Precision ion polishing system and sample clamp thereof

A sample and ion technology, applied in the field of semiconductor and precision ion milling machines, can solve the problems of sample breakage, affecting production efficiency, wasting manpower and material resources, and achieving the effect of avoiding excessive grinding, saving manpower and material resources, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] The first aspect of the present invention provides a sample holder for a precision ion mill table, which includes one or more clips, and the one or more clips can move in their respective horizontal planes to adjust the relative The fixed position of the ion beam on the precision ion machine. The sample holder also includes one or more control devices for controlling the movement of the clip in its own plane.

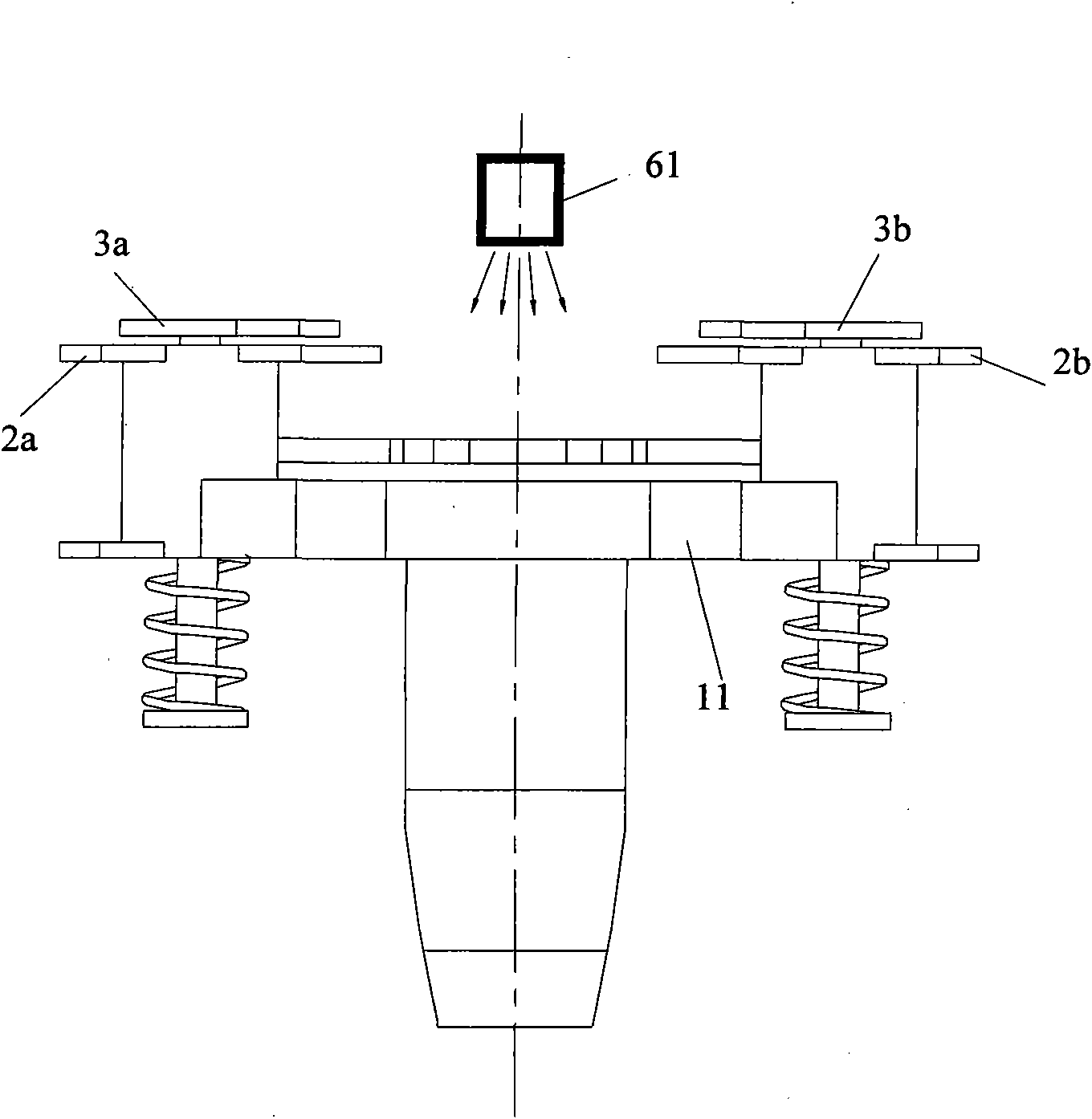

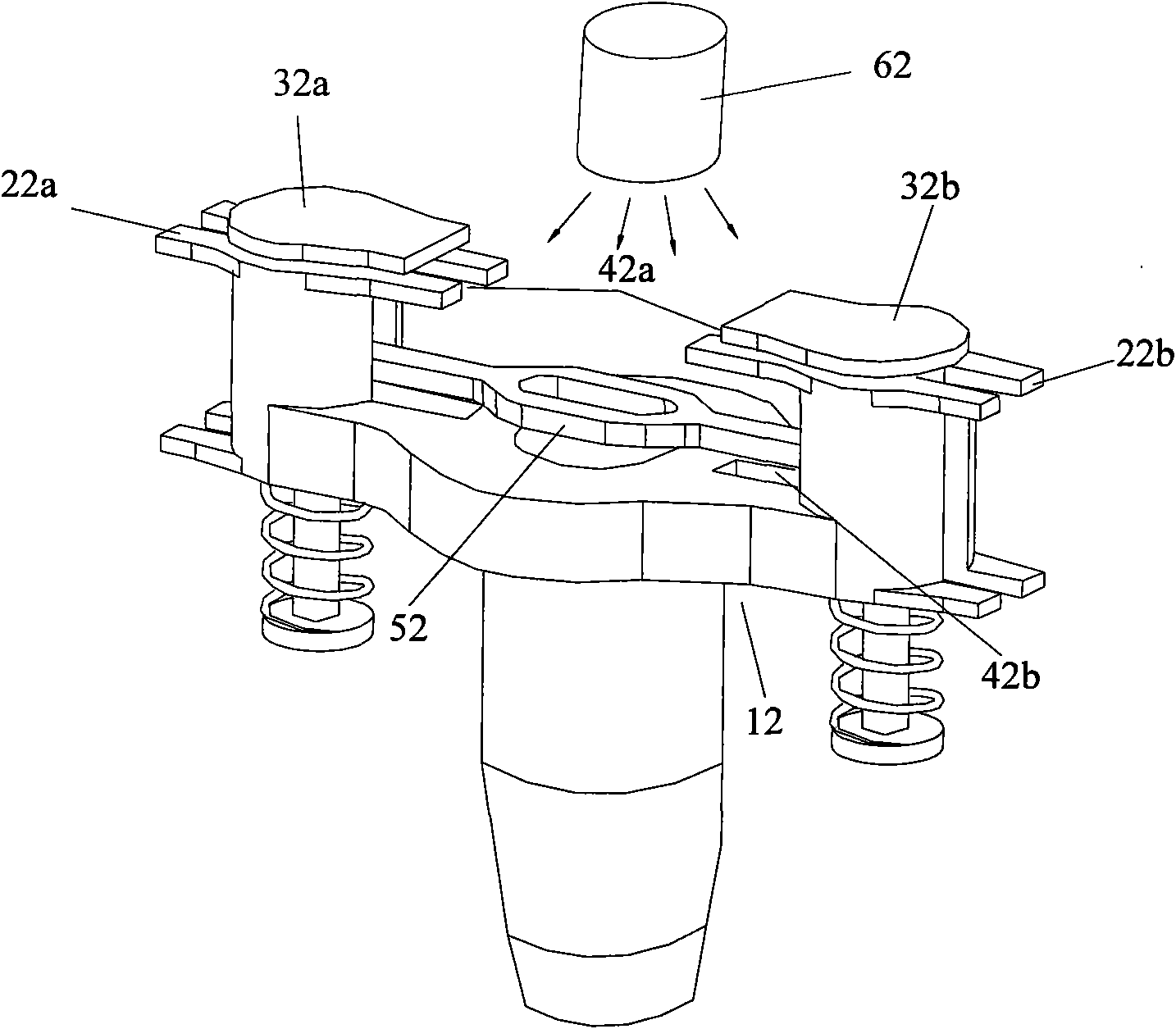

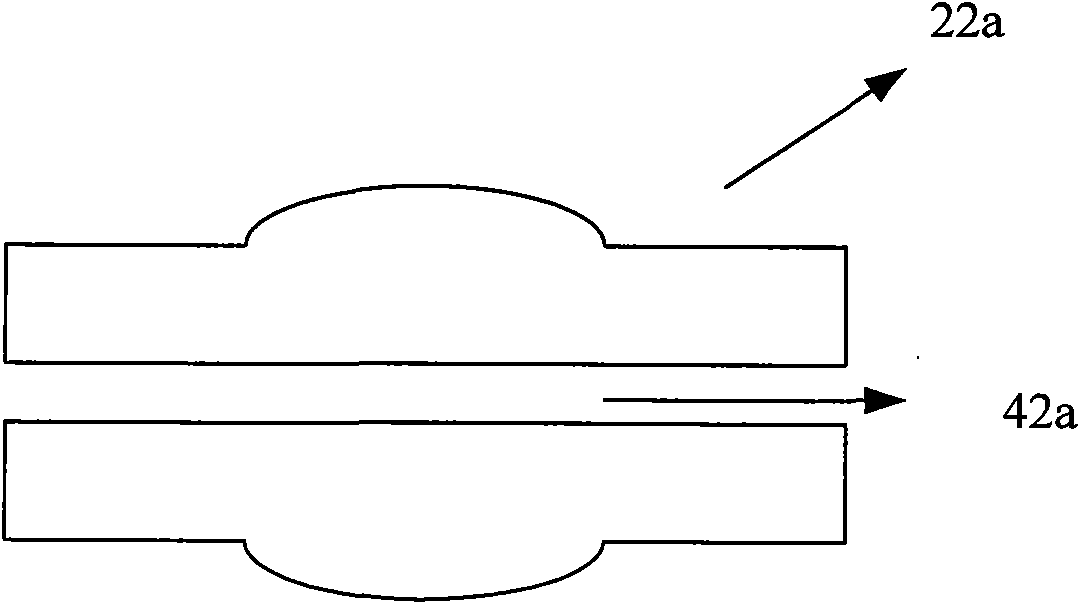

[0026] figure 2 A schematic structural view of a sample holder for a precision ion mill according to a specific embodiment of the present invention. For the convenience of description, this embodiment is only described in the case that the sample holder includes two clips, but those skilled in the art should understand that there is no strict limit on the number of clips in practical applications, as long as the clips included in the sample h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com