Improved ion gun

An ion gun and an improved technology, applied in the field of ion guns, can solve the problems of reducing the effective area of deposition, reducing the yield of peripheral filters, and reducing production capacity, and achieving the effect of improving production capacity and production yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

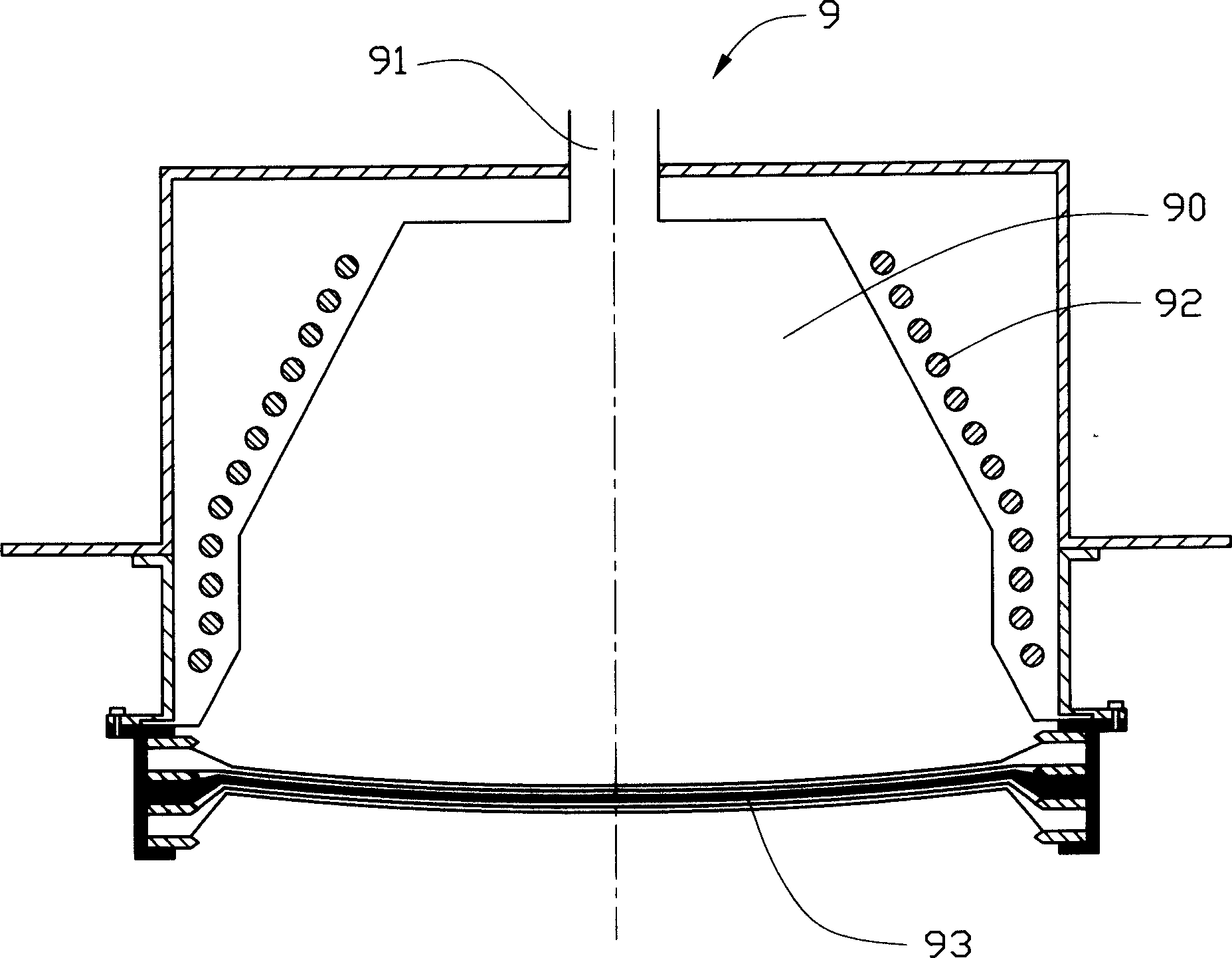

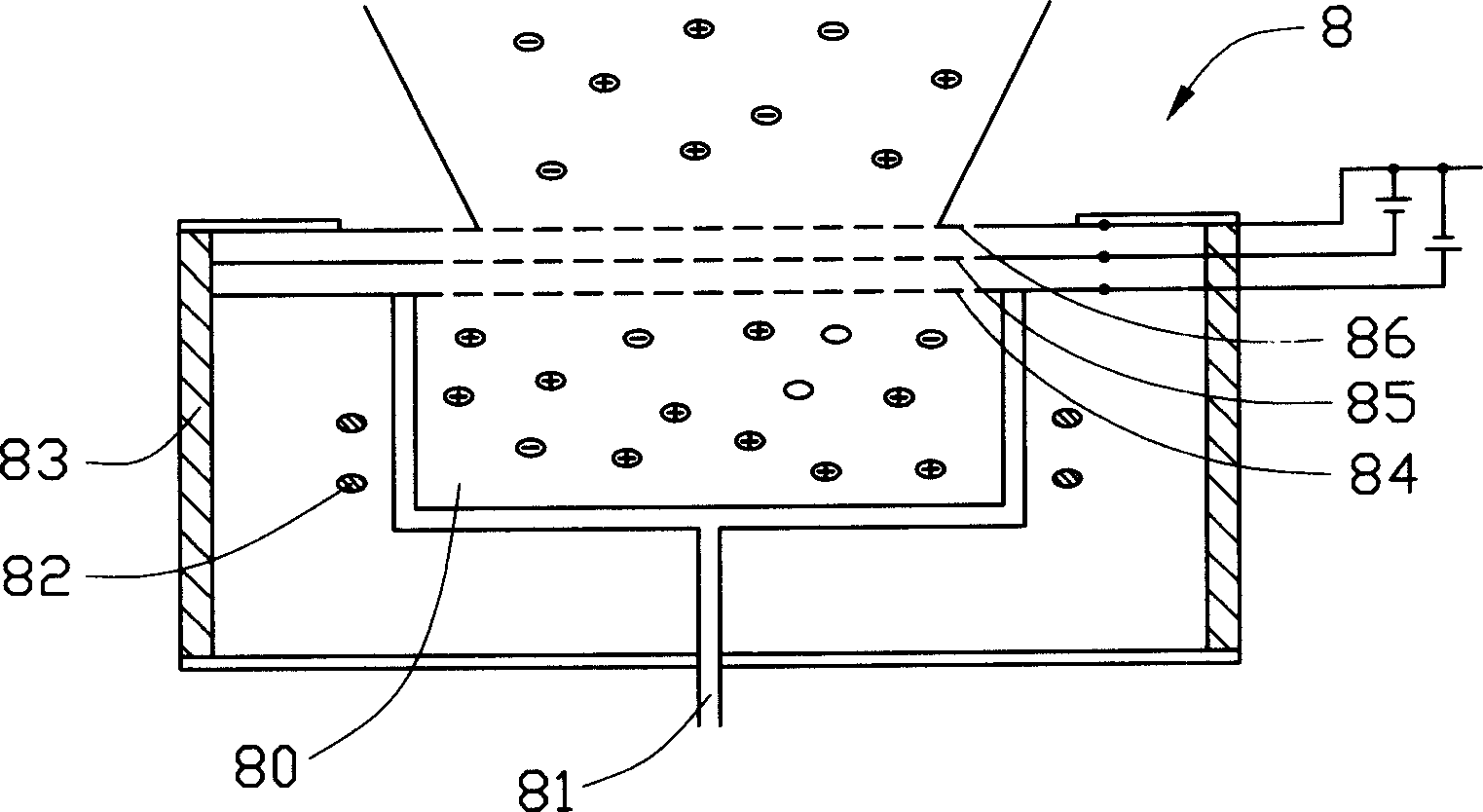

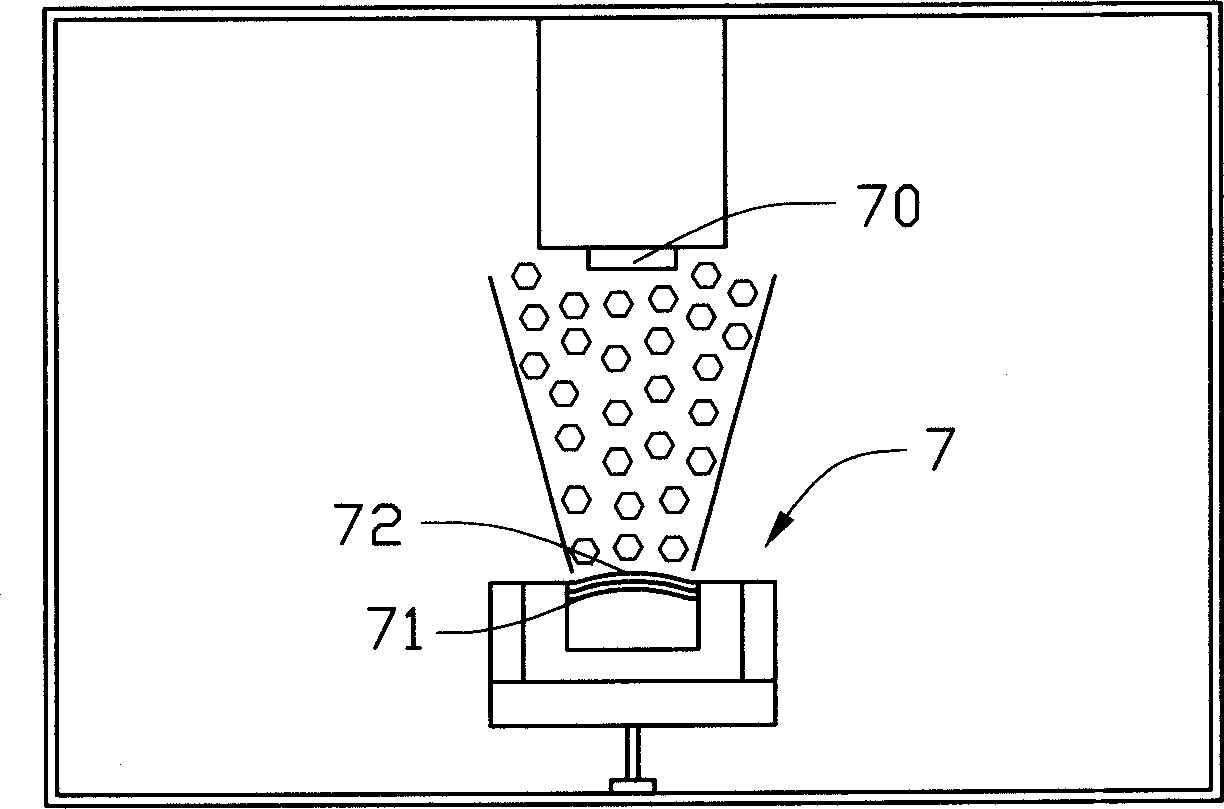

[0020] Please also see Figure 4 and Figure 5 , the main components of the improved ion gun 1 of the present invention are similar to existing products, and it is equipped in the coating chamber 100 (which can be a vacuum chamber) and is applied to the ion-assisted deposition process for manufacturing optical thin films. The ion gun 1 mainly includes a discharge Chamber (plasma chamber) 10, a gas source for supplying the gas to be ionized, an exciter located at the side of the discharge chamber, an ion beam extraction device installed at the opening of the discharge chamber, and a peripheral device located at the periphery of the discharge chamber and the exciter Shield 30 . Wherein, the discharge chamber 10 is made of non-conductive material, the shielding member 30 may be a metal member, and the exciter may be a radio frequency coil to generate a high frequency electromagnetic field to ionize the gas to generate plasma.

[0021] The above-mentioned ion beam extraction dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com