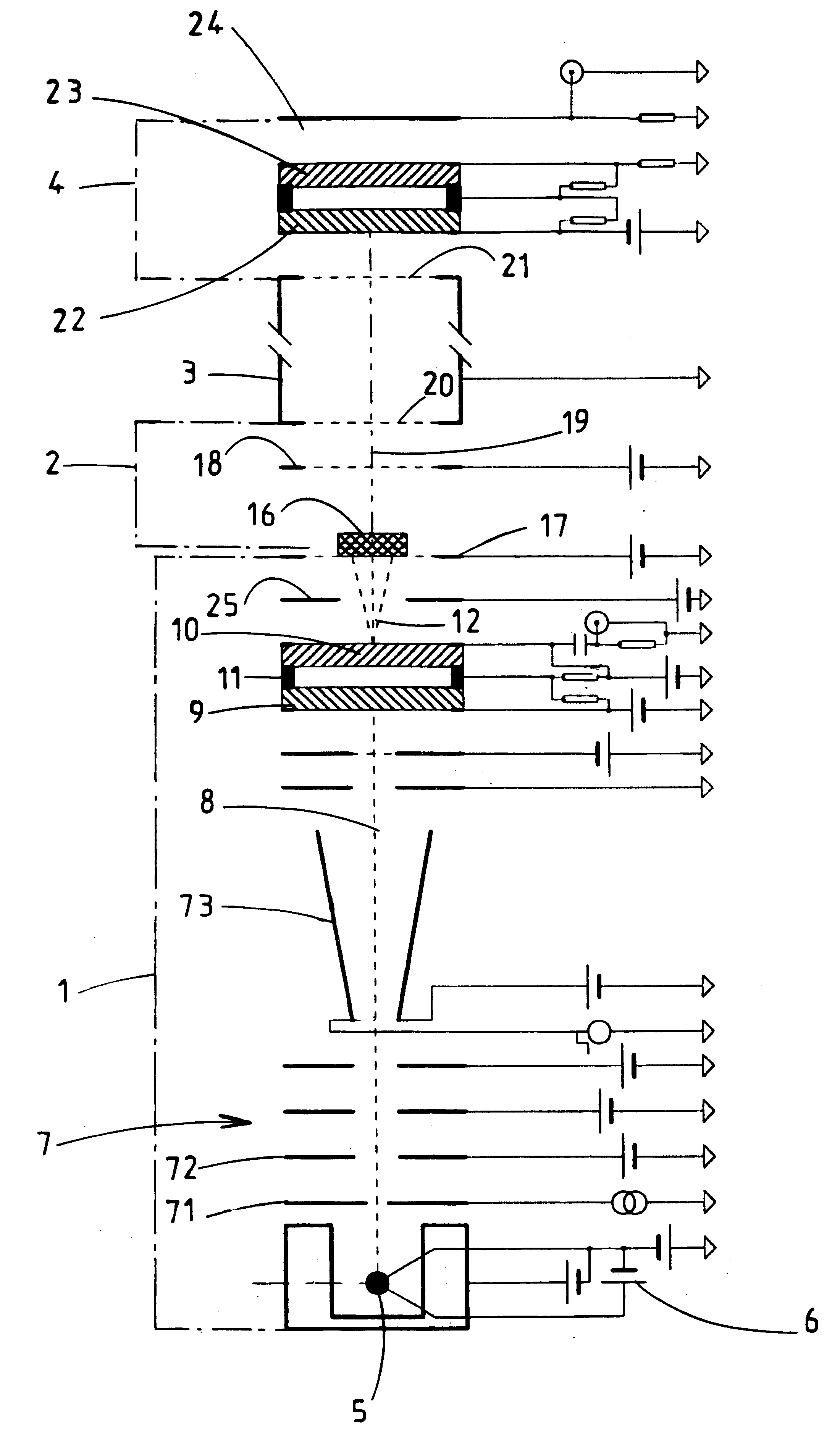

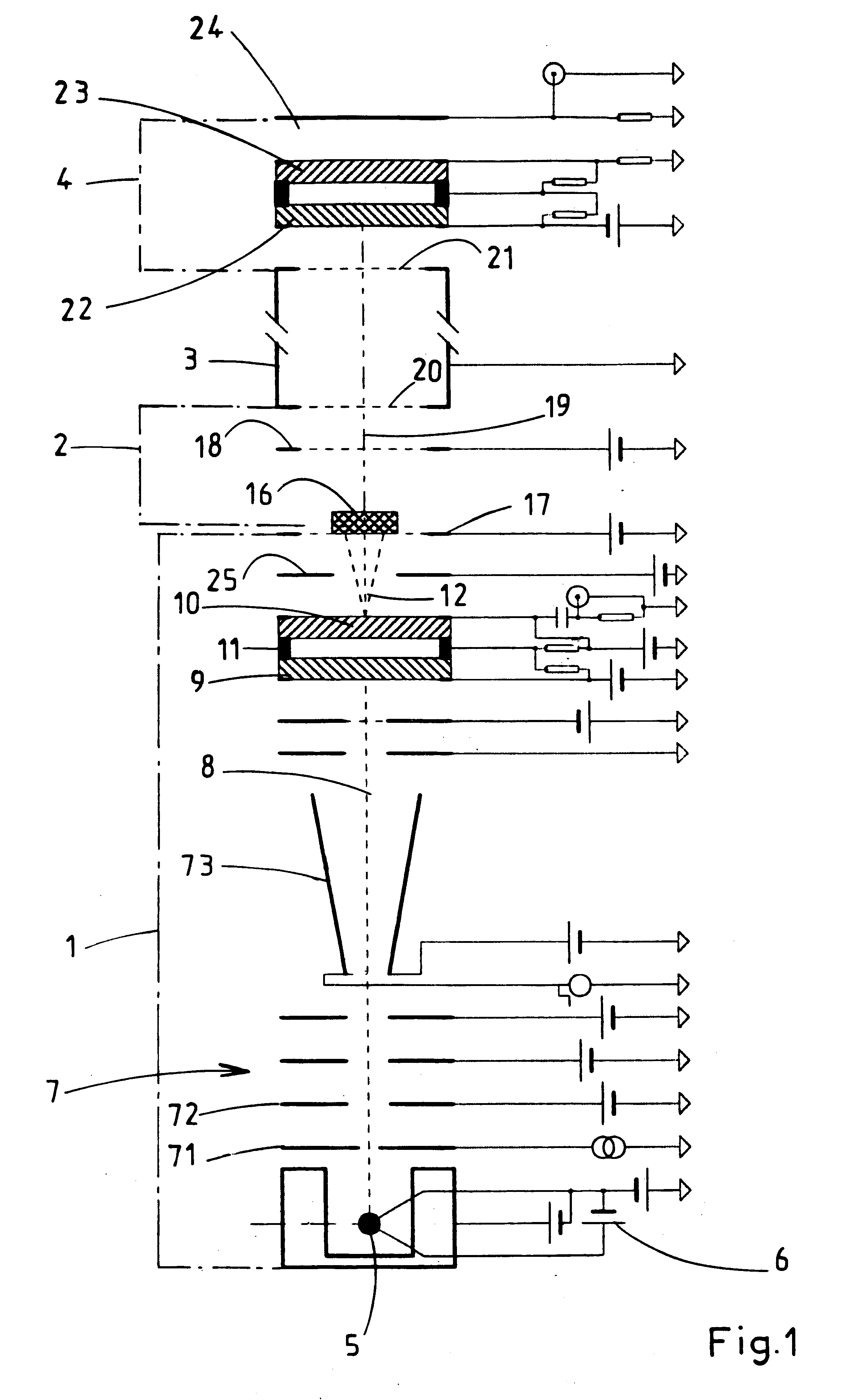

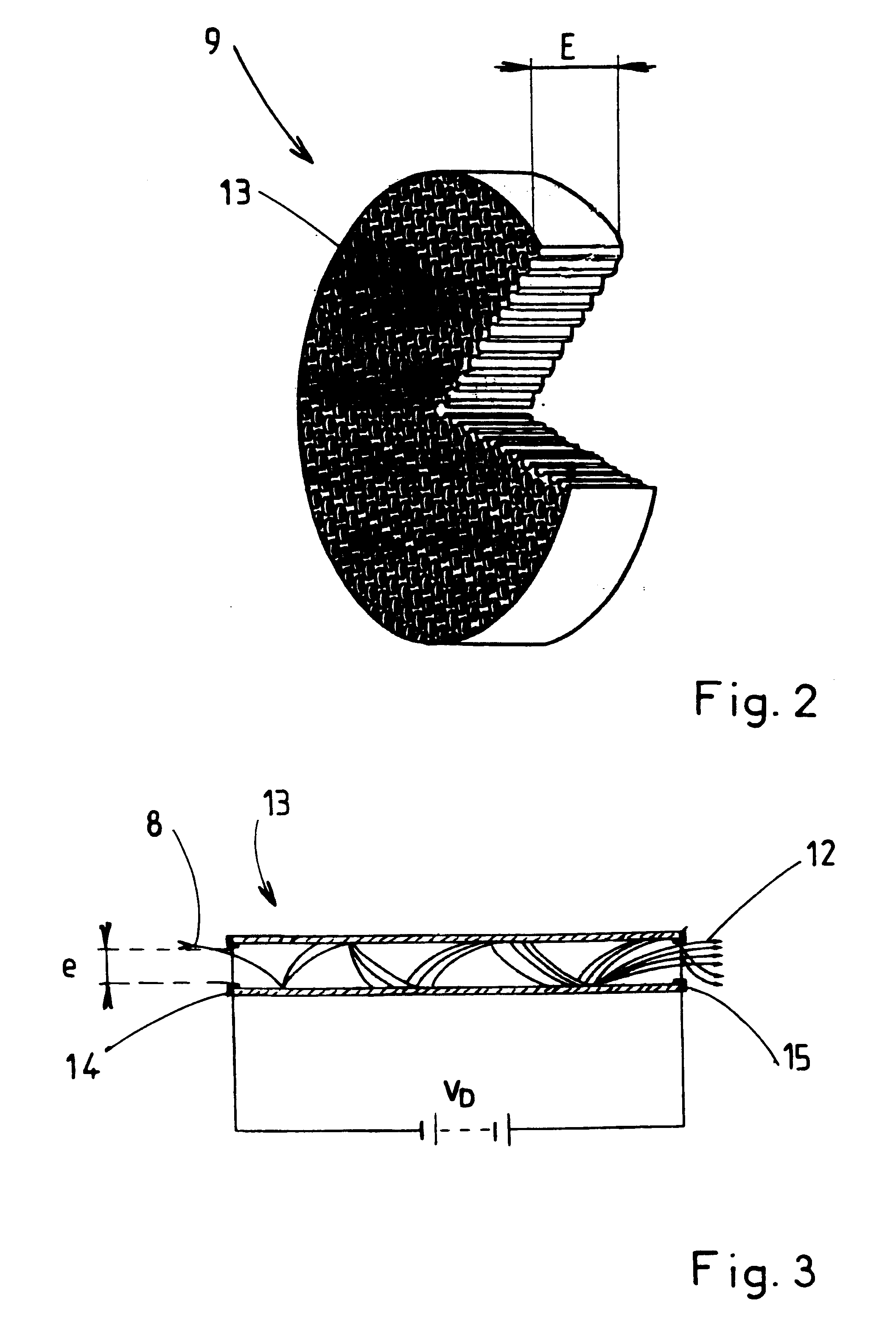

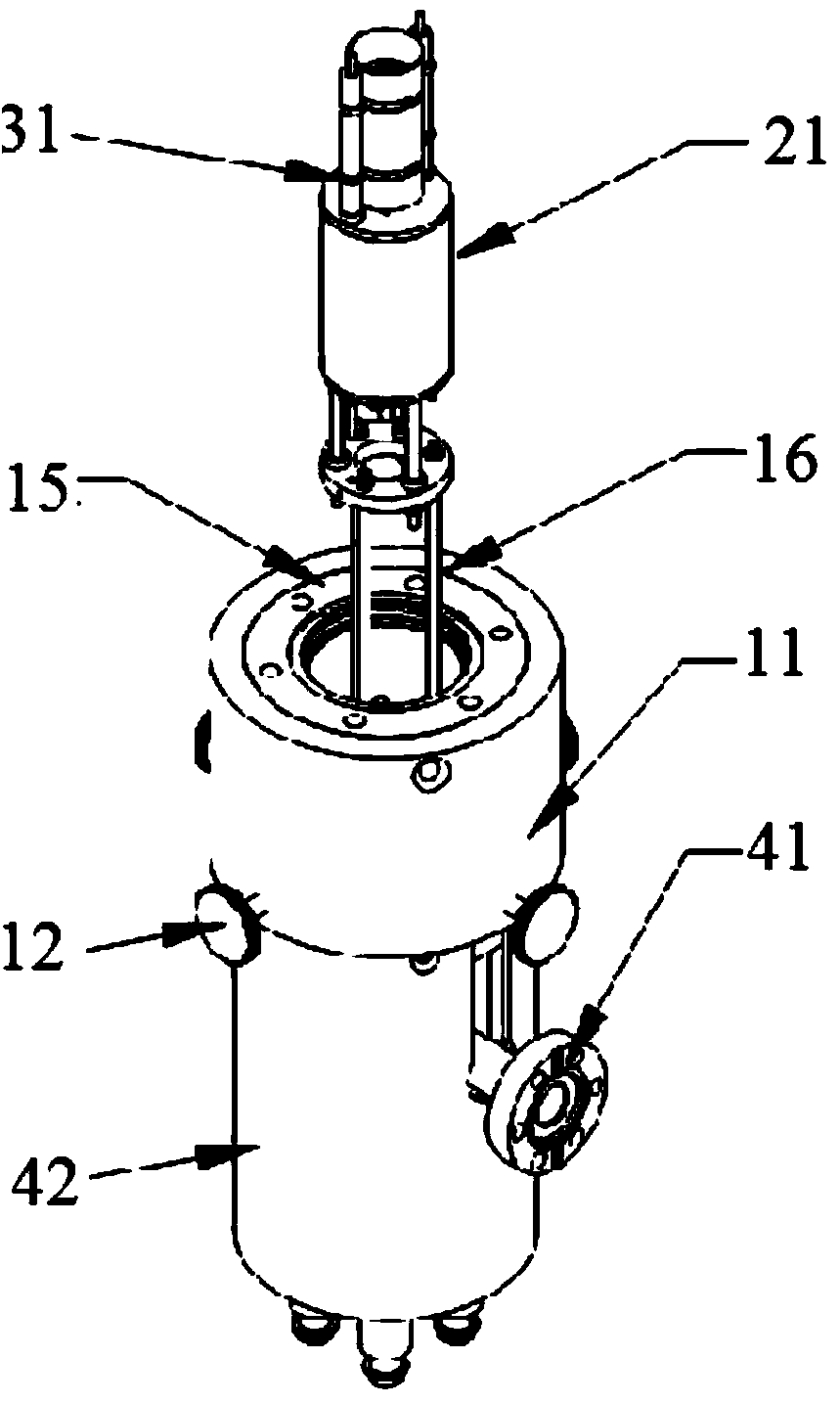

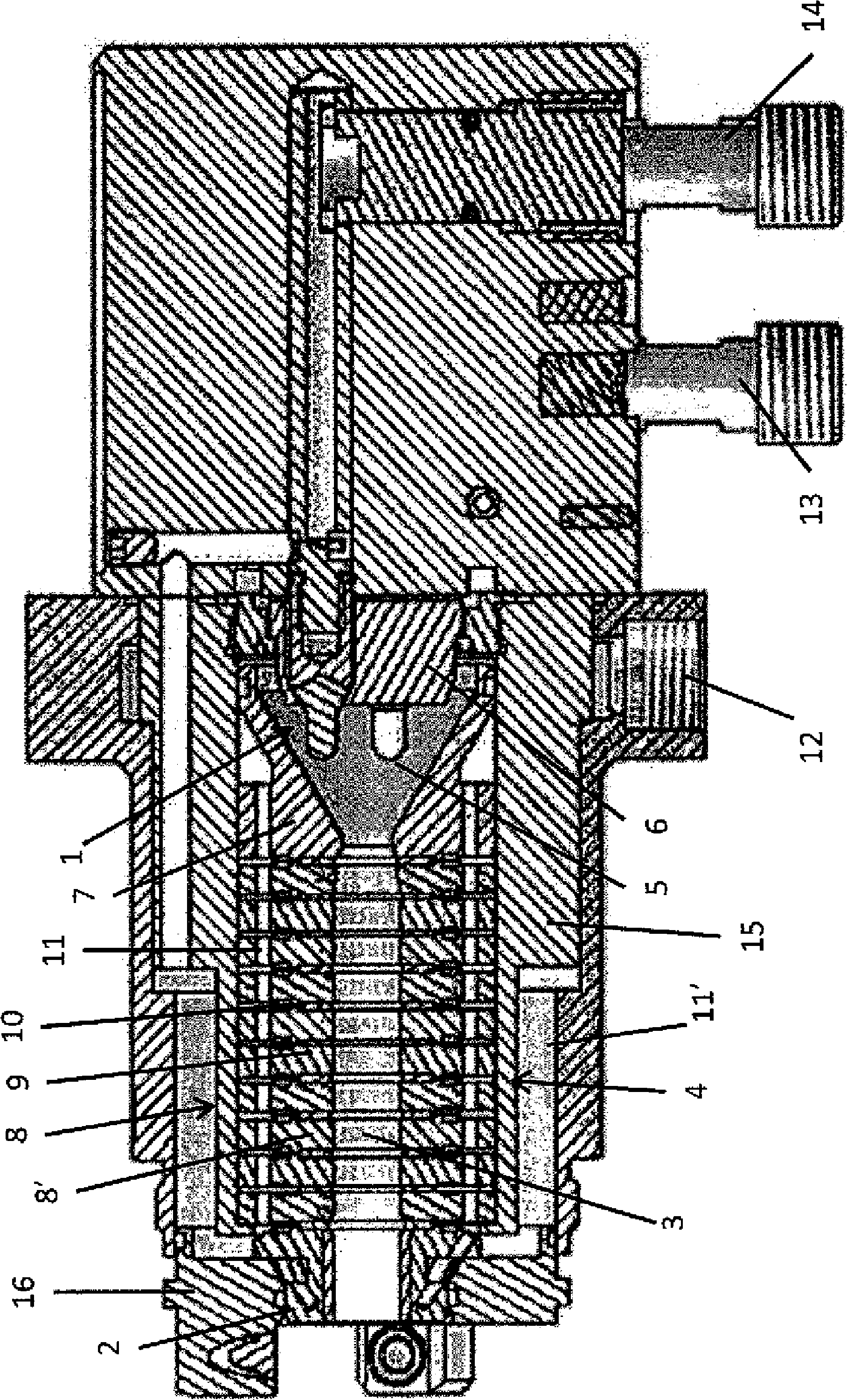

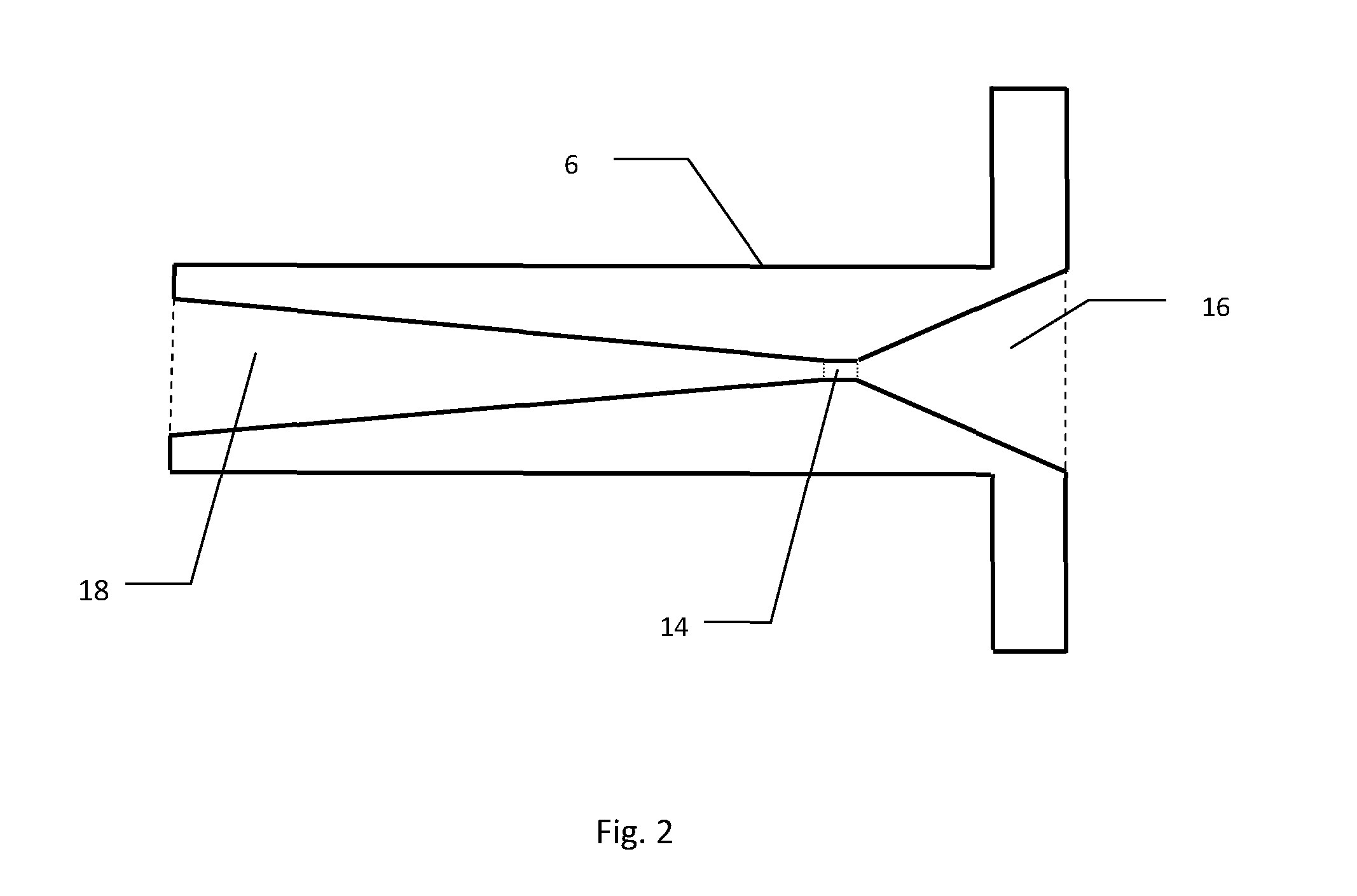

Improved ion gun

InactiveCN1725424AImprove qualityIncrease production capacityMachines/enginesIon beam tubesIon gunAcceleration Unit

This invention discloses a reformed ion gun including a discharge chamber, a gas source, an exciter, a grid component and a screen component, among which, the grid component includes a screen grid acceleration grid and a stop grid, the screen grid belongs to the anode and closes to the ionized ions, the acceleration grid belongs to the cathode and inter leaved with the screen grid, the stop grid belongs to the earth grid above the acceleration grid, the central zone of each grid has a curved surface, several aligned punches are set on these curved surfaces to form an extraction channel for ion beams, the curved grid surface is in a concave state and the angle of the ion beam led out from said grid components is in collection state so as to get qualified optical films.

Owner:ASIA OPTICAL CO INC

Ion source for time-of-flight mass spectrometers for analyzing gas samples

InactiveUS6545269B1Easy to integrateCompact and more sensitiveTime-of-flight spectrometersTube electron sourcesTime-of-flight mass spectrometryElectron source

Owner:ALCATEL LUCENT SAS

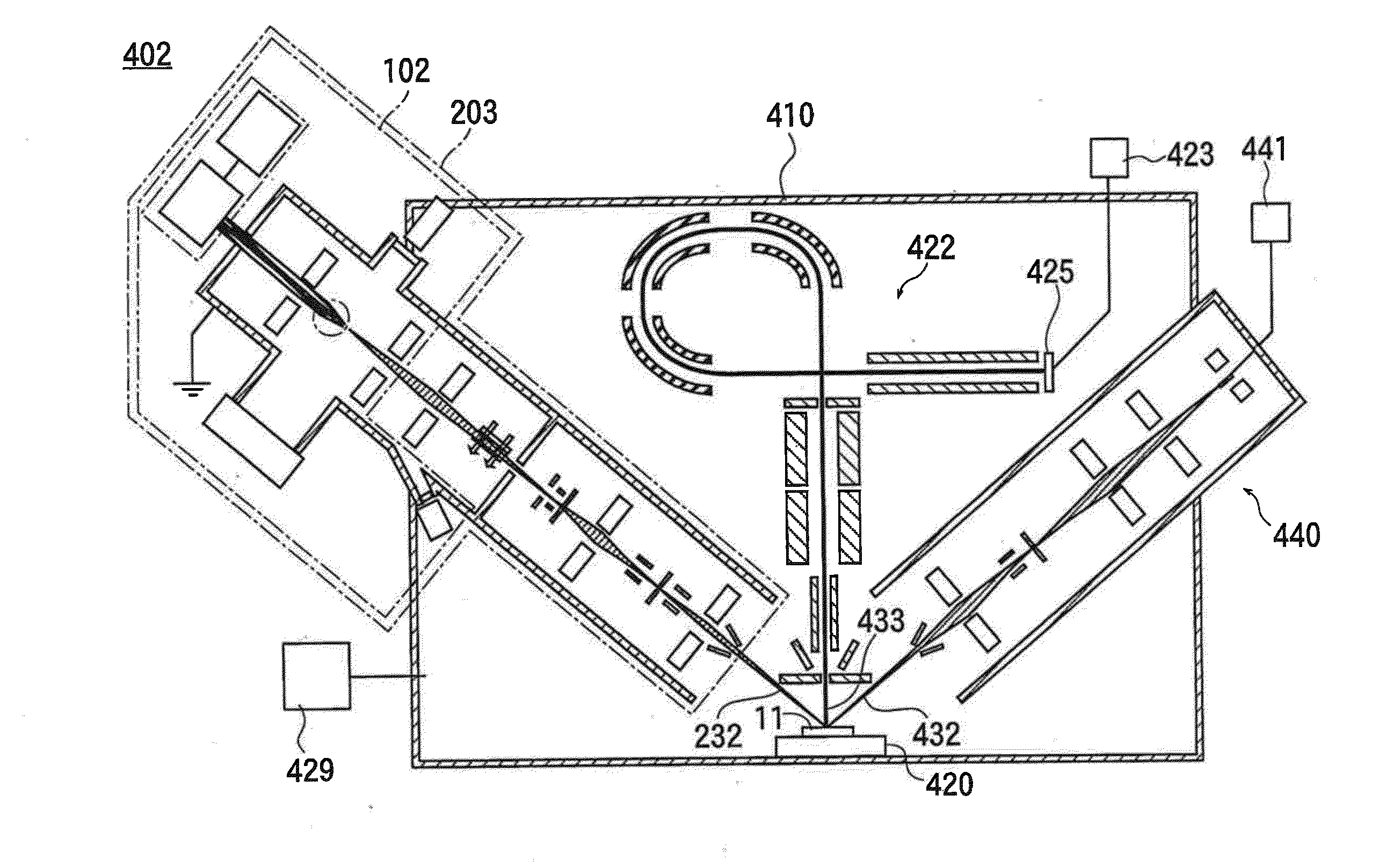

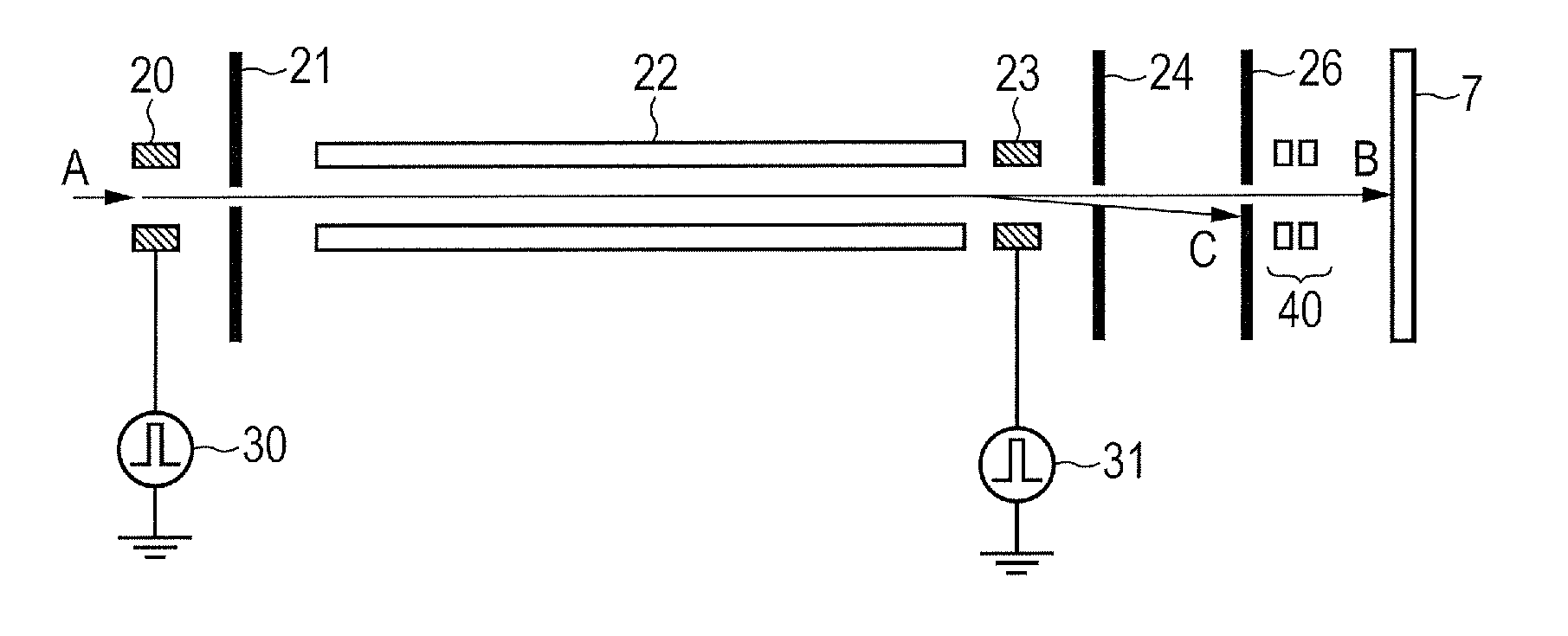

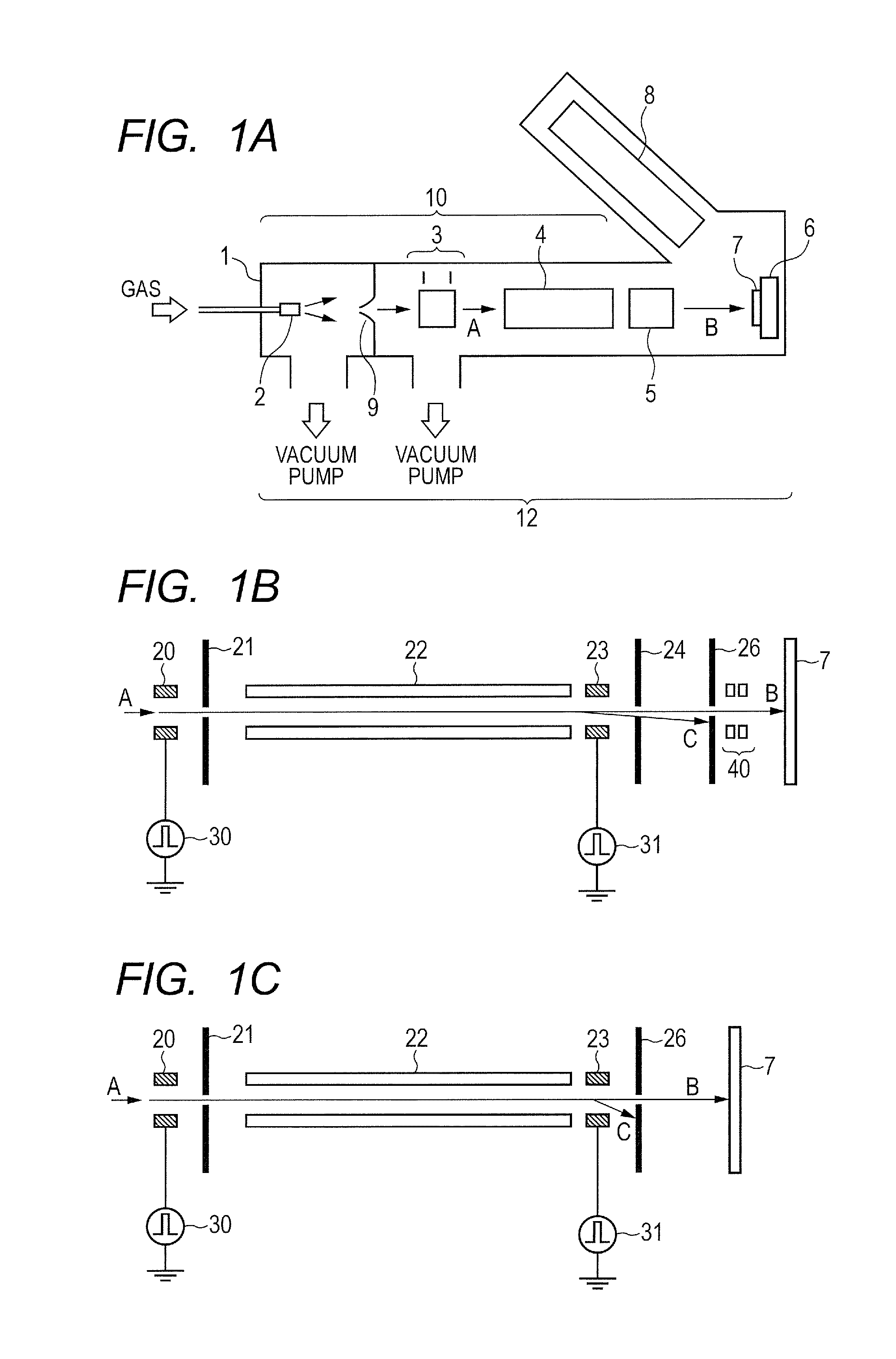

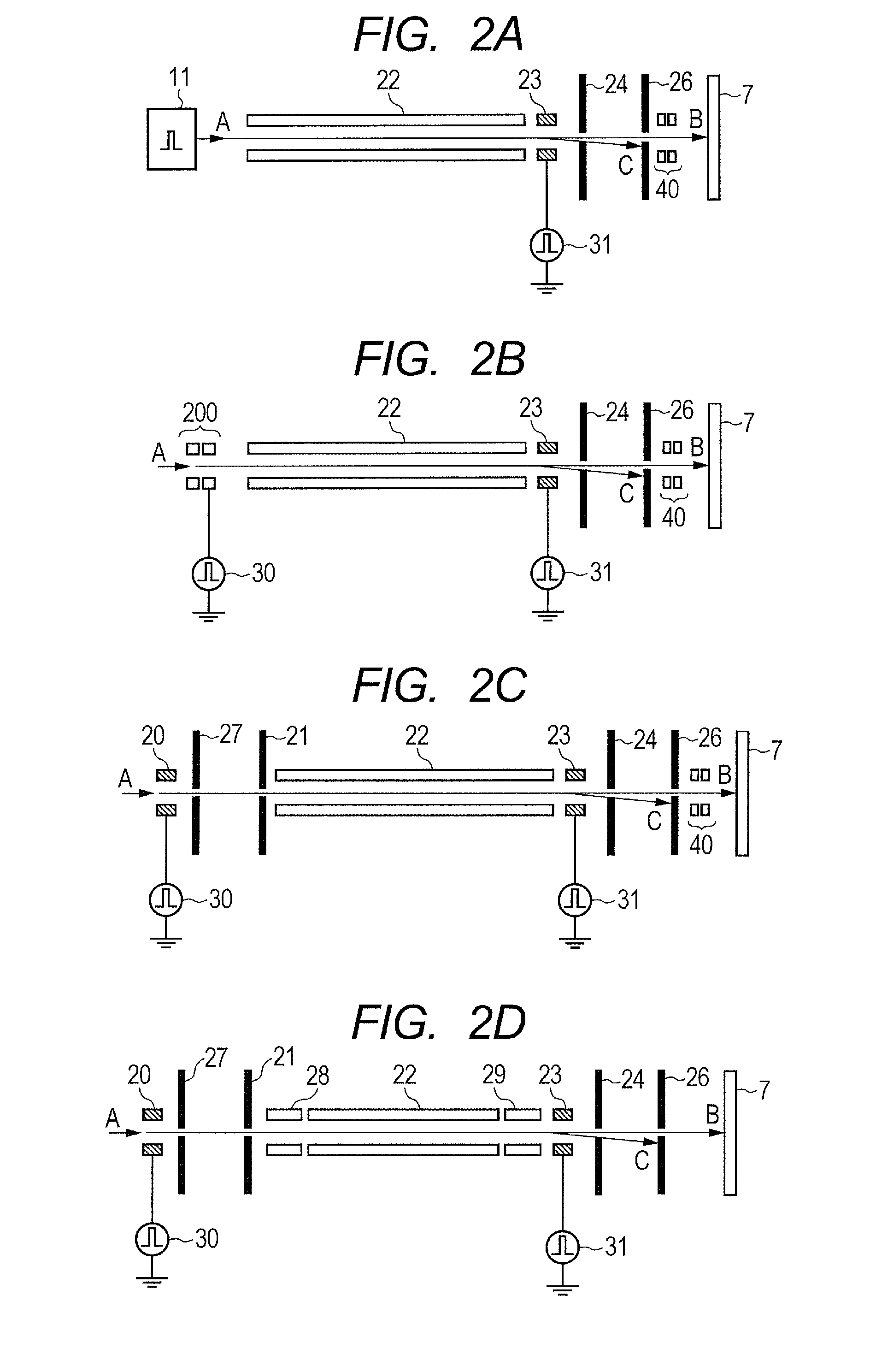

Mass selector, and ion gun, ion irradiation apparatus and mass microscope

InactiveUS20140252225A1Stability-of-path spectrometersMaterial analysis using wave/particle radiationIrradiationTime of flight

When a time-of-flight mass selector having a chopper using a deflector selects the masses of the ions, an ion beam is deflected. As a result, at least a part of the ion beams diagonally pass through an aperture electrode with respect to the axis. Accordingly, there has been a problem that a position on an object irradiated with a cluster ion beam, results in moving. This mass selector includes: a flight tube having an equipotential space that makes a charged substance fly therein; a deflector that is installed in a downstream side with respect to the flight tube in a direction in which the charged substance flies; a first aperture electrode that is installed in a downstream side with respect to the deflector in a direction in which the charged substance flies; and a second aperture electrode that is installed in between the deflector and the first aperture electrode.

Owner:CANON KK

Focused ion beam apparatus

InactiveUS20110215256A1Increase resistanceUnnecessary componentStability-of-path spectrometersBeam/ray focussing/reflecting arrangementsIrradiationGas supply

A focused ion beam apparatus includes an ion gun unit having an emitter tip, a gas supply unit including an ion source gas nozzle configured to supply gas to the tip and an ion source gas supply source. An extracting electrode ionizes the gas adsorbed onto the surface of the tip and extracts ions by applying a voltage between the extracting electrode and the tip. A cathode electrode accelerates the ions toward a sample, and a gun alignment electrode positioned on the side of the sample with respect to the ion gun unit and adjusts the direction of irradiation of the ion beam ejected from the ion gun unit. A lens system includes a focusing lens electrode and an objective lens electrode to focus the ion beam onto the sample.

Owner:SII NANOTECHNOLOGY INC

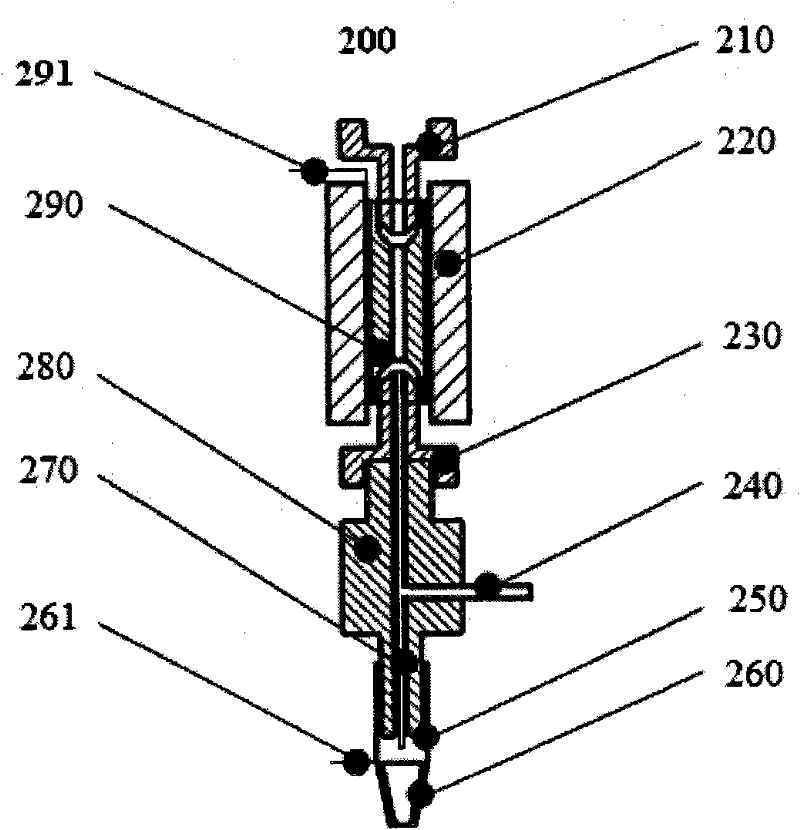

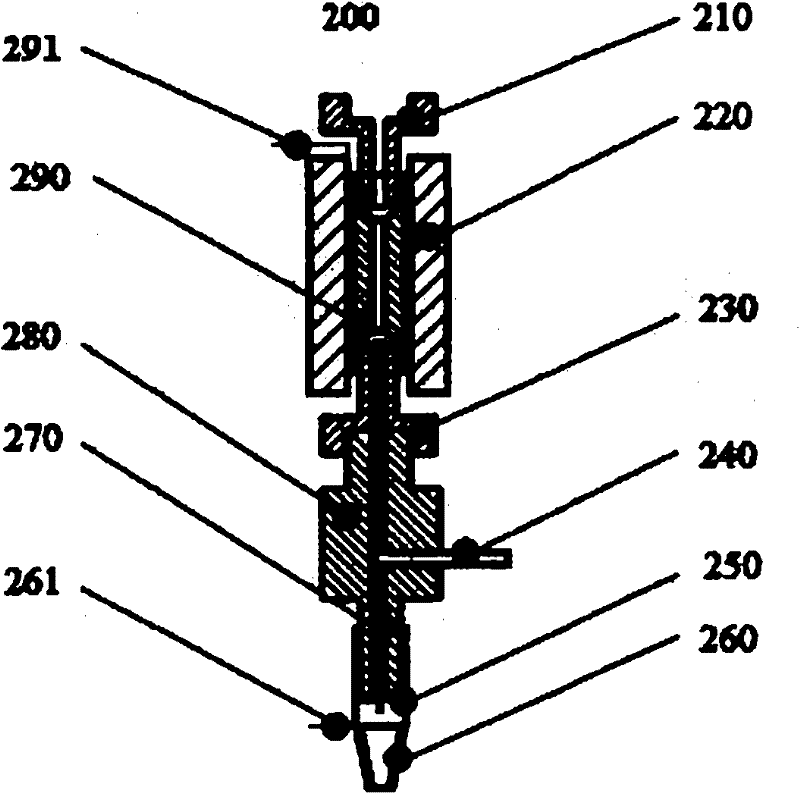

Ion gun used under atmospheric pressure

ActiveCN102243980AImproved mass determination accuracyHigh sensitivityStability-of-path spectrometersIon sources/gunsEngineeringAtmospheric pressure

The invention discloses an ion gun used under an atmospheric pressure. The ion gun comprises a liquid introduction joint, a conductive liquid guide piece, a connecting joint, a connecting piece, a transparent tube, a spraying capillary tube, an auxiliary gas introduction tube and a metal electrode, wherein the liquid introduction joint, the conductive liquid guide piece, the connecting joint, theconnecting piece and the transparent tube are connected in sequence and are used for transmitting the liquid introduced by the liquid introduction joint; the conductive liquid guide piece and the metal electrode are respectively used for being electrically connected with the electrode joint of an outer power supply; the spraying capillary tube passes through the connecting piece and the interior of the connecting joint and is connected with the conductive liquid guide piece; the auxiliary gas introduction tube penetrates into the cavity of the connecting piece so as to provide auxiliary gas; and the metal electrode is connected with the transparent tube and the port of the metal electrode is used as the gunpoint of the ion gun.

Owner:INST OF CHEM CHINESE ACAD OF SCI

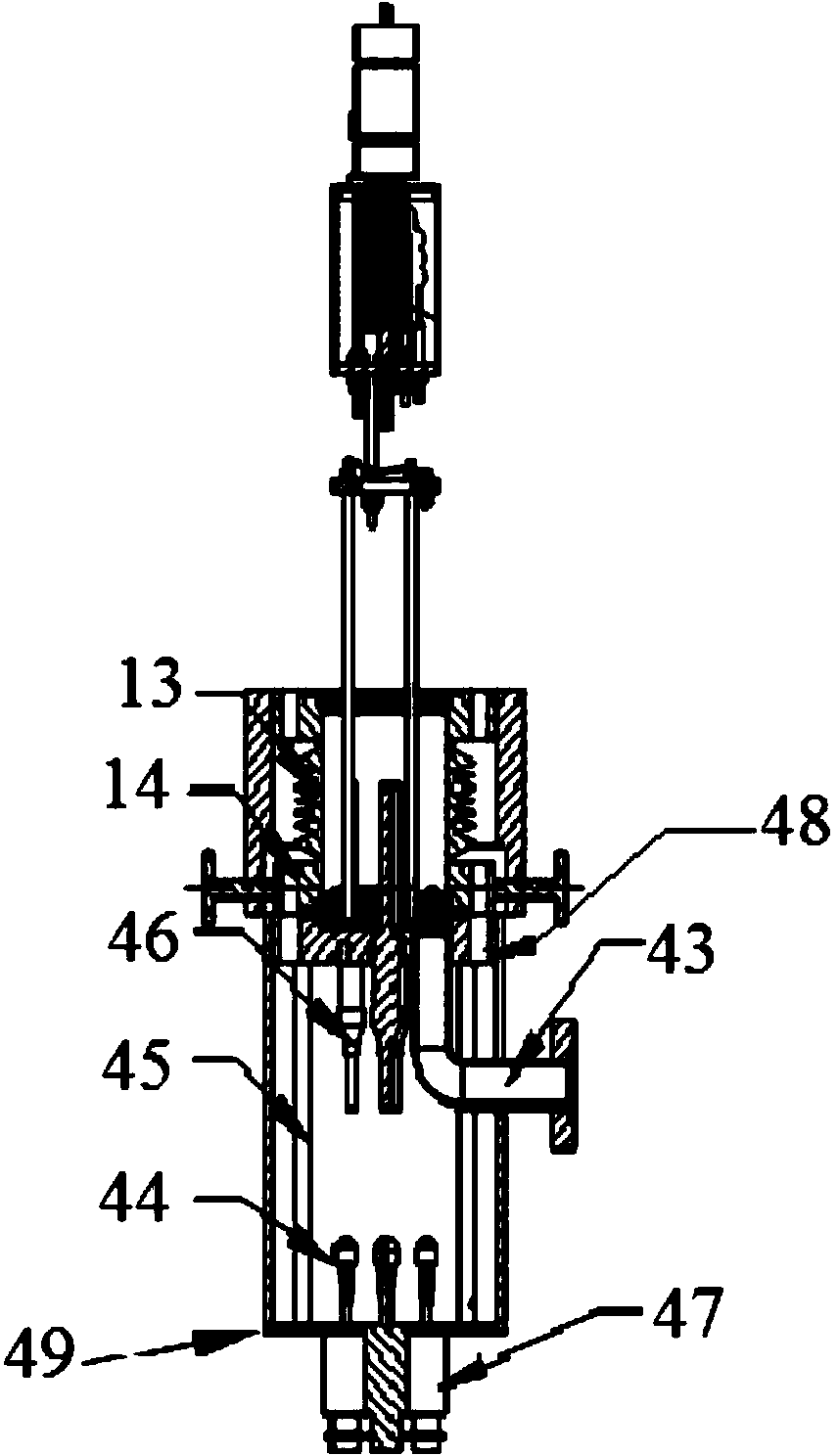

Sputtering ion gun

InactiveCN103474318ASimple structureEasy to useElectric discharge tubesSurface cleaningTherapeutic effect

The invention discloses a sputtering ion gun which is provided with an airflow direction regulating device, an argon ion generating device and a focusing lens, wherein the argon ion generating device is internally provided with an on-load voltage adjustable electronic accelerating grid mesh and a lamp filament correlated with a reference point position of the electronic accelerating grid mesh; one side wall of the electronic accelerating grid mesh is provided with a circular tube of a metal mesh; the electronic accelerating grid mesh is provided with a grid mesh anode at the front end and a grid mesh cathode at the rear end; the motion speeds of argon ions along the axial direction of the grid mesh are controlled through regulating a voltage loaded on the electronic accelerating grid mesh, thus the ion generating efficiency is regulated. The sputtering ion gun can be used alone during surface etching or deep analysis, and can be used for obtaining an improved surface treatment effect and ensuring that a surface treatment process is controllable. The ion sputtering and vacuum annealing can be adopted for performing repeated circular treatment during sample surface cleaning treatment or surface reconstruction. The material of the whole set of ion gun completely meets the requirement for use in an ultrahigh-vacuum environment, and can resist to baking at high temperature of over 200 DEG C.

Owner:DALIAN JIAOTONG UNIVERSITY

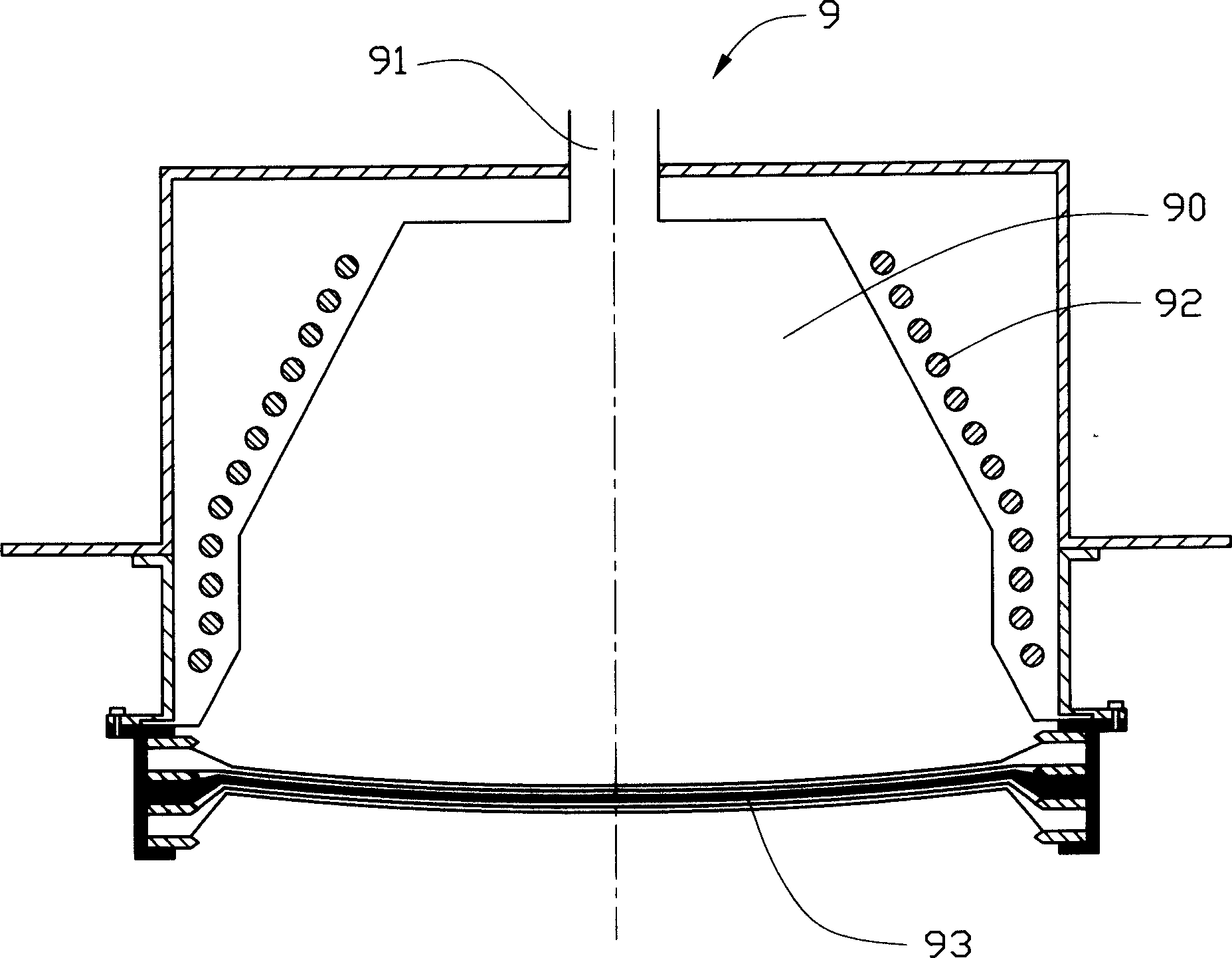

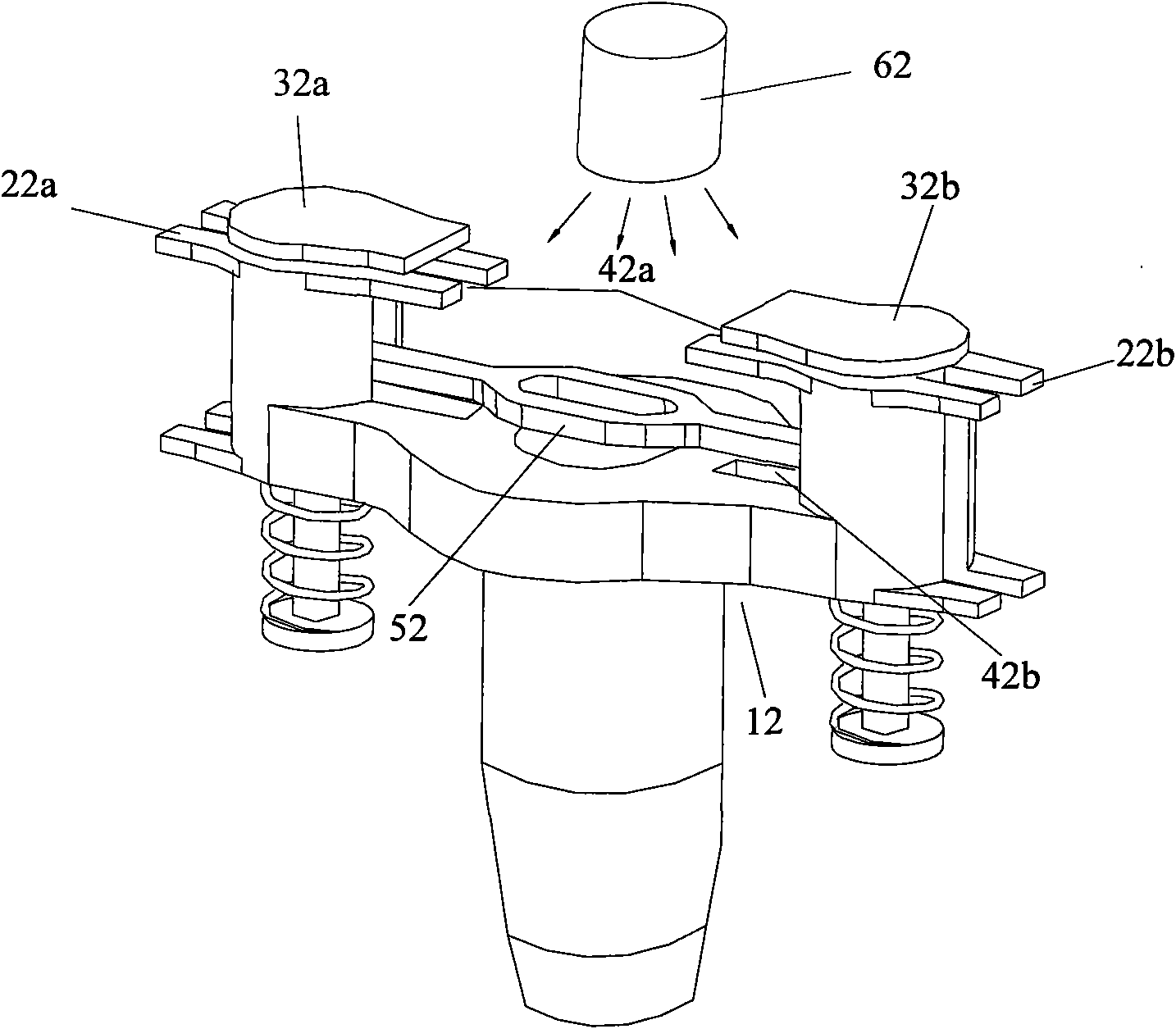

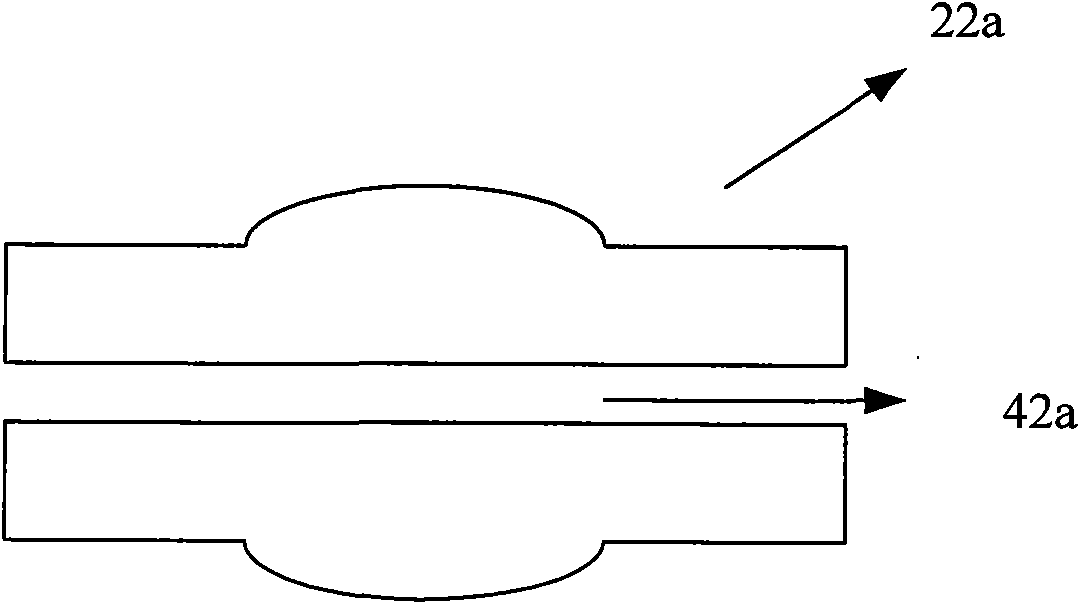

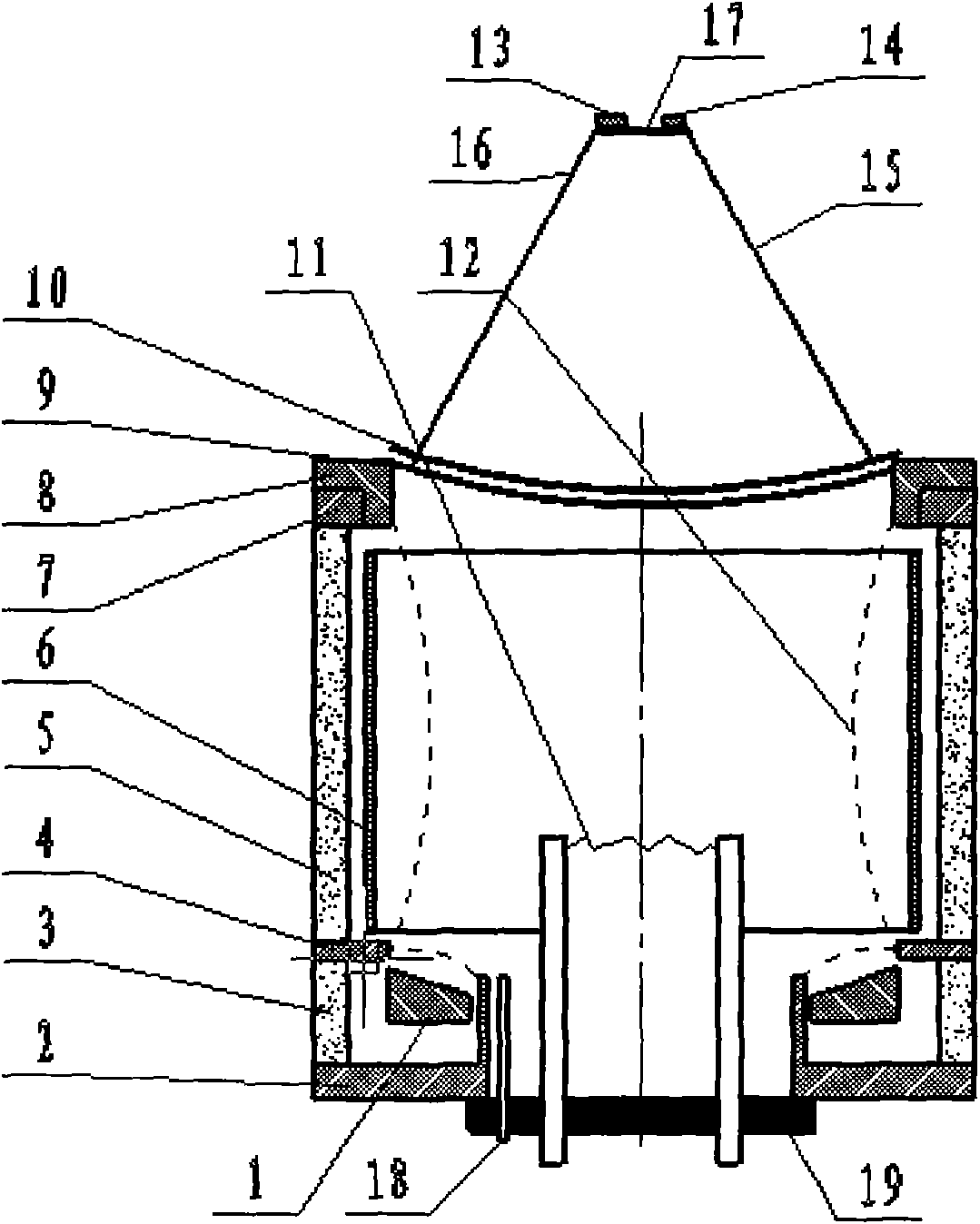

Precision ion polishing system and sample clamp thereof

InactiveCN101876605AAvoid breakingIncrease productivityPreparing sample for investigationMaterial analysis by transmitting radiationIn planeFixed position

The invention provides a precision ion polishing system and a sample clamp thereof. The precision ion polishing system comprises one or more clamping pieces which can move in planes of the clamping pieces so as to adjust the fixed positions of samples relative to ion beams of the precision ion polishing system. The invention also provides the precision ion polishing system, which comprises the sample clamps provided by the embodiment. The precision ion polishing system and the sample clamp thereof can adjust the positions of the TEM samples relative to ion guns of the precision ion polishing system so as to effectively avoid the condition that the samples are excessively polished even damaged while structures to be observed are still on the relatively thicker parts of damaged edges.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Method for preparing scanning electron microscope sample by ion beam bombing

InactiveCN101236143ANo damageSuitable for microscopic morphology analysisSurface/boundary effectPreparing sample for investigationElectricityCrystal structure

A preparing method of a scanning electron microscope sample bombarded by ion beams relates to the preparing of the scanning electron microscope sample. The method is as follows: argon gas is continuously charged in under the condition of microvac 2x10<-3>Pa, the argon gas is ionized through an ion gun under the action of a high voltage field to obtain ion beams bombarding the surface of the sample, and the sample simultaneously rotates in 360 DEG to ensure an even bombarding on the surface of the sample. The included angle between the surface of the sample and the ion beams is generally a range from 7 DEG to 12 DEG, the bombarding voltage of the ion gun is a range from 4 kilovolt to 7 kilovolt, and the ion beams fall into a range from 0.4 milliampere to 0.5 milliampere. The method which is free of the impact of the sample material electrical property and does not bring about stress and strain to the sample during the bombarding process of the ion beams and also has no damage on the self crystal structure of the material is suitable for microscopic shape and appearance analysis of metals and nonmetal materials.

Owner:UNIV OF SCI & TECH BEIJING

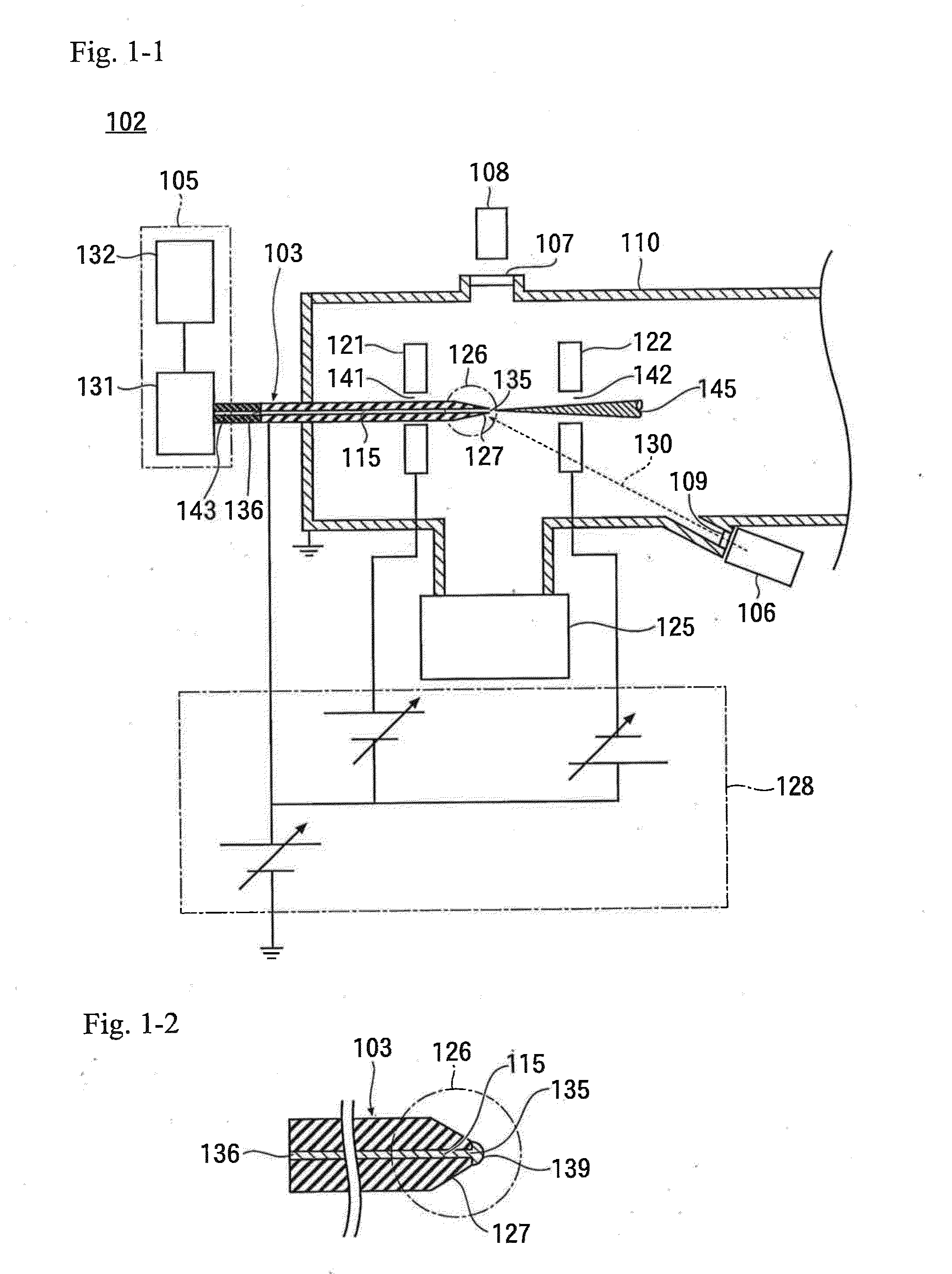

Focused ion beam apparatus

ActiveUS20110204252A1Reduce variationUnnecessary componentStability-of-path spectrometersBeam/ray focussing/reflecting arrangementsGas supplyCathode electrode

A focused ion beam apparatus includes an ion gun unit having an emitter tip, a gas supply unit that supplies gas to the tip, and an ion source gas supply source. An extracting electrode ionizes the gas adsorbed onto the surface of the tip and extracts ions by applying a voltage between the extracting electrode and the tip. A cathode electrode accelerates the ions toward a sample. An aperture member has an opening that passes therethrough a part of the ion beam ejected from the ion gun unit, and a lens system focuses the ion beam onto the sample.

Owner:HITACHI HIGH TECH SCI CORP

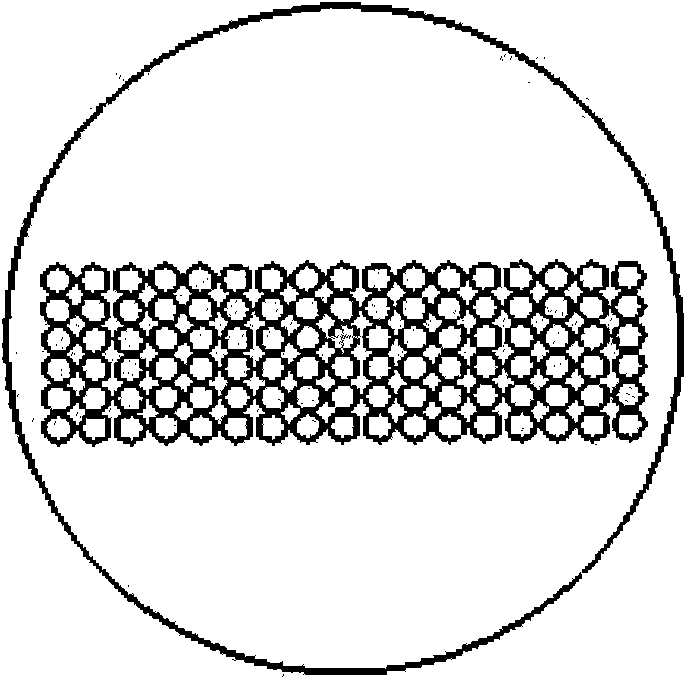

Rectangular etching ion gun

InactiveCN101908458ASolution to short lifeSmall beam currentAfter-treatment detailsElectric discharge tubesGas-filled tubeIon gun

The invention relates to a rectangular etching ion gun which comprises a first pole shoe, a second pole shoe, a third pole shoe, a fourth pole shoe, a first magnet, a second magnet, a fourth pole shoe, a rectangular annular upper anode, a rectangular annular lower anode, a rectangular conical surface, an arc plate-shaped screen grid, an arc plate-shaped accelerating grid, a base, a cathode lamp, a lamp filament and an inflating pipe, wherein the first pole shoe, the second pole shoe, the third pole shoe and the fourth pole shoe are coaxially arranged from bottom to top; the first magnet is positioned between the end surfaces of the first pole shoe and the second pole shoe; the second magnet is positioned between the end surfaces of the second pole shoe and the third pole shoe; the fourth pole shoe is positioned on the end surface of the third pole shoe; the rectangular annular upper anode is positioned in the second magnet; the rectangular annular lower anode is positioned between the first magnet and a rectangular pipe; the rectangular conical surface with high outside and low inside is arranged on the upper end surface of the rectangular annular lower anode; the arc plate-shaped screen grid is overlapped at the upper end surface of the fourth pole shoe; the arc plate-shaped accelerating grid is suspended on the screen grid; the base is arranged in the center of the lower surface of the first pole shoe and covers an inner hole of the rectangular pipe; the cathode lamp is fixed on the base and positioned in the rectangular pipe; the lamp filament is positioned in a rectangular ring of the rectangular annular upper anode; and the inflating pipe is positioned between the rectangular pipe and the cathode lamp after penetrating through the base and communicated with an argon source. The invention has the advantages of less etching gas dosage, small size, low power consumption, even ion beam, and the like.

Owner:马利民

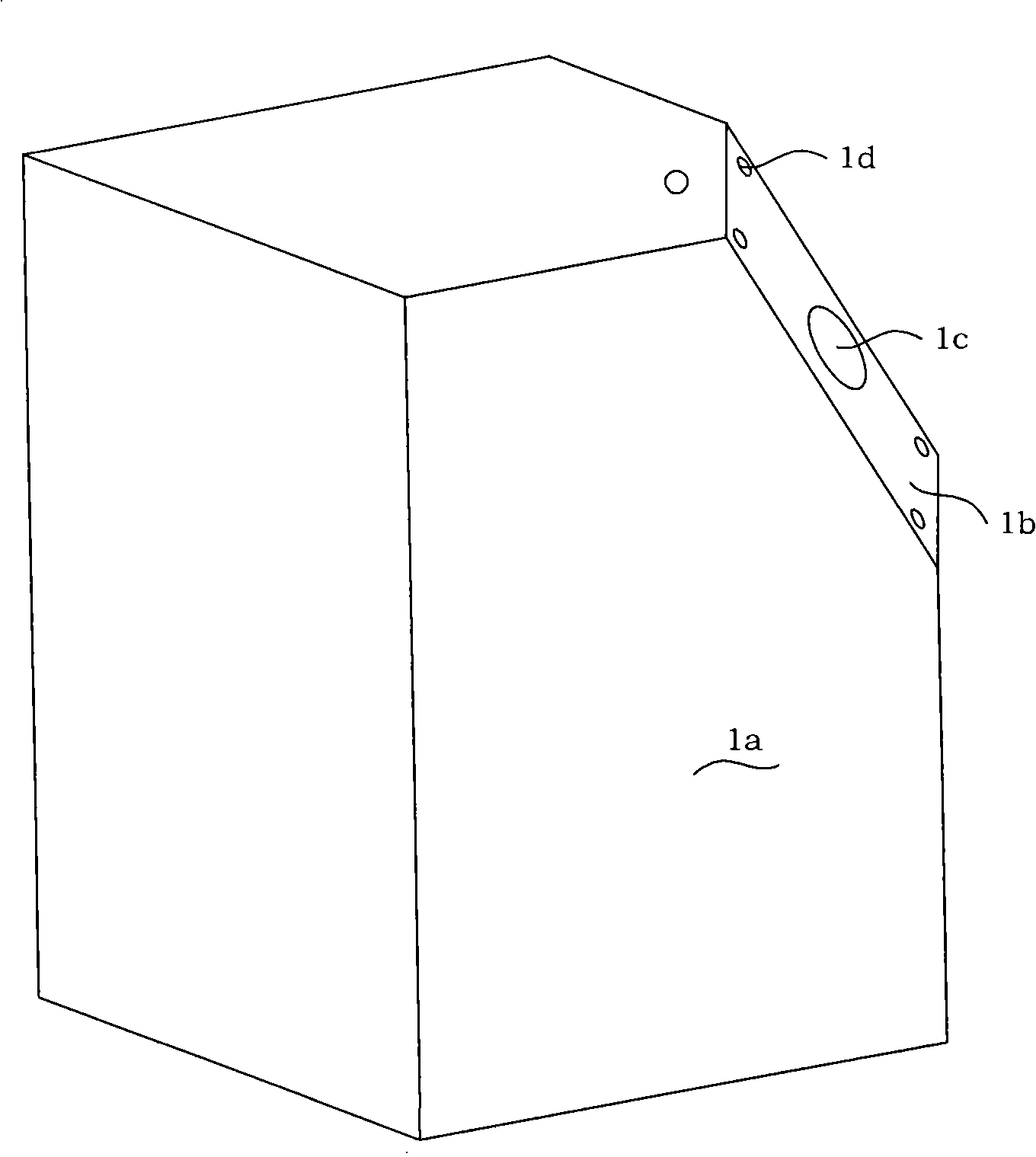

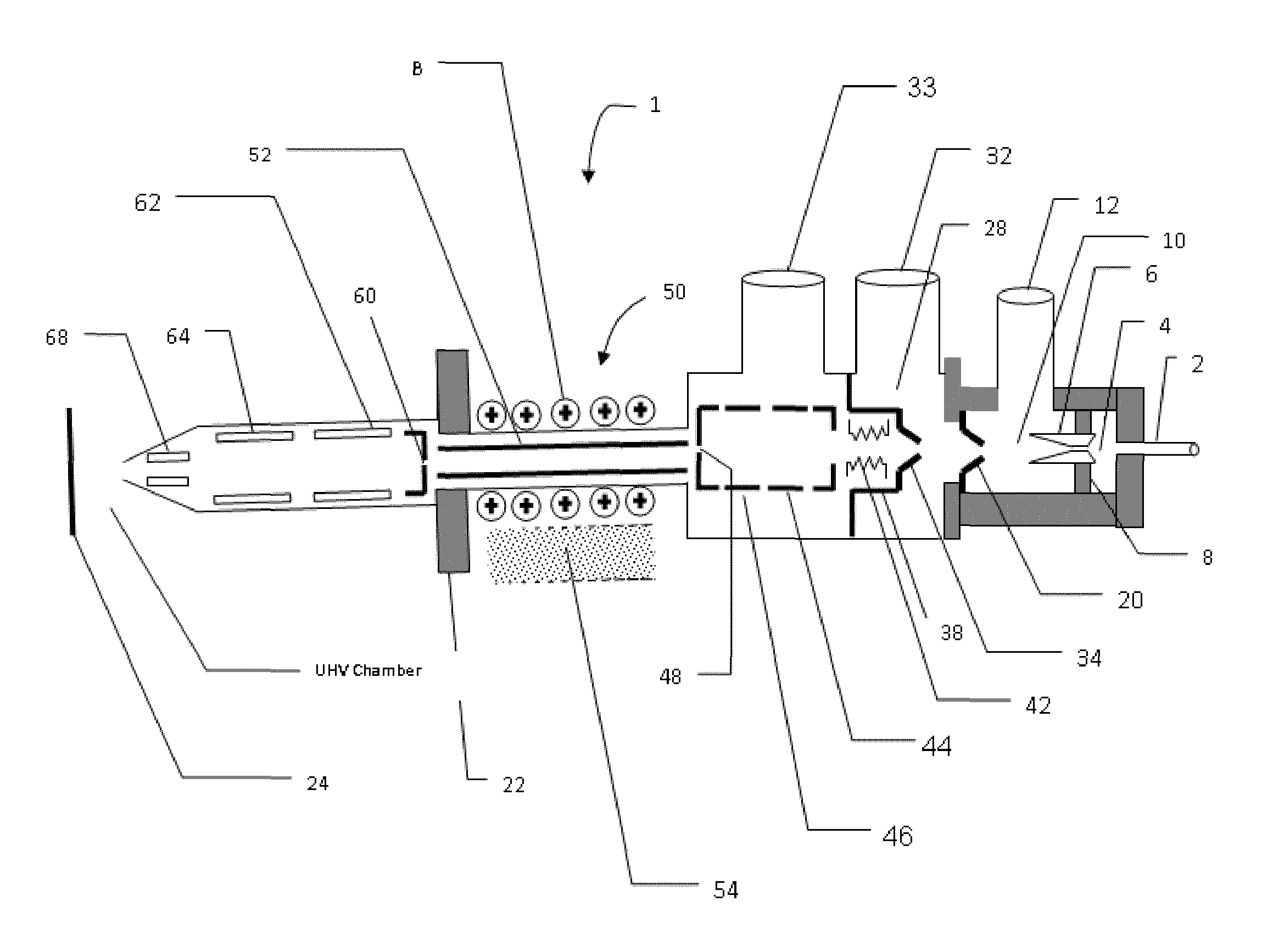

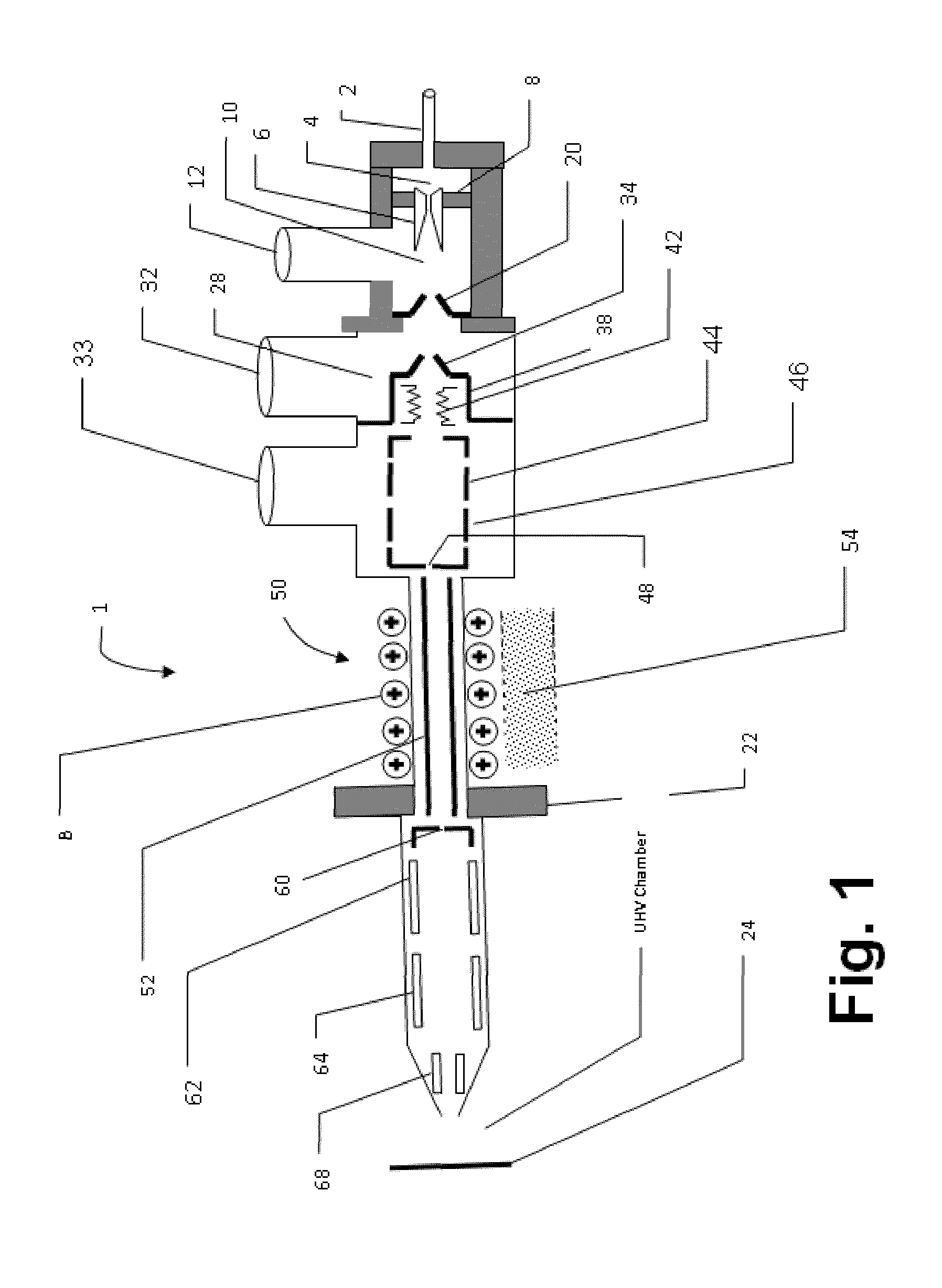

Extended cascade plasma gun

Plasma gun and method of applying powder to a substrate with a plasma gun. The plasma gun includes a cathode assembly (1), an anode (2), a rear neutrode (7), and an extended neutrode (8) positioned adjacent the rear neutrode (7) to define a channel bore (3) between the cathode assembly (1) and the anode (2). The extended neutrode (8) has a length greater than 38 mm. The plasma gun can also include at least one gas inlet to supply a gas to the channel bore (3) and a power supply.

Owner:SULZER METCO (US) INC

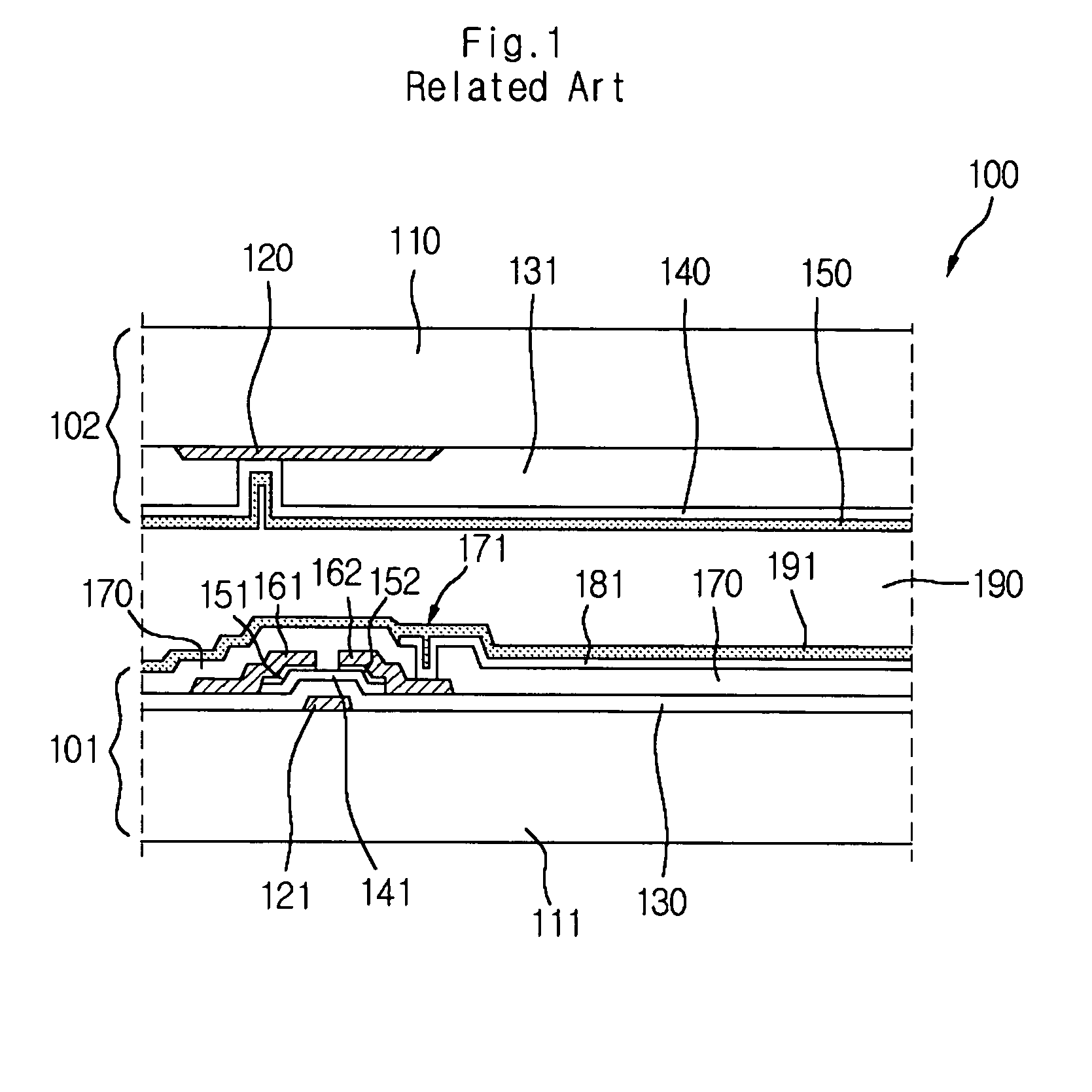

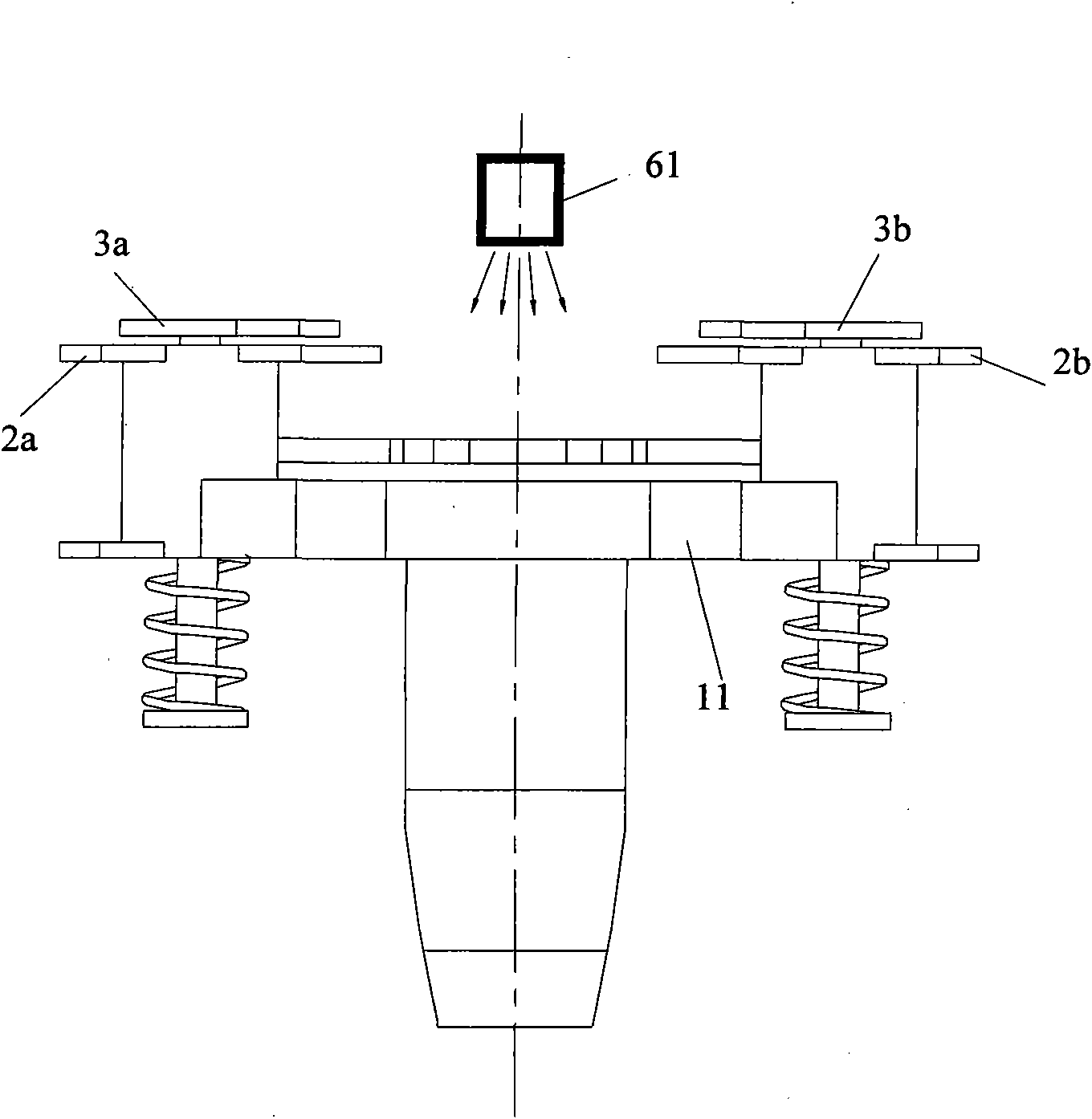

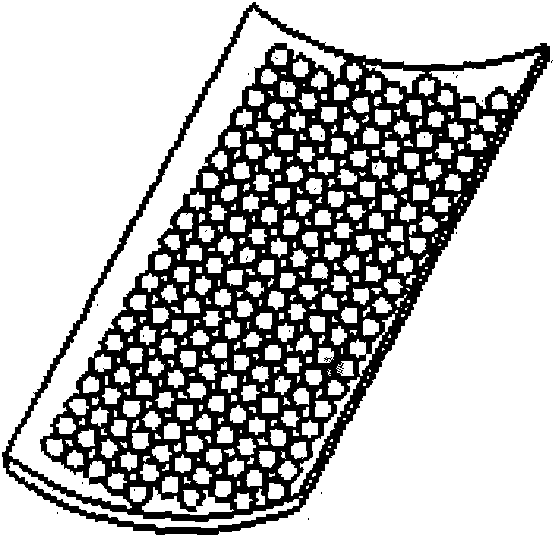

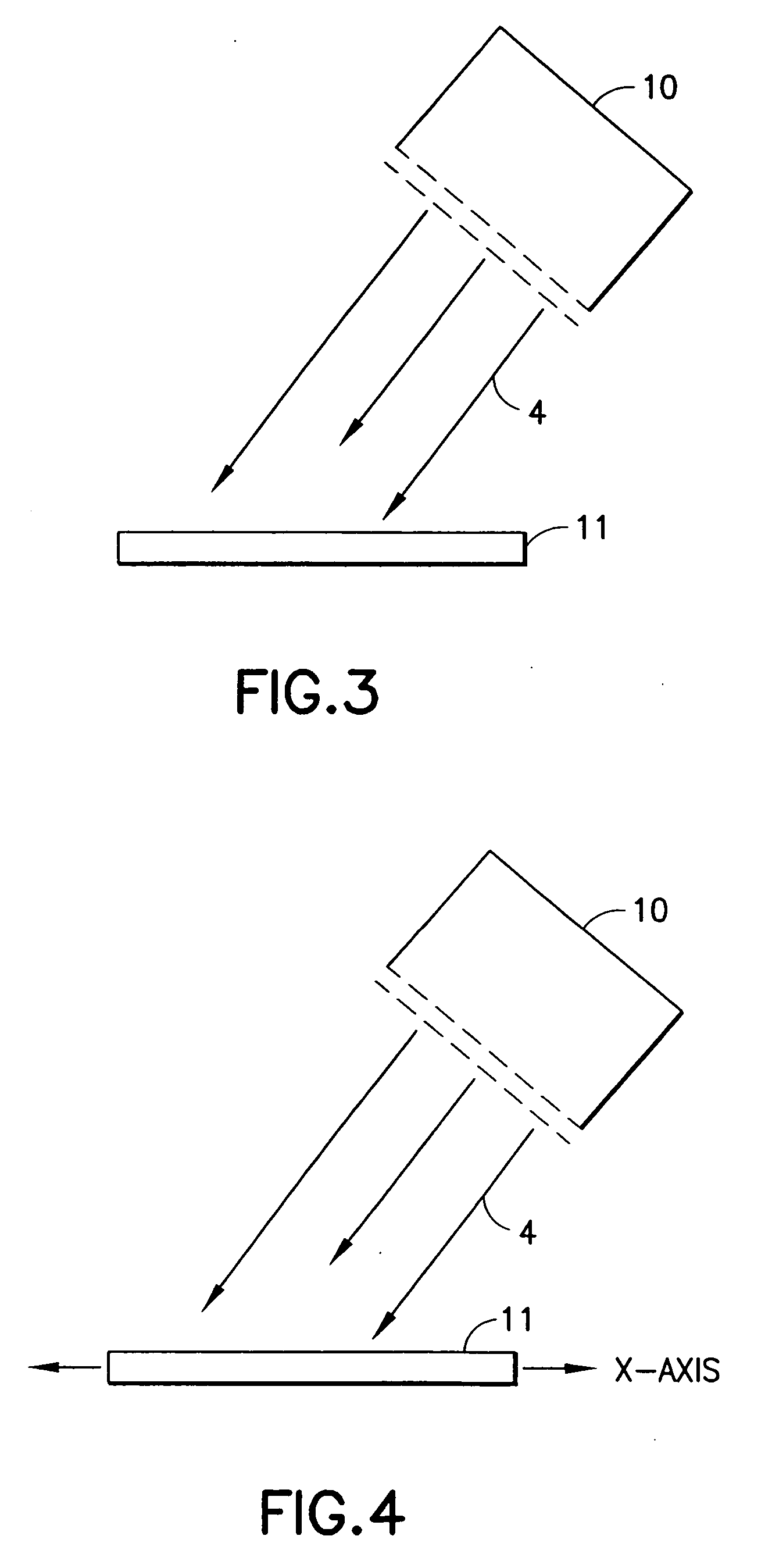

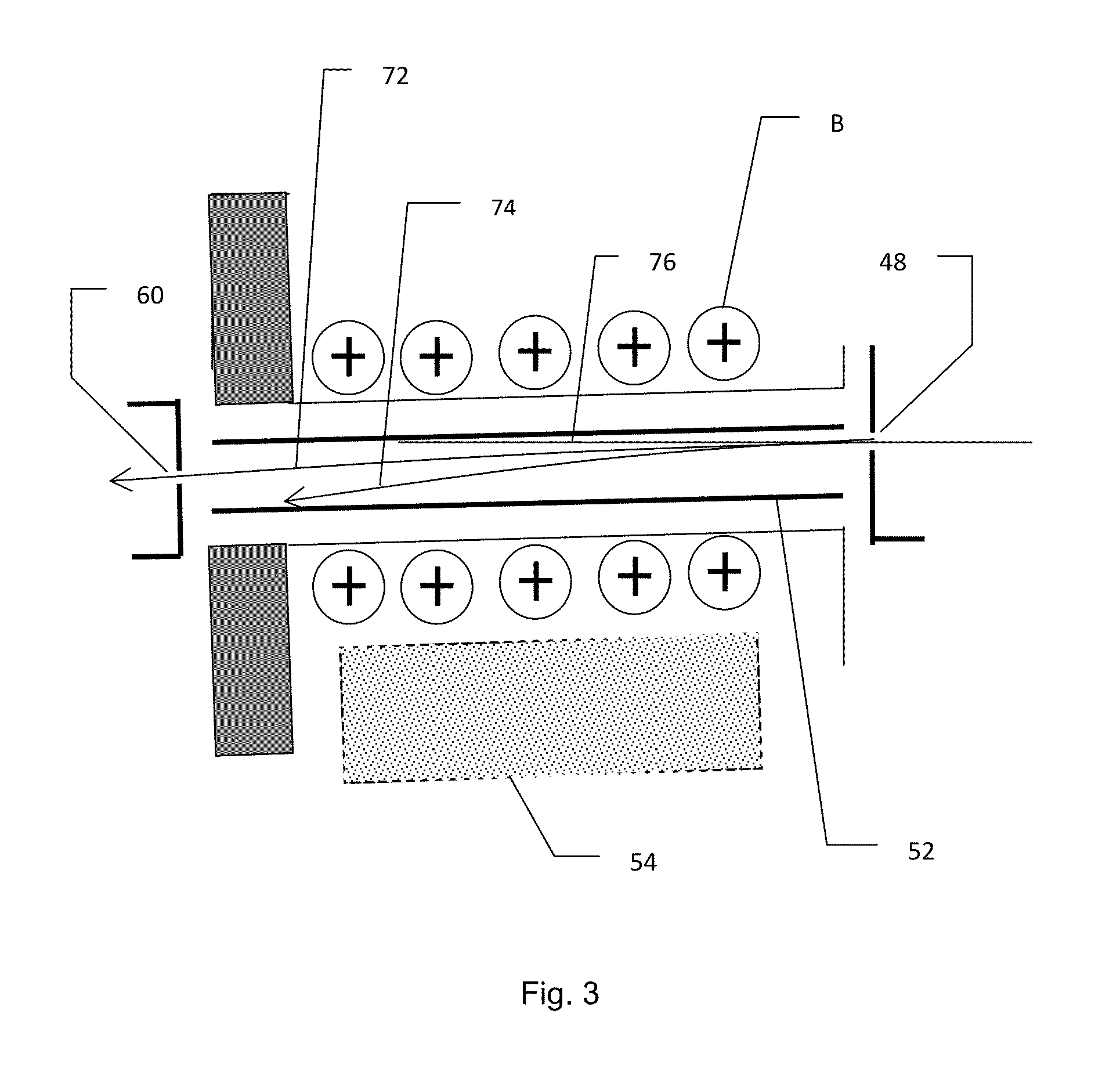

Ion gun deposition and alignment for liquid-crystal applications

InactiveUS20060150912A1Reduce Surface ContaminationReduce needVacuum evaporation coatingSputtering coatingIon beam processingLiquid crystal

An apparatus for depositing and aligning an amorphous film in a single step, a method of forming an aligned film on a substrate in a single step by combining the deposition and alignment of an alignment layer into a single-step using ion beam processing and an amorphous film having an aligned atomic structure prepared by a method in which an aligned film is deposited and aligned in a single step are provided. The film is deposited and aligned in a single step by bombarding a substrate with an ion beam at a designated incident angle to simultaneously (a) deposit the film onto the substrate and (b) arrange an atomic structure of the film in at least one predetermined aligned direction.

Owner:GLOBALFOUNDRIES INC

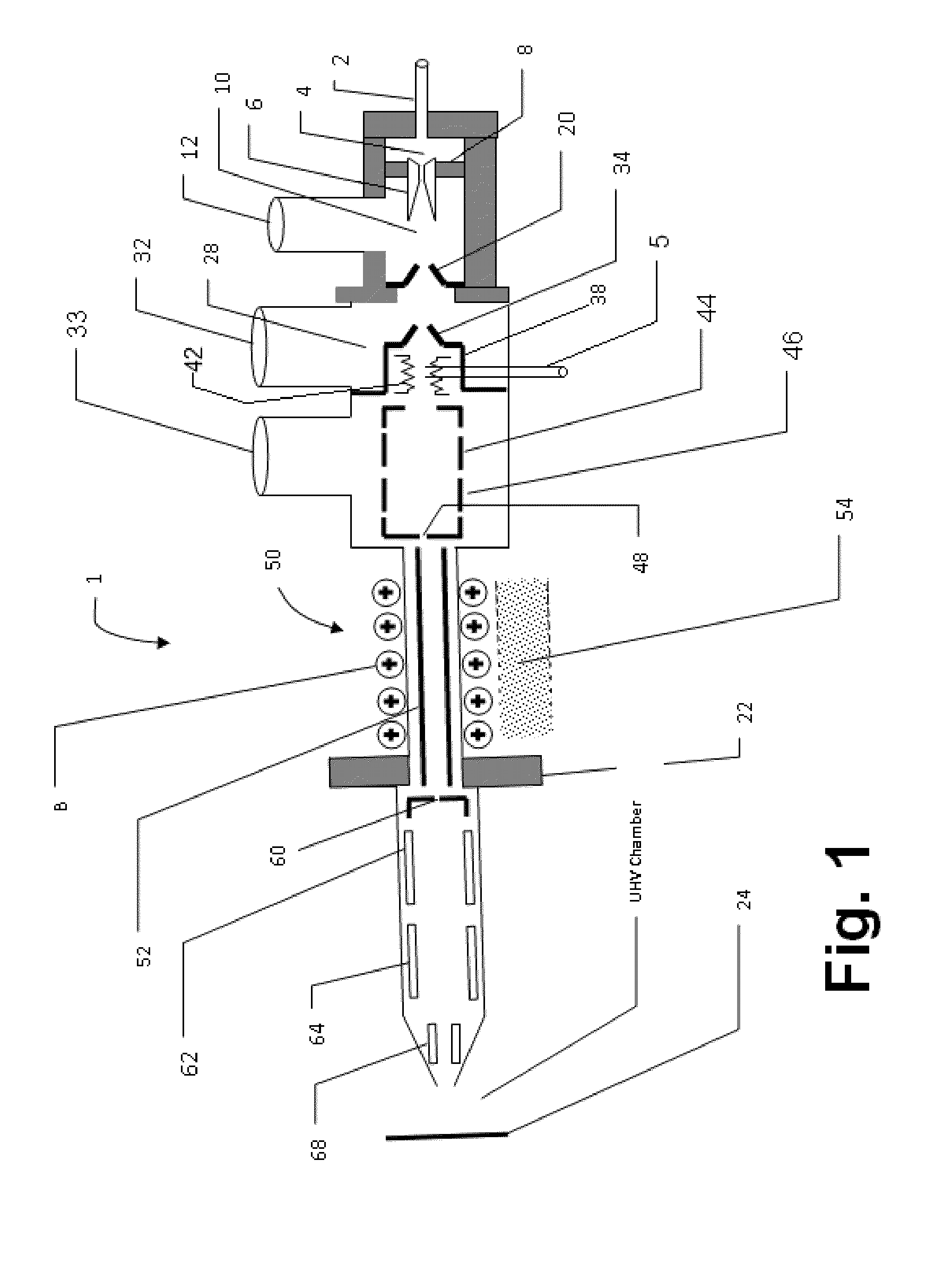

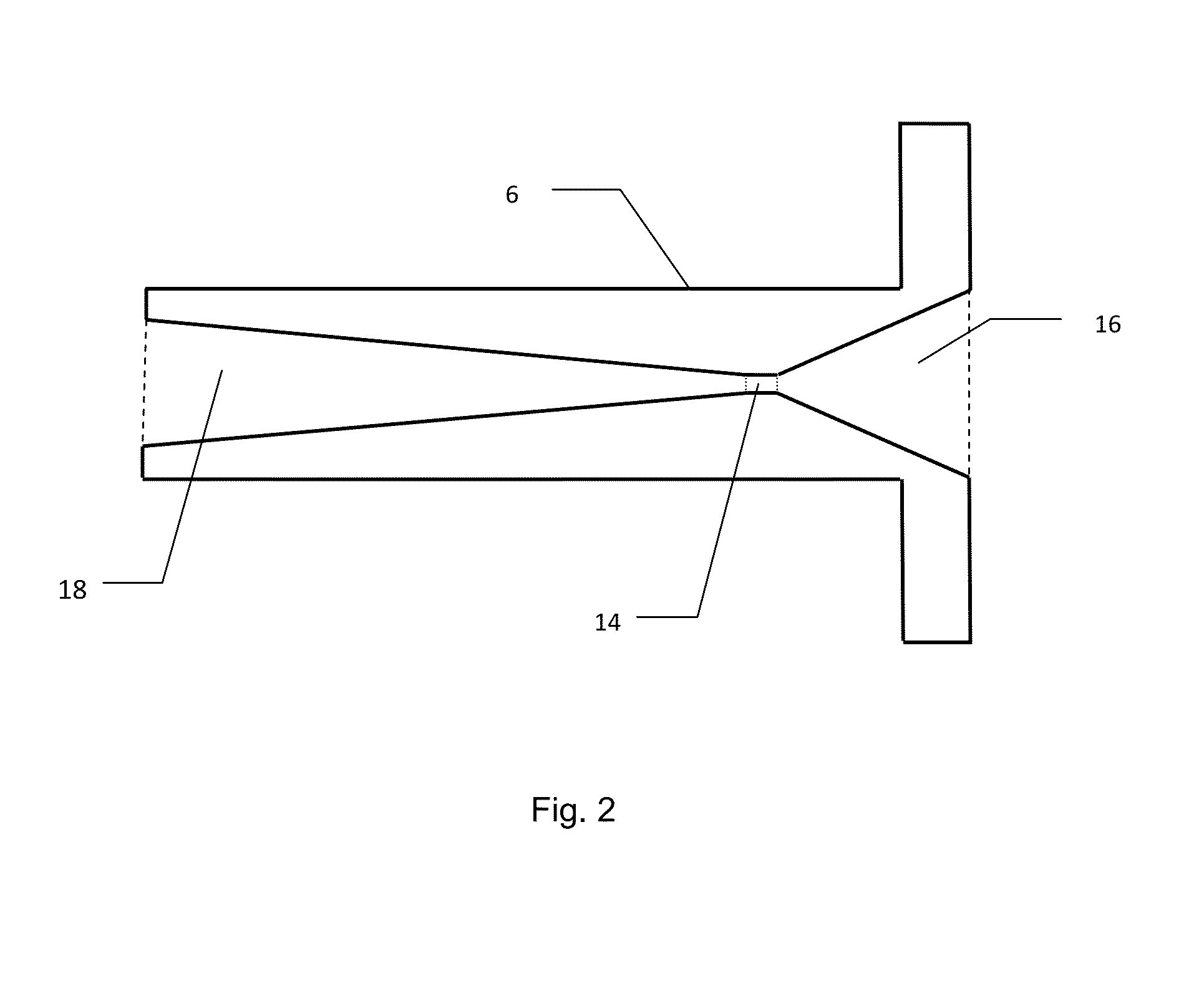

Switchable ion gun with improved gas inlet arrangement

ActiveUS20150014275A1Flexible adjustmentMinimize space charge effectDecorative surface effectsTransit-tube focussing arrangementsSpray nozzleIonization chamber

A switchable ion gun switchable between a cluster mode setting for producing an ion beam substantially comprising ionised gas clusters and an atomic mode setting for producing an ion beam substantially comprising ionised gas atoms, comprising:a source chamber having a first gas inlet;a gas expansion nozzle for producing gas clusters in the presence of gas atoms by expansion of a gas from the source chamber through the nozzle;an ionisation chamber for ionising the gas clusters and gas atoms; wherein the ionisation chamber has a second gas inlet for admitting gas directly into the ionisation chamber to form ionised gas atoms; anda variable mass selector for mass selecting the ionised gas clusters and ionised gas atoms to produce an ion beam variable between substantially comprising ionised gas clusters and substantially comprising ionised gas atoms.

Owner:VG SYST

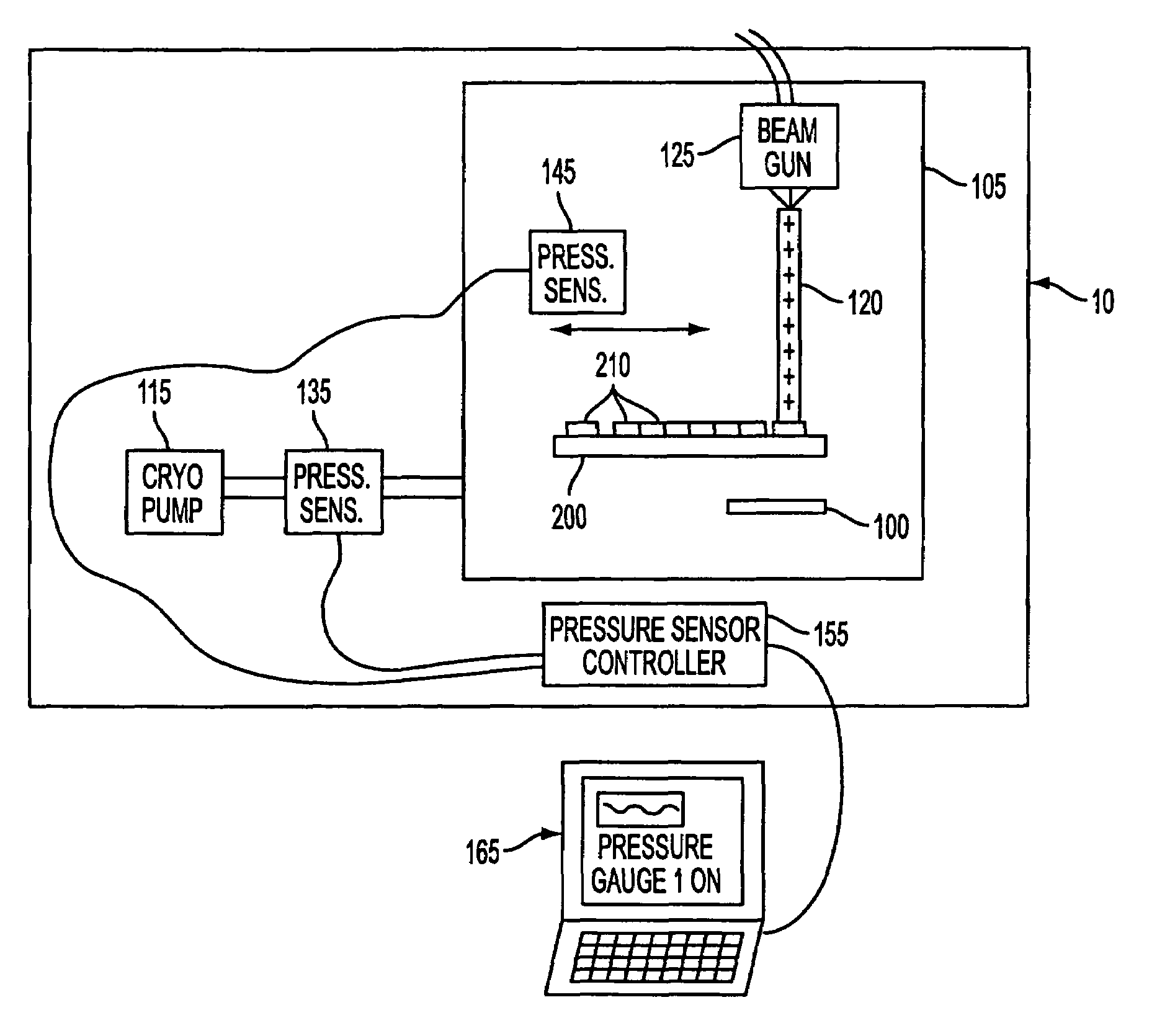

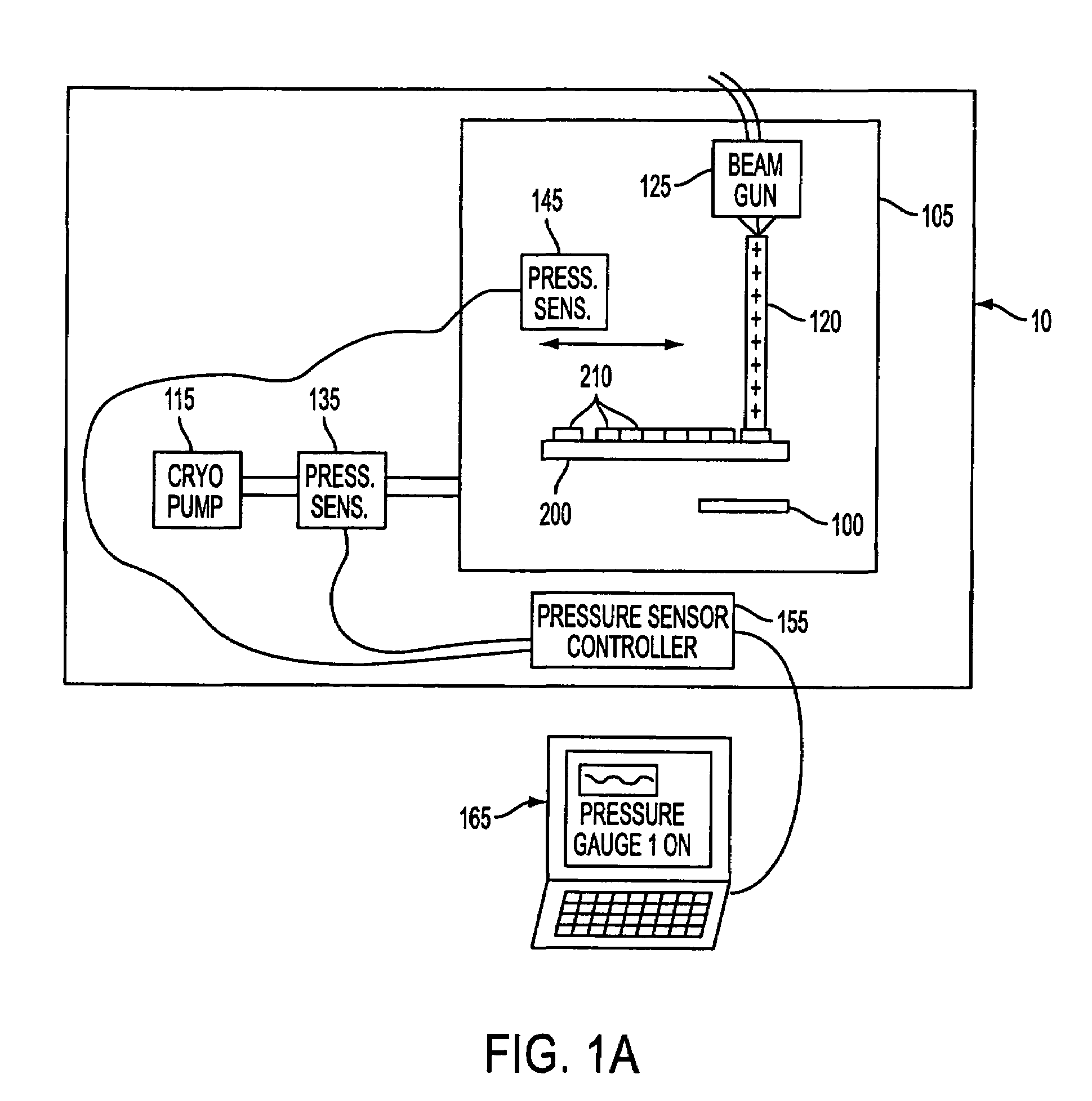

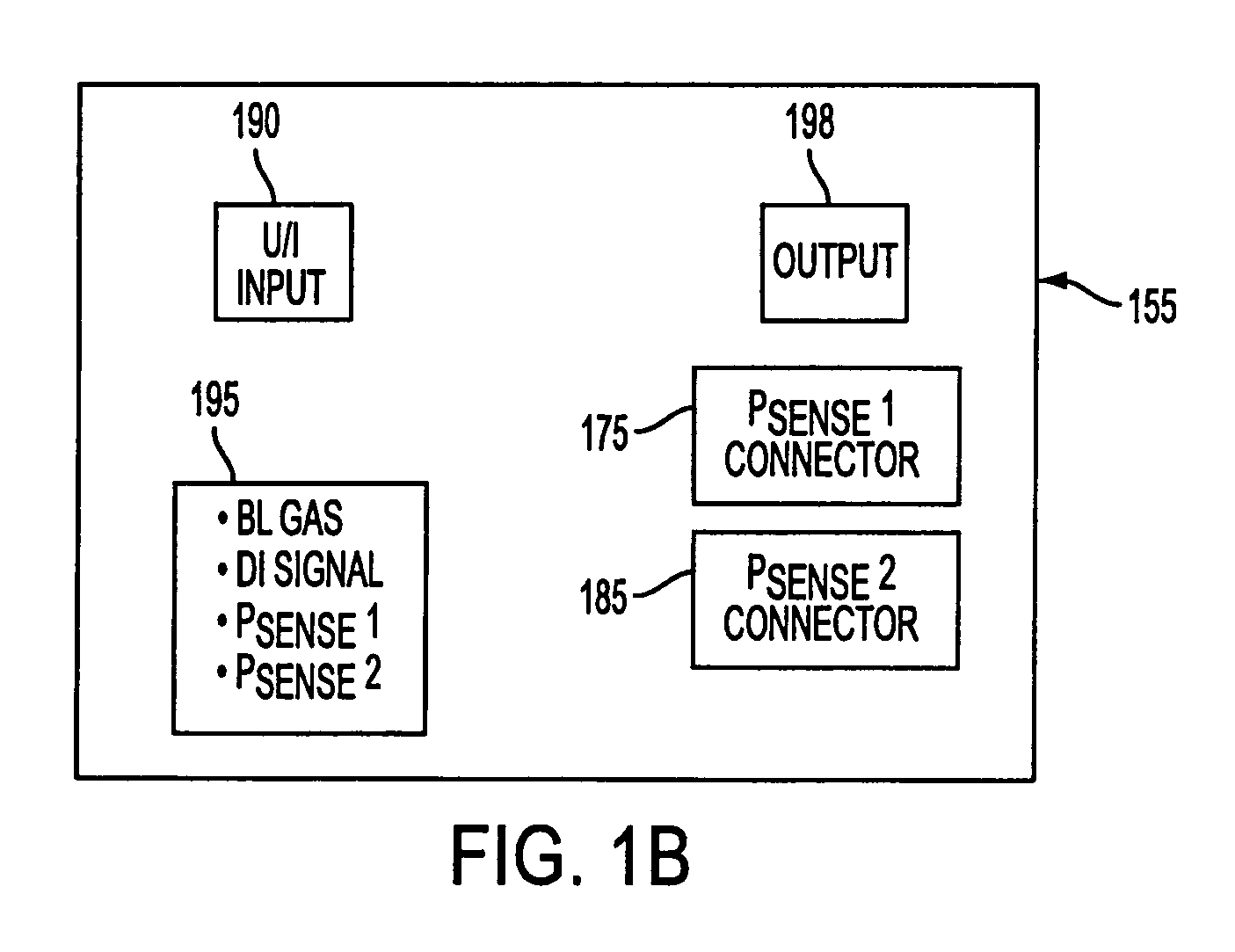

Utilization of an ion gauge in the process chamber of a semiconductor ion implanter

Owner:POLARIS INNOVATIONS LTD

Switchable gas cluster and atomic ion gun, and method of surface processing using the gun

A method of processing one or more surfaces is provided, comprising: providing a switchable ion gun which is switchable between a cluster mode setting for producing an ion beam substantially comprising ionized gas clusters for irradiating a surface and an atomic mode setting for producing an ion beam substantially comprising ionized gas atoms for irradiating a surface; and selectively operating the ion gun in the cluster mode by mass selecting ionized gas clusters using a variable mass selector thereby irradiating a surface substantially with ionized gas clusters or the atomic mode by mass selecting ionized gas atoms using a variable mass selector thereby irradiating a surface substantially with ionized gas atoms. Also provided is a switchable ion gun comprising: a gas expansion nozzle for producing gas clusters; an ionization chamber for ionizing the gas clusters and gas atoms; and a variable (preferably a magnetic sector) mass selector for mass selecting the ionized gas clusters and ionized gas atoms to produce an ion beam variable between substantially comprising ionized gas clusters and substantially comprising ionized gas atoms. Preferably, the gun comprises an electrically floating flight tube for adjusting the energy of the ions while within the mass selector.

Owner:VG SYST

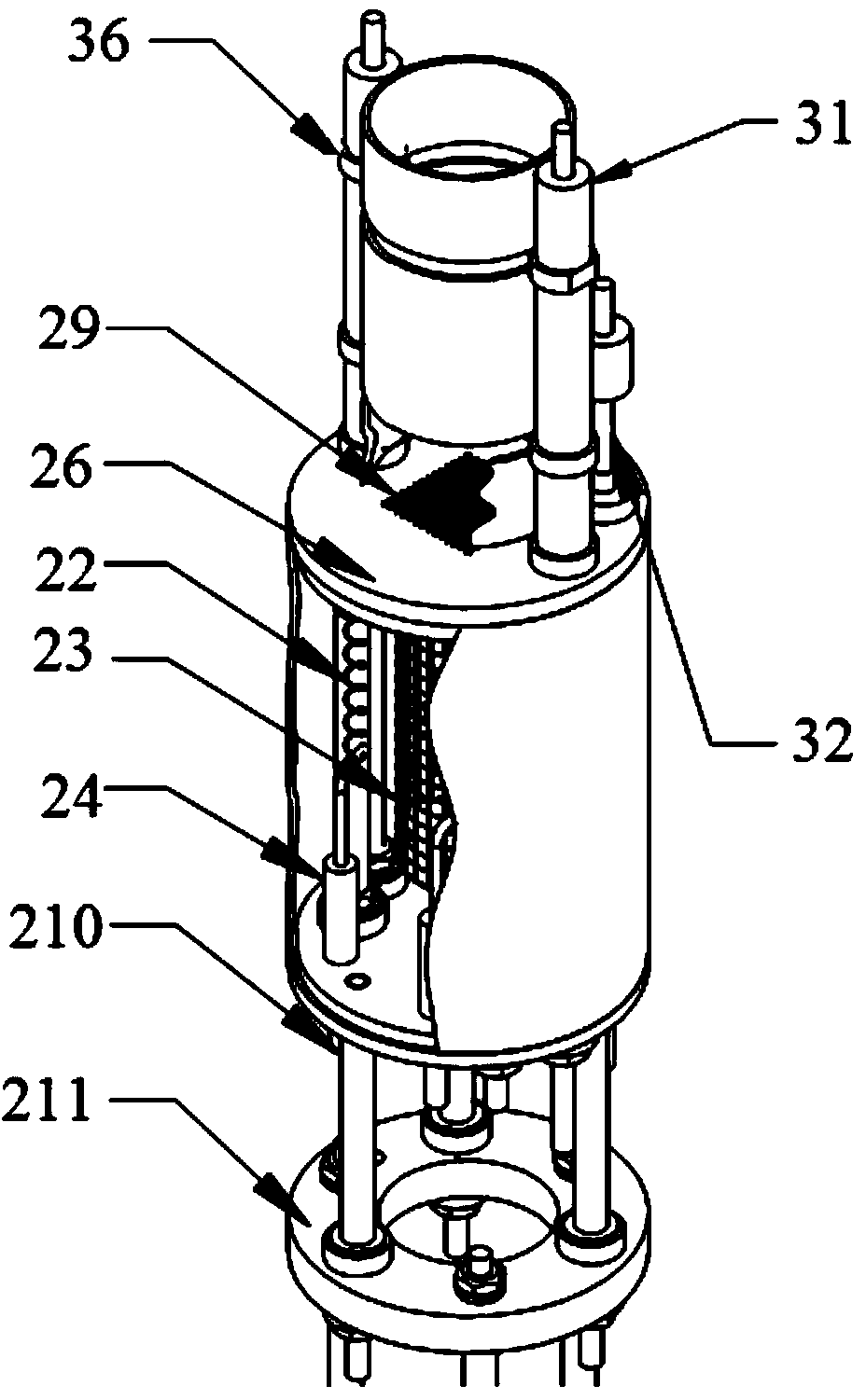

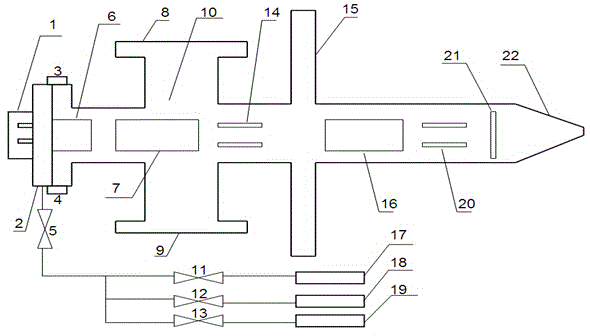

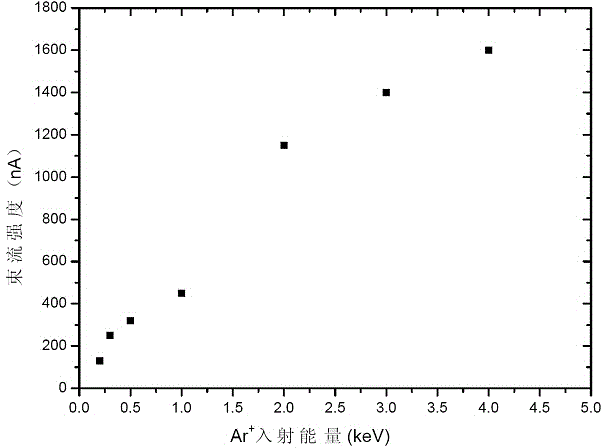

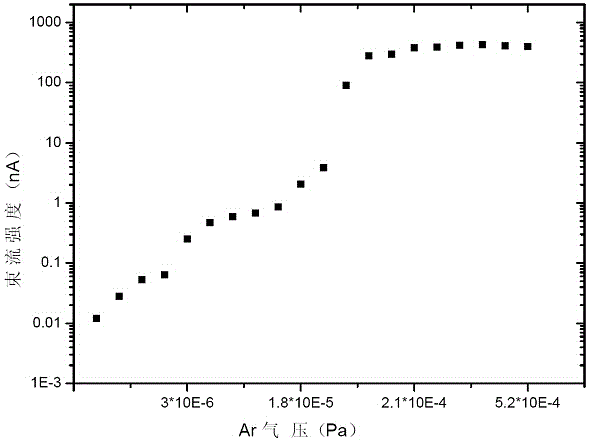

Multifunctional ion gun

ActiveCN104091741ALong transmission distanceImprove transmission distanceElectric discharge tubesDischarge tube ion gunsIonization chamberEngineering

The invention discloses a multifunctional ion gun which comprises an ionization chamber, a first lens, a second lens, a first deflecting plate, a second deflecting plate, a slot, a four-way flange, a transition flange and a cone-shaped cylinder. The ionization chamber, the first lens and first deflecting plate are placed in a pipeline of the four-way flange. The first lens is placed between the ionization chamber and the first deflecting plate. The first deflecting plate is placed at the near end of the transition flange. The ionization chamber is arranged at the far end of the transition flange. The second lens, the second deflecting plate and the slot are placed in the cone-shaped cylinder. The second deflecting plate is placed between the second lens and the slot. The second lens is arranged at the near end of the transition flange. The slot is formed in the far end of the transition flange. The four-way flange and the cone-shaped cylinder are connected through the transition flange. The purposes that the structure is compact, functions are various, performance is stable, and ion beam transmission distance is enhanced are achieved.

Owner:LANZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com