Patents

Literature

223 results about "Neutral particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In physics, a neutral particle is a particle with no electric charge. This is not to be confused with a truly neutral particle, a neutral particle that is also identical to its own antiparticle.

Apparatus for treating the surface with neutral particle beams

InactiveUS6935269B2Wide effective cross sectionImprove throughputRadiation/particle handlingElectric discharge tubesTarget surfaceMetal

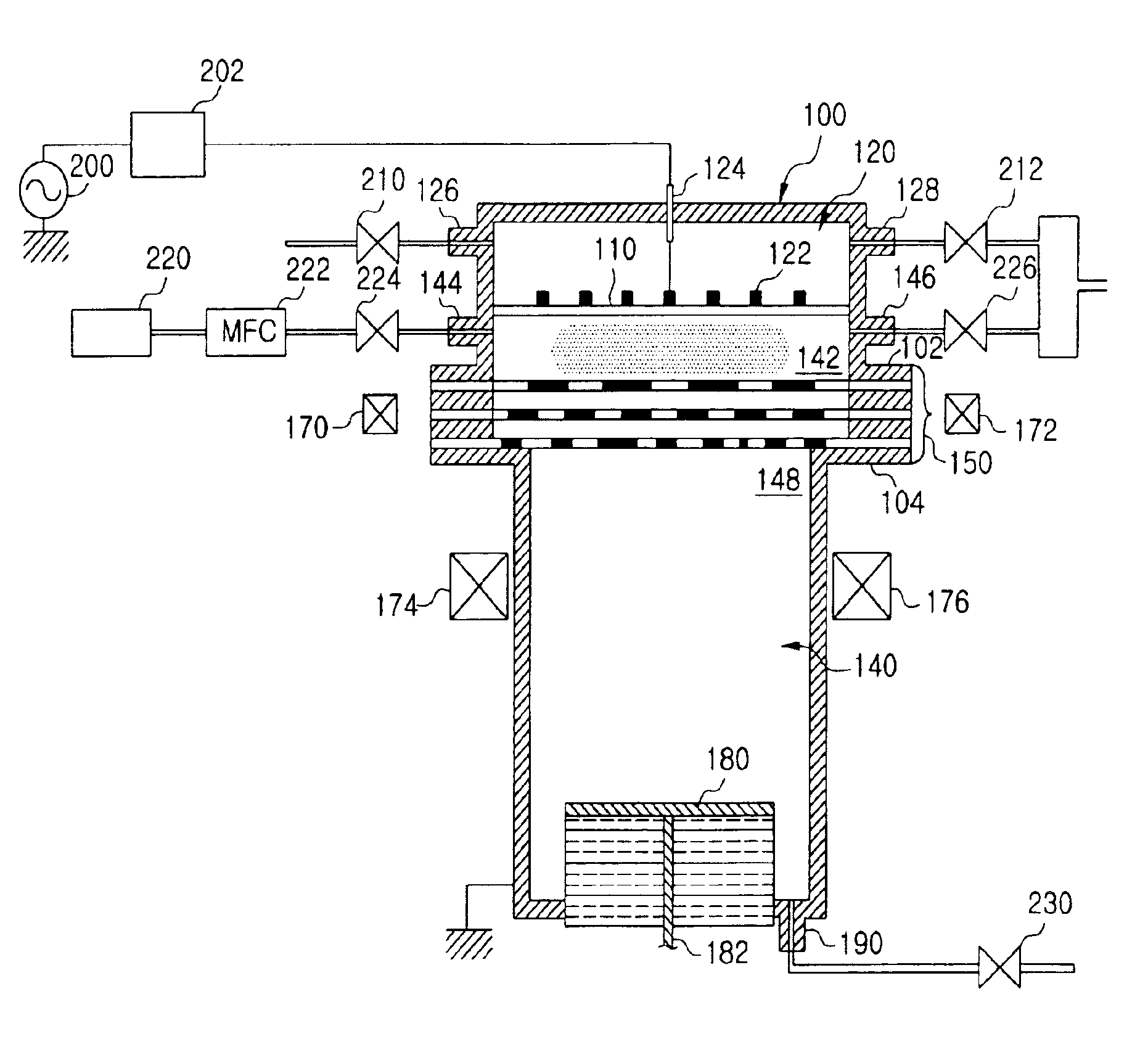

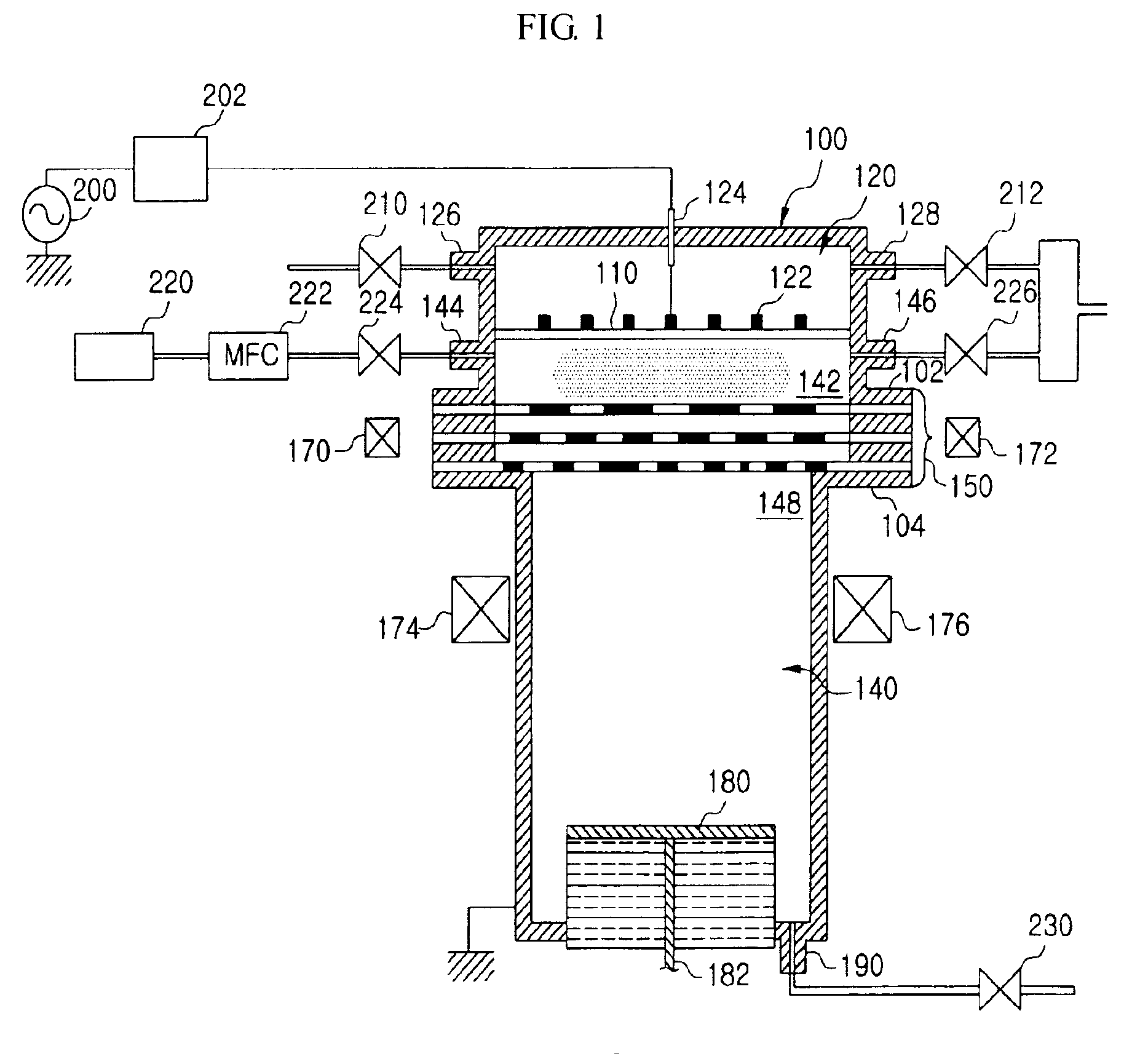

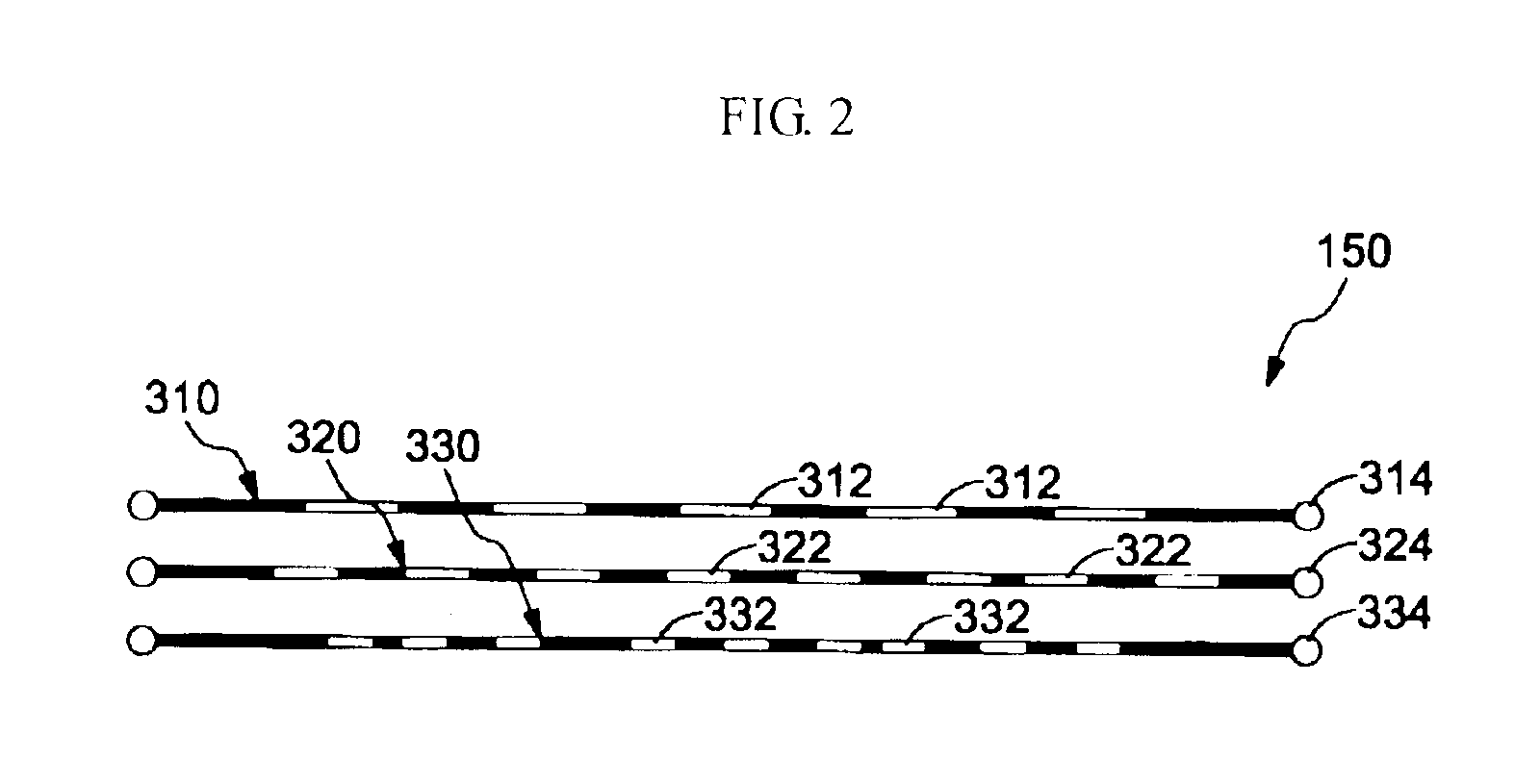

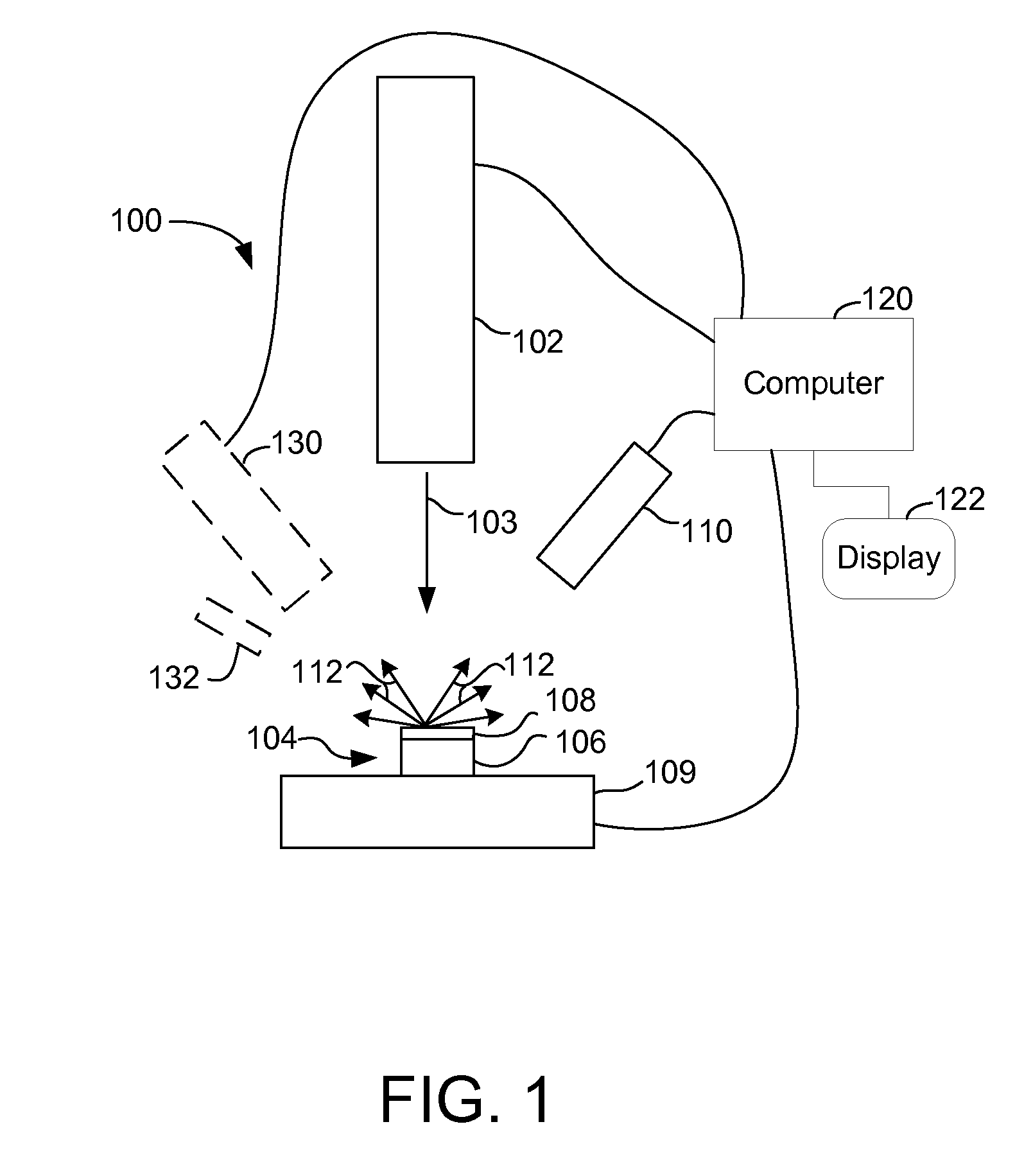

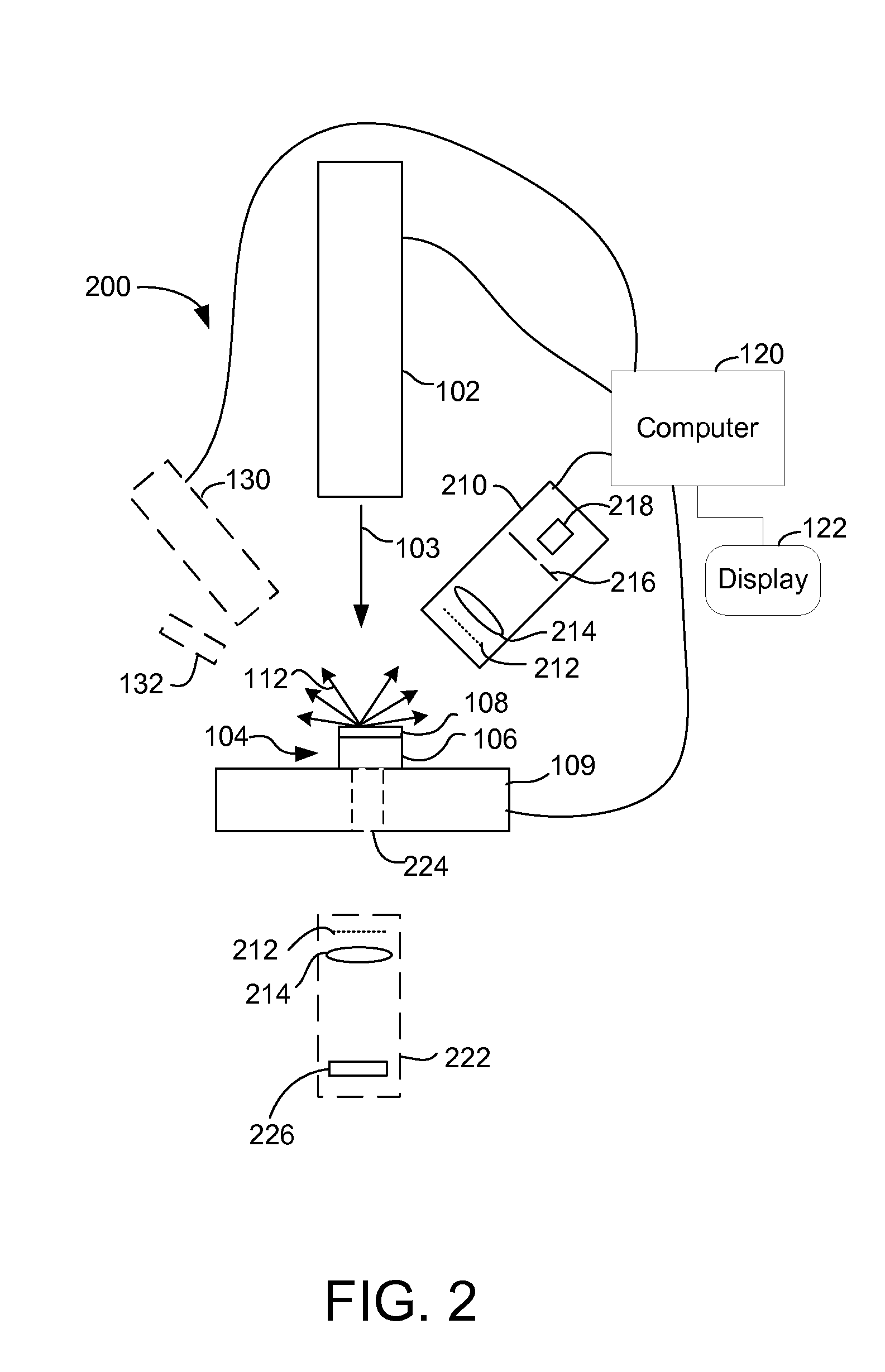

The present invention relates to an apparatus for treating the surface with neutral particle beams comprising an antenna container, a plasma generating part, a neutral particle beam generating part and a treating part, wherein the antenna container comprises antennas connected to high frequency electric power supply through which high frequency electric power supplies, the plasma generating part transfers gases from a gas injector into plasmas with the supplied power, the neutral particle beam generating part reverts the obtained plasmas to neutral particle beams via the collision thereof with metal plates, and the treating part treats the surface of a target with the neutral particle beams.

Owner:SEM TECH CO LTD +1

Neutral particle beam processing apparatus

InactiveUS6861642B2Inexpensive and compact structureImprove neutralization efficiencyLaser detailsVacuum evaporation coatingDielectricPlasma generator

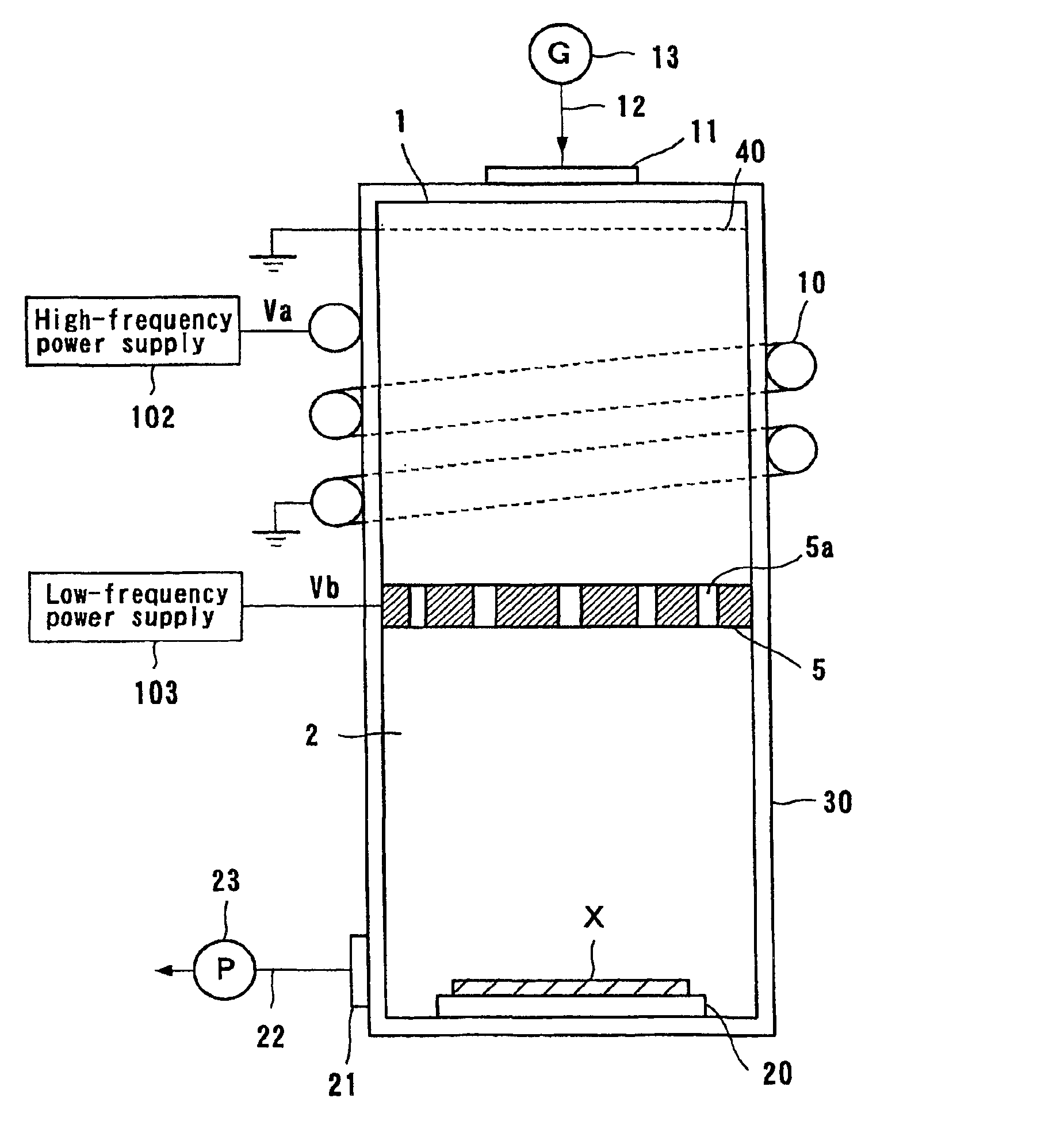

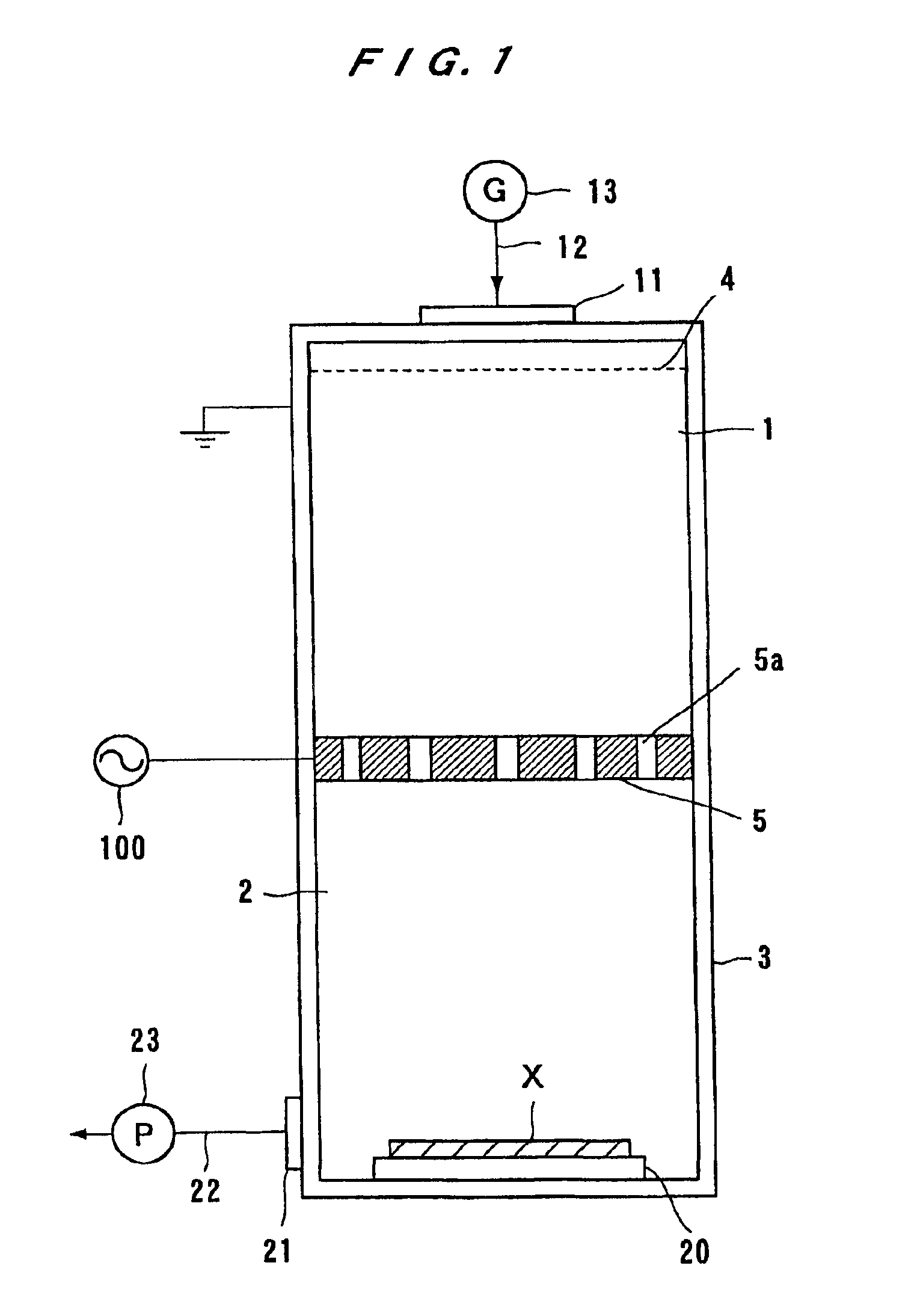

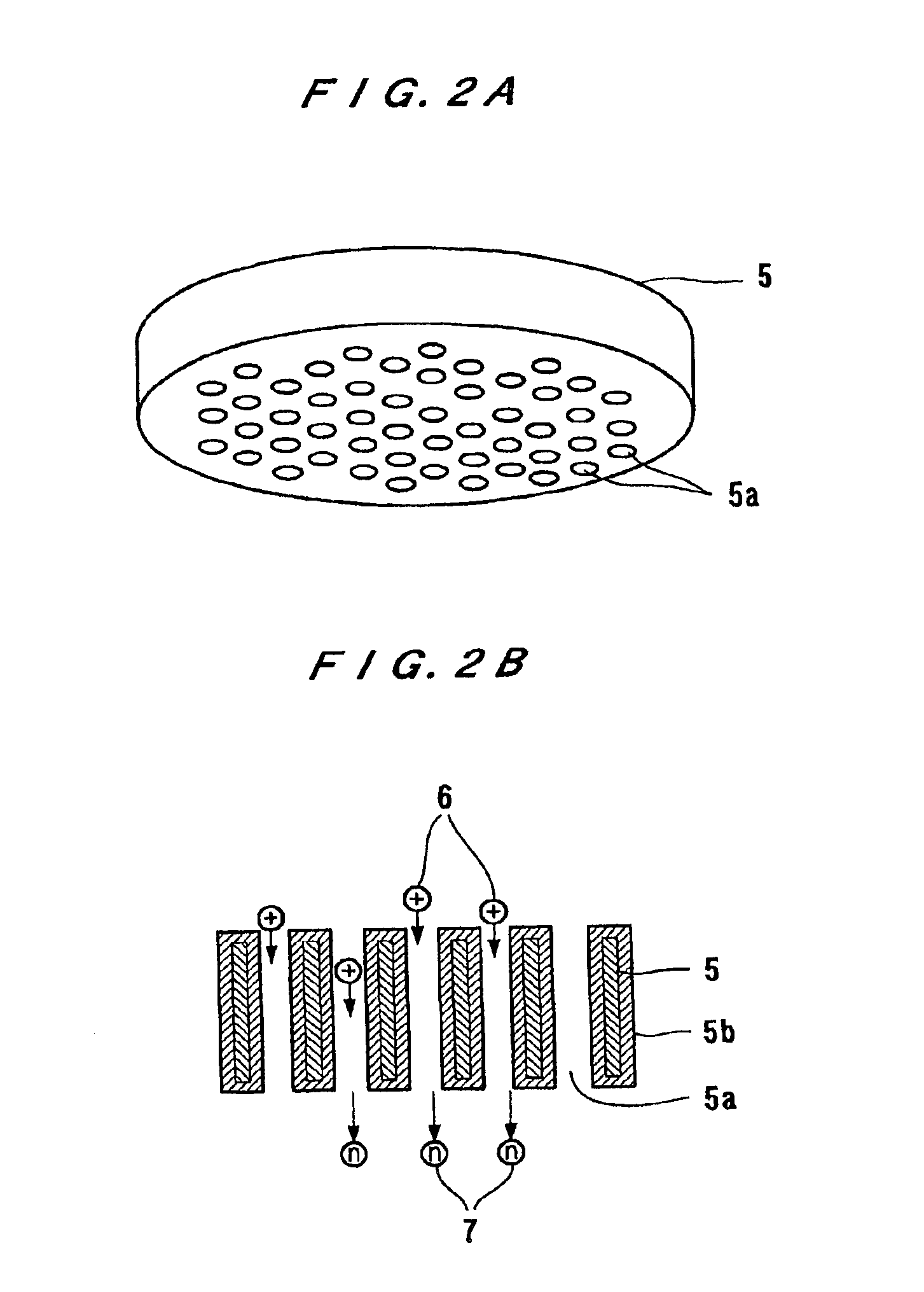

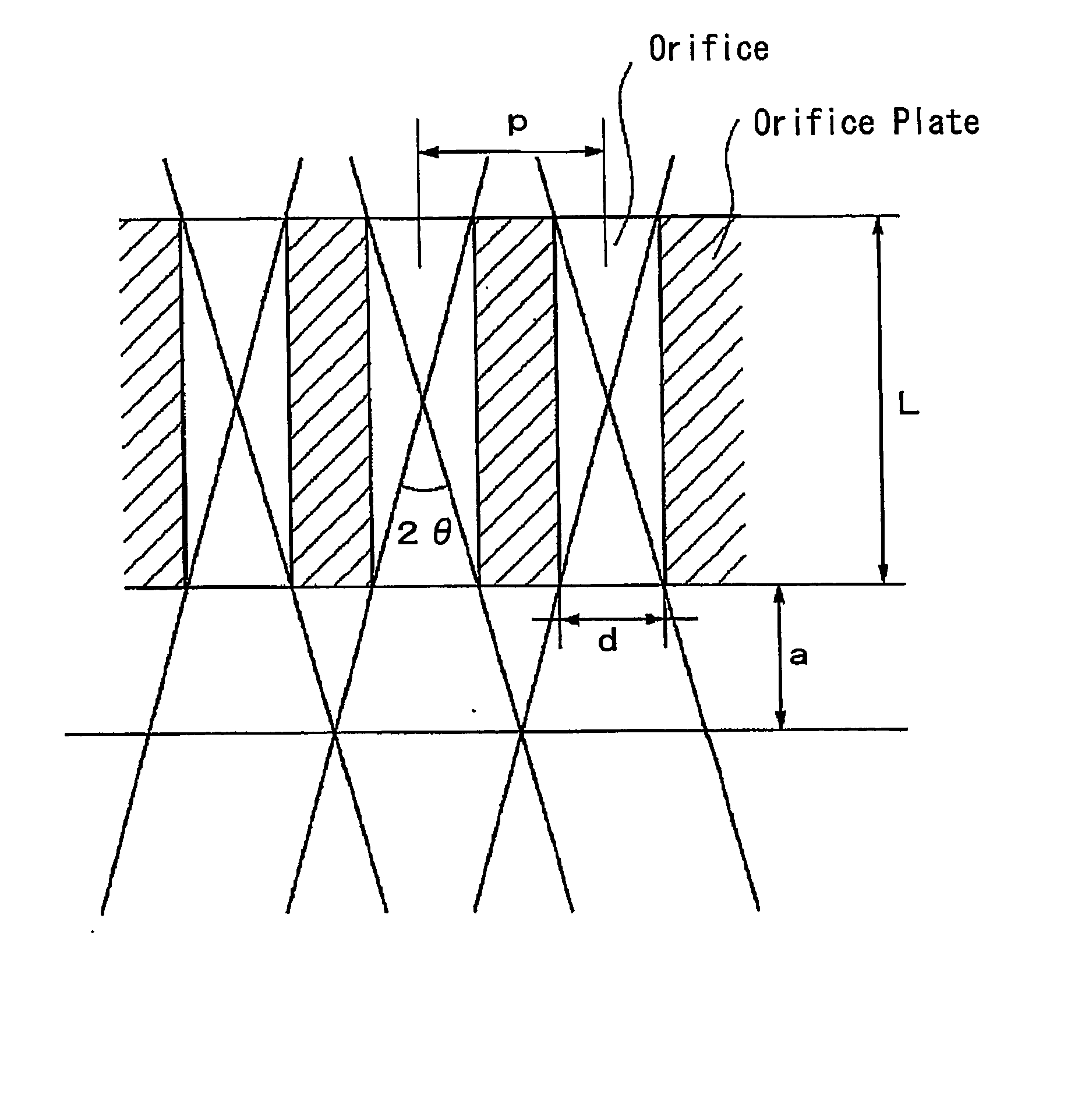

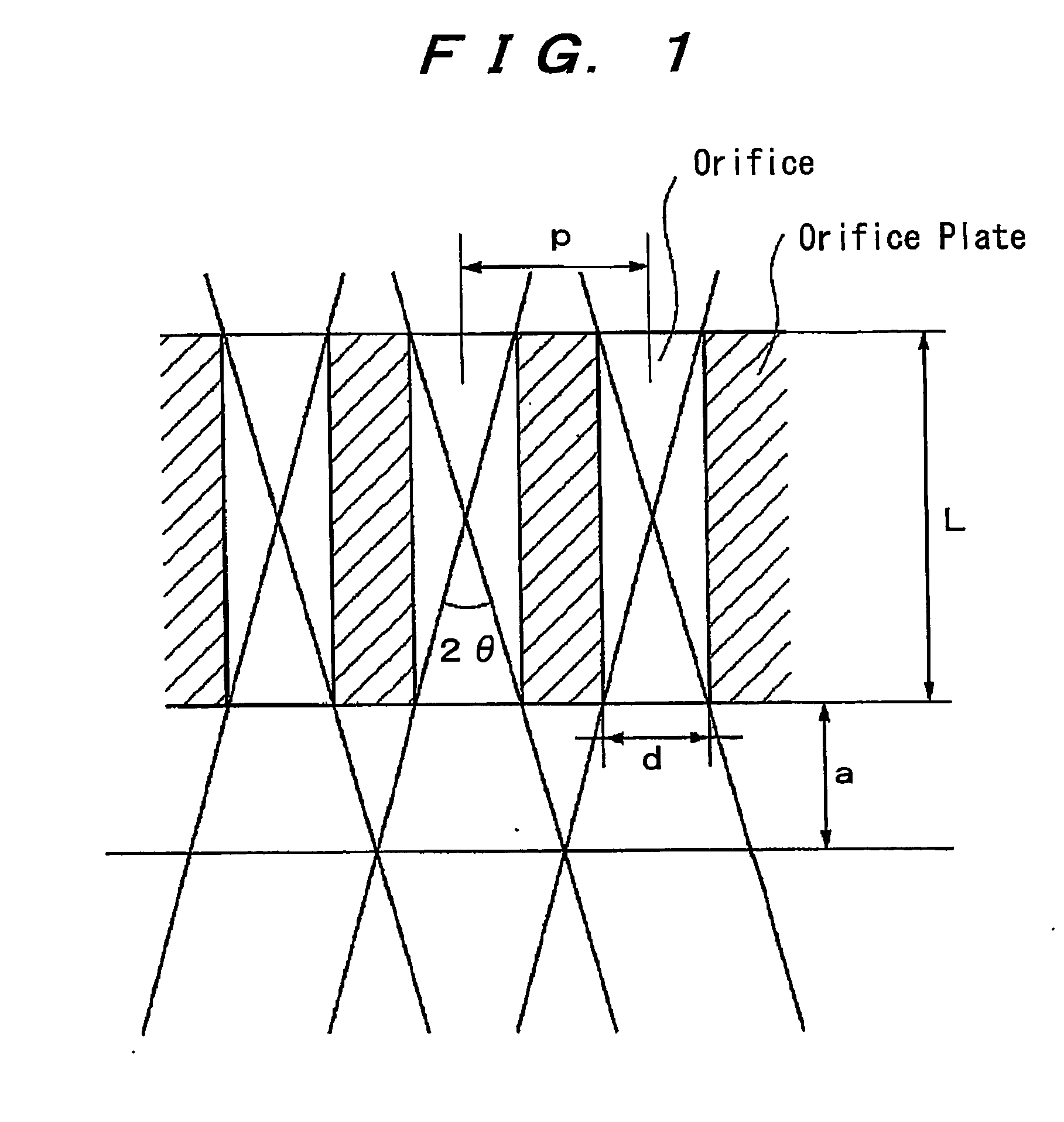

A neutral particle beam processing apparatus comprises a workpiece holder (20) for holding a workpiece (X), a plasma generator for generating a plasma in a vacuum chamber (3), an orifice electrode (5) disposed between the workpiece holder (20) and the plasma generator, and a grid electrode (4) disposed upstream of the orifice electrode (5) in the vacuum chamber (3). The orifice electrode (5) has orifices (5a) defined therein. The neutral particle beam processing apparatus further comprises a voltage applying unit for applying a voltage between the orifice electrode (5) and the grid electrode (4) via a dielectric (5b) to extract positive ions from the plasma generated by the plasma generator and pass the extracted positive ions through the orifices (5a) in the orifice electrode (5).

Owner:ASM IP HLDG BV

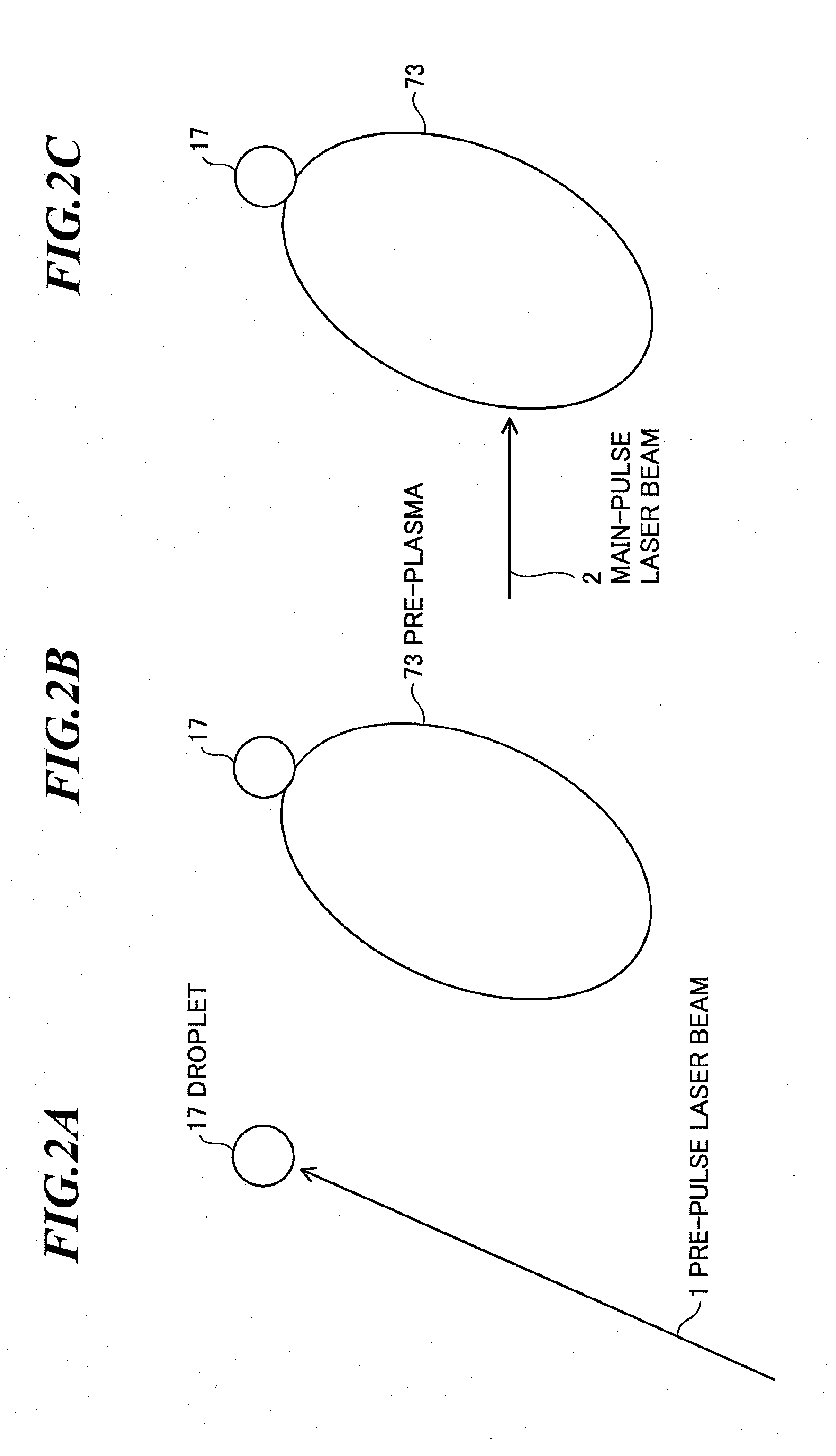

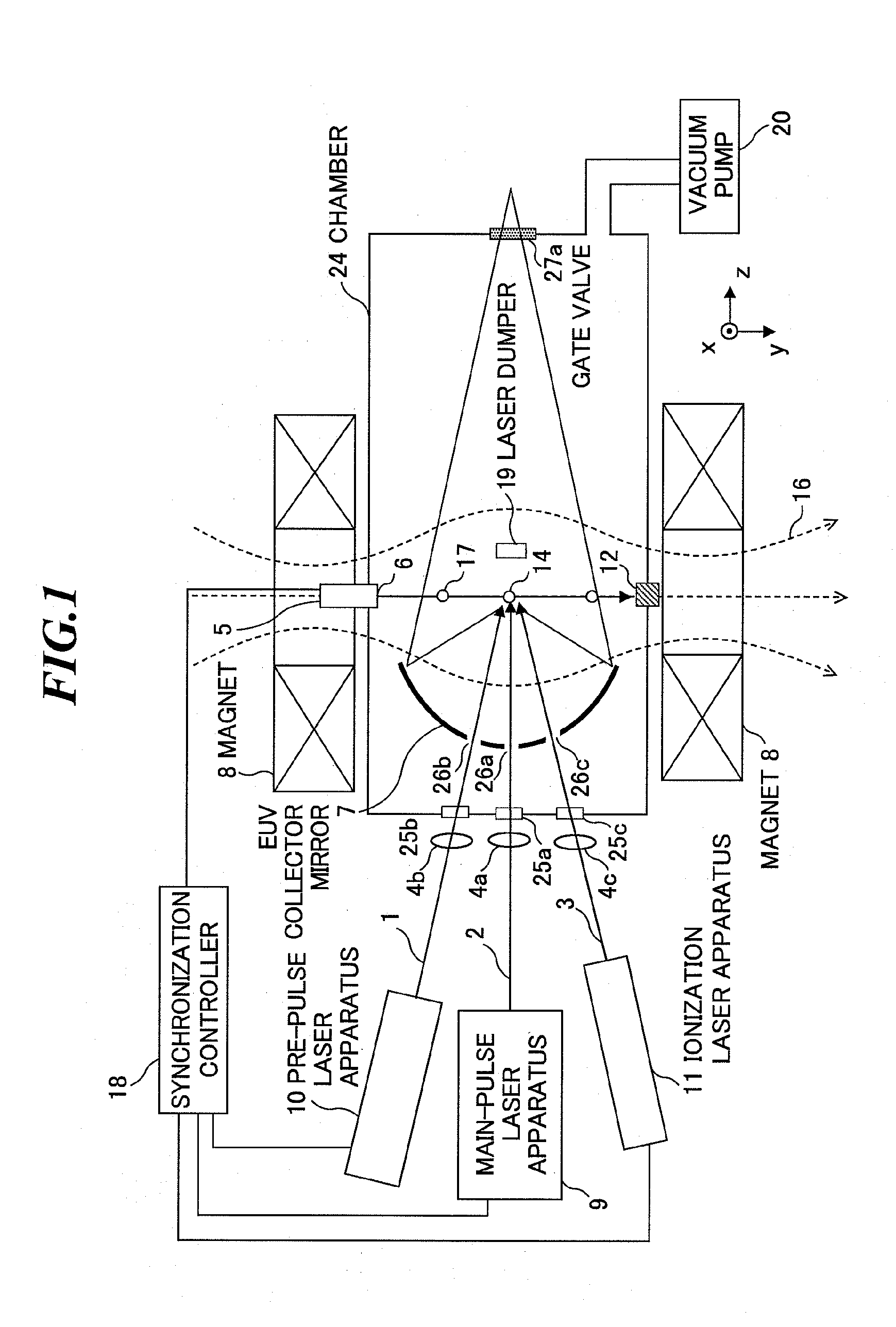

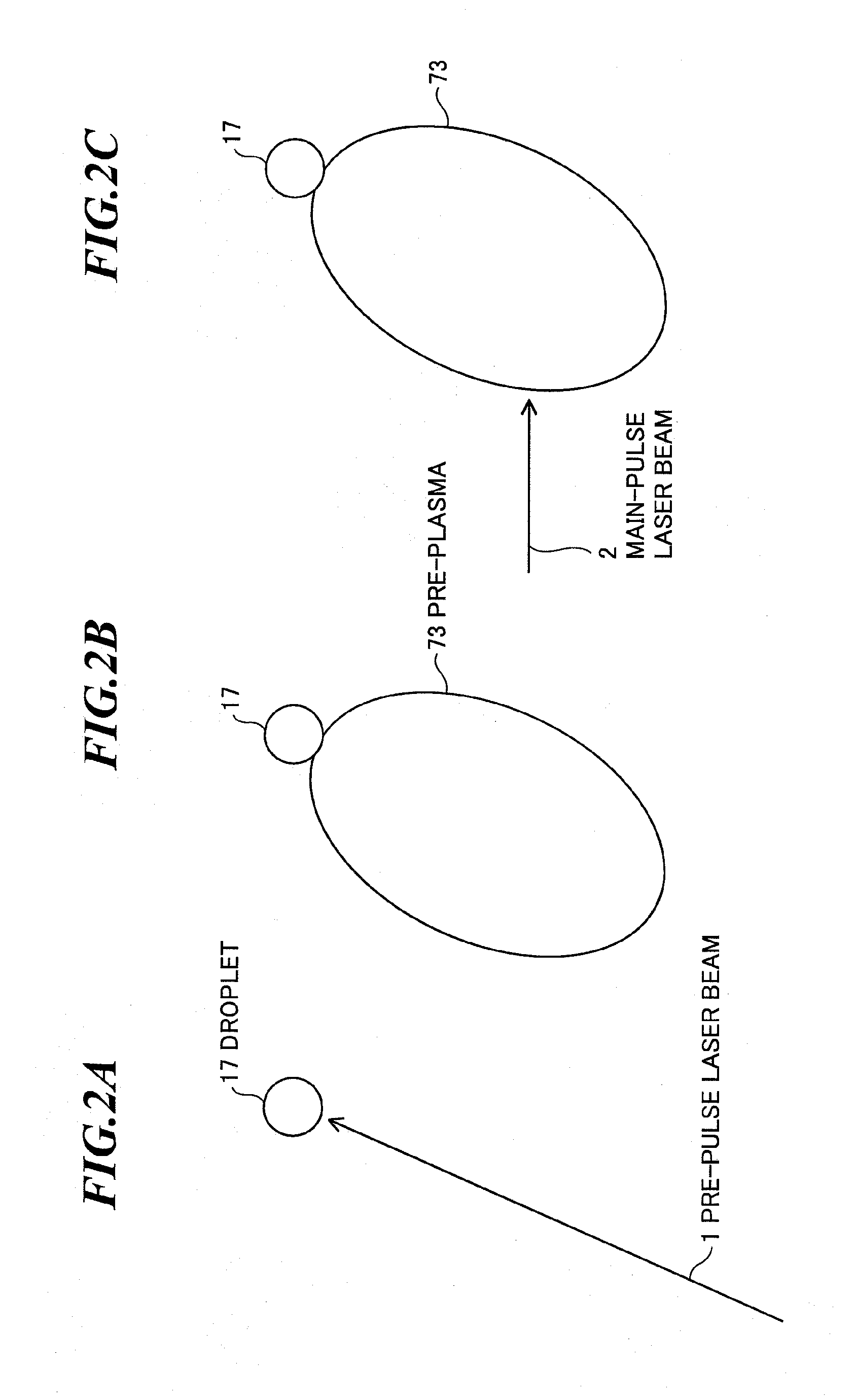

Extreme ultraviolet light source apparatus

ActiveUS20100181503A1Improve efficiencyDamage to coatingRadiation pyrometryPhotomechanical apparatusExtreme ultravioletIonization

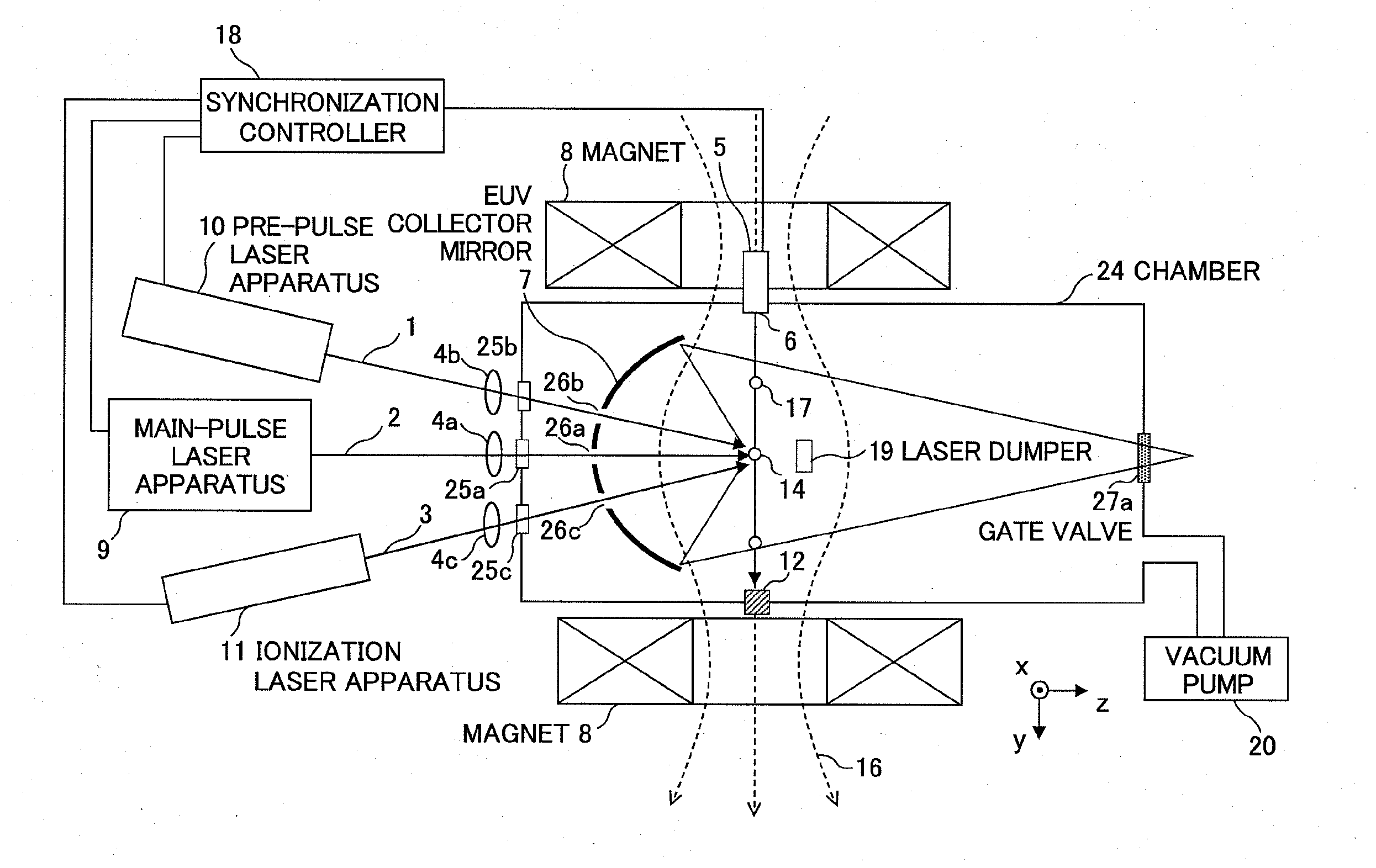

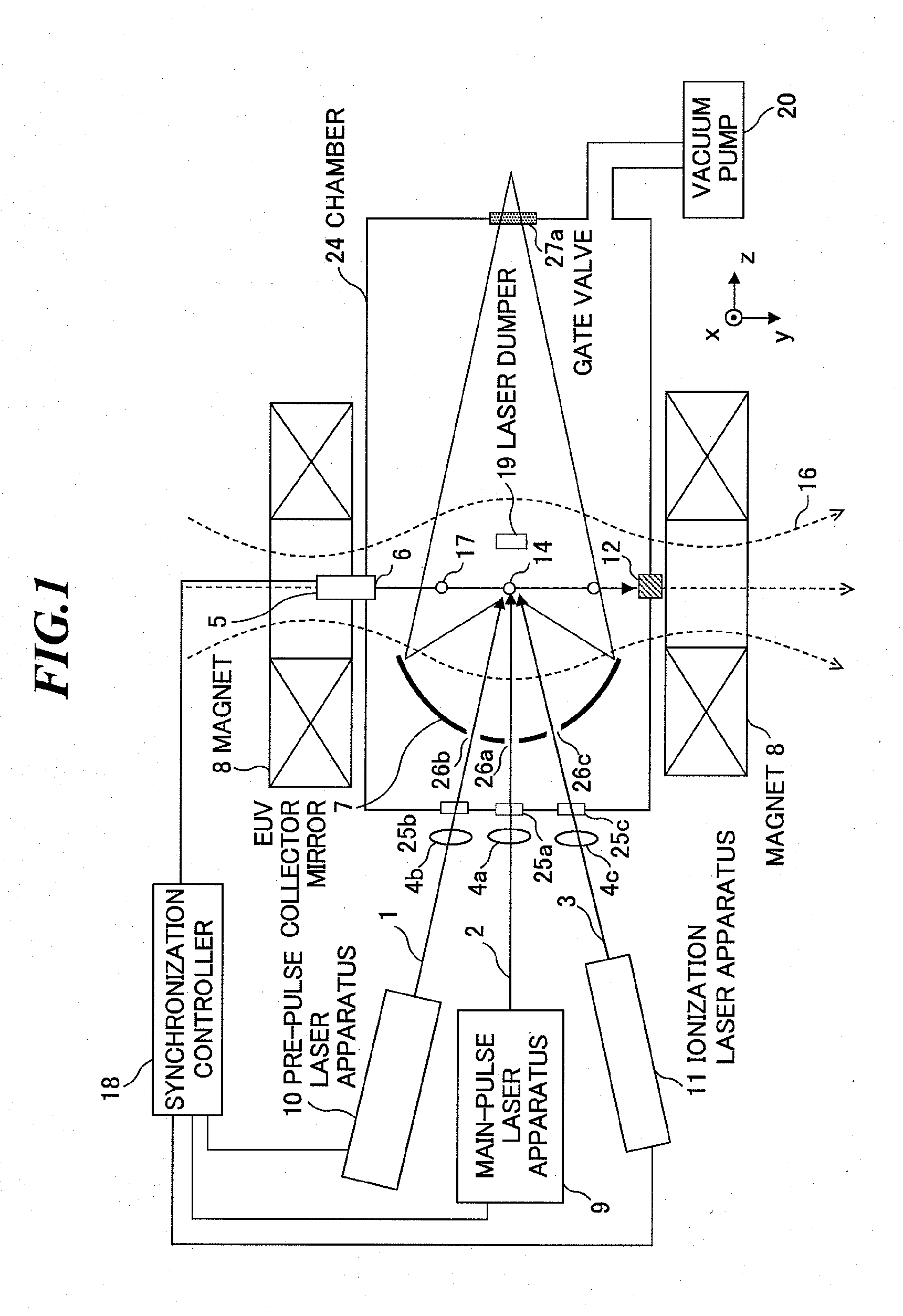

In an EUV light source apparatus, a collector mirror is protected from debris damaging a mirror coating. The EUV light source apparatus includes: a chamber in which extreme ultraviolet light is generated; a target supply unit for supplying a target material into the chamber; a plasma generation laser unit for irradiating the target material within the chamber with a plasma generation laser beam to generate plasma; an ionization laser unit for irradiating neutral particles produced at plasma generation with an ionization laser beam to convert the neutral particles into ions; a collector mirror for collecting the extreme ultraviolet light radiated from the plasma; and a magnetic field or electric field forming unit for forming a magnetic field or an electric field within the chamber so as to trap the ions.

Owner:GIGAPHOTON

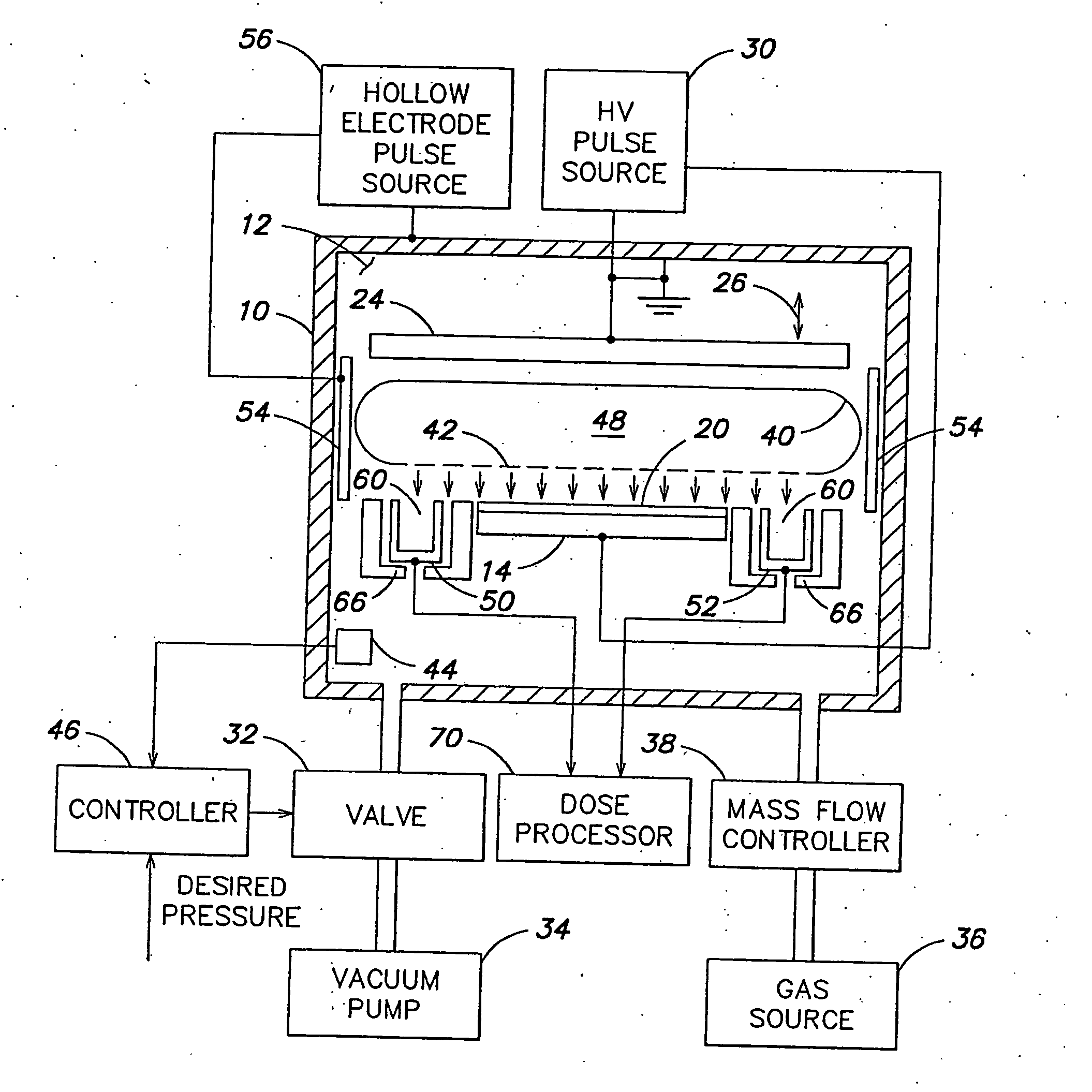

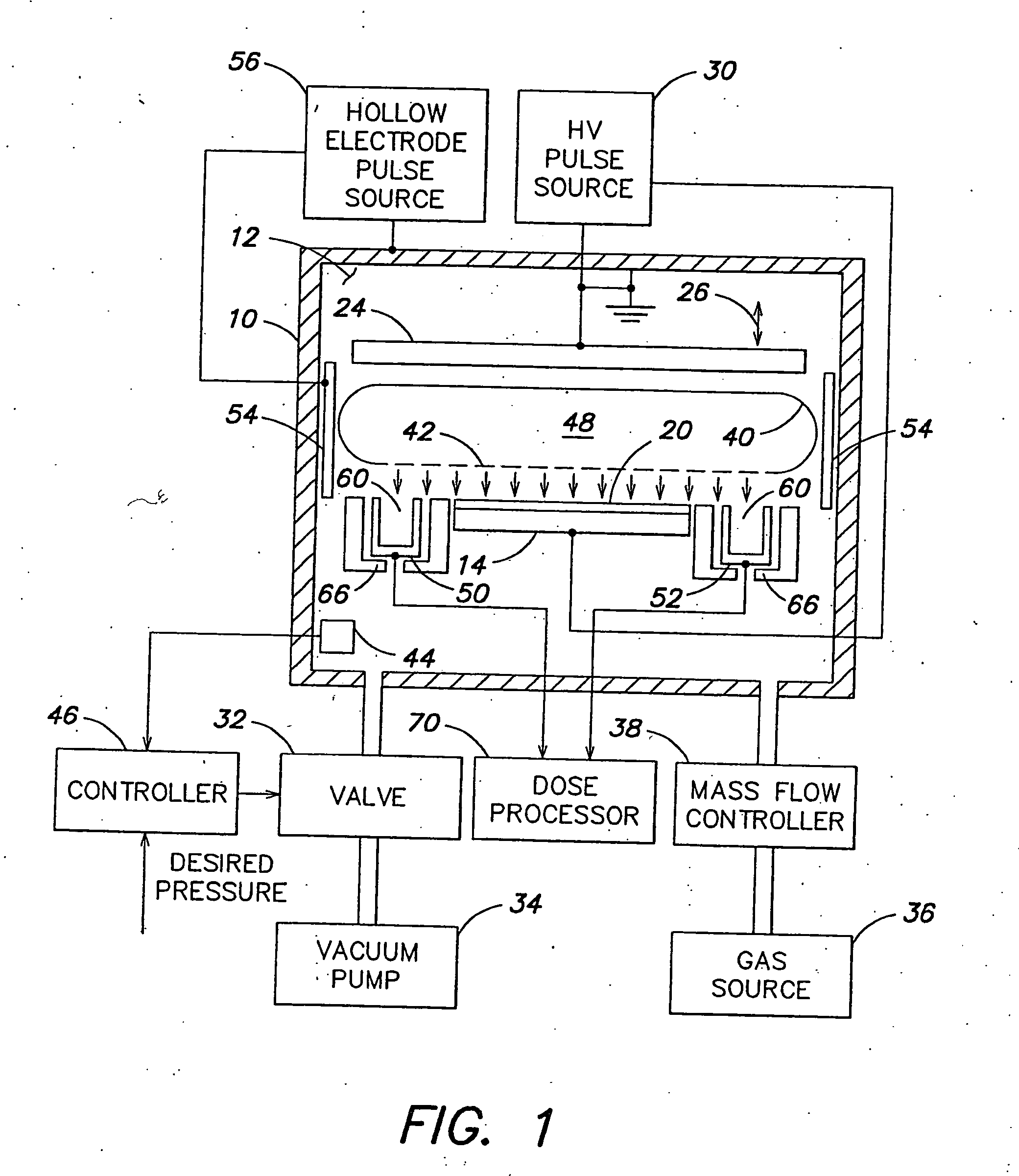

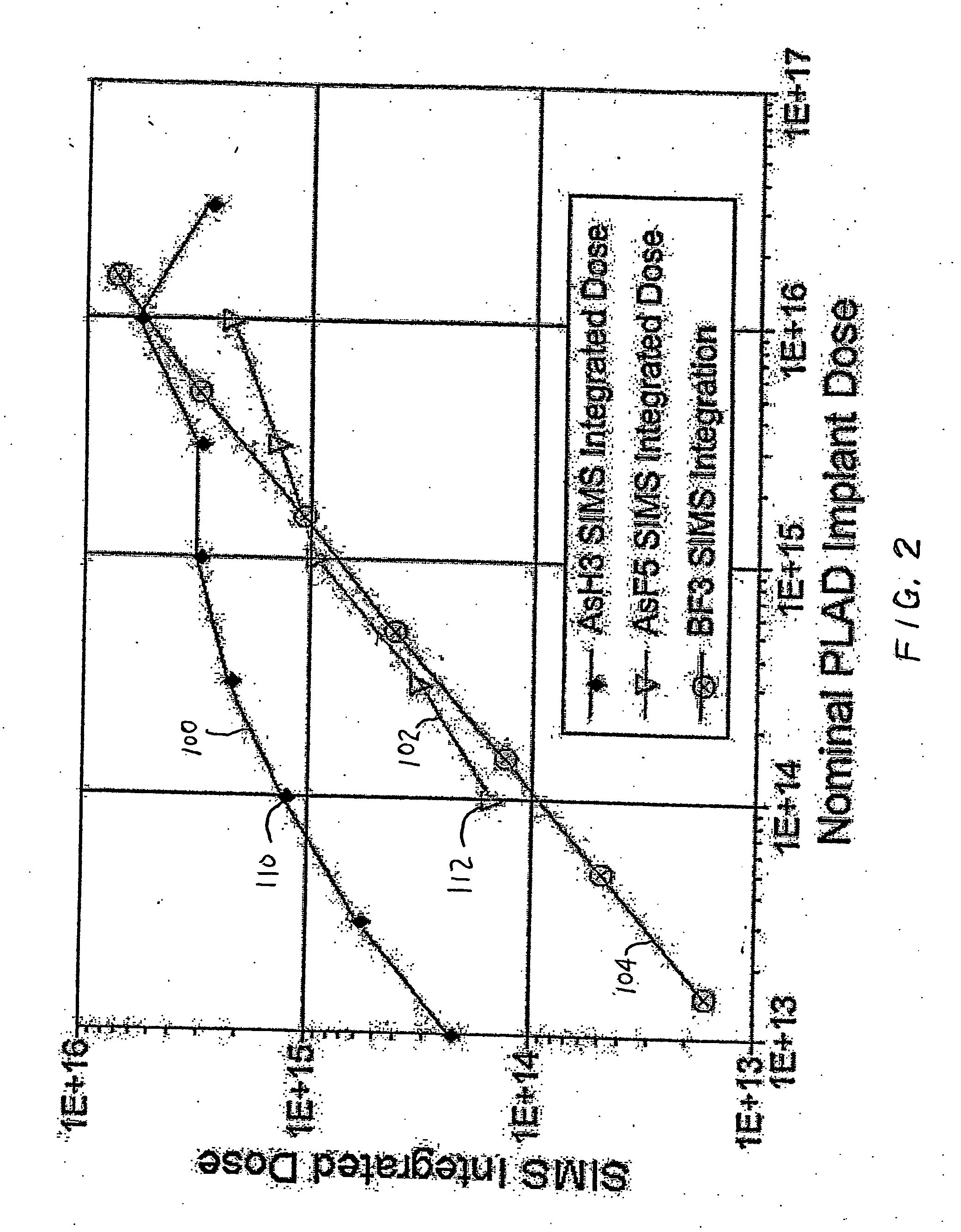

Plasma implantation using halogenated dopant species to limit deposition of surface layers

Methods and apparatus for plasma implantation of a workpiece, such as a semiconductor wafer, are provided. A method includes introducing into a plasma doping chamber a dopant gas selected from the group consisting of PF3, AsF3, AsF5 and mixtures thereof, forming in the plasma doping chamber a plasma containing ions of the dopant gas, the plasma having a plasma sheath at or near a surface of the workpiece, and accelerating the dopant gas ions across the plasma sheath toward the workpiece, wherein the dopant gas ions are implanted into the workpiece. The selected dopant gas limits deposition of neutral particles on the workpiece.

Owner:VARIAN SEMICON EQUIP ASSOC INC

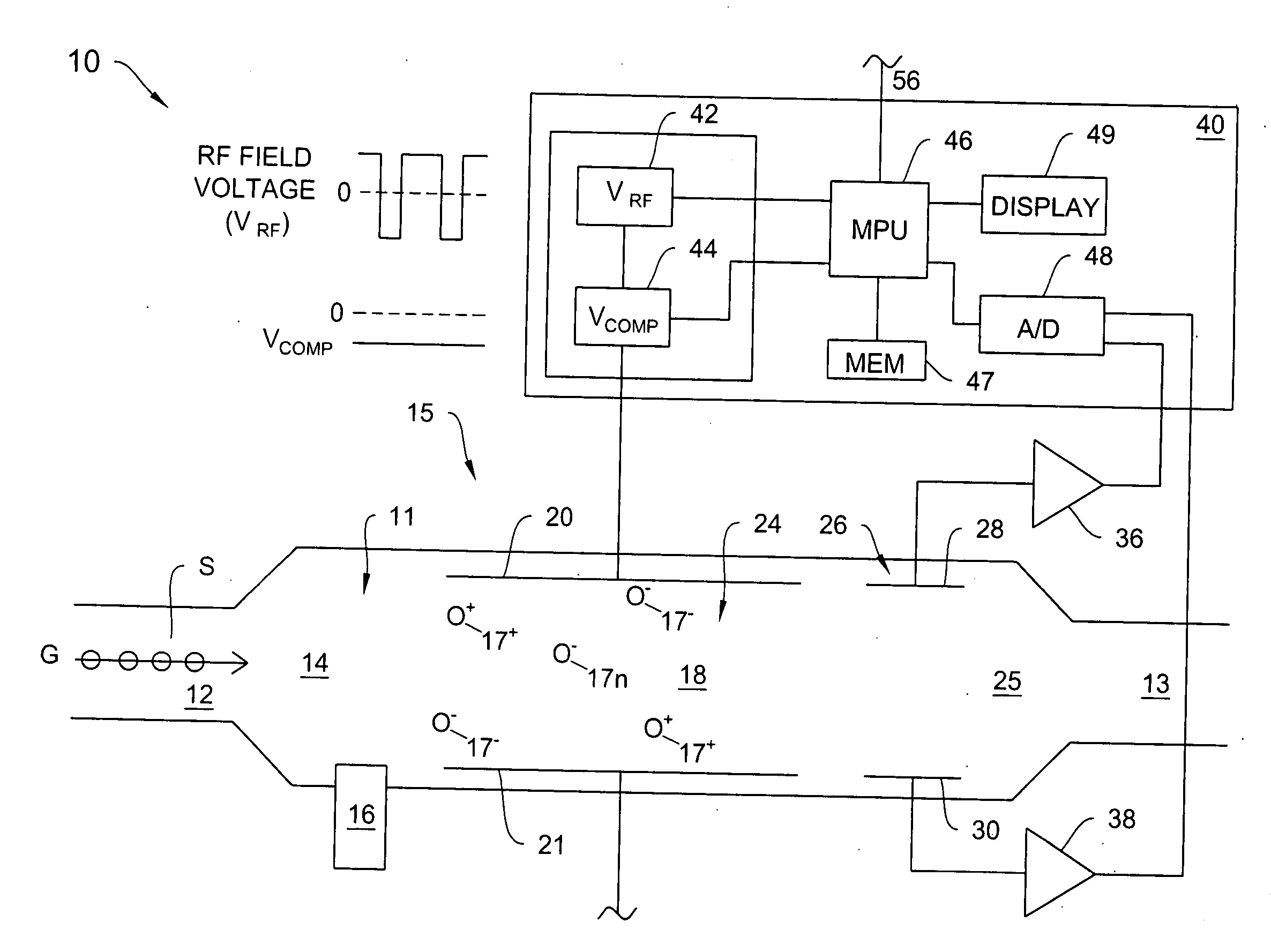

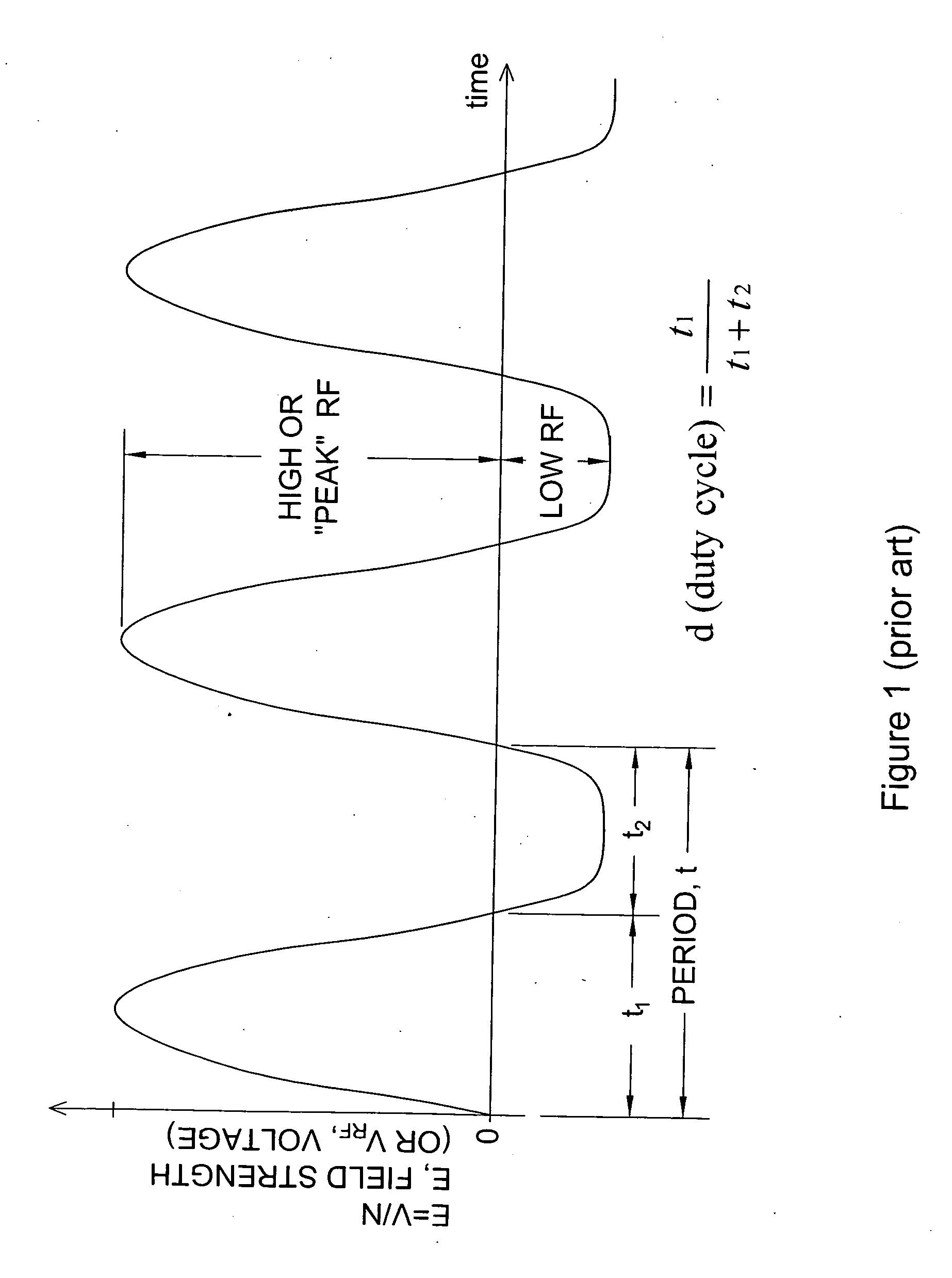

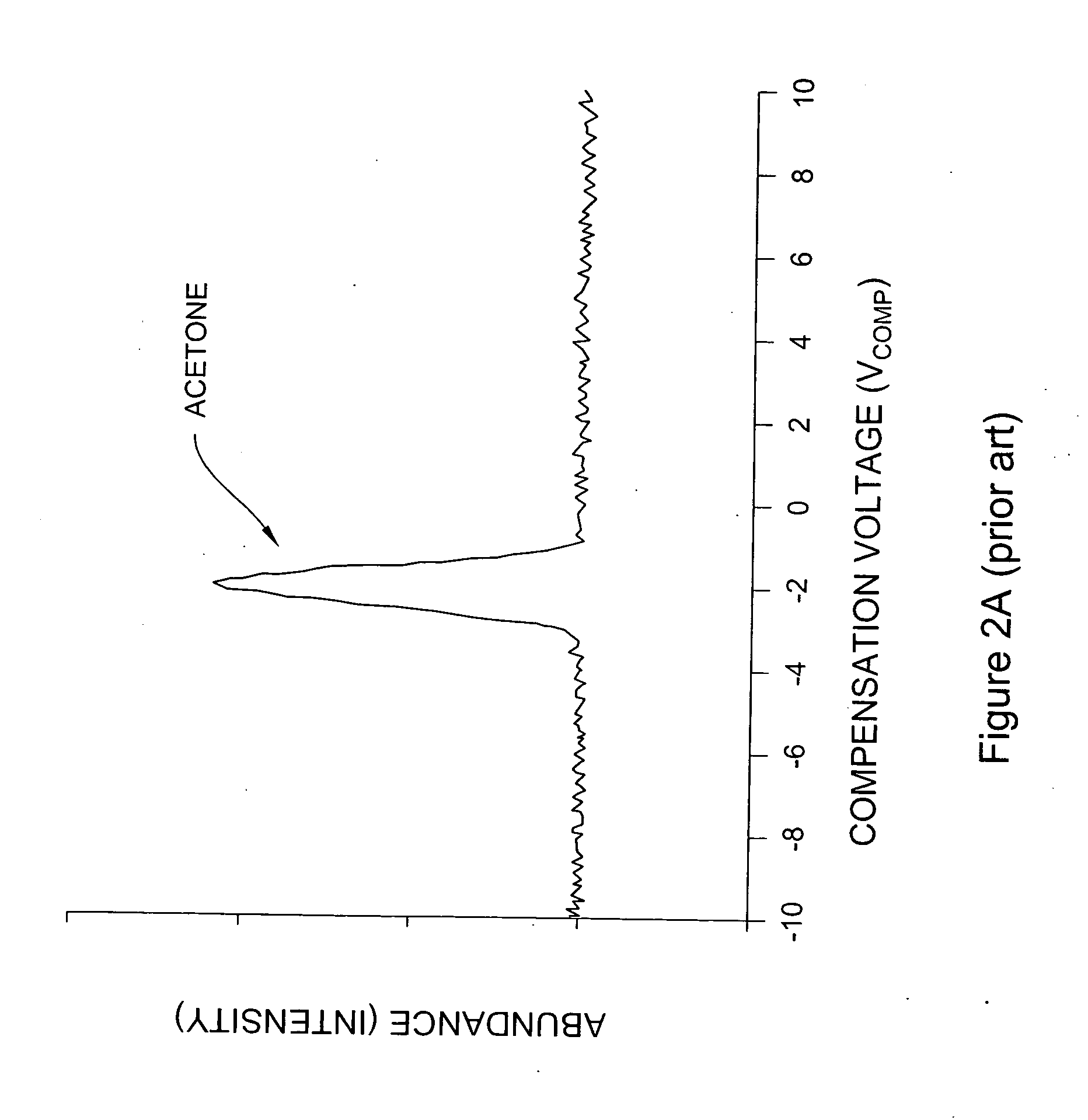

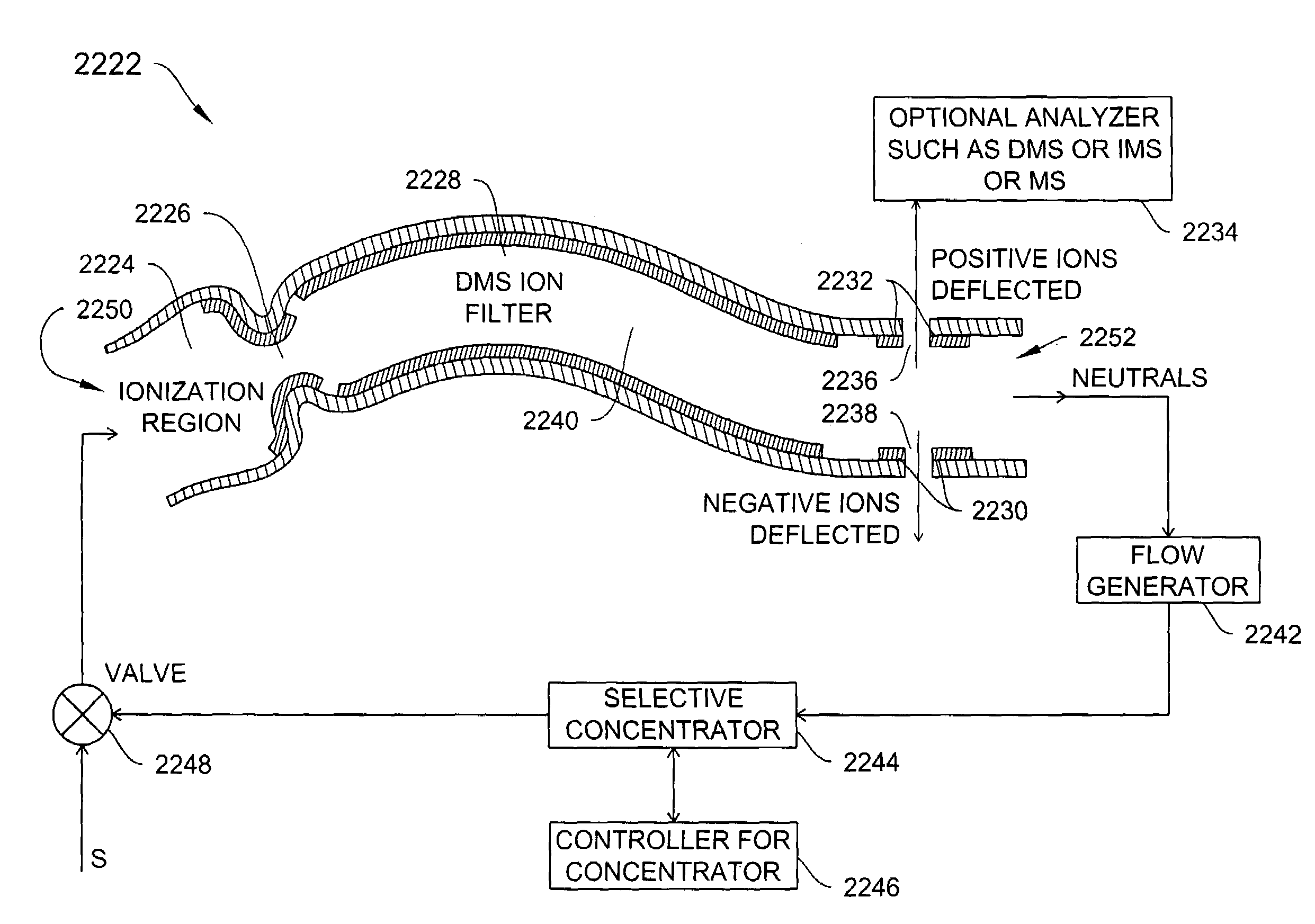

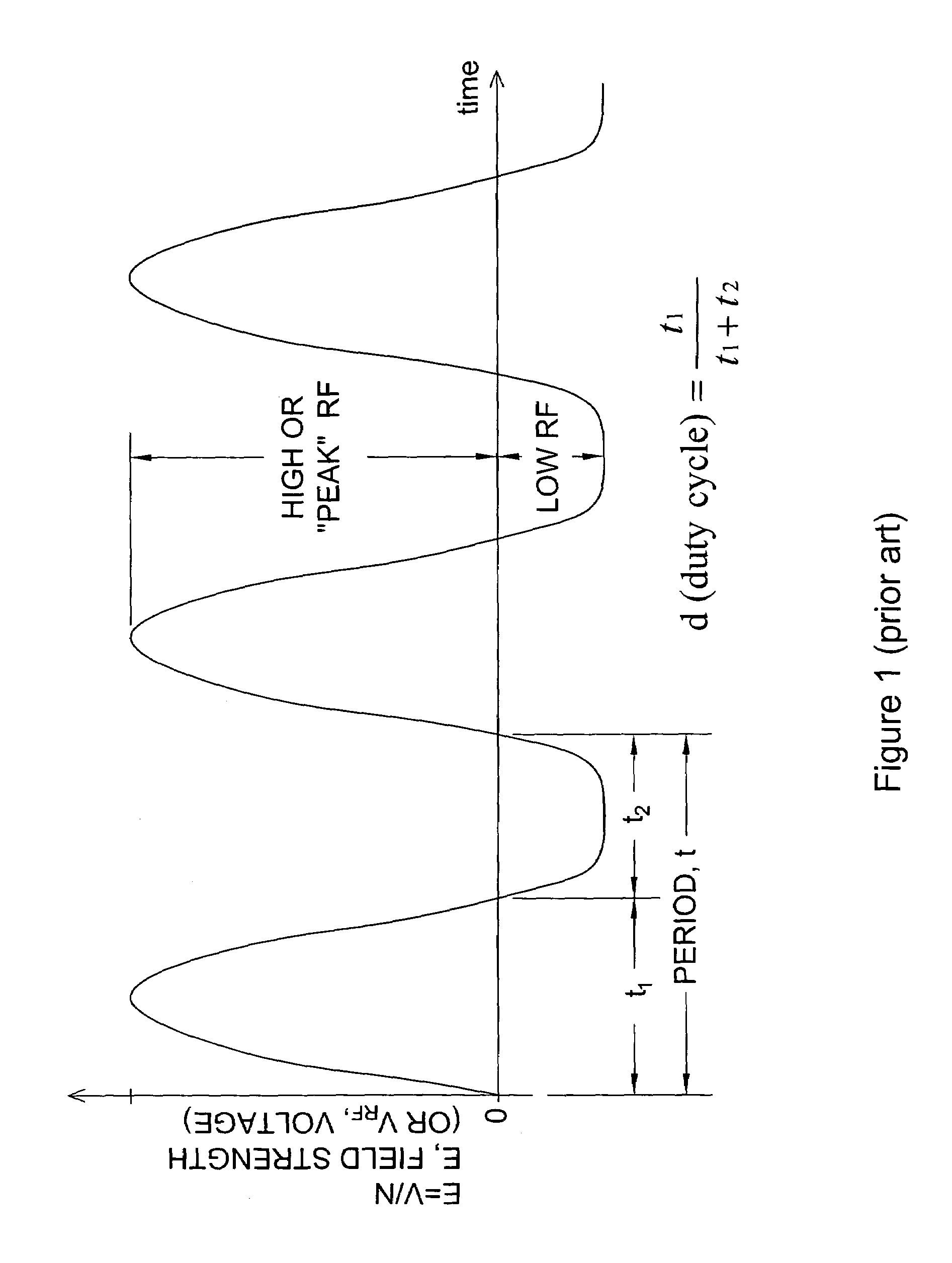

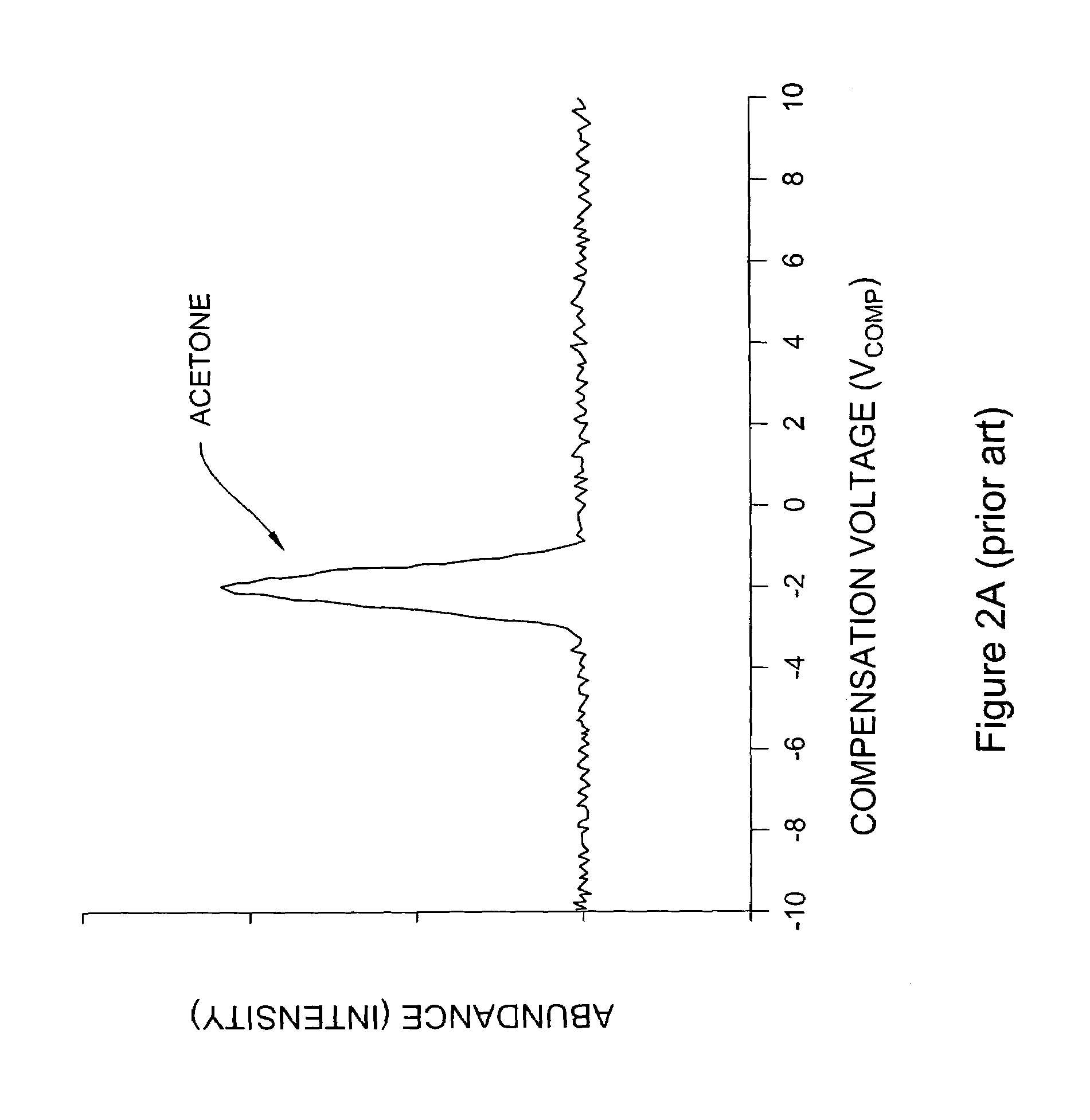

Method and apparatus for enhanced ion mobility based sample analysis using various analyzer configurations

InactiveUS20070176092A1Easy to analyzeEasy to identifyTime-of-flight spectrometersMaterial analysis by electric/magnetic meansAtomic physicsIon flow

A system for analyzing one or more ion species of a sample including a first ion mobility filter associated with a first flow path for passing first ions of the sample, a second ion mobility filter associated with a second flow path for passing second ions of the sample, a first outlet from the first flow path for passing a portion of the first ions from the first flow path to the second flow path, and a first outlet from the second flow path for removing neutral particles from the second flow path where the first outlet from the second flow path is upstream of the second ion mobility filter in relation to the ion flow in the second flow path.

Owner:DH TECH DEVMENT PTE

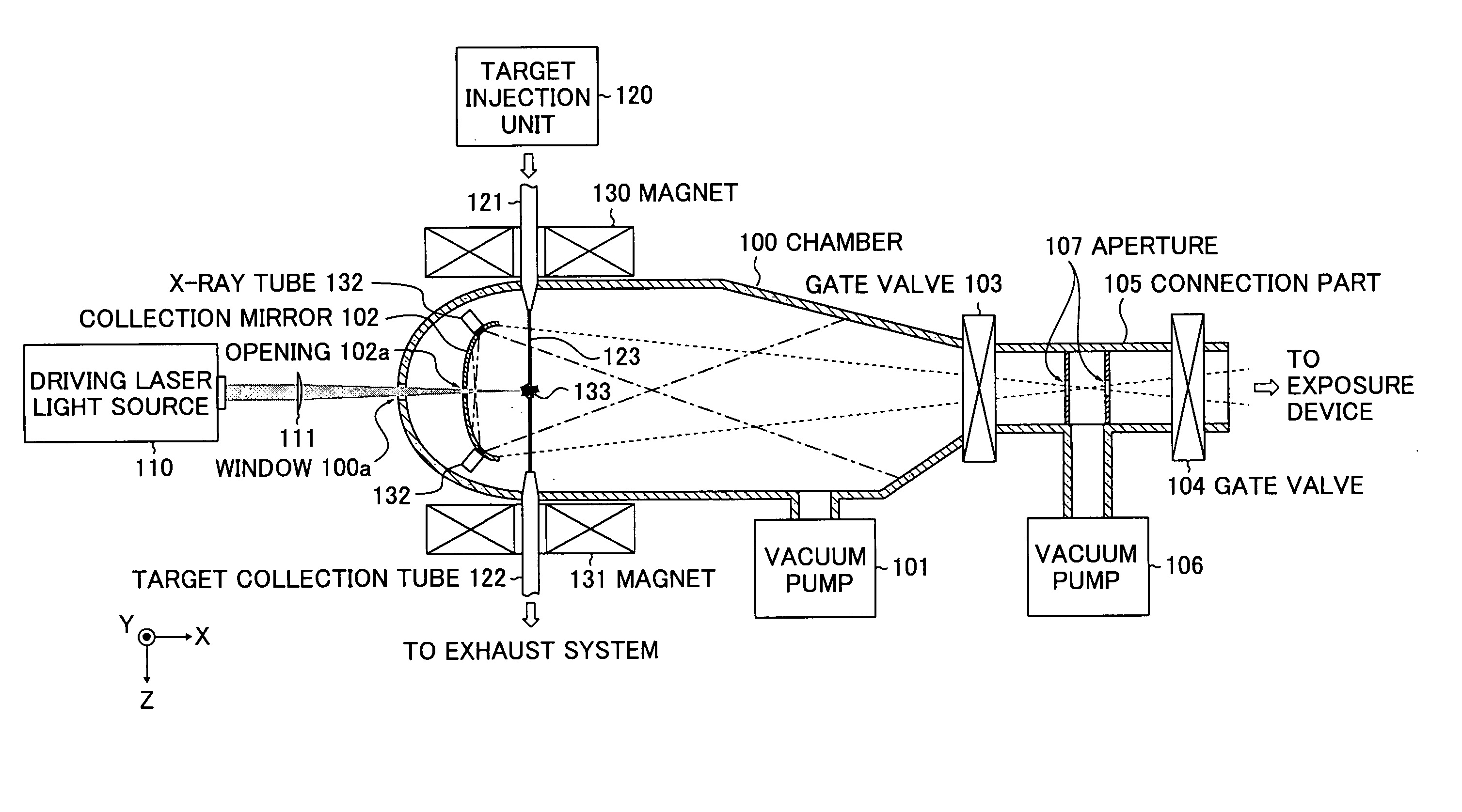

Extreme ultra violet light source device

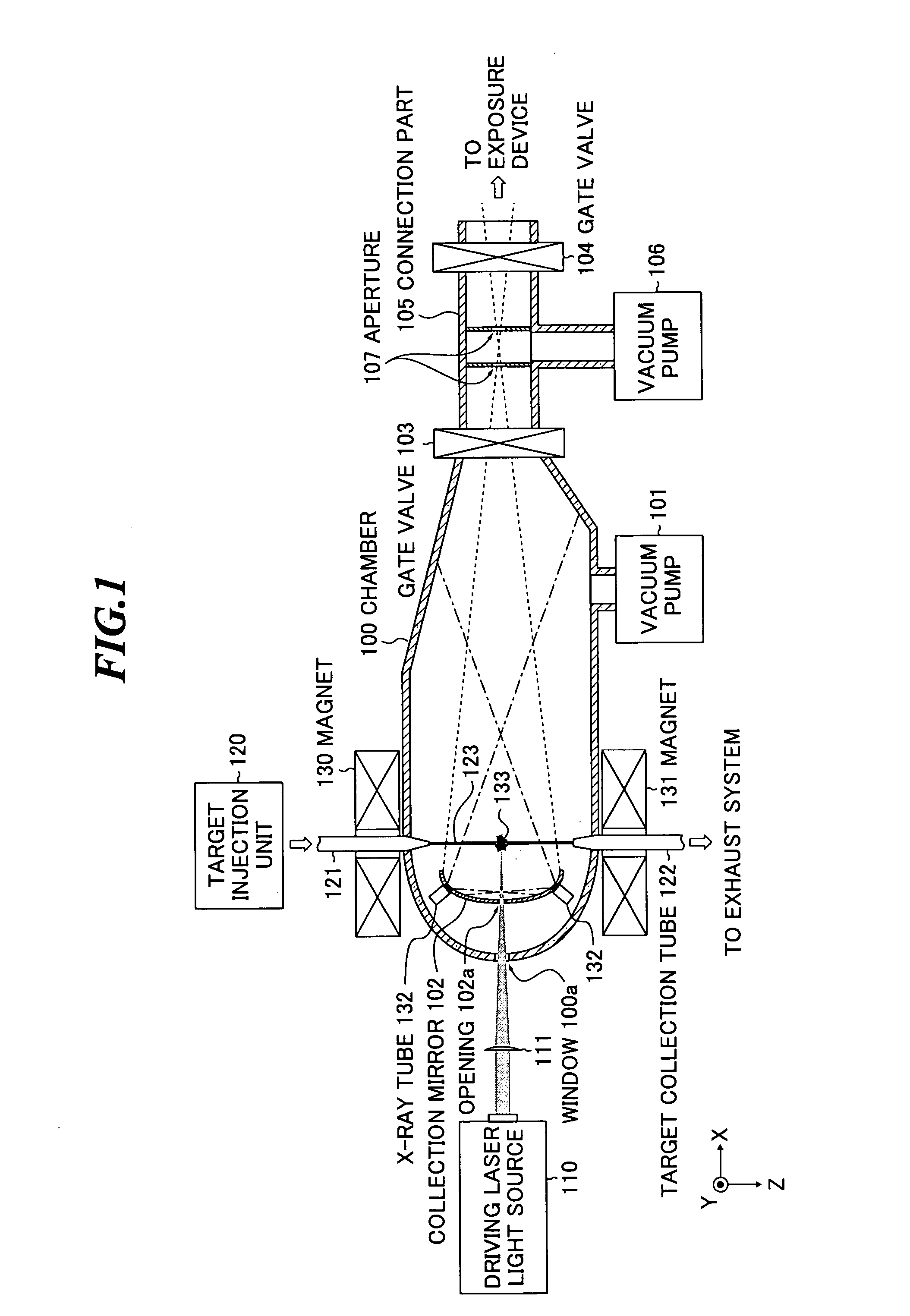

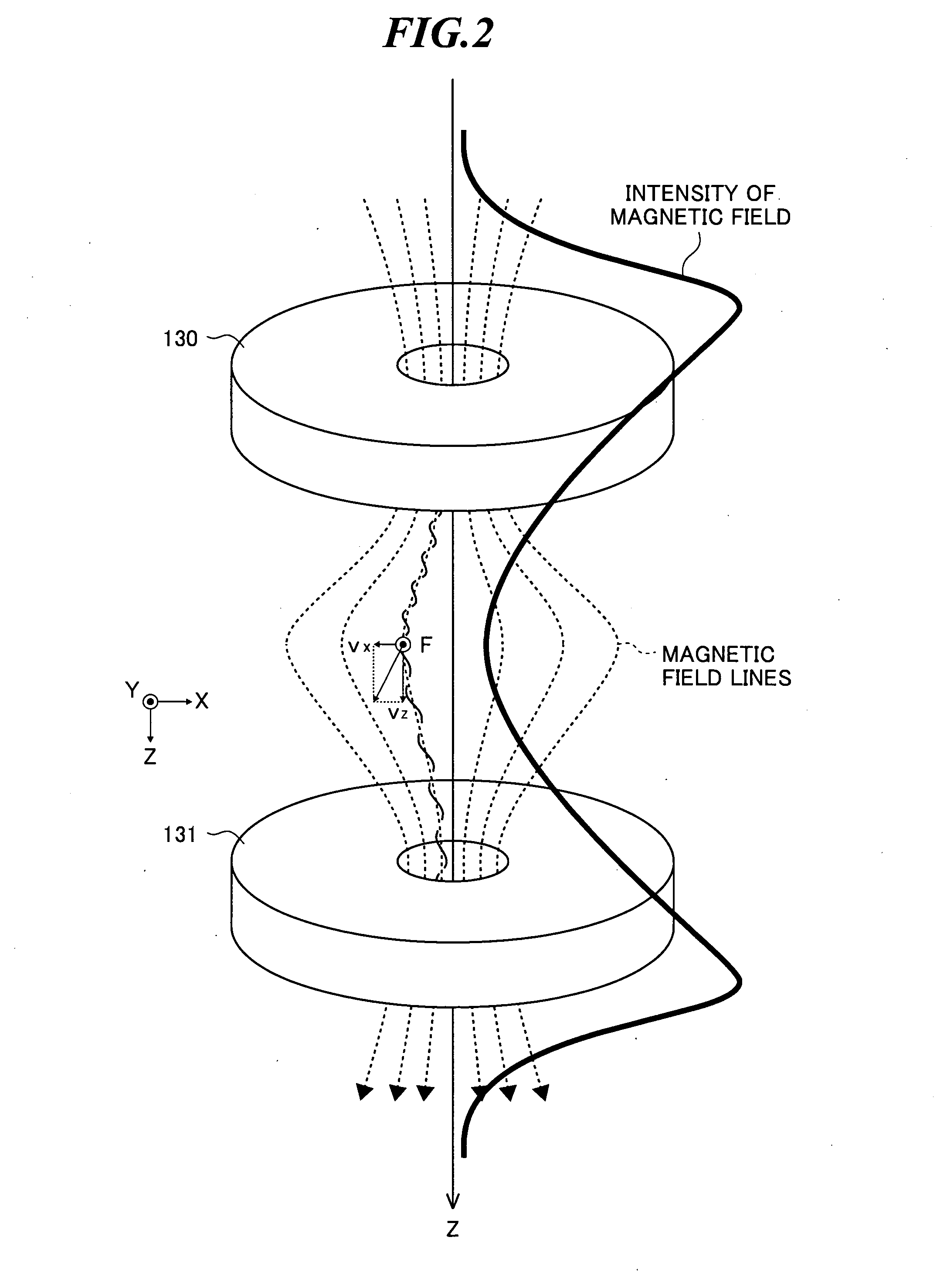

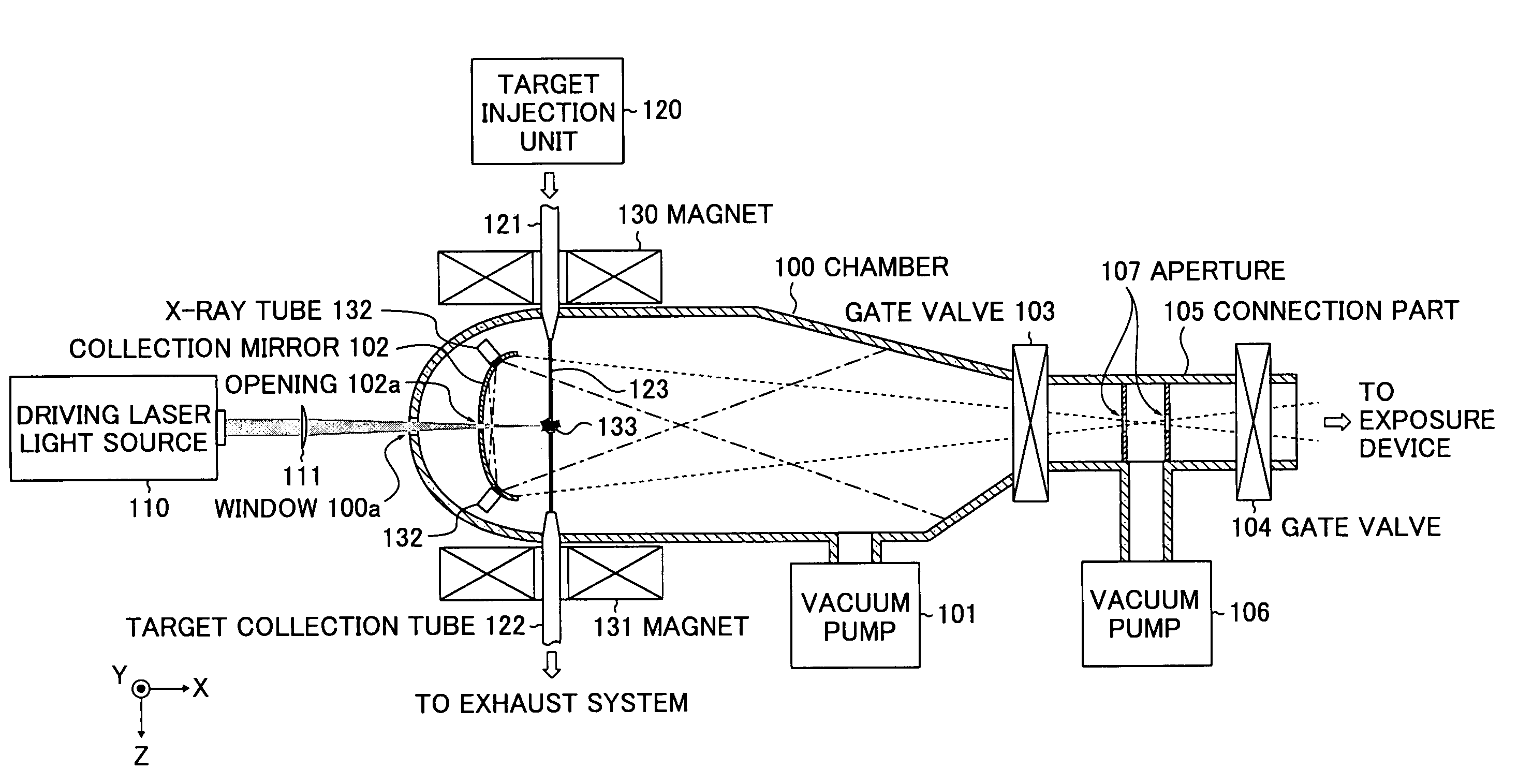

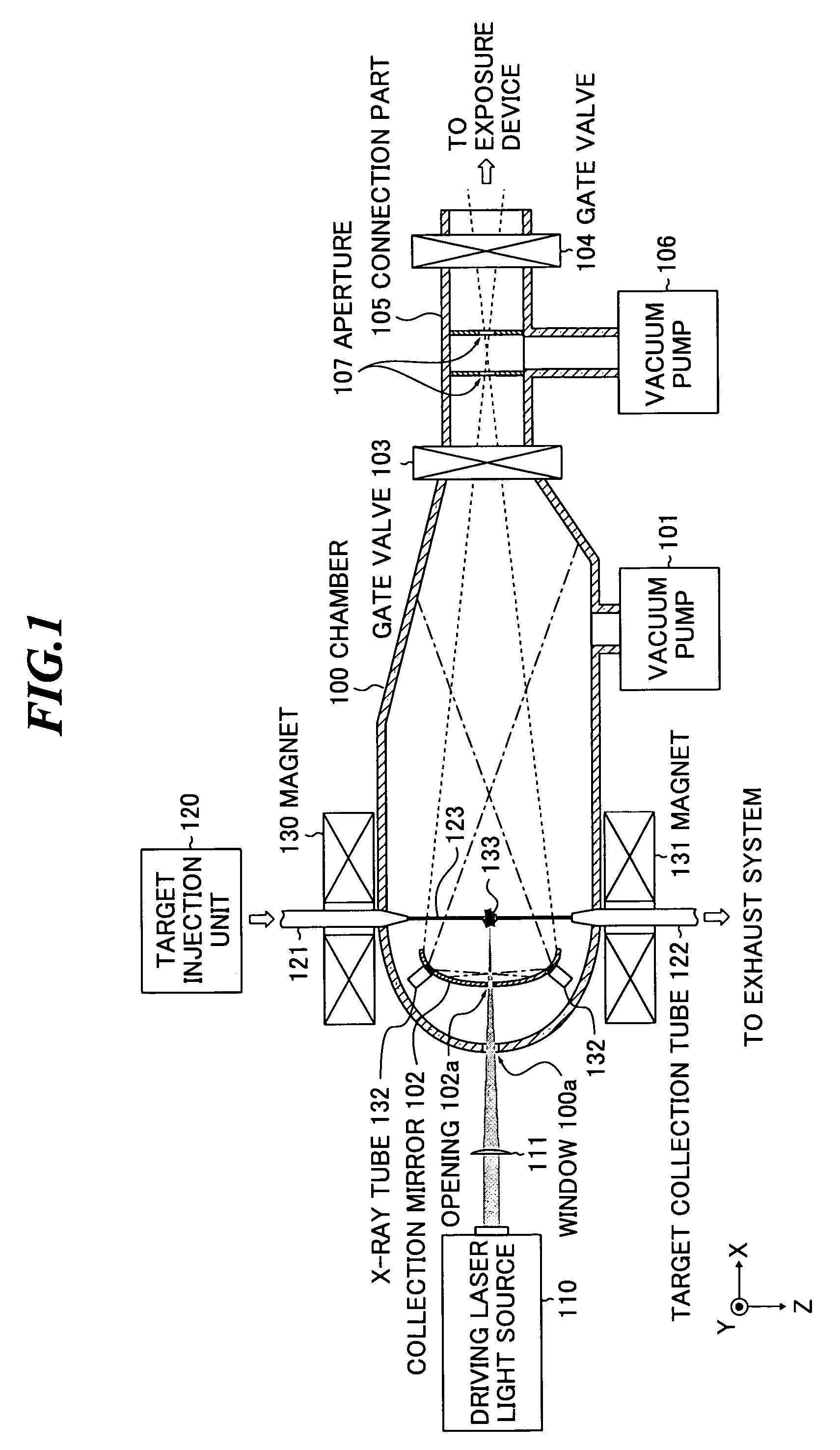

ActiveUS20060186356A1Extending the life of a collection mirrorLow costRadiation pyrometryNanoinformaticsX-rayLaser light

An EUV light source device for protecting a collection mirror from debris that is considered harmful to a mirror coating. The EUV light source device includes: a chamber in which extreme ultra violet light is generated; a target injection unit and a target injection nozzle that supply the chamber with a material to become the target; a laser light source that applies a laser beam to the target so as to generate plasma; a collection mirror that collects the extreme ultra violet light emitted from the plasma; an X-ray source that ionizes neutral particles included in particles emitted from the plasma into charged particles; and plural magnets that generate a magnetic field within the chamber so as to trap at least the charged particles ionized by the X-ray source.

Owner:GIGAPHOTON

Extreme ultra violet light source device

ActiveUS7271401B2Extending the life of a collection mirrorLow costRadiation pyrometryNanoinformaticsX-rayLaser light

An EUV light source device for protecting a collection mirror from debris that is considered harmful to a mirror coating. The EUV light source device includes: a chamber in which extreme ultra violet light is generated; a target injection unit and a target injection nozzle that supply the chamber with a material to become the target; a laser light source that applies a laser beam to the target so as to generate plasma; a collection mirror that collects the extreme ultra violet light emitted from the plasma; an X-ray source that ionizes neutral particles included in particles emitted from the plasma into charged particles; and plural magnets that generate a magnetic field within the chamber so as to trap at least the charged particles ionized by the X-ray source.

Owner:GIGAPHOTON

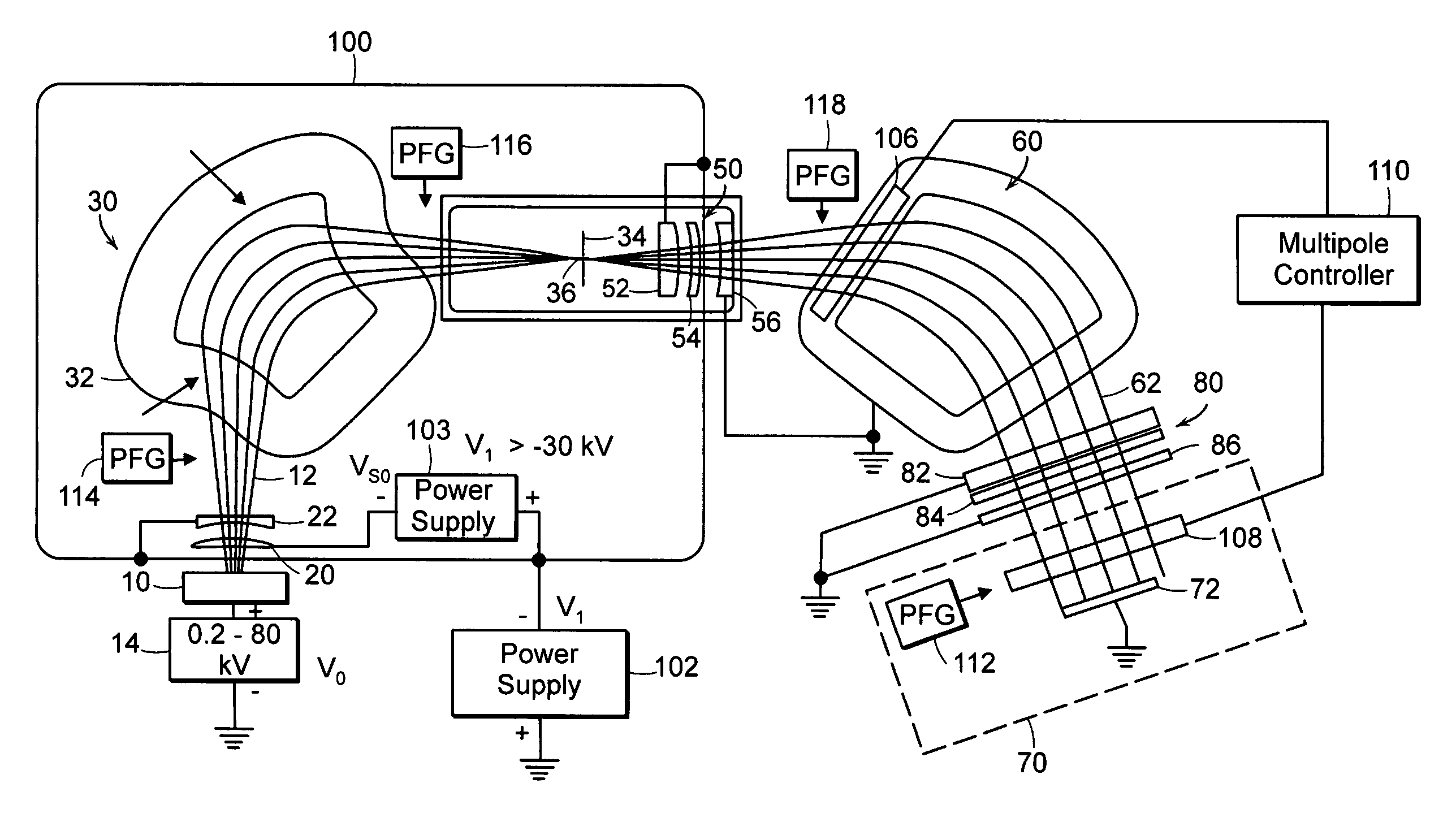

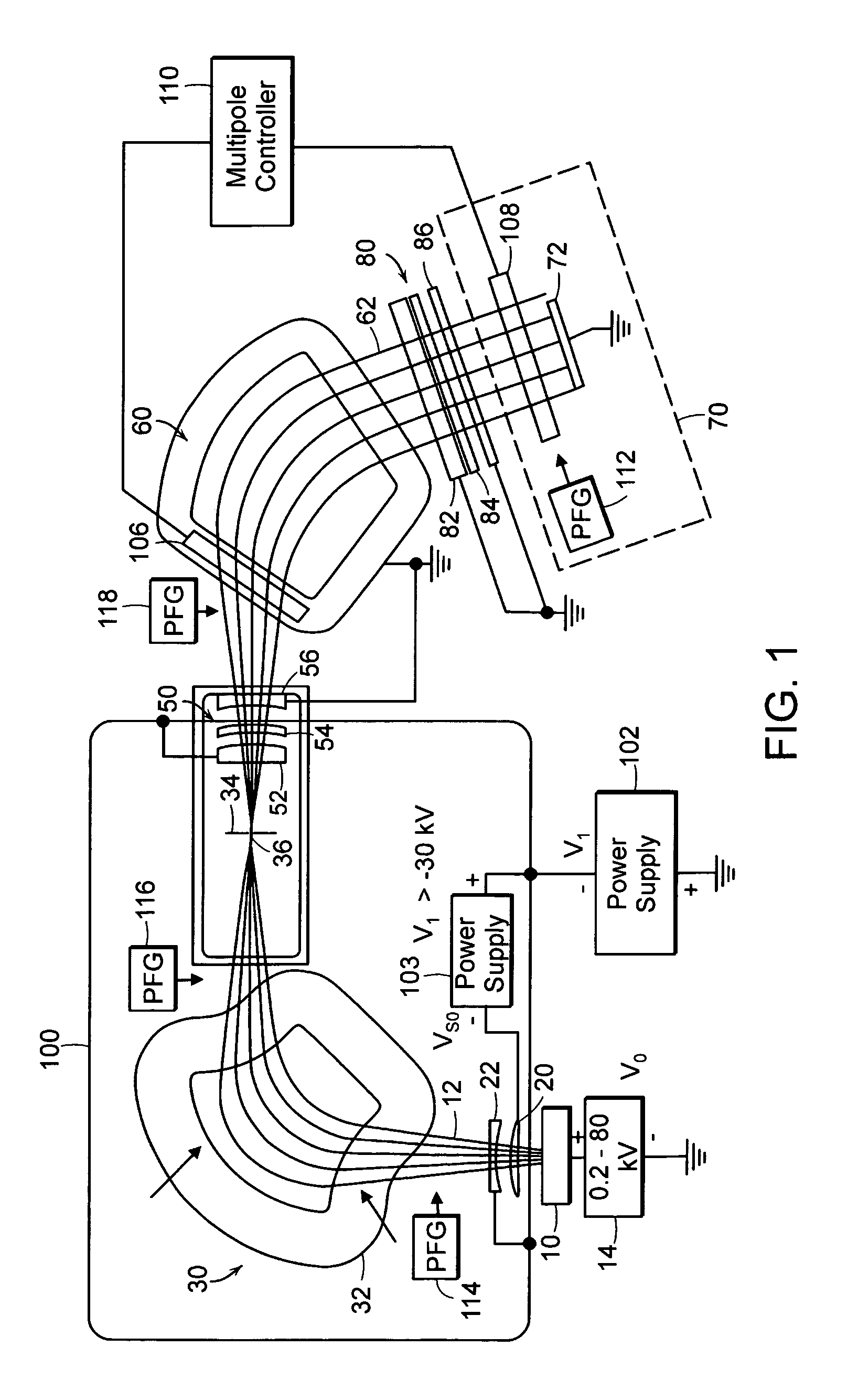

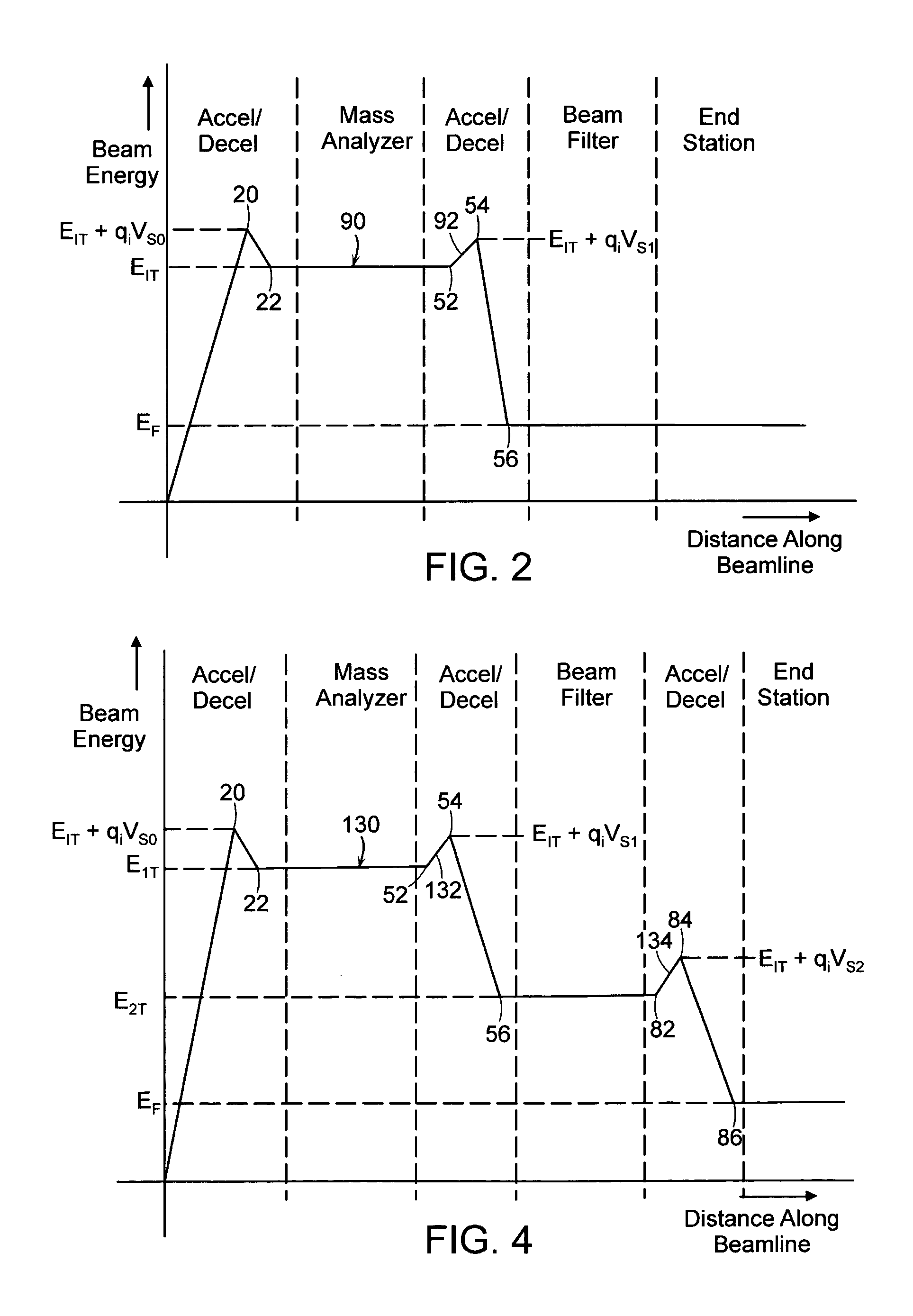

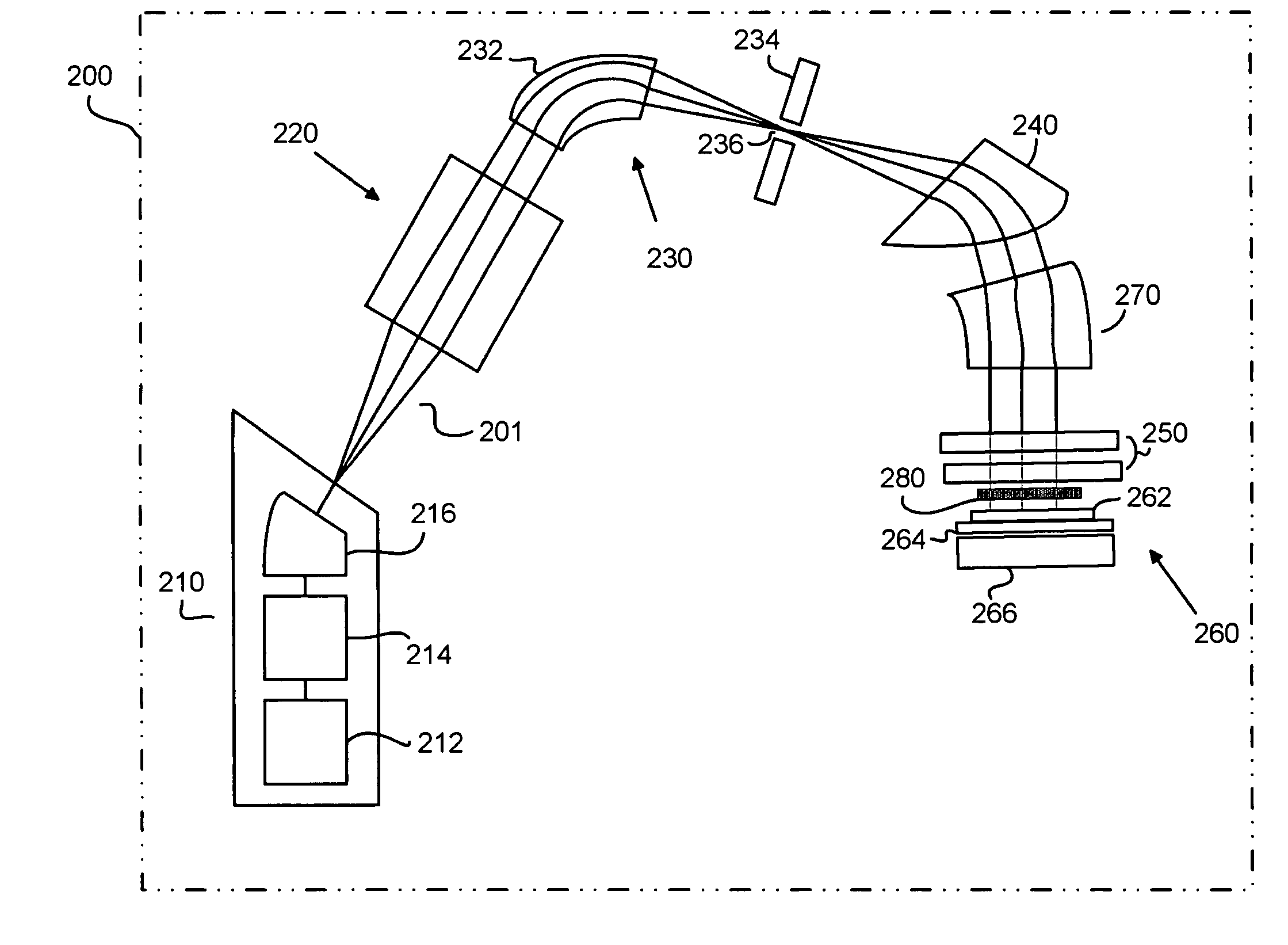

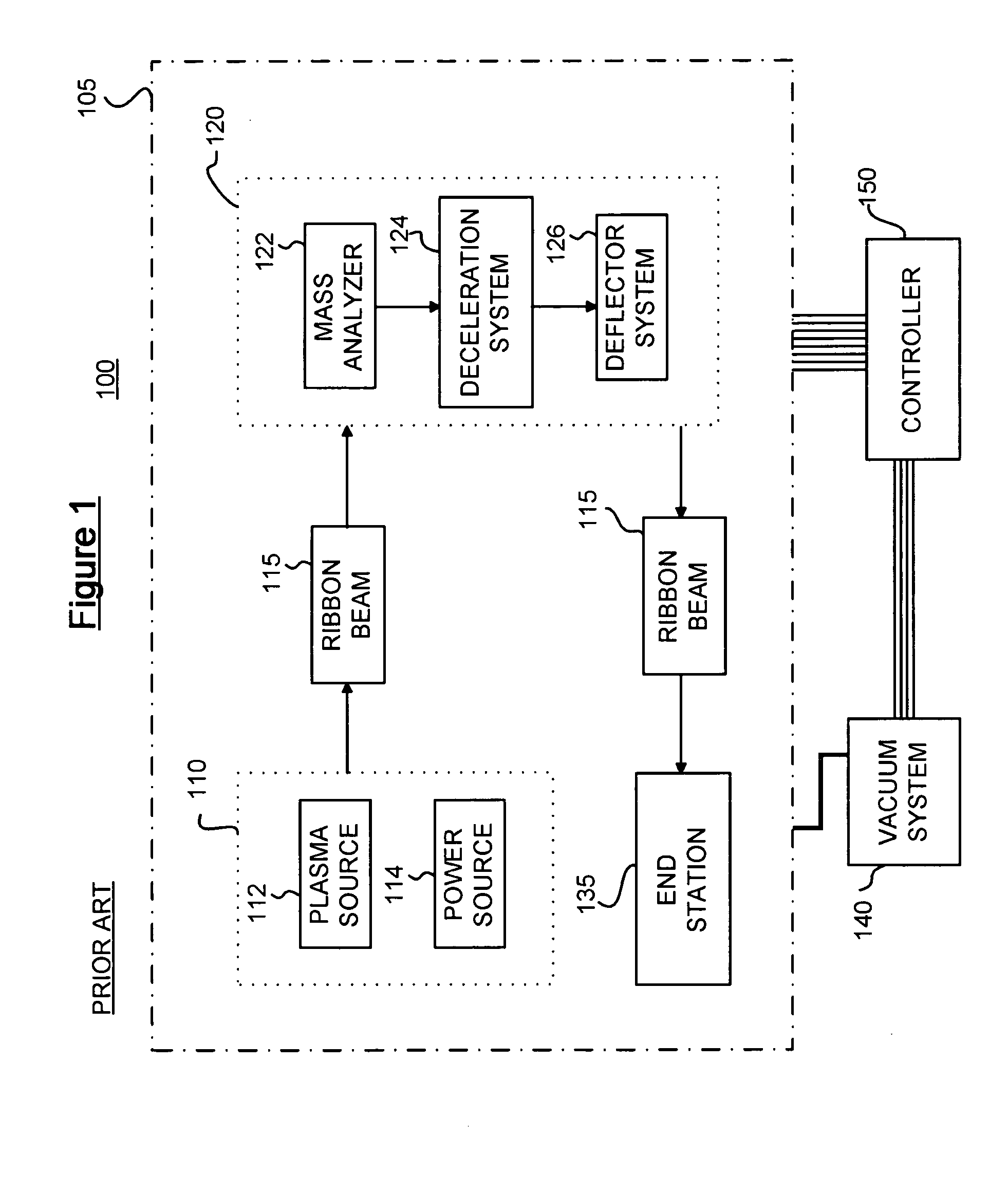

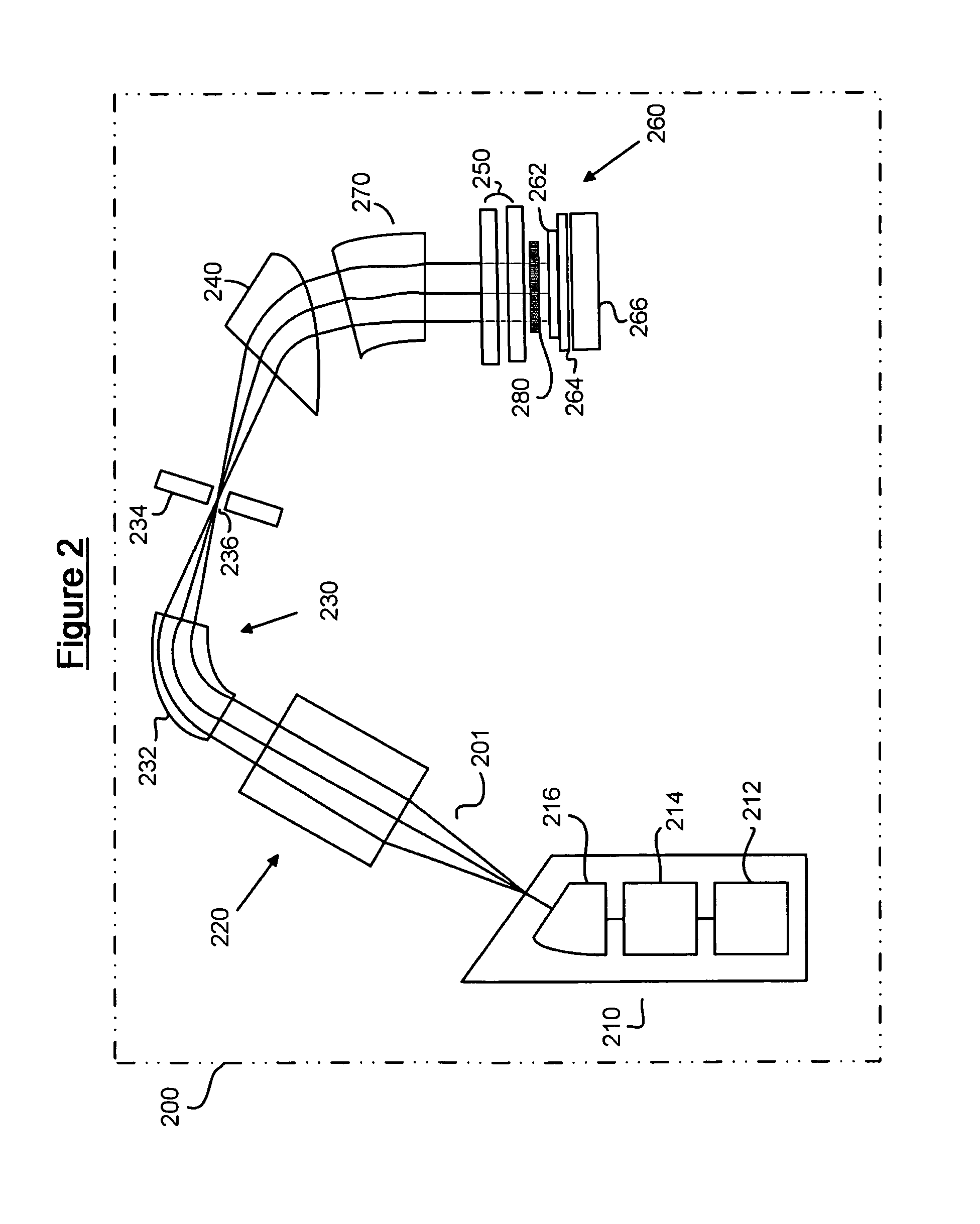

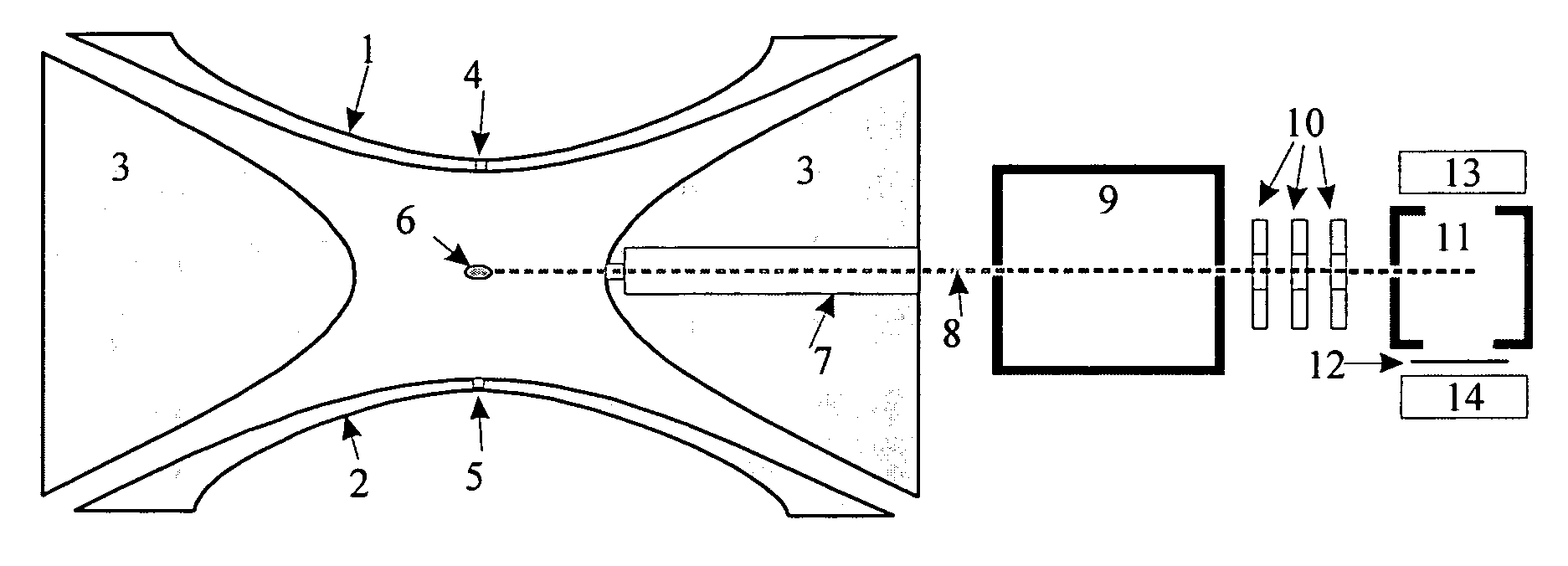

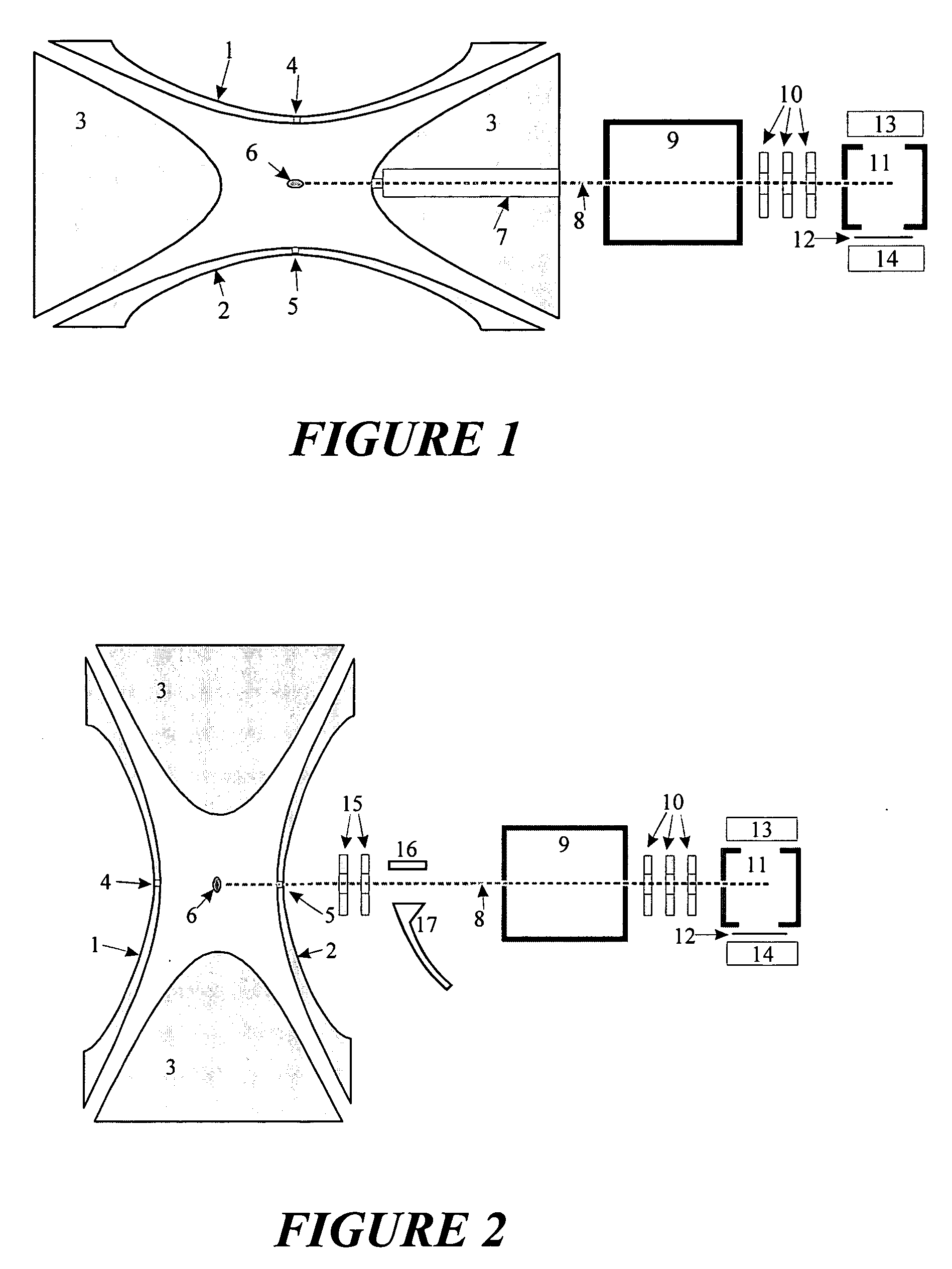

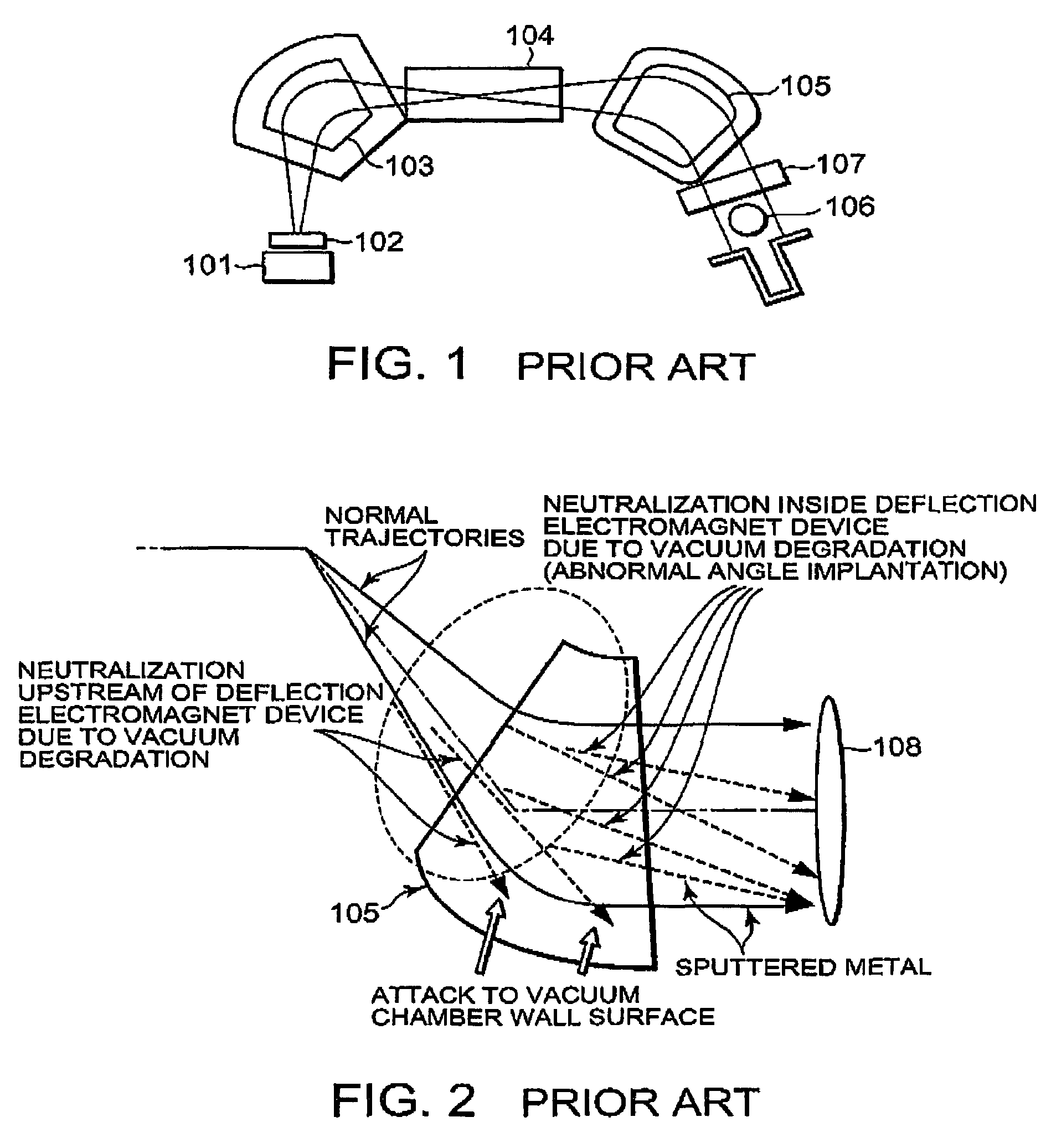

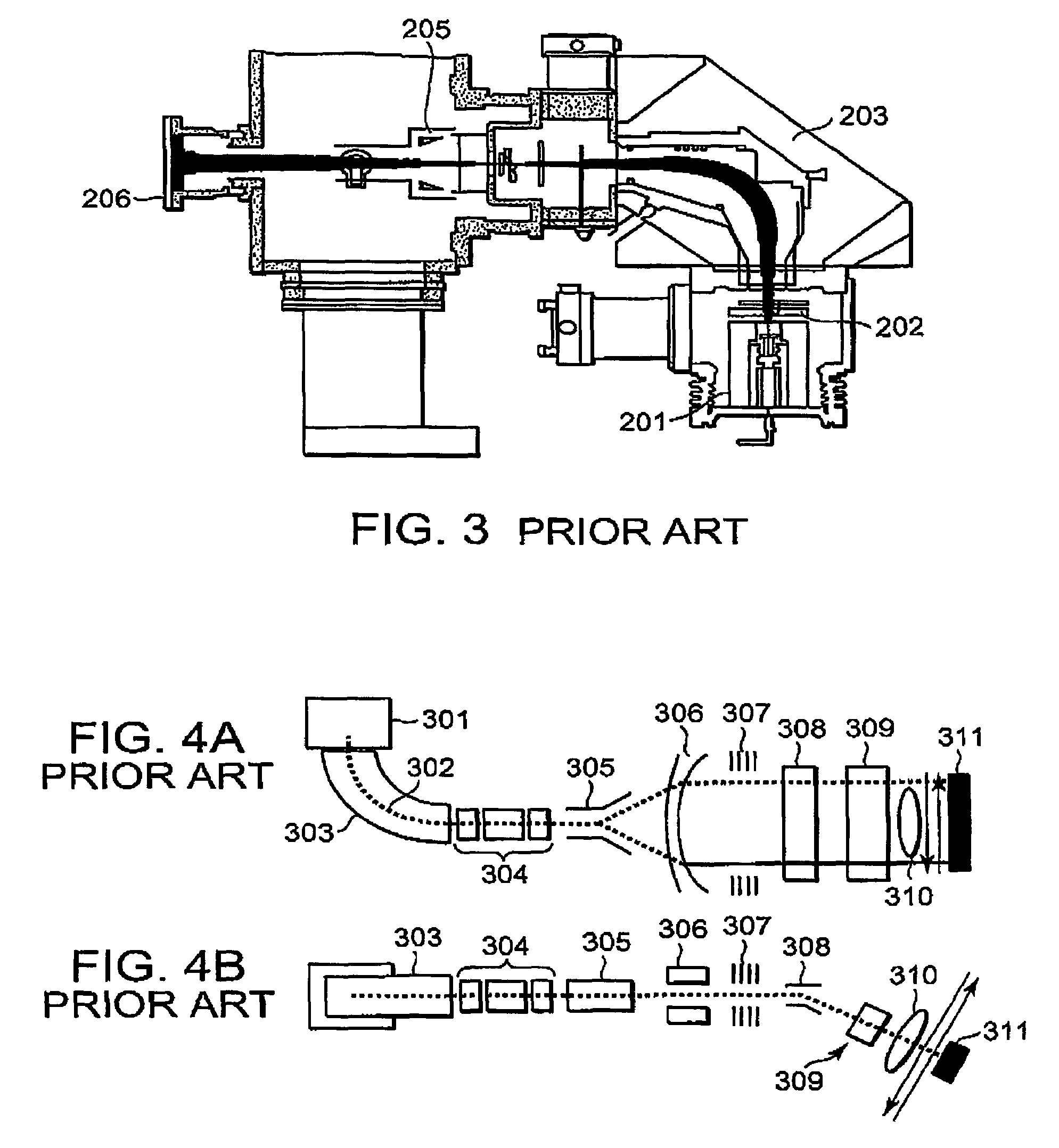

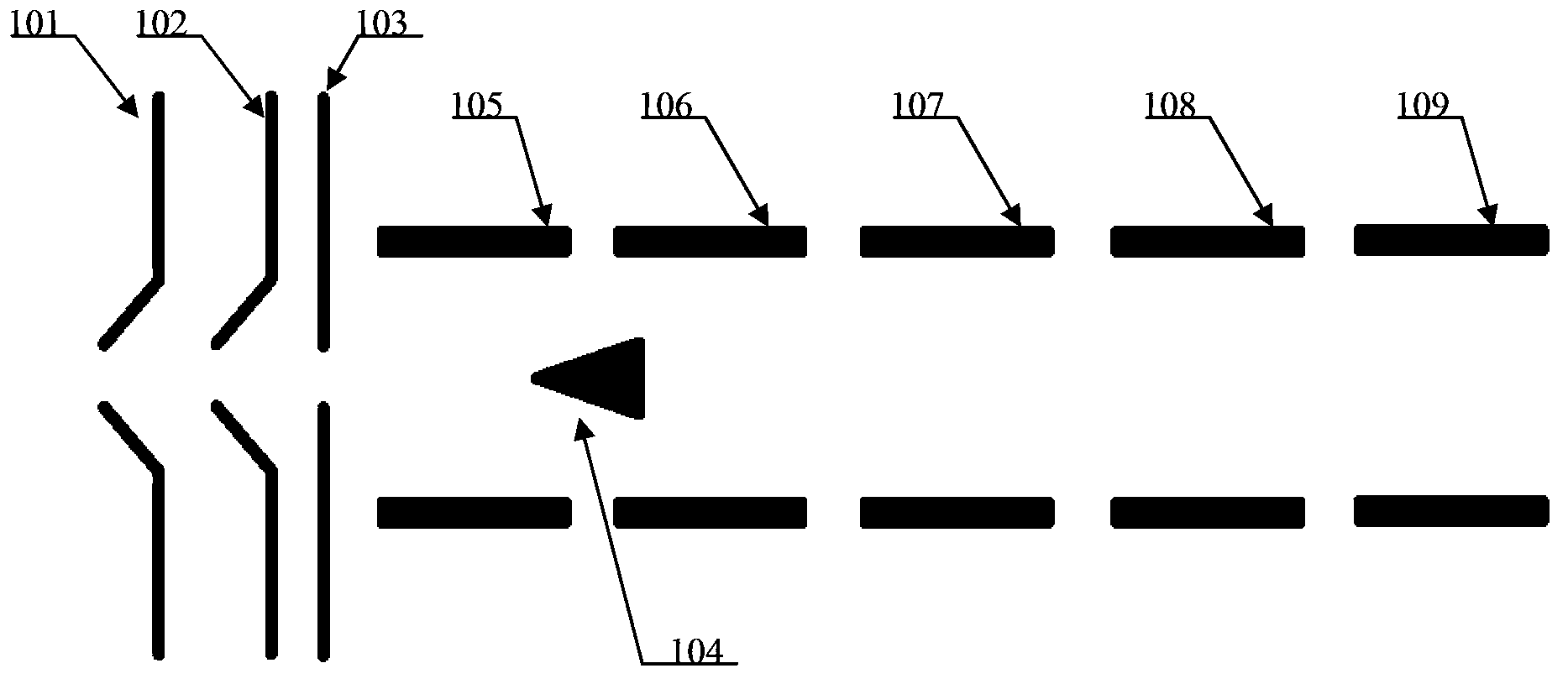

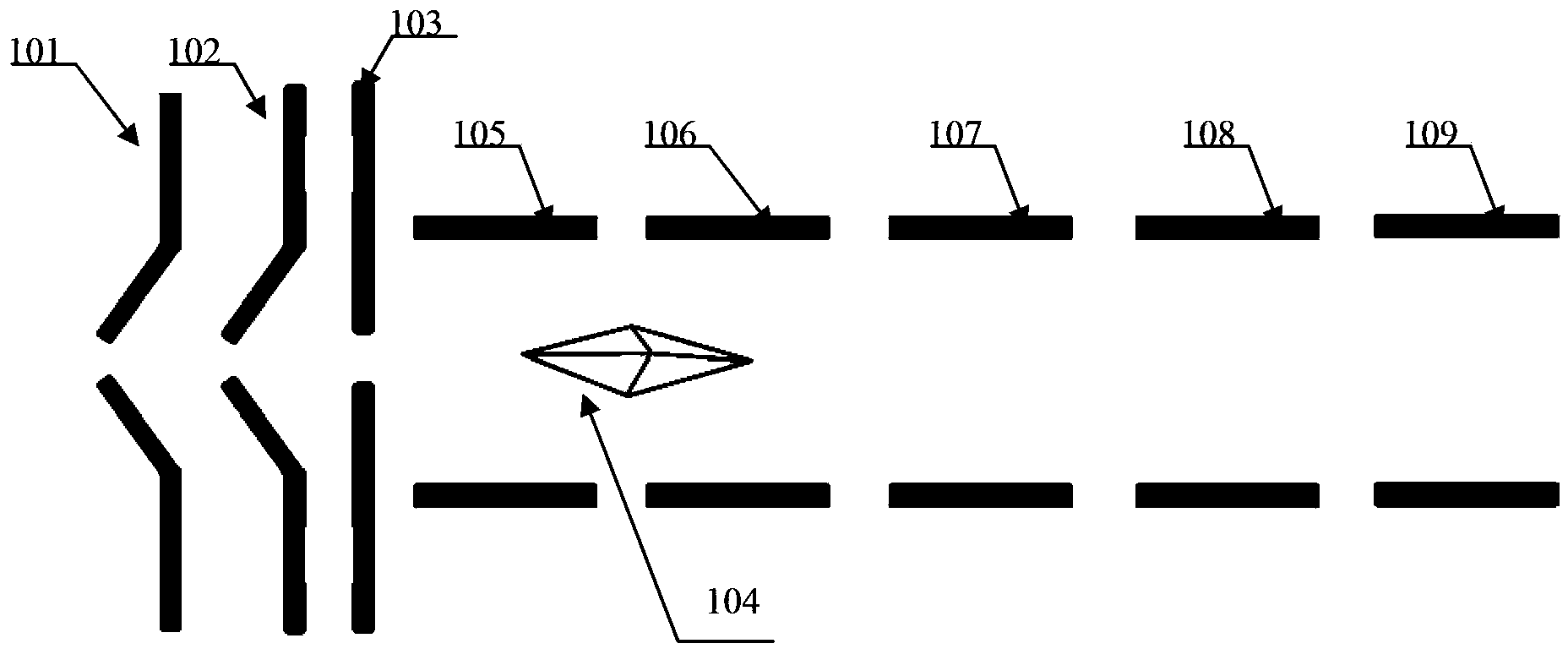

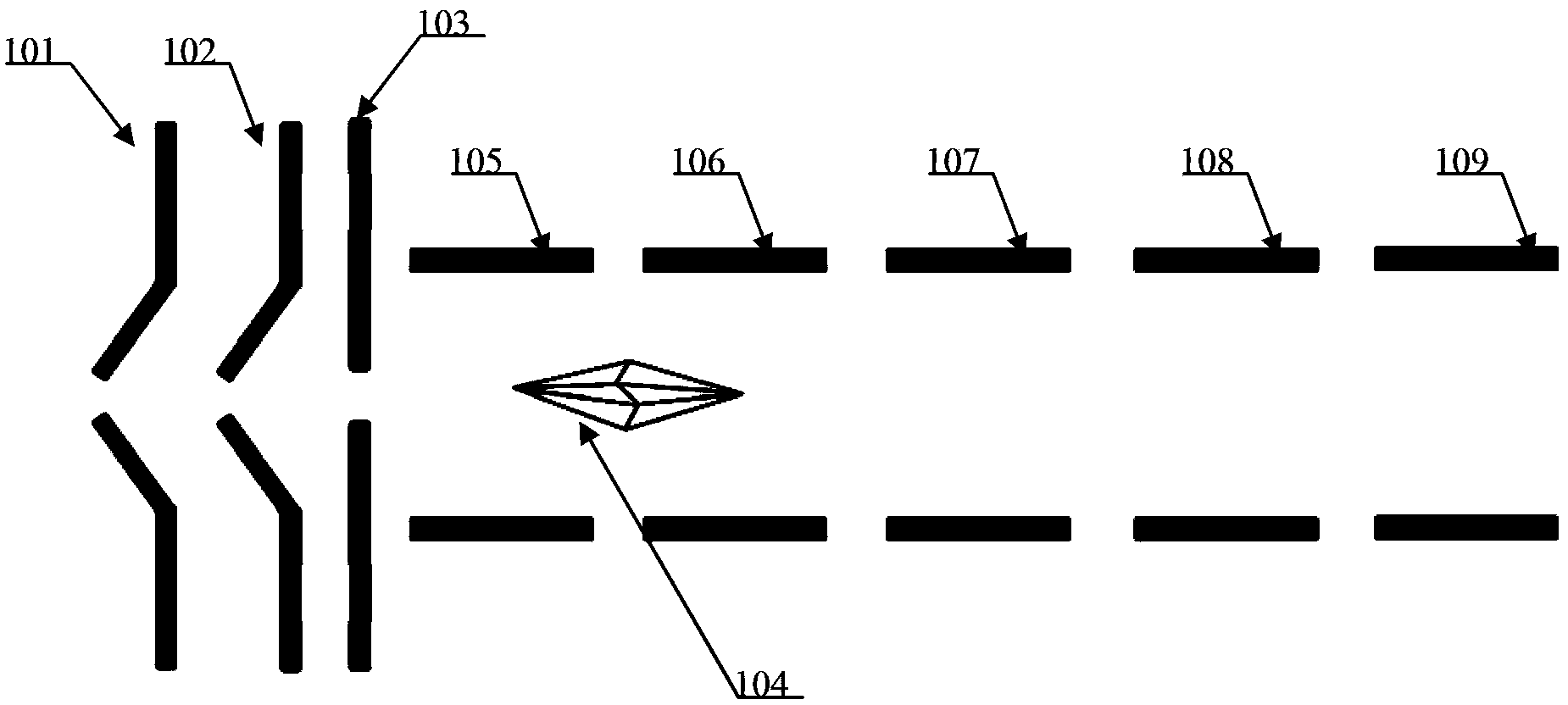

Ion implanter having two-stage deceleration beamline

An ion implanter includes an ion source for generating an ion beam, an analyzer for separating unwanted components from the ion beam, a first beam transport device for transporting the ion beam through the analyzer at a first transport energy, a first deceleration stage positioned downstream of the analyzer for decelerating the ion beam from the first transport energy to a second transport energy, a beam filter positioned downstream of the first deceleration stage for separating neutral particles from the ion beam, a second beam transport device for transporting the ion beam through the beam filter at the second transport energy, a second deceleration stage positioned downstream of the beam filter for decelerating the ion beam from the second transport energy to a final energy, and a target site for supporting a target for ion implantation. The ion beam is delivered to the target site at the final energy. In a double deceleration mode, the second transport energy is greater than the final energy for highest current at low energy. In an enhanced drift mode, the second transport energy is equal to the final energy for highest beam purity at low energy.

Owner:VARIAN SEMICON EQUIP ASSOC INC

Crosslinked hyperbranched polyalcohol composite nano filter membrance and method of preparing the same

InactiveCN101254417AImprove throughputHigh retention rateSemi-permeable membranesFood additiveUltrafiltration

The invention discloses a crosslinking hyper branched polymer composite nanofiltration membrane as well as the preparation method thereof. The crosslinking hyper branched polymer composite nanofiltration membrane is prepared by taking an ultrafiltration membrane as a basement membrane and crosslinking hyper branched polymer as a selecting layer through hyper branched polymer and the interfacial polymerization of polybasic acid, polybasic acyl chloride, polybasic anhydride and polybasic amine; and the interfacial polymerization takes the mixed solution of water and ethanol as the water phase and n-hexane, n-heptane or n-octane as the organic phase. As the hyper branched polymer has the spheroidal structure, a plurality of nano-voids exist in the interior of the molecule, so as to enable the selecting layer of the crosslinking hyper branched polymer composite nanofiltration membrane to be looser, and leads the nanofiltration membrane to maintain high flux and retention rate under the lower operating pressure. The nanofiltration membrane can be used in the fields of medicament, foodstuff, environmental protection, etc. The composite nanofiltration membrane is applicable to the separation and the condensation of high valence ions, low valence ions, neutral particles, drugs, food additives, etc.

Owner:ZHEJIANG UNIV

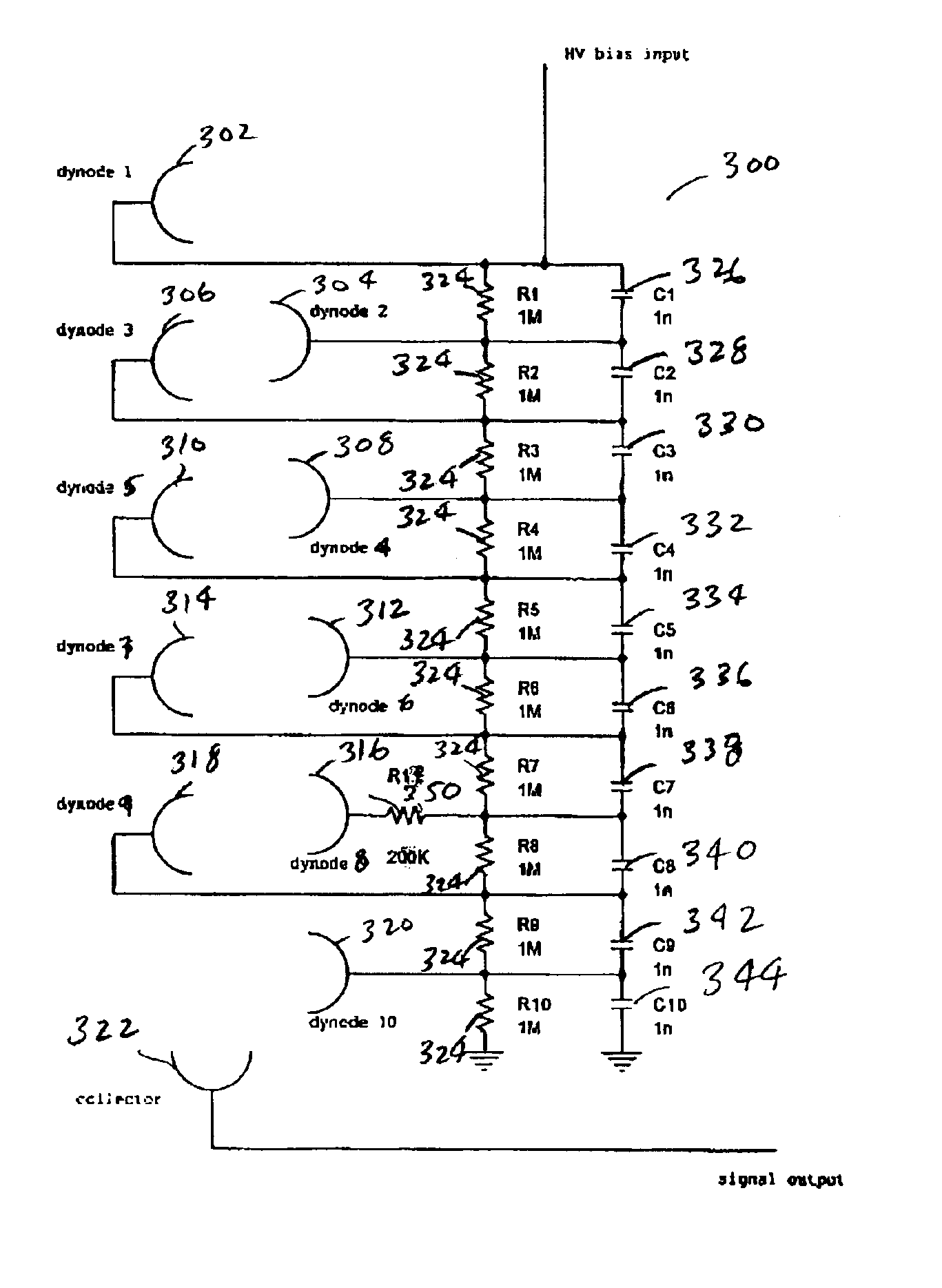

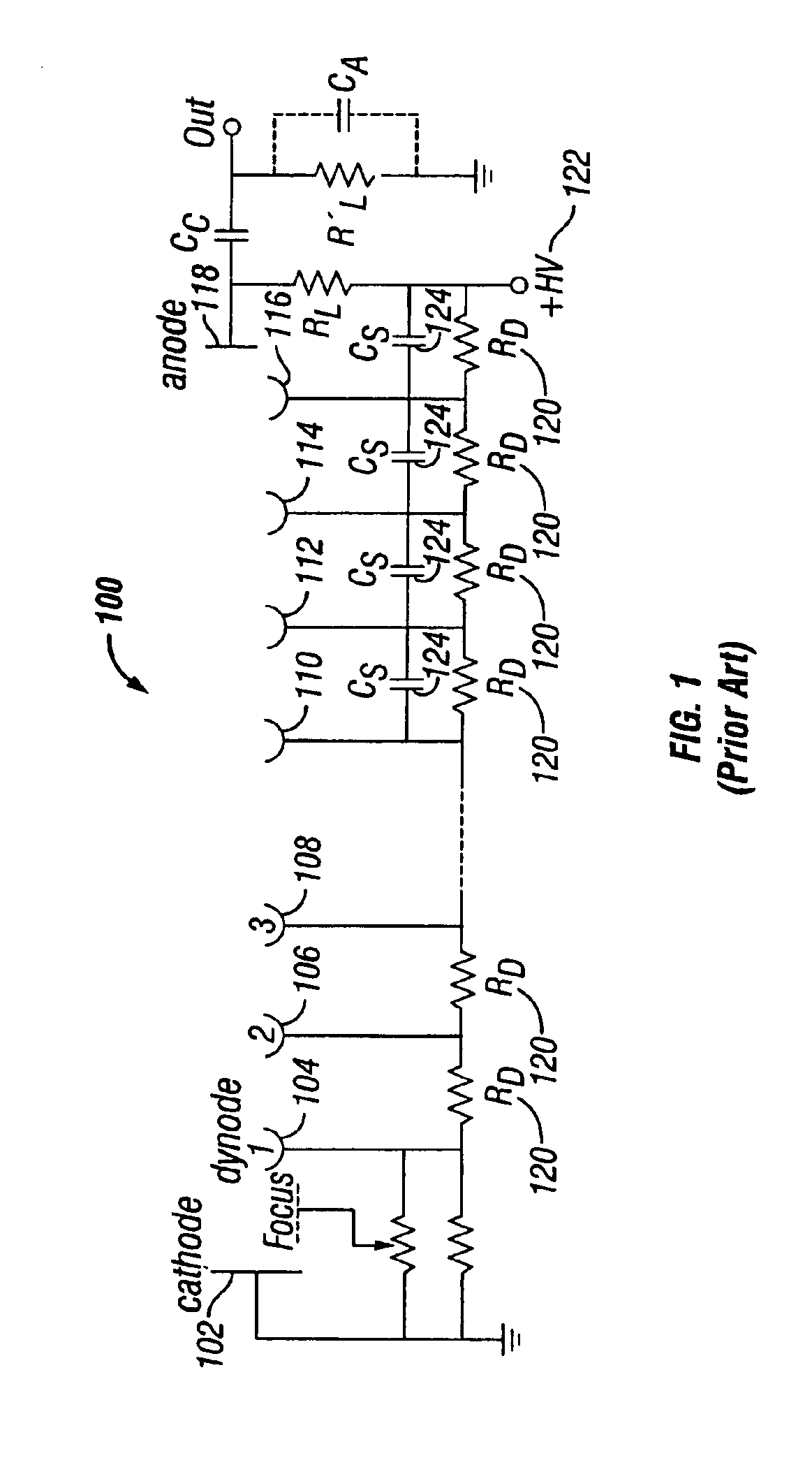

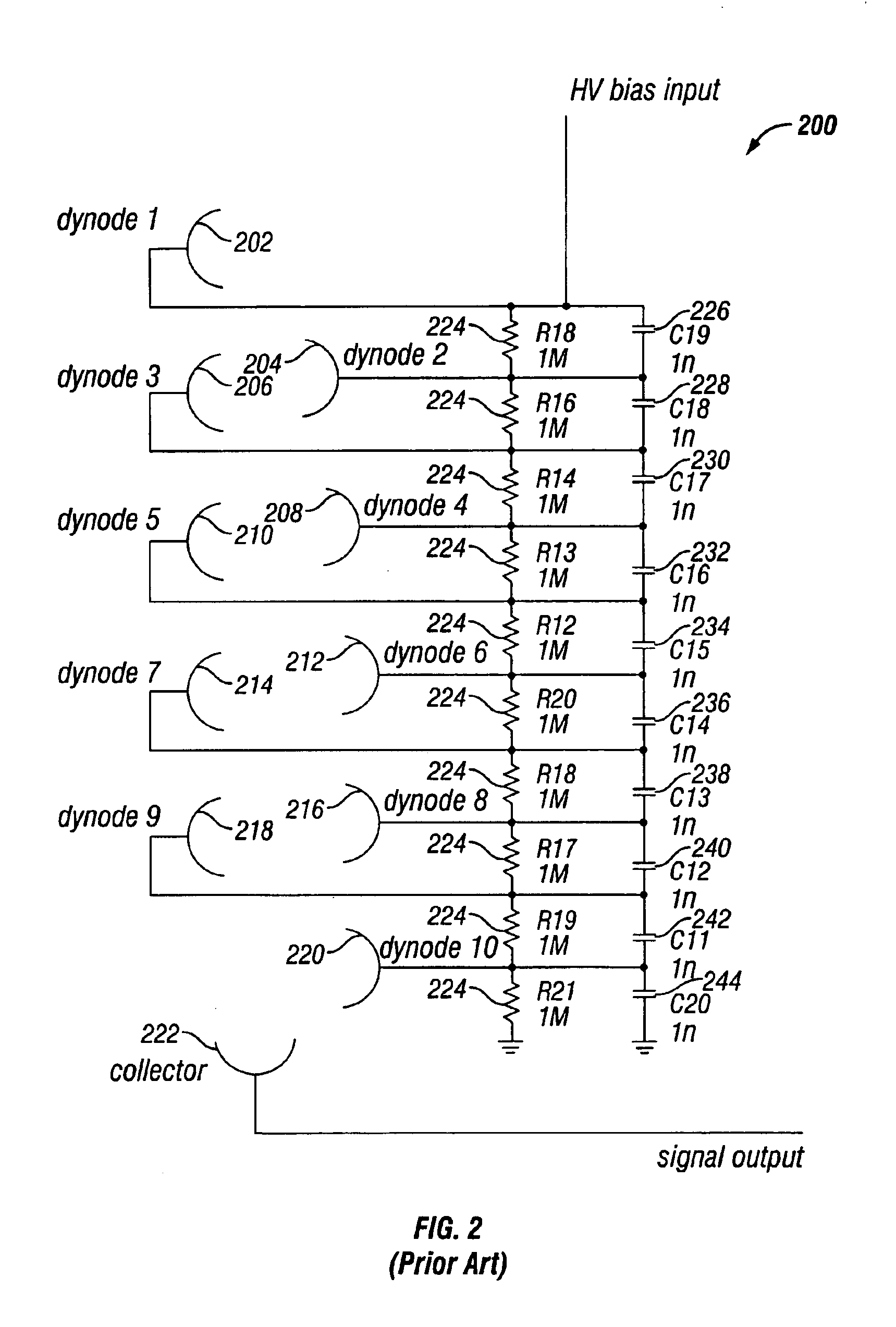

Fast recovery electron multiplier

InactiveUS6841936B2Short timeControls are responsiveElectrode and associated part arrangementsAlternating current plasma display panelsElectron multiplierDynode

An improved electron multiplier bias network that limits the response of the multiplier when the multiplier is faced with very large input signals, but then permits the multiplier to recover quickly following the large input signal. In one aspect, this invention provides an electron multiplier, having a cathode that emits electrons in response to receiving a particle, wherein the particle is one of a charged particle, a neutral particle, or a photon; an ordered chain of dynodes wherein each dynode receives electrons from a preceding dynode and emits a larger number of electrons to be received by the next dynode in the chain, wherein the first dynode of the ordered chain of dynodes receives electrons emitted by the cathode; an anode that collects the electrons emitted by the last dynode of the ordered chain of dynodes; a biasing system that biases each dynode of the ordered chain of dynodes to a specific potential; a set of charge reservoirs, wherein each charge reservoir of the set of charge reservoirs is connected with one of the dynodes of the ordered chain of dynodes; and an isolating element placed between one of the dynodes and its corresponding charge reservoir, where the isolating element is configured to control the response of the electron multiplier when the multiplier receives a large input signal, so as to permit the multiplier to enter into and exit from saturation in a controlled and rapid manner.

Owner:BIO RAD LAB INC

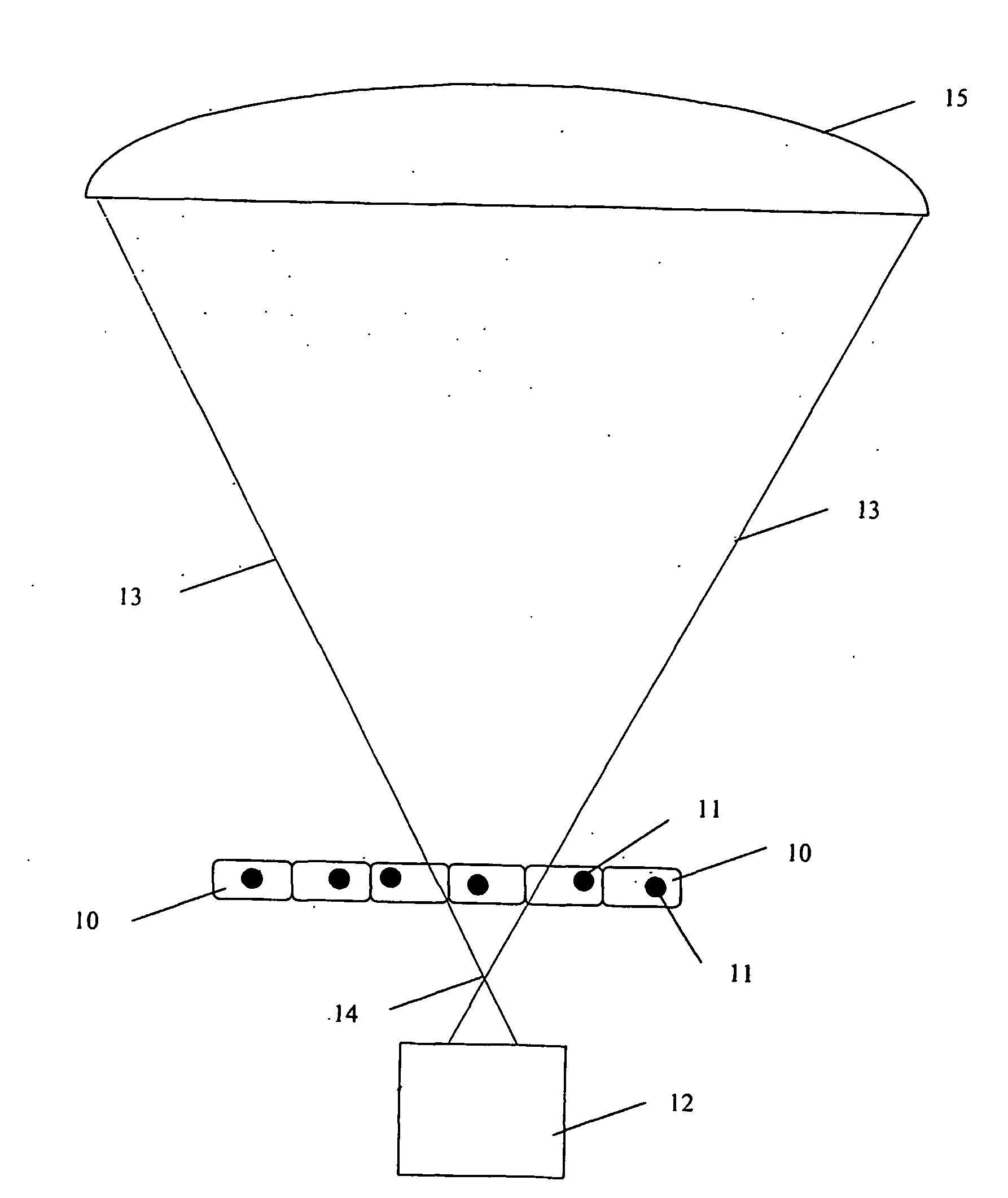

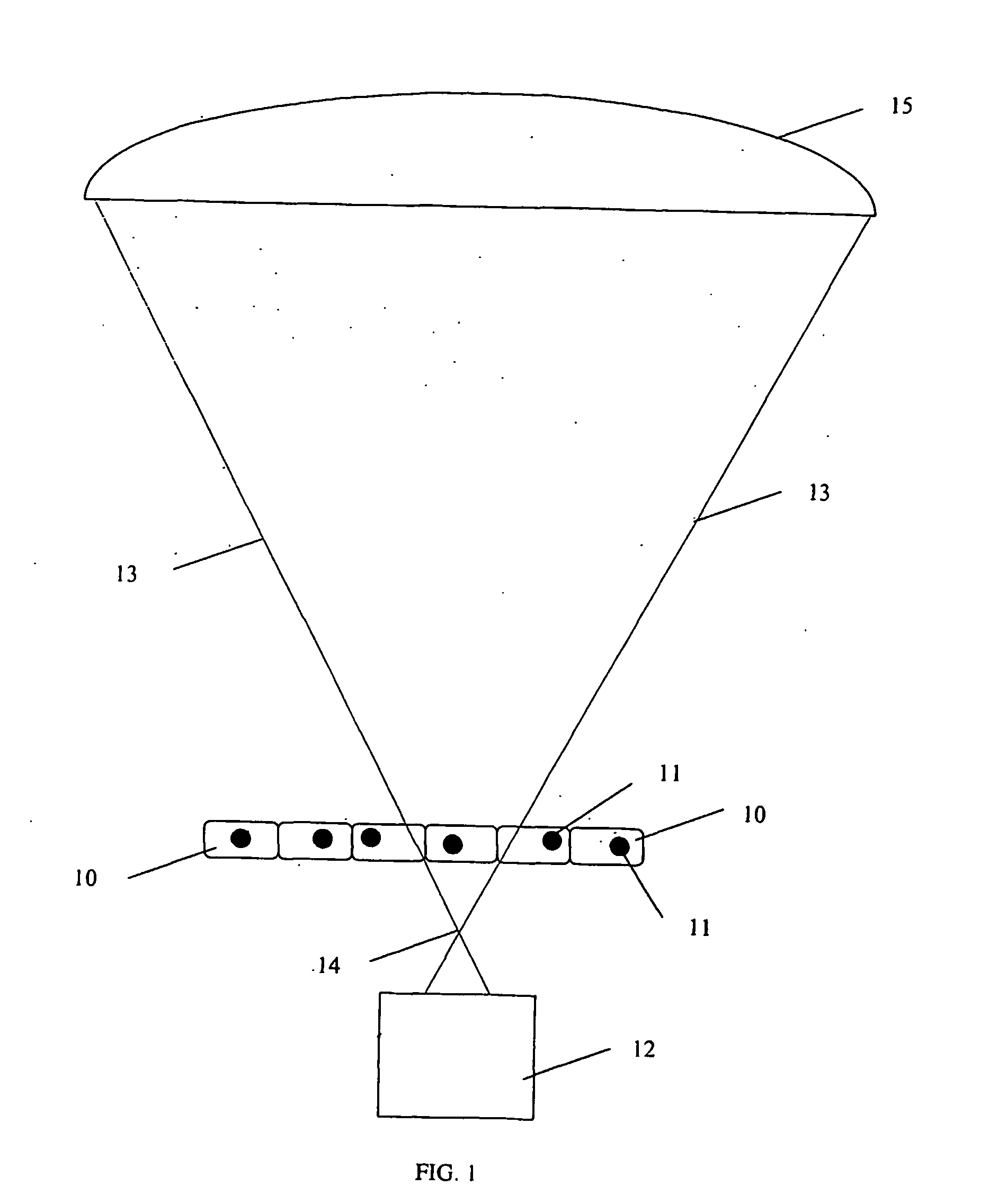

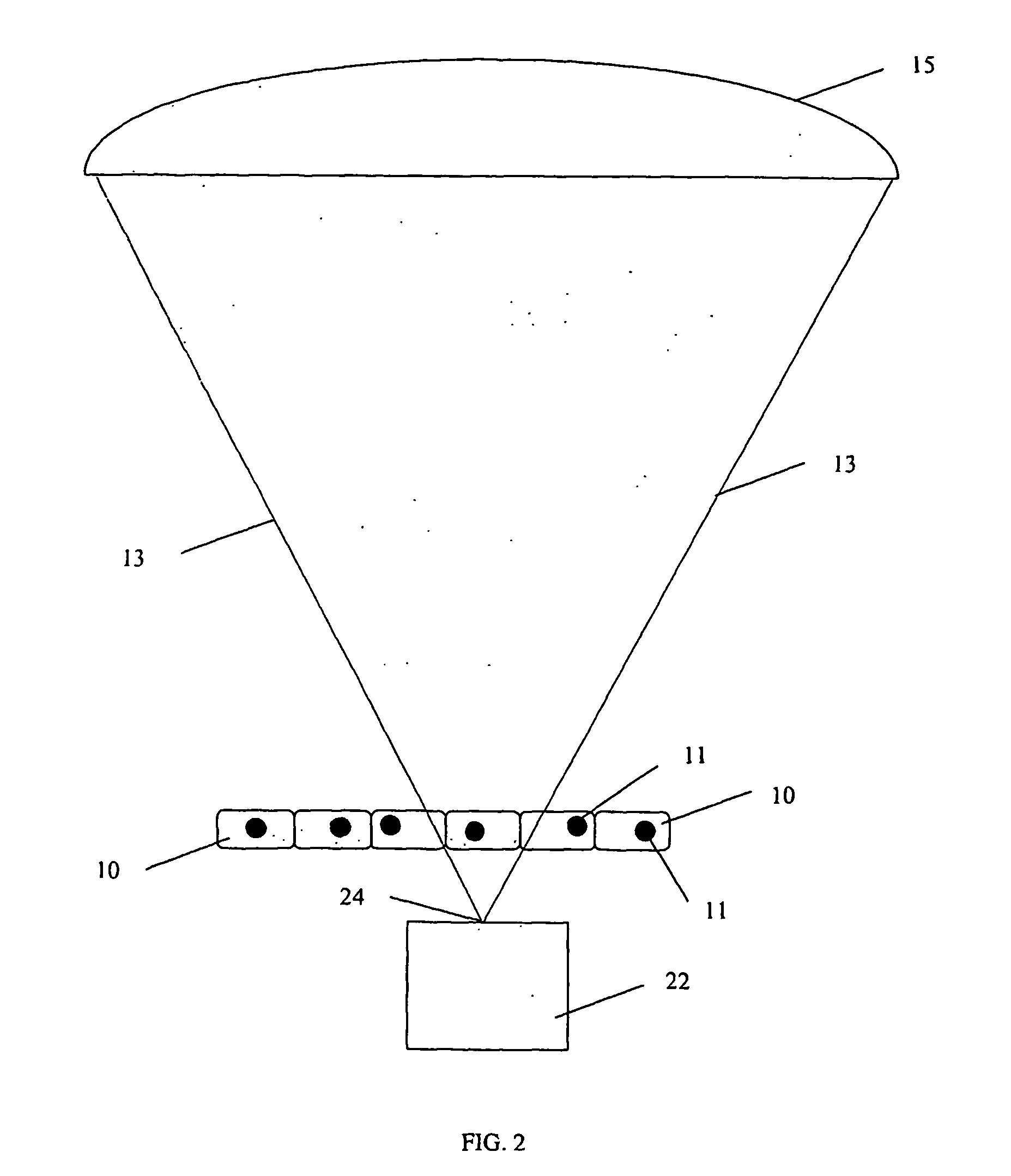

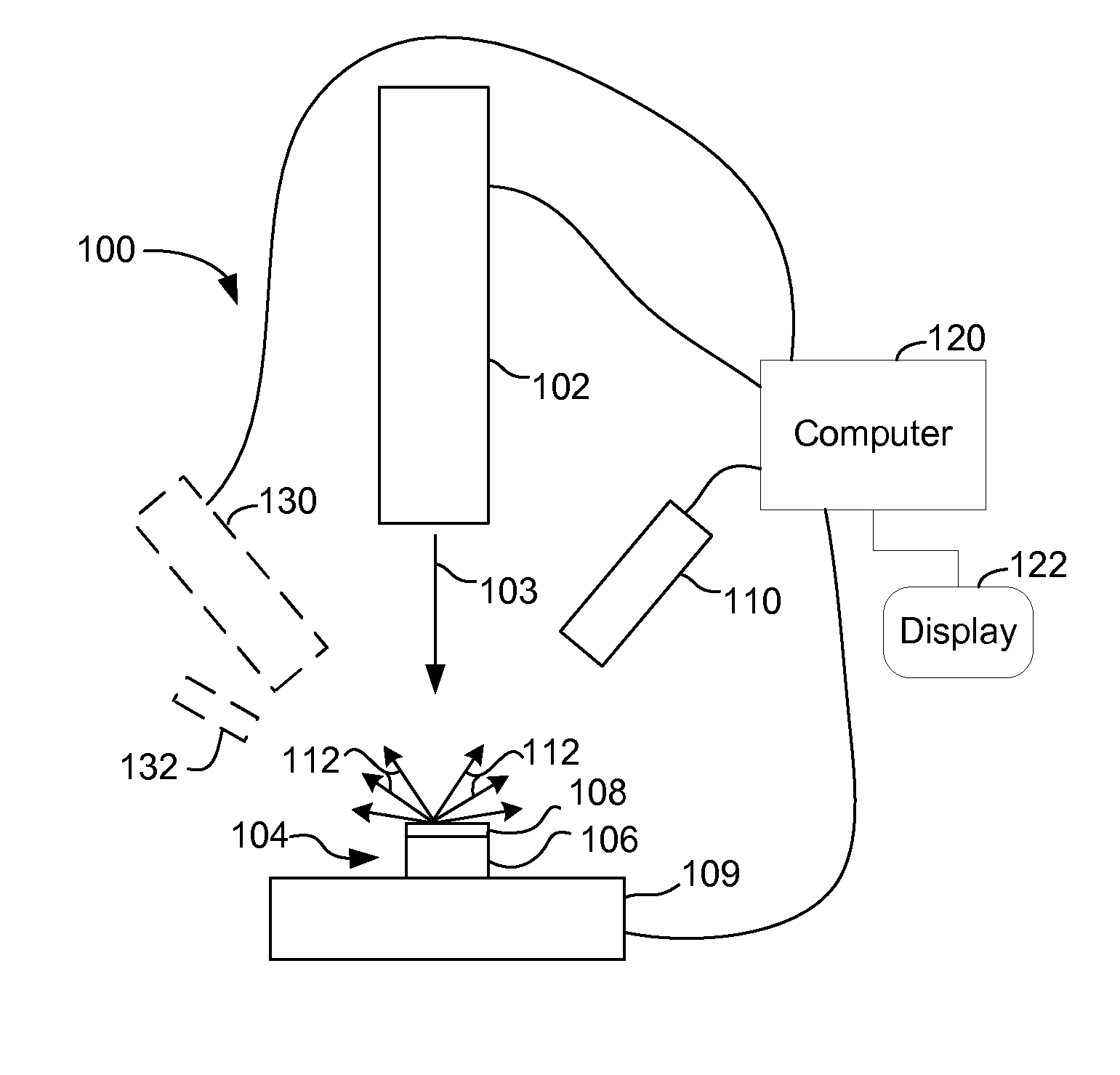

System for molecular imaging

InactiveUS20070025504A1Promote recoveryMass extinctionDiagnostics using lightMicrobiological testing/measurementSensor arrayPhotonics

Charged and neutral particles, photons (13), photonic optics, detectors (15) and sensor arrays are used for application to molecular imaging, communication with biological organisms and monitoring and learning biological activity inside living organisms. The living organisms include among others living tissue, biological organs, cells (10), eukaryotes, prokaryotes, viruses and phages. Molecular imaging can be an effective new tool to understand the mechanisms of life and communicate, modify and control it. Techniques, methods and devices are described to achieve these aims. The probes used in molecular imaging described above will include the full spectrum of photons; charged and uncharged particles (13); chemicals; and biological probes.

Owner:TUMER TUMAY O

Method and apparatus for enhanced ion mobility based sample analysis using various analyzer configurations

InactiveUS7399958B2Easy to analyzeEasy to identifyTime-of-flight spectrometersMaterial analysis by electric/magnetic meansAtomic physicsIon flow

A system for analyzing one or more ion species of a sample including a first ion mobility filter associated with a first flow path for passing first ions of the sample, a second ion mobility filter associated with a second flow path for passing second ions of the sample, a first outlet from the first flow path for passing a portion of the first ions from the first flow path to the second flow path, and a first outlet from the second flow path for removing neutral particles from the second flow path where the first outlet from the second flow path is upstream of the second ion mobility filter in relation to the ion flow in the second flow path.

Owner:DH TECH DEVMENT PTE

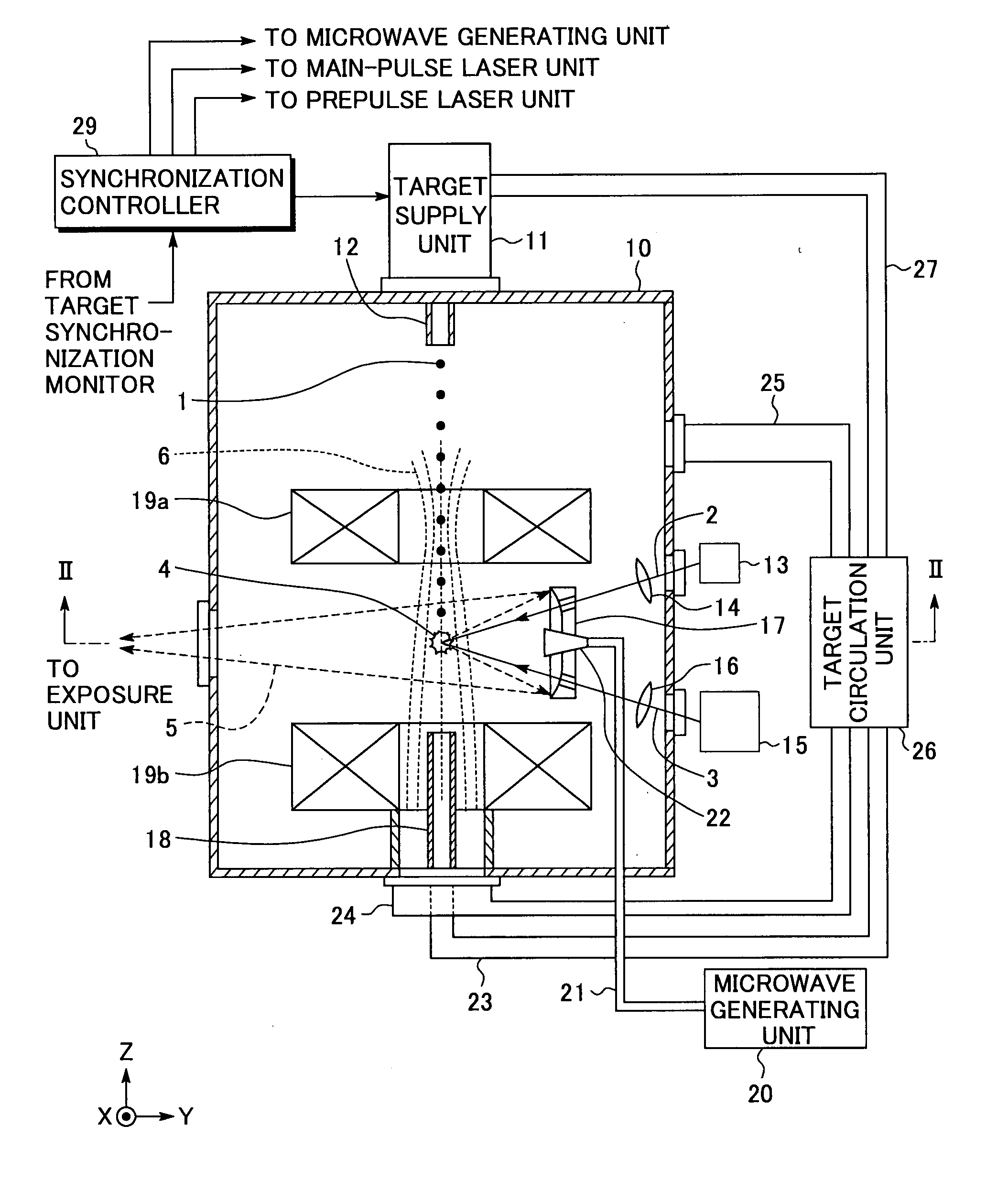

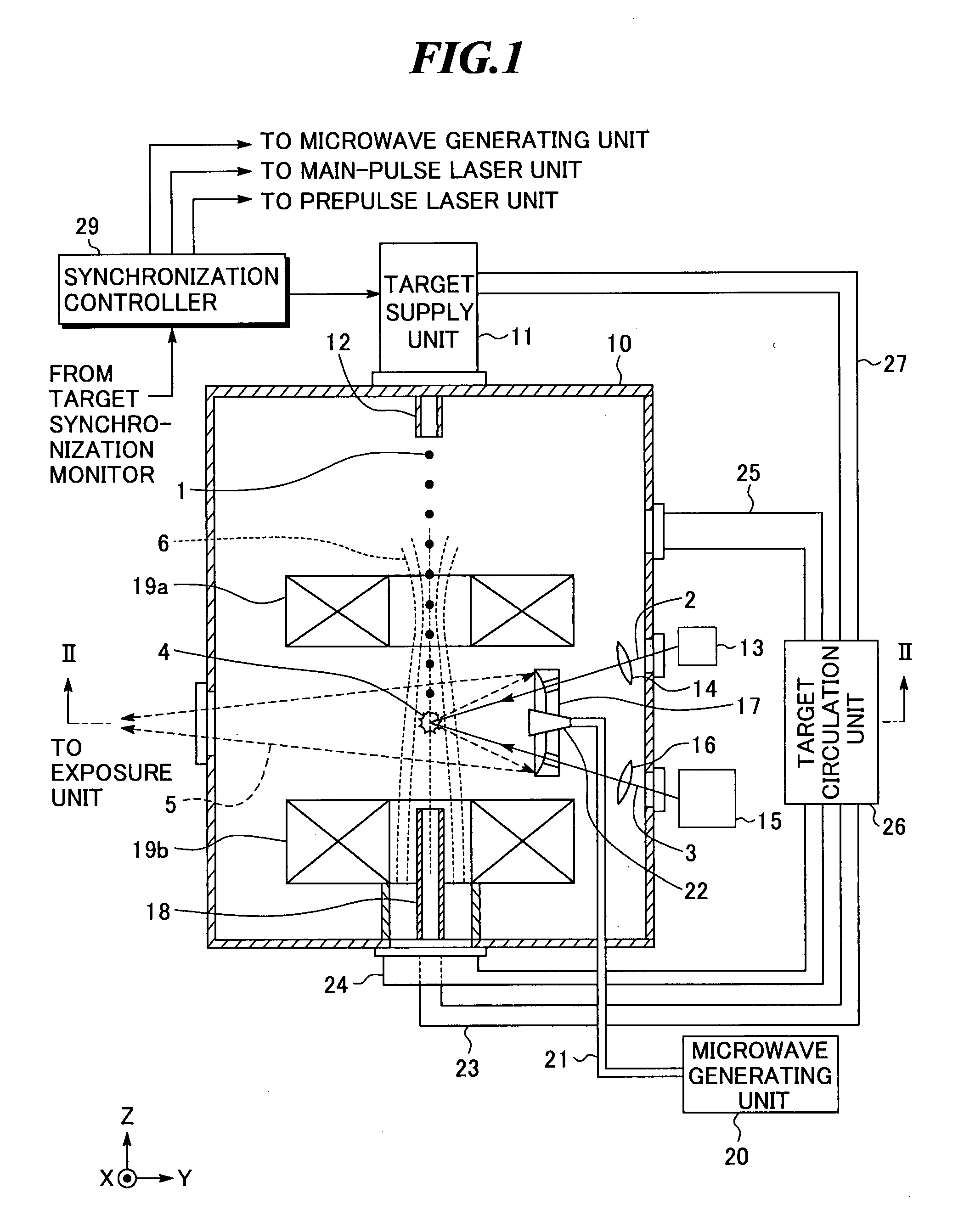

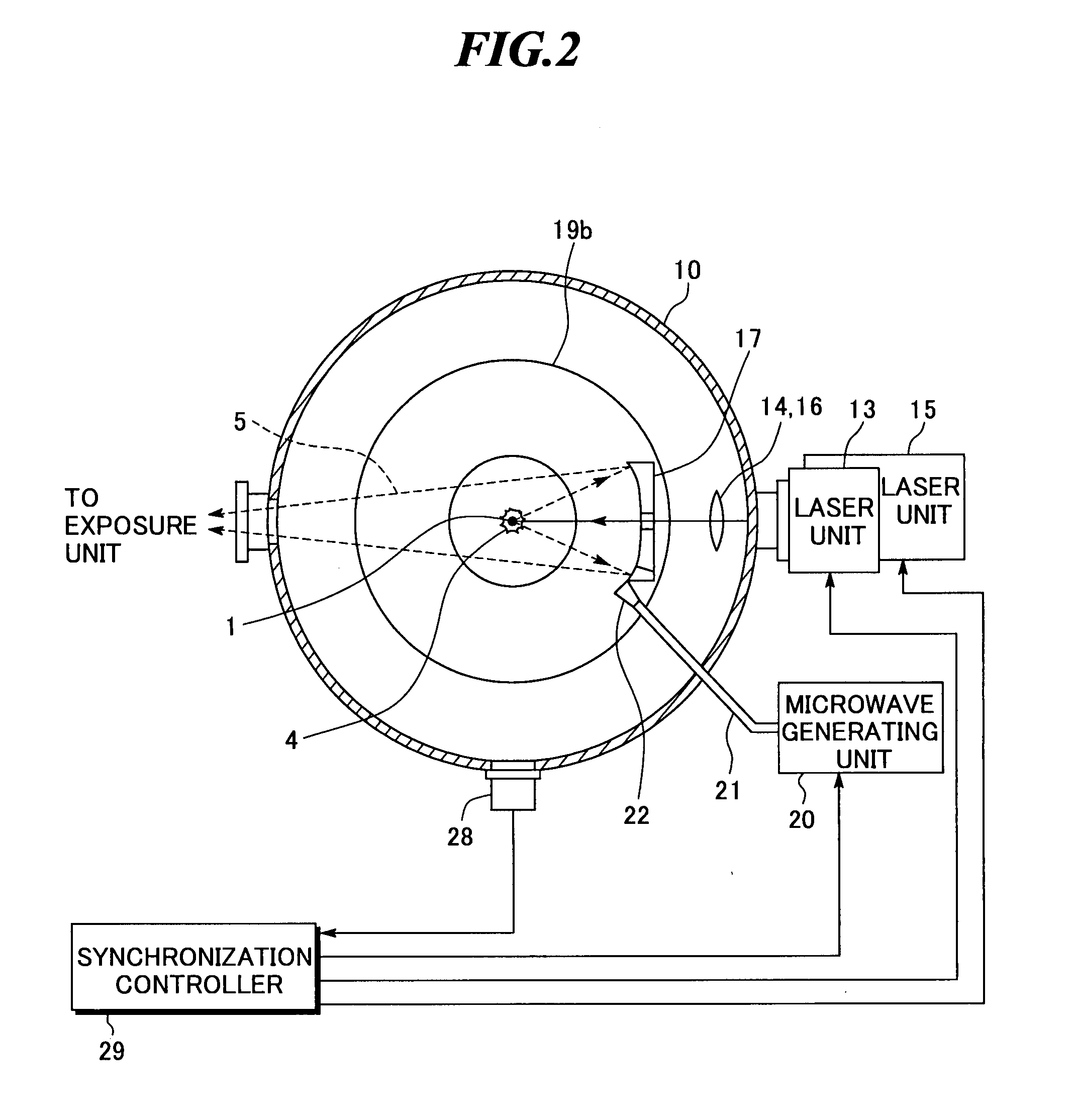

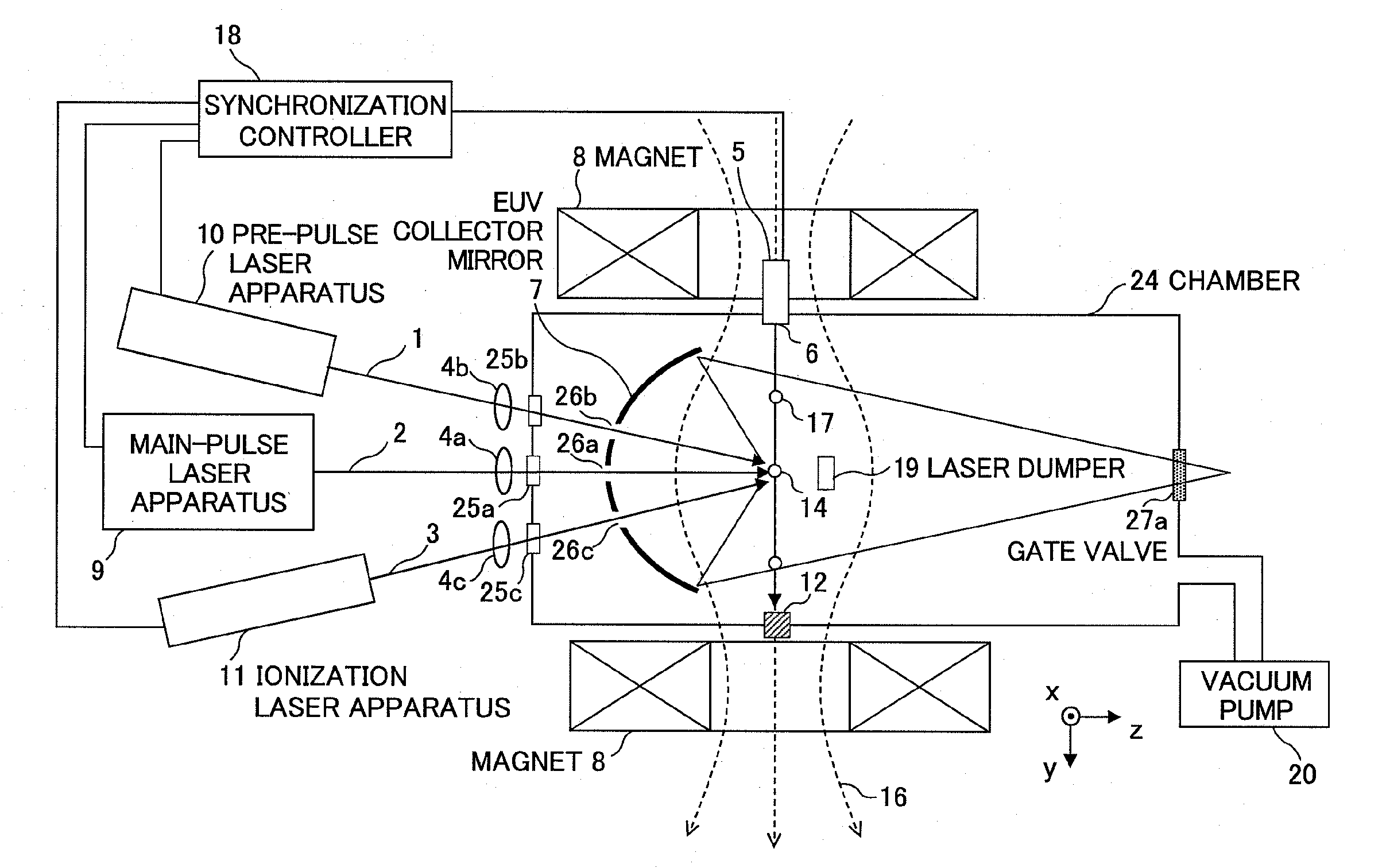

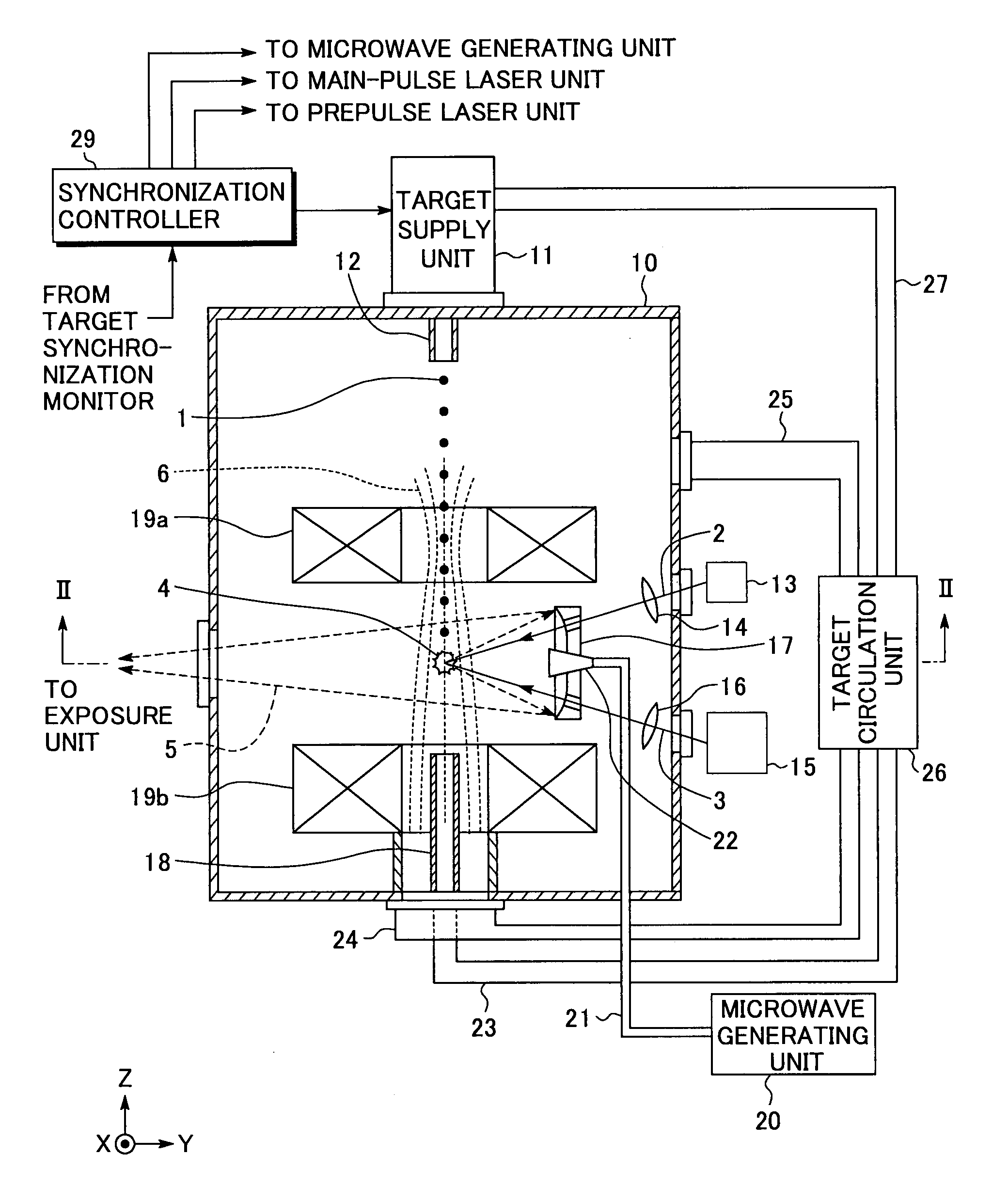

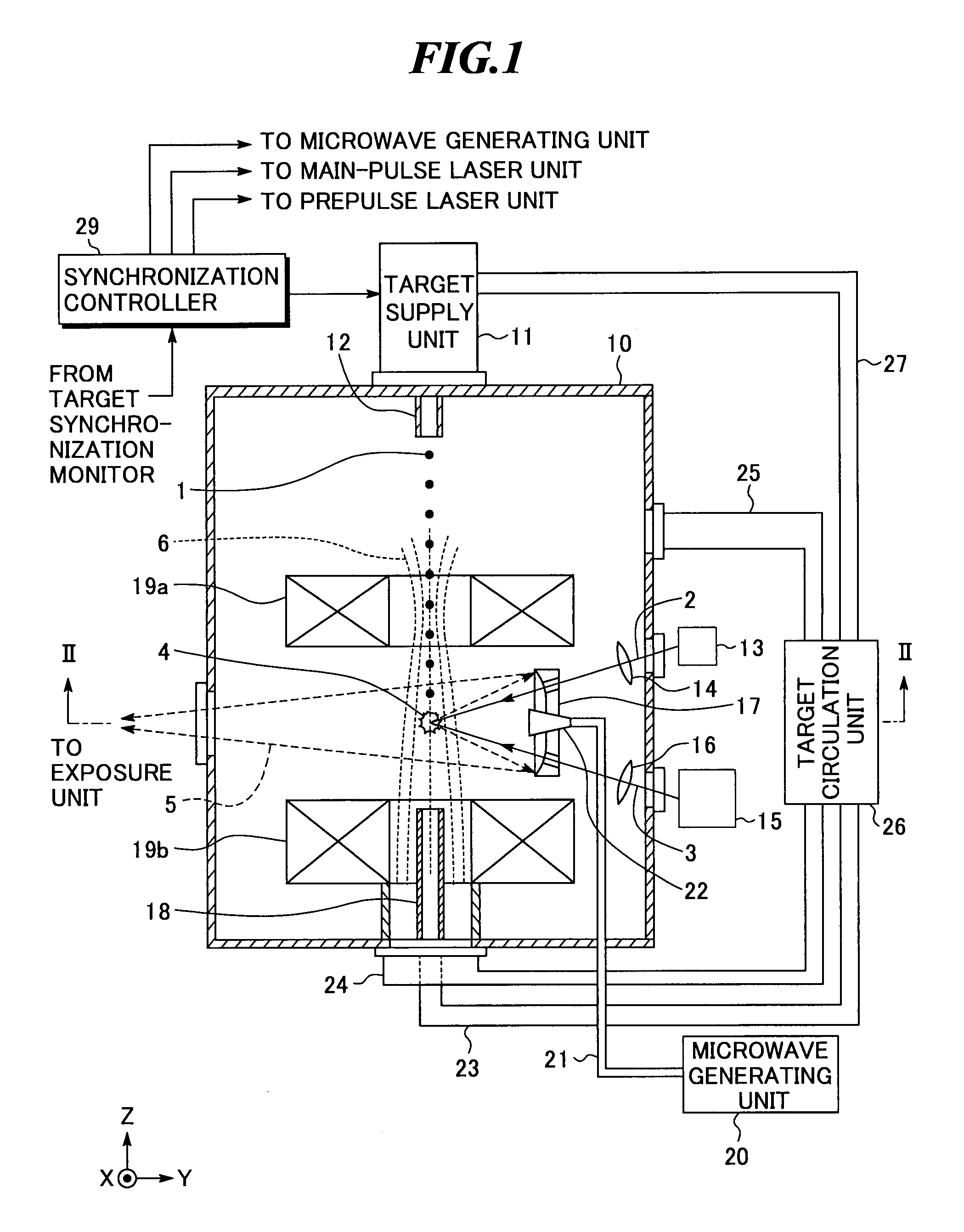

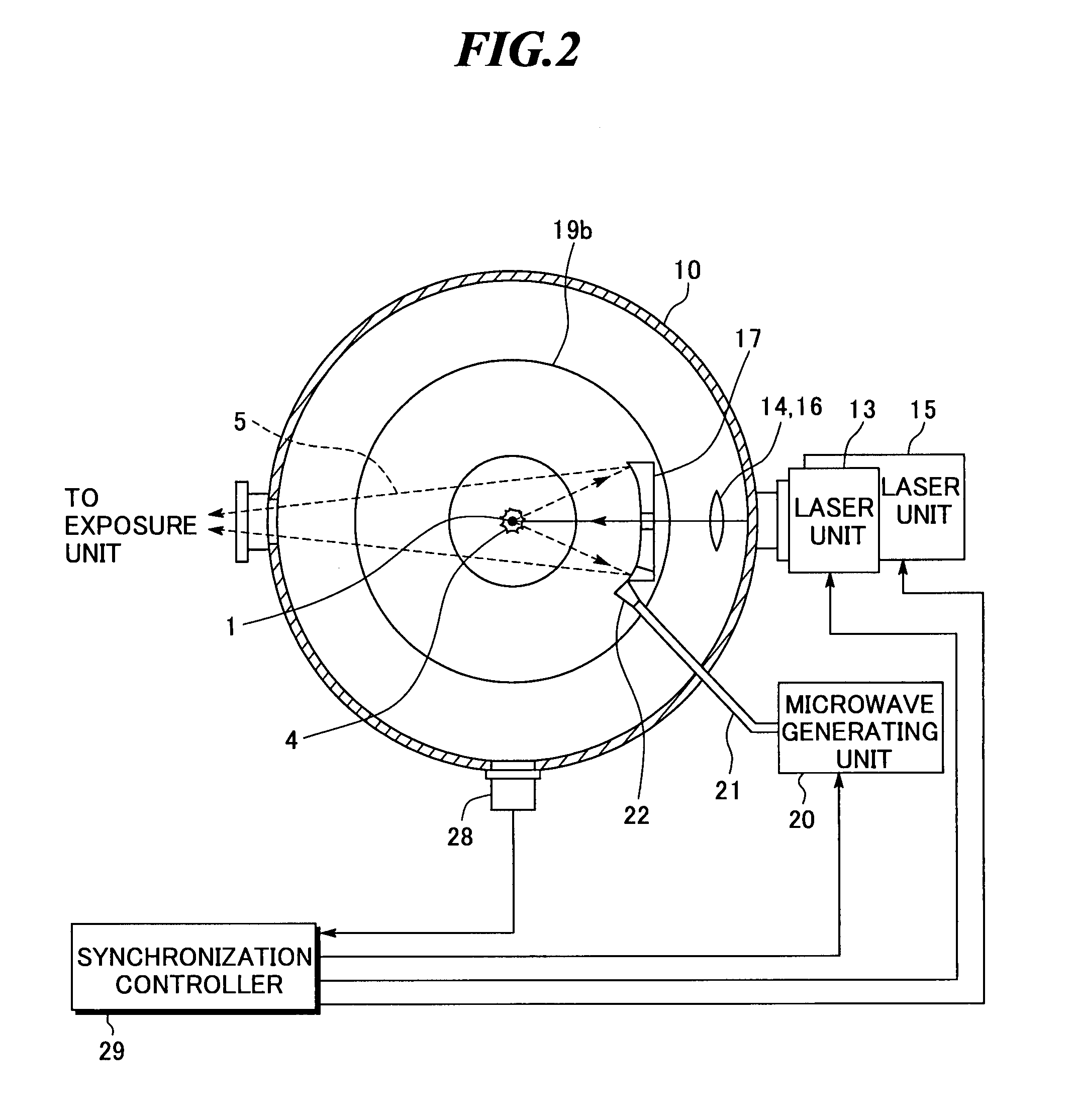

Extreme ultra violet light source apparatus

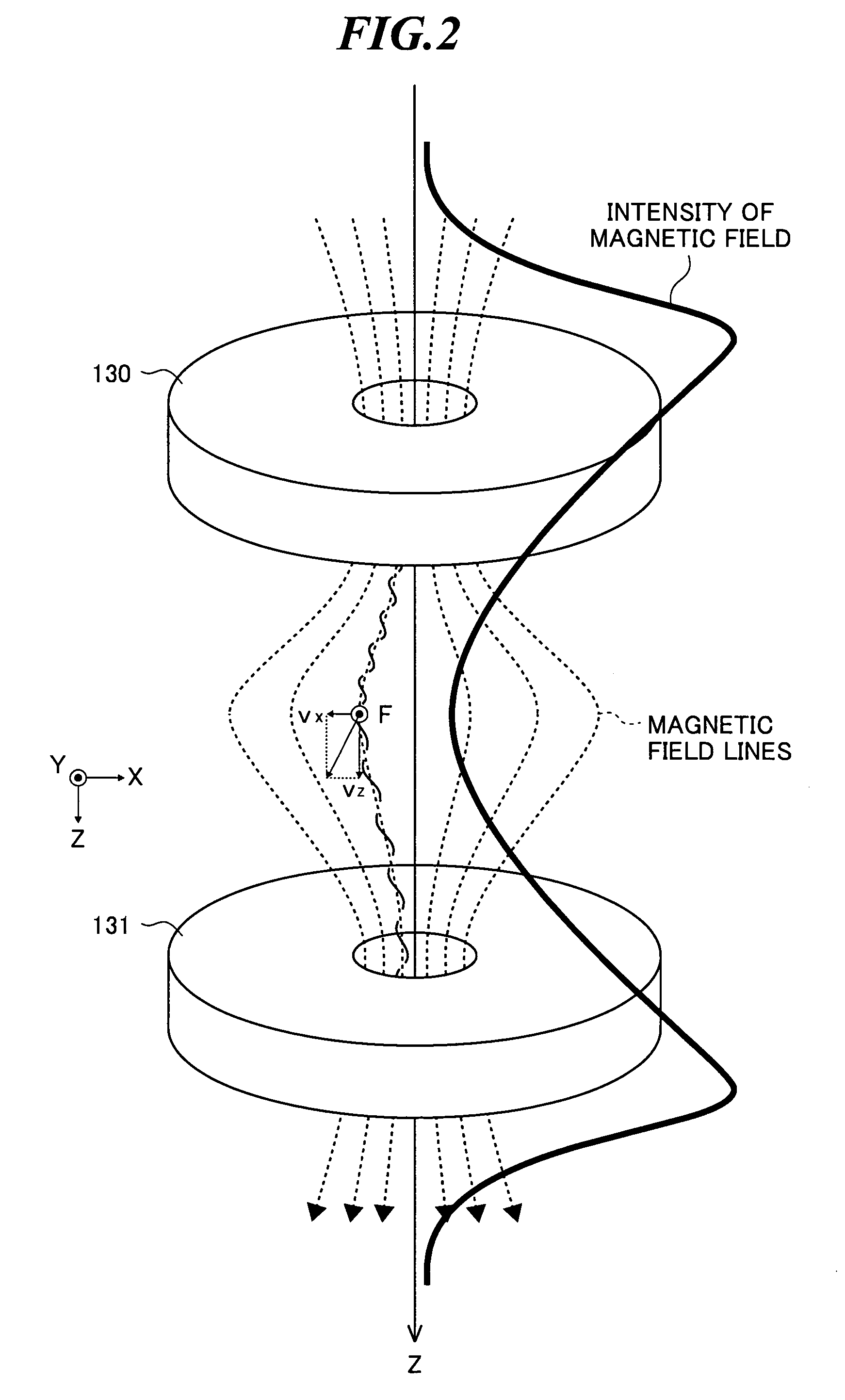

ActiveUS20080083887A1Improve efficiencyEfficient ionizationLaser detailsSemiconductor/solid-state device manufacturingMicrowaveElectron cyclotron resonance

In an extreme ultra violet light source apparatus that exhausts debris including fast ions and neutral particles by the effect of a magnetic field, neutral particles emitted from plasma are efficiently ionized. The extreme ultraviolet light source apparatus includes: a plasma generating unit that generates plasma, that radiates at least extreme ultra violet light, through pulse operation; collective optics that collects the extreme ultra violet light radiated from the plasma; a microwave generating unit that radiates microwave through pulse operation into a space in which a magnetic field is formed to cause electron cyclotron resonance, and thereby ionizes neutral particles emitted from the plasma; a magnetic field forming unit that forms the magnetic field and a magnetic field for trapping at least ionized particles; and a control unit that synchronously controls at least the plasma generating unit and the microwave generating unit.

Owner:GIGAPHOTON

Plasma Ion Source Mass Spectrometer

ActiveUS20090266984A1High signal sensitivityStability-of-path spectrometersBeam/ray focussing/reflecting arrangementsTransmittanceSpectrometer

Provided is a plasma ion source mass spectrometer with an ion deflector lens having an improved removal ratio of photons and neutral particles as compared with the conventional art while an ion transmittance is maintained. The ion deflector includes an input side plate-like electrode, an output side plate-like electrode, and a tubular electrode disposed between the input side plate-like electrode and the output side plate-like electrode. The tubular electrode is of a point asymmetrical configuration. The tubular electrode is arranged so that a center axis of the tubular electrode is closer to an axis of travel of ions upstream of the input side plate-like electrode than an axis of travel of ions downstream of the output side plate-like electrode.

Owner:AGILENT TECH INC

Ferroelectric or electret memory circuit

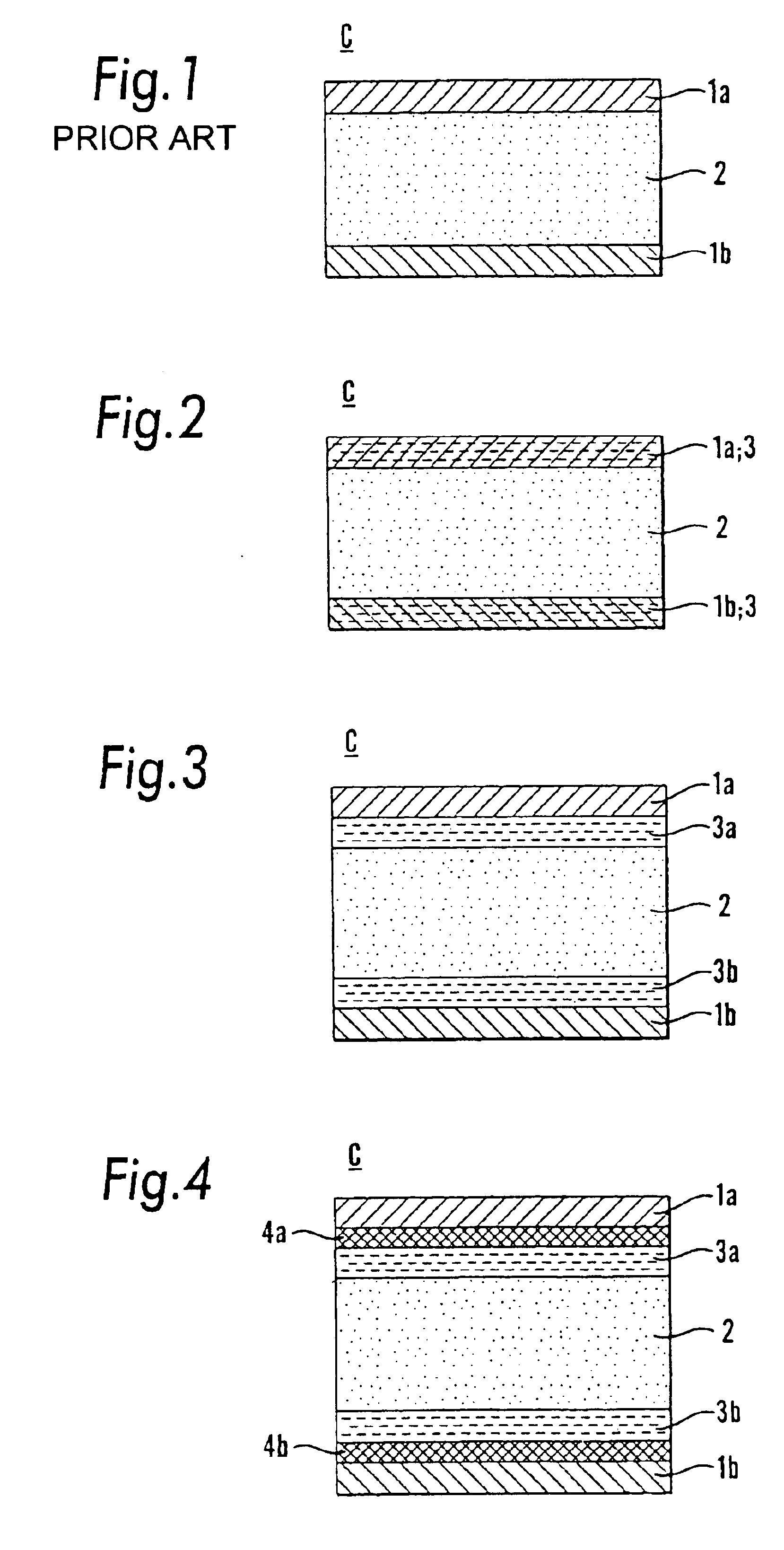

InactiveUS6878980B2Reducing and avoiding effect of fatigueSolid-state devicesSemiconductor/solid-state device manufacturingOligomerThin-film memory

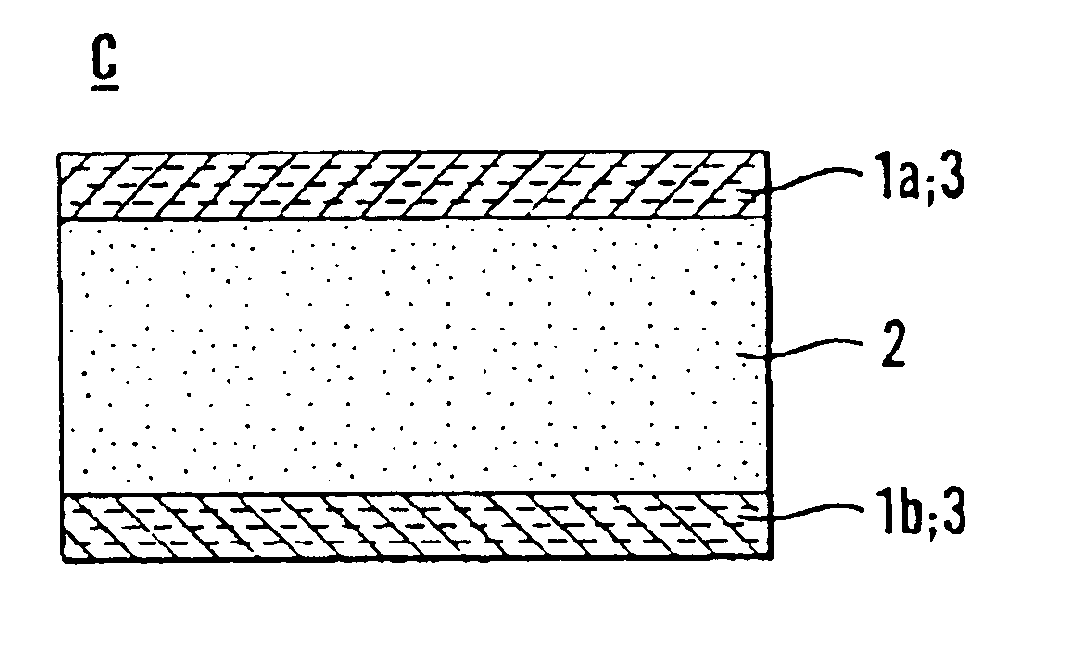

A ferroelectric or electret memory circuit, particularly a ferroelectric or electret memory circuit with improved fatigue resistance, including a ferroelectric or electret memory cell with a polymer or oligomer memory material contacting first and second electrodes, at least one of the electrodes is comprised of at least one functional material capable of physical and / or chemical bulk incorporation of atomic or molecular species contained in either the electrode or the memory material and displaying a propensity for migrating in the form of mobile charged and / or neutral particles between an electrode and a memory material, something which can be detrimental to both. A functional material with the above-mentioned properties shall serve to offset any adverse effect of a migration of this kind, leading to an improvement in the fatigue resistance of the memory cell. The memory circuit being used in a matrix-addressable memory device where the memory cells are formed in distinct portions in a global layer of a ferroelectric or electret thin-film memory material, particularly a polymer material.

Owner:THIN FILM ELECTRONICS ASA

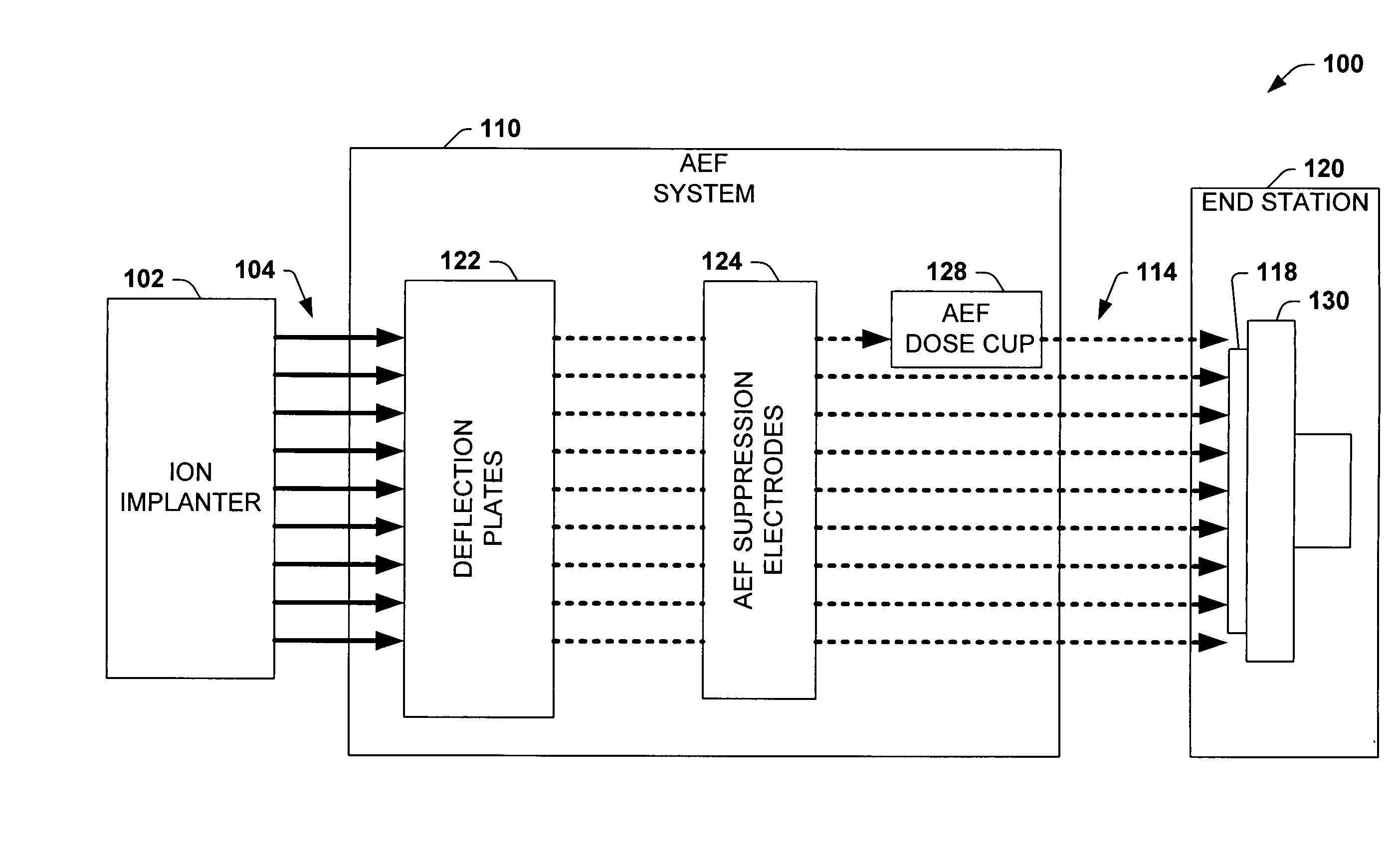

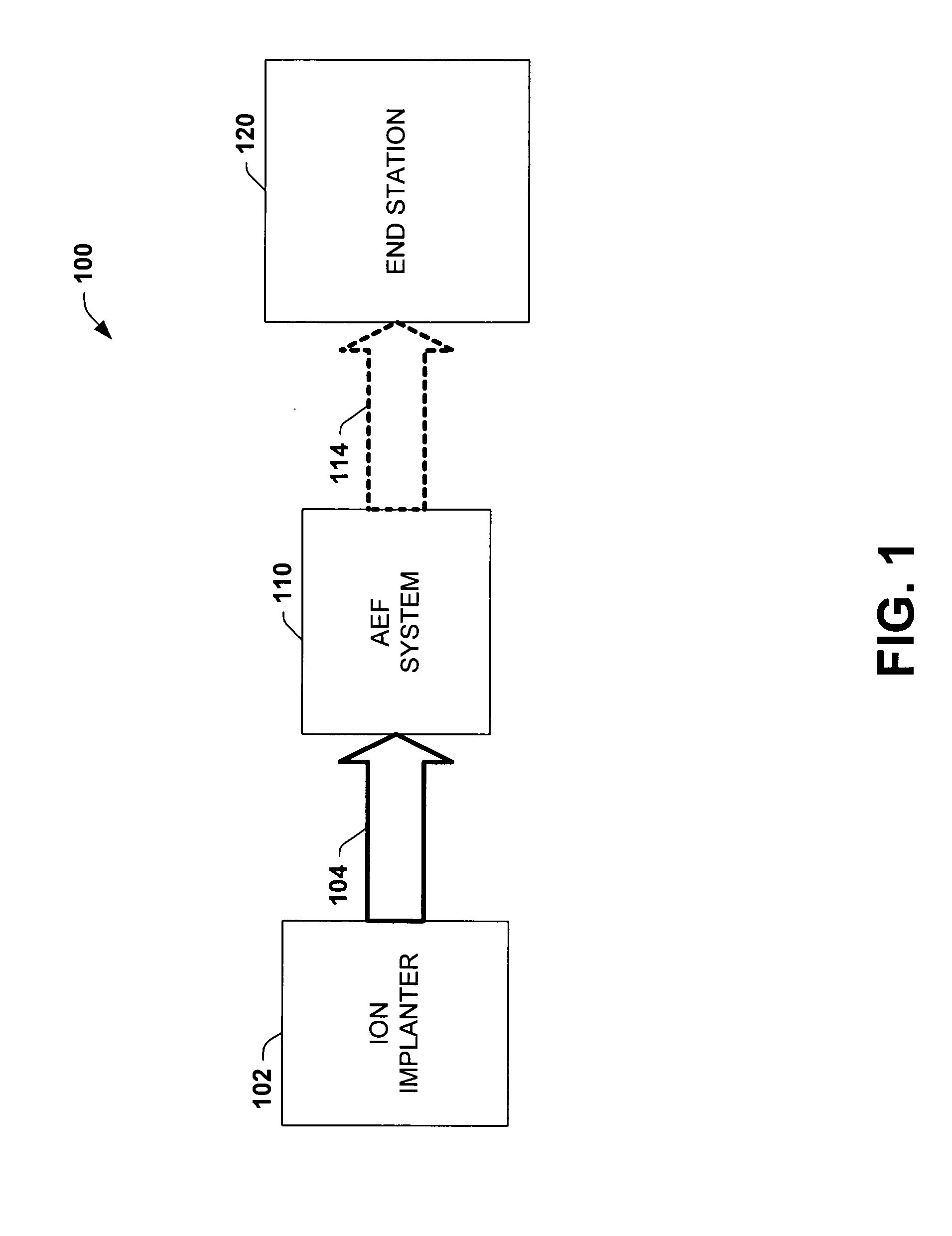

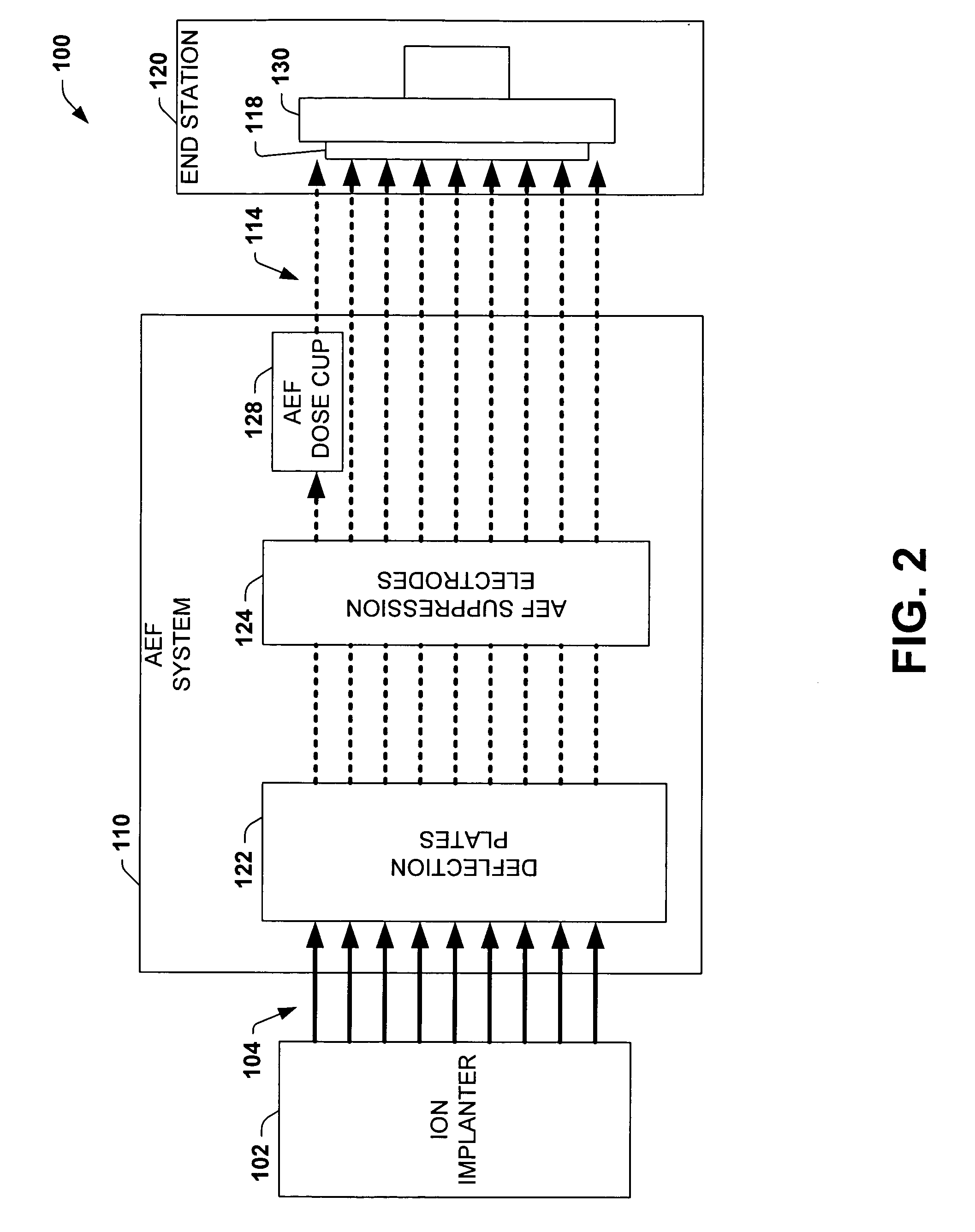

Dose cup located near bend in final energy filter of serial implanter for closed loop dose control

ActiveUS20050269526A1Reduce pressureEliminate the effects ofElectric discharge tubesRadiation therapyIon currentDosimetry radiation

An ion implantation system having a dose cup located near a final energy bend of a scanned or ribbon-like ion beam of a serial ion implanter for providing an accurate ion current measurement associated with the dose of a workpiece or wafer. The system comprises an ion implanter having an ion beam source for producing a ribbon-like ion beam. The system further comprises an AEF system configured to filter an energy of the ribbon-like ion beam by bending the beam at a final energy bend. The AEF system further comprises an AEF dose cup associated with the AEF system and configured to measure ion beam current, the cup located substantially immediately following the final energy bend. An end station downstream of the AEF system is defined by a chamber wherein a workpiece is secured in place for movement relative to the ribbon-like ion beam for implantation of ions therein. The AEF dose cup is beneficially located up stream of the end station near the final energy bend mitigating pressure variations due to outgassing from implantation operations at the workpiece. Thus, the system provides accurate ion current measurement before such gases can produce substantial quantities of neutral particles in the ion beam, generally without the need for pressure compensation. Such dosimetry measurements may also be used to affect scan velocity to ensure uniform closed loop dose control in the presence of beam current changes from the ion source and outgassing from the workpiece.

Owner:AXCELIS TECHNOLOGIES

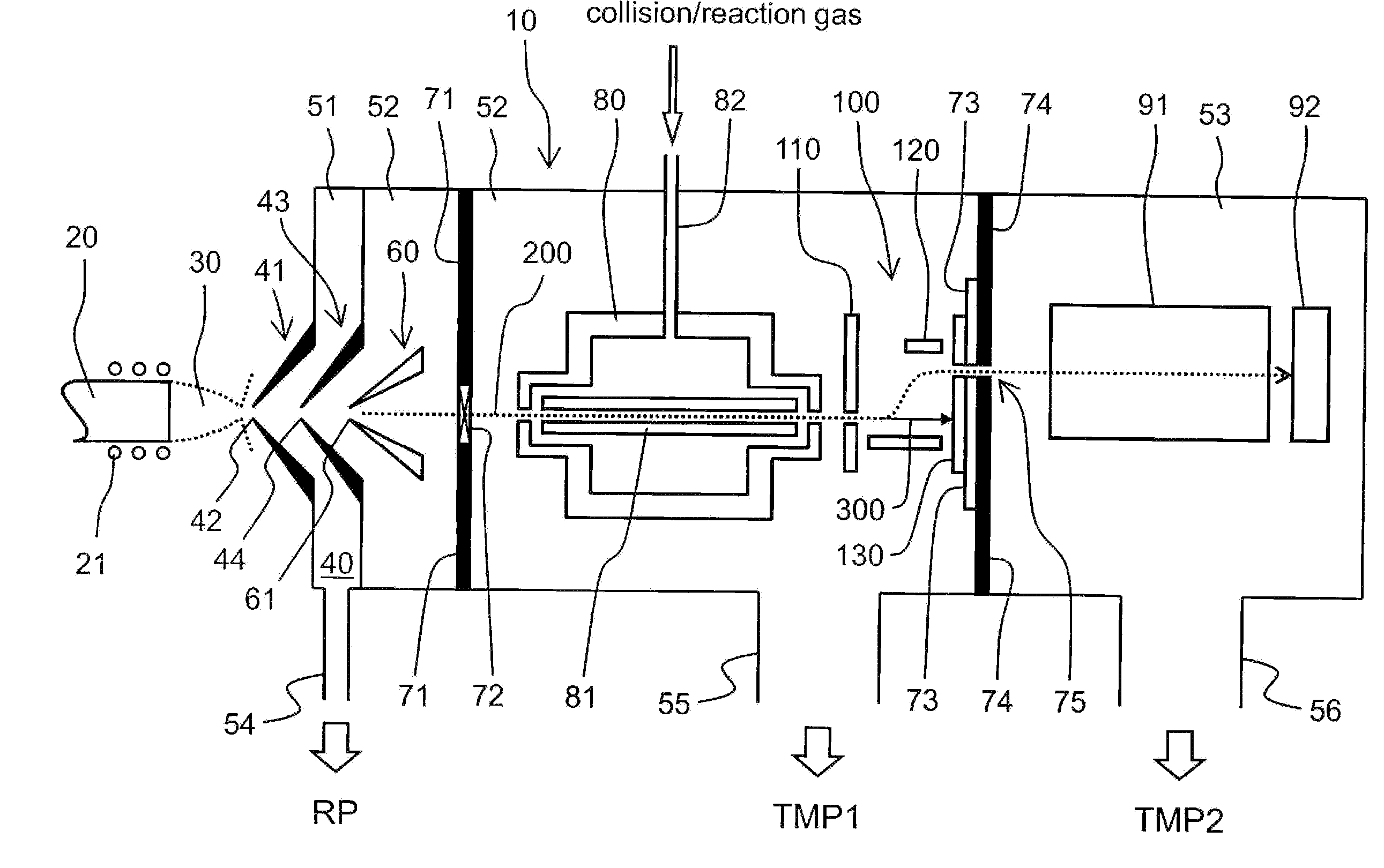

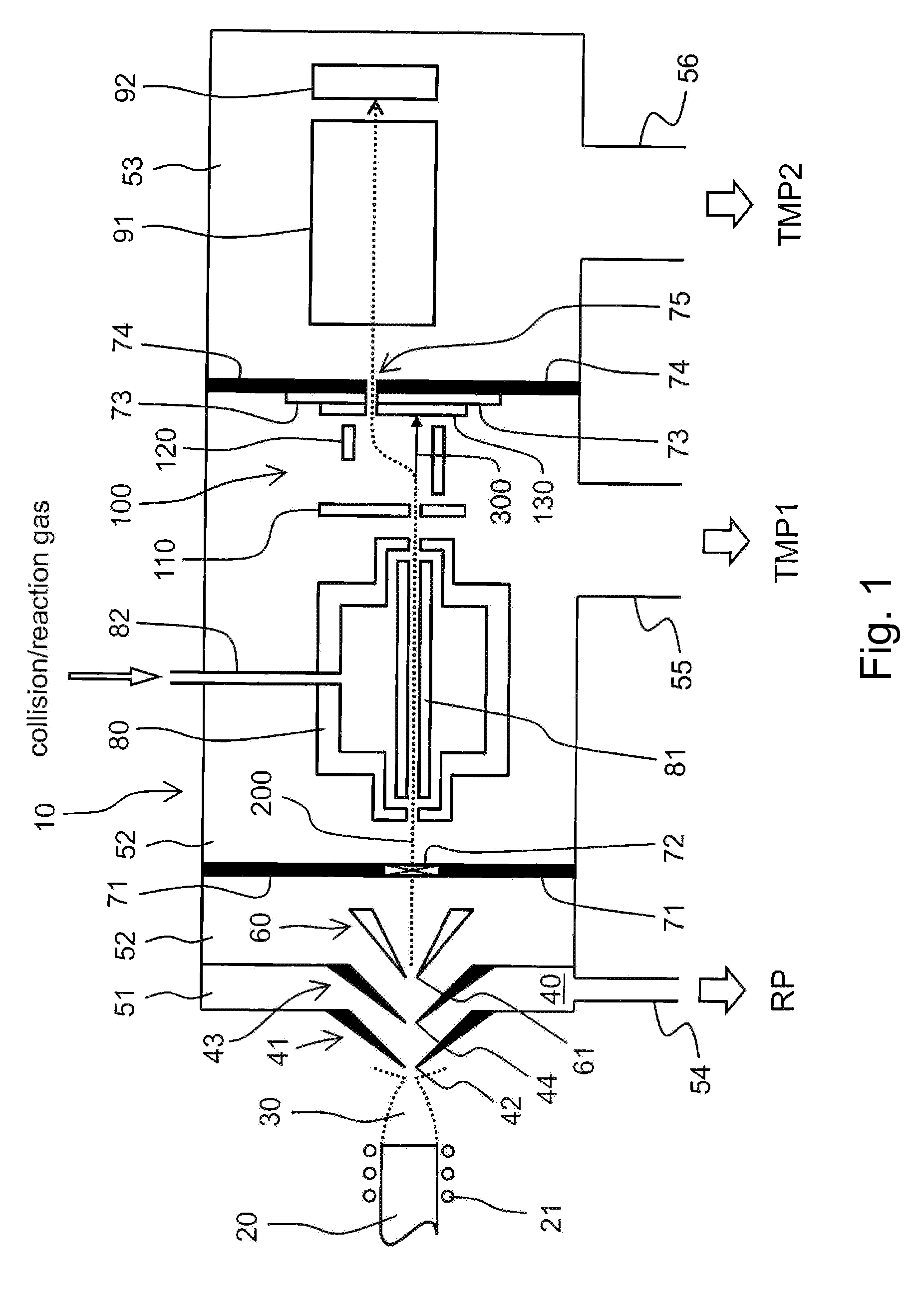

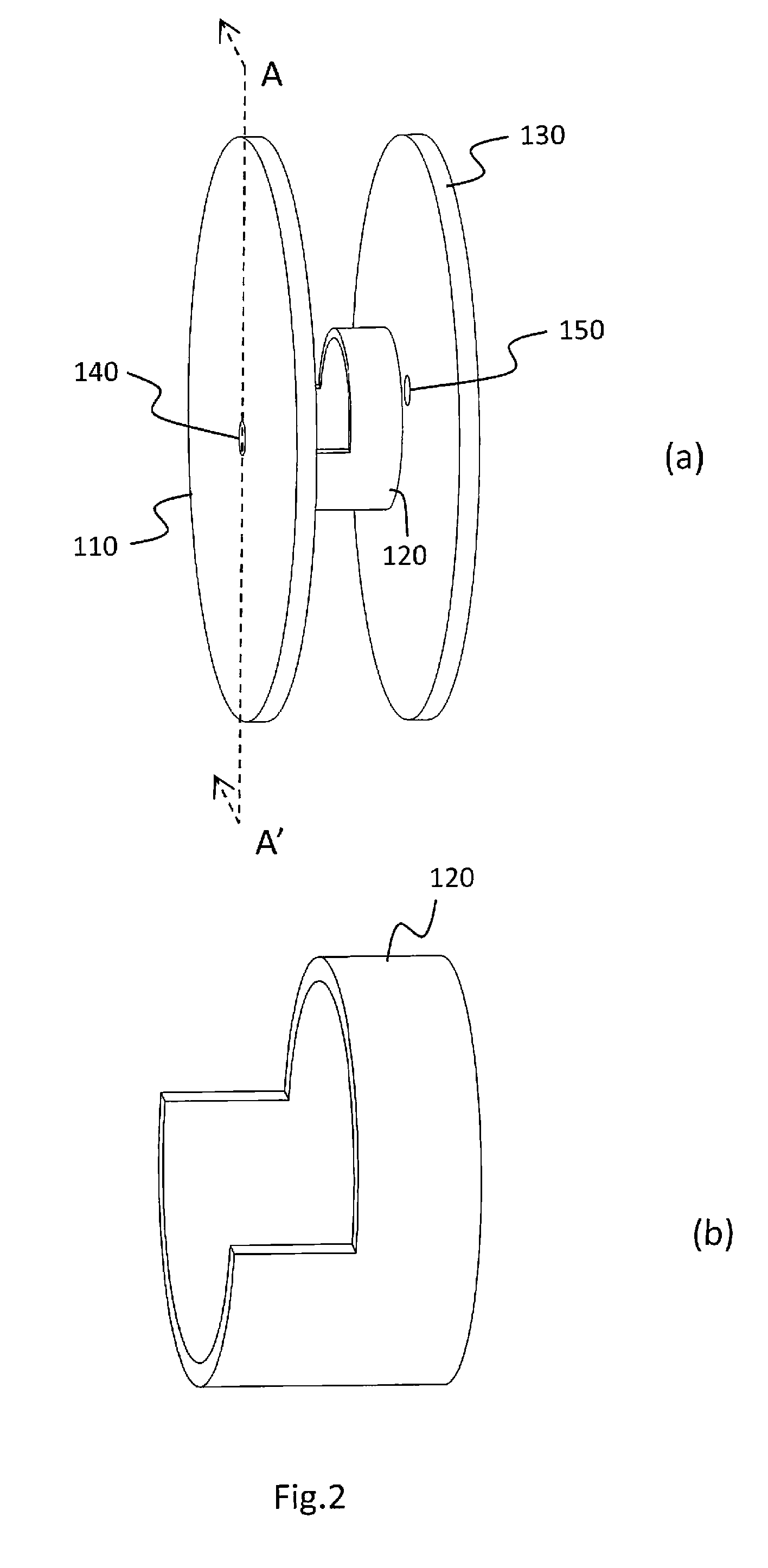

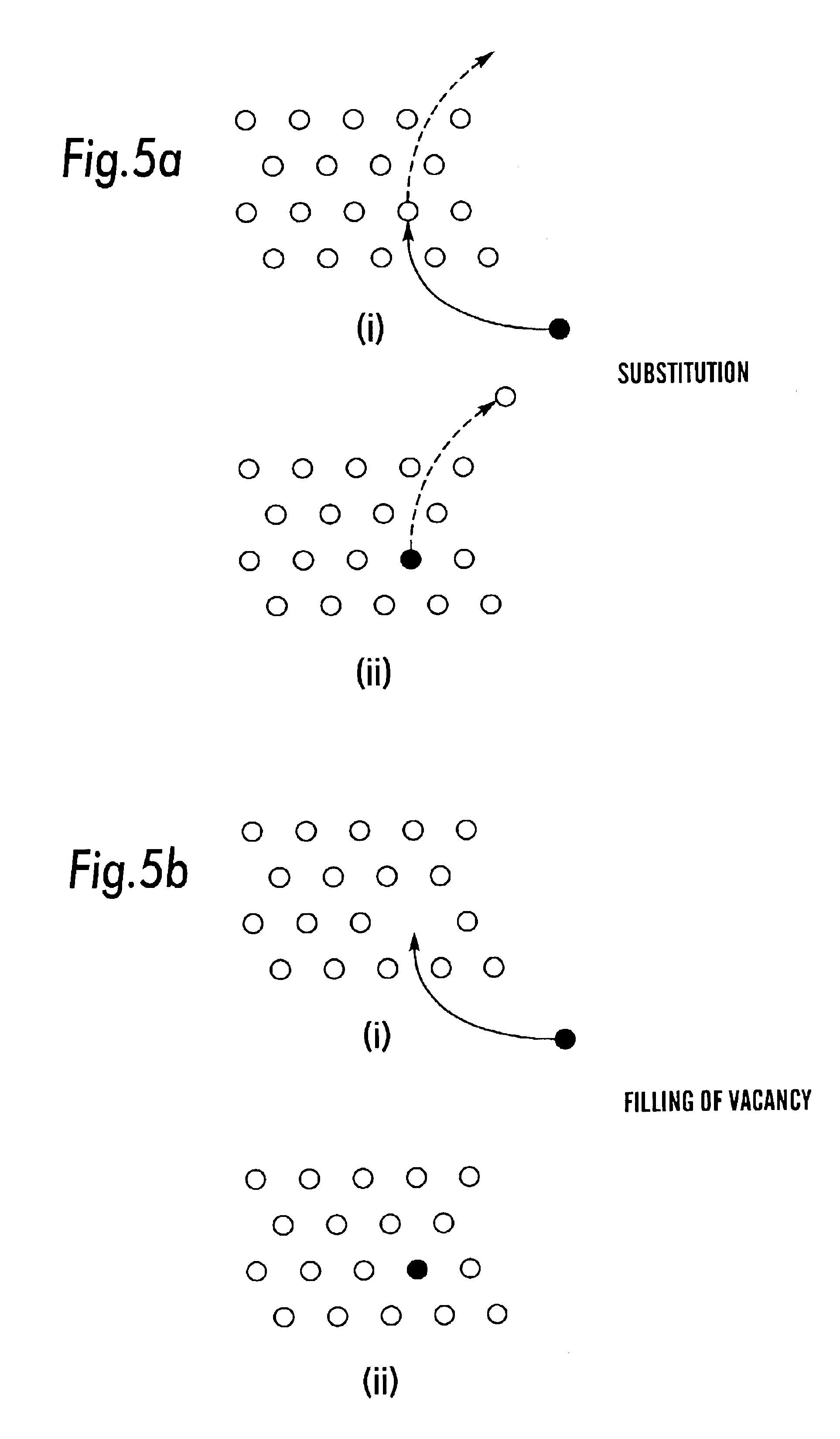

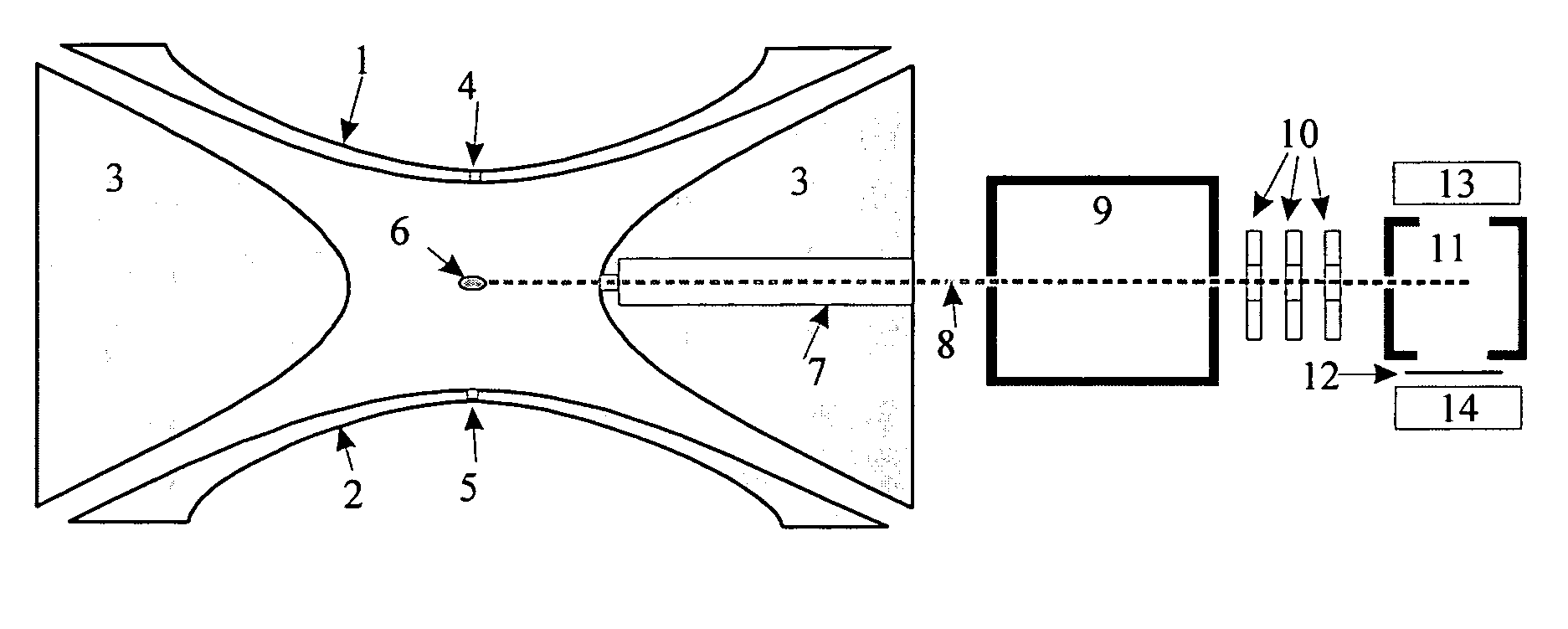

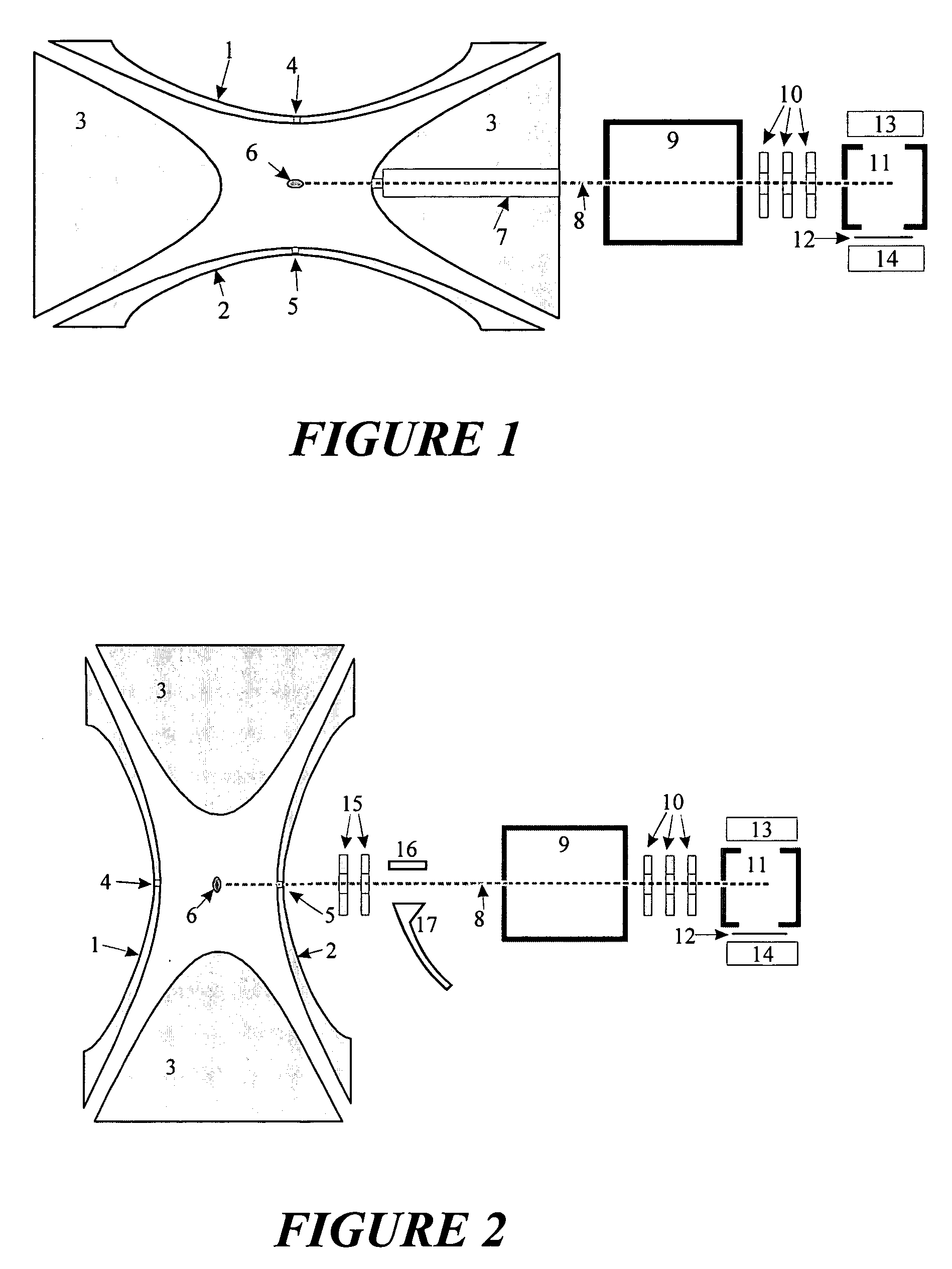

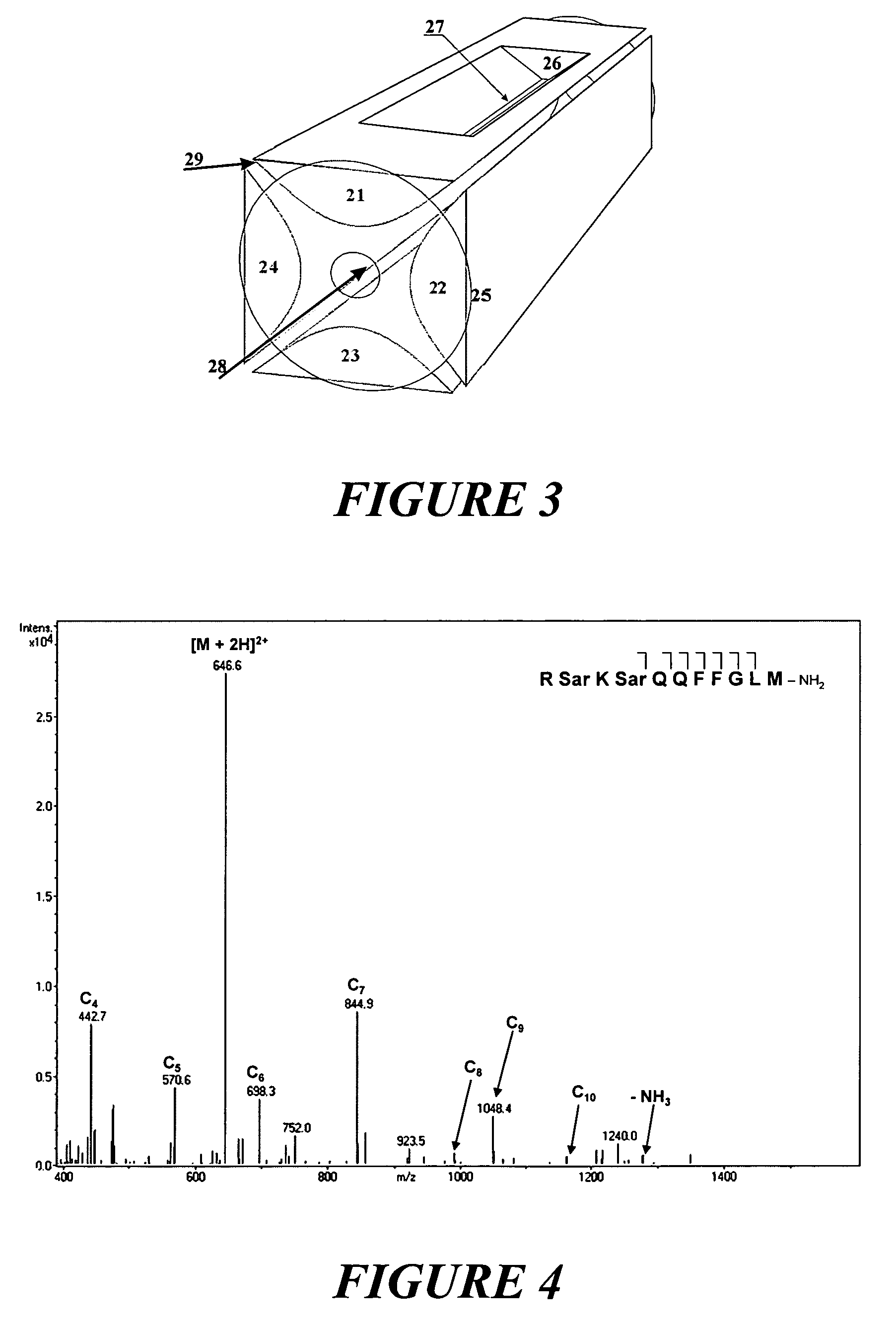

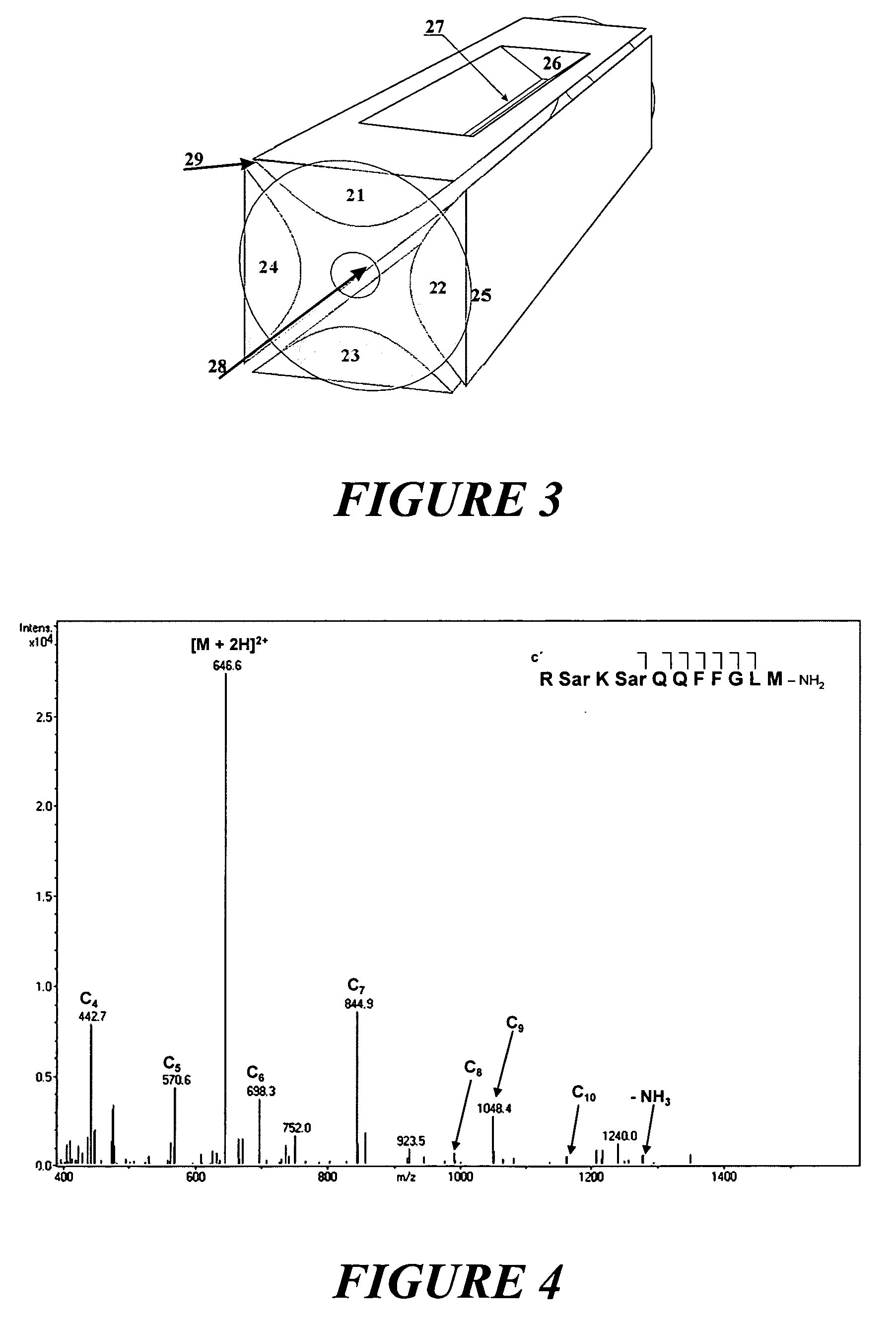

Ion fragmentation by reaction with neutral particles

The invention relates to a method and apparatus for the fragmentation of large molecules, especially biopolymers. The invention consists in reacting analyte ions with excited or radical neutral particles, whereby, at least in the case of bombardment of analyte ions with helium atoms from an FAB generator, a new type of fragmentation occurs which strongly resembles fragmentation by electron capture (ECD). The reactions may be performed in magnetic ion traps (ion cyclotron resonance cells, ICR), in RF ion traps according to Wolfgang Paul, in RF ion guides, or in free beams of analyte ions or neutral particles.

Owner:BRUKER DALTONIK GMBH & CO KG

Etching method and apparatus

InactiveUS20050020070A1Improve accuracyHigh selectivityRadiation/particle handlingElectric discharge tubesPlasma generatorEngineering

An etching apparatus comprises a workpiece holder (21) for holding a workpiece (X), a plasma generator (10, 20) for generating a plasma (30) in a vacuum chamber (3), an orifice electrode (4) disposed between the workpiece holder (21) and the plasma generator (10, 20), and a grid electrode (5) disposed upstream of the orifice electrode (4) in the vacuum chamber (3). The orifice electrode (4) has orifices (4a) defined therein. The etching apparatus further comprises a voltage applying unit (25, 26) for applying a voltage between the orifice electrode (4) and the grid electrode (5) to accelerate ions from the plasma (30) generated by the plasma generator (10, 20) and to pass the extracted ions through the orifices (4a) in the orifice electrode (4), for generating a collimated neutral particle beam having an energy ranging from 10 eV to 50 eV.

Owner:TOHOKU TECHNO ARCH CO LTD

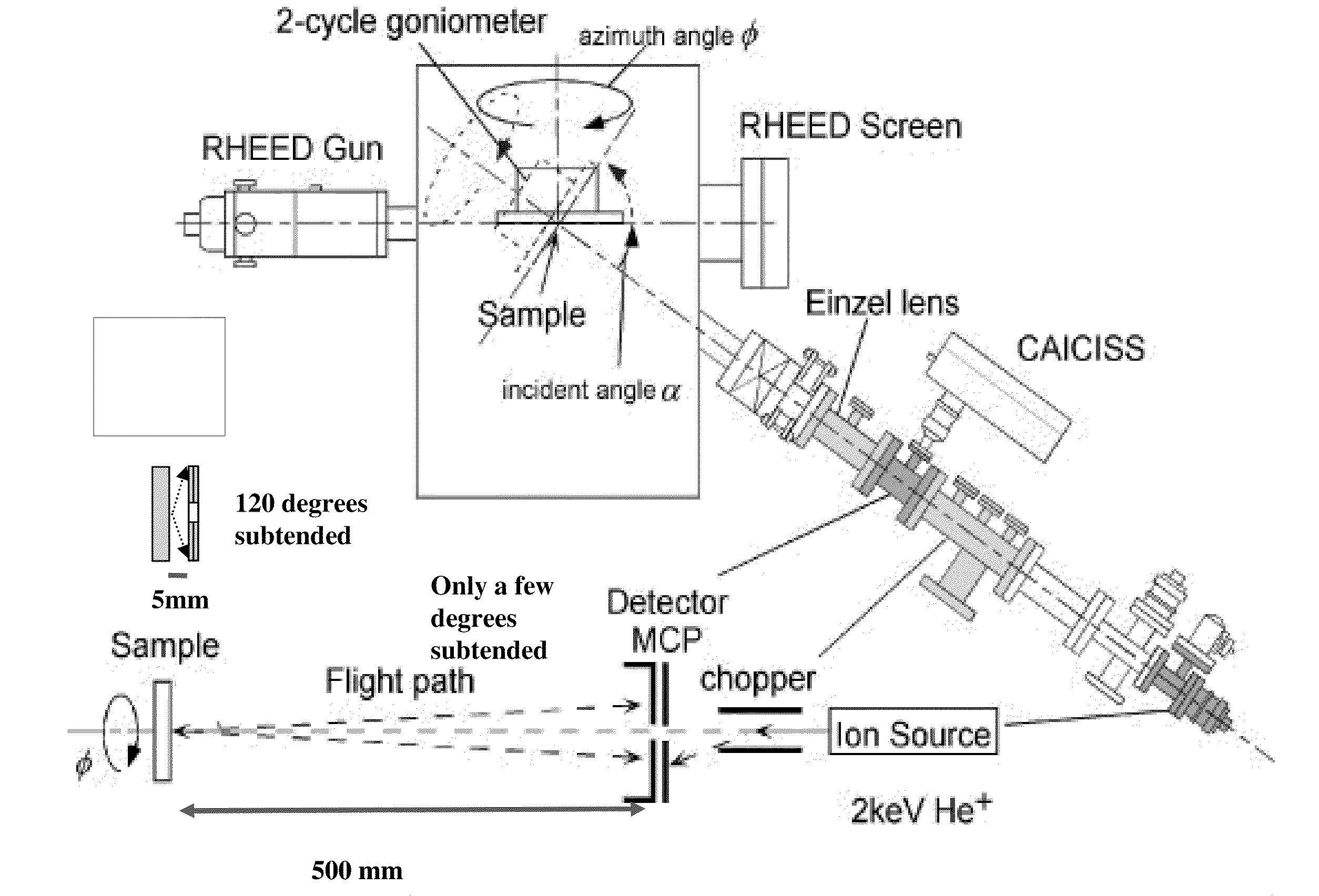

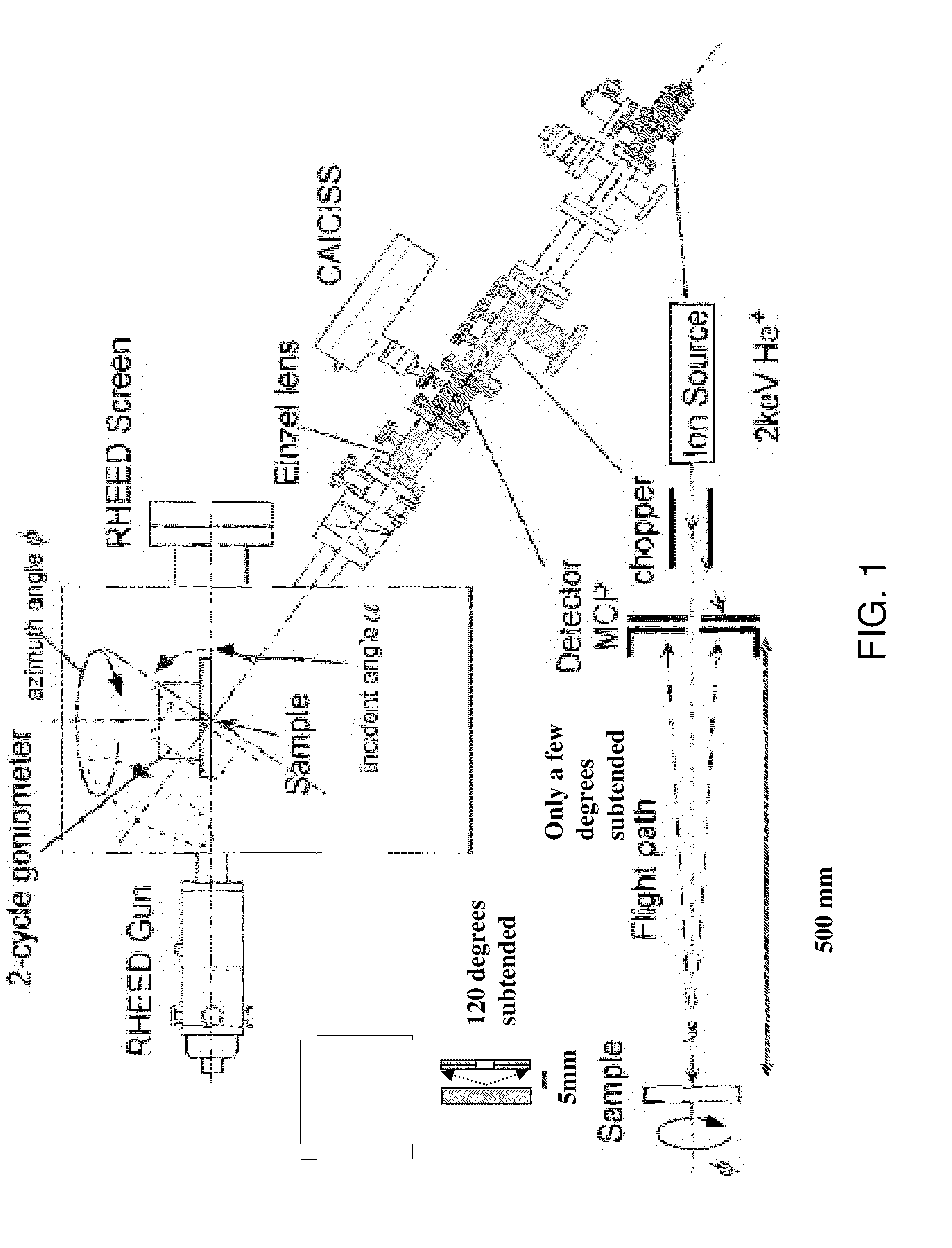

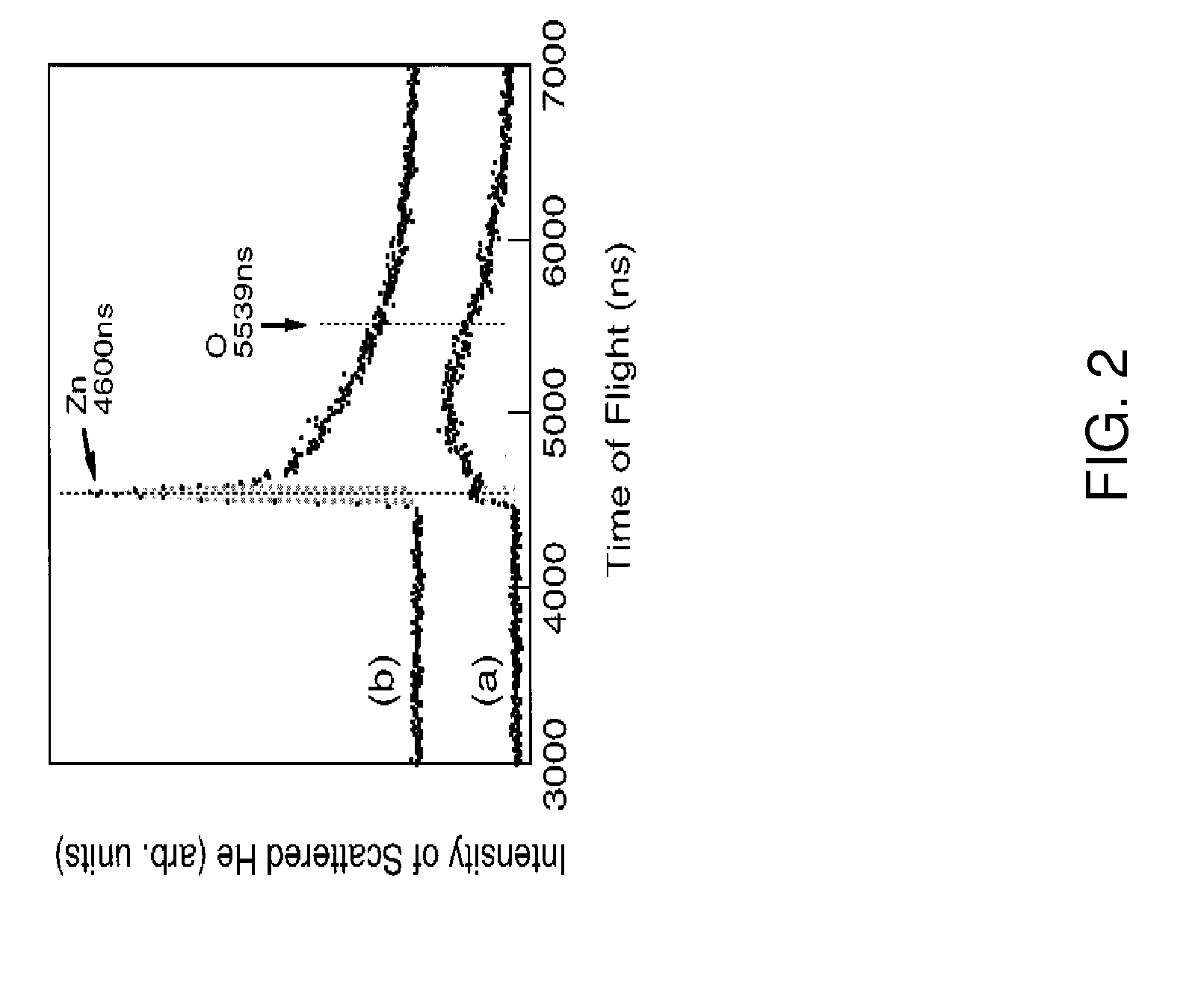

Time-of-flight mass spectrometry of surfaces

ActiveUS20090189072A1Material analysis using wave/particle radiationTime-of-flight spectrometersSecondary electronsTime of flight

The present invent provides a particle detector for counting and measuring the flight time of secondary electrons and scattered ions and neutrals and to correlate coincidences between these and backscattered ions / and neutrals while maintaining a continuous unpulsed microfocused primary ion beam for impinging a surface. Intensities of the primary particle scattering and secondary particle emissions are correlated with the position of impact of the focused beam onto a materials surface so that a spatially resolved surface elemental and electronic structural mapping is obtained by scanning the focused beam across the surface.

Owner:IONWERKS

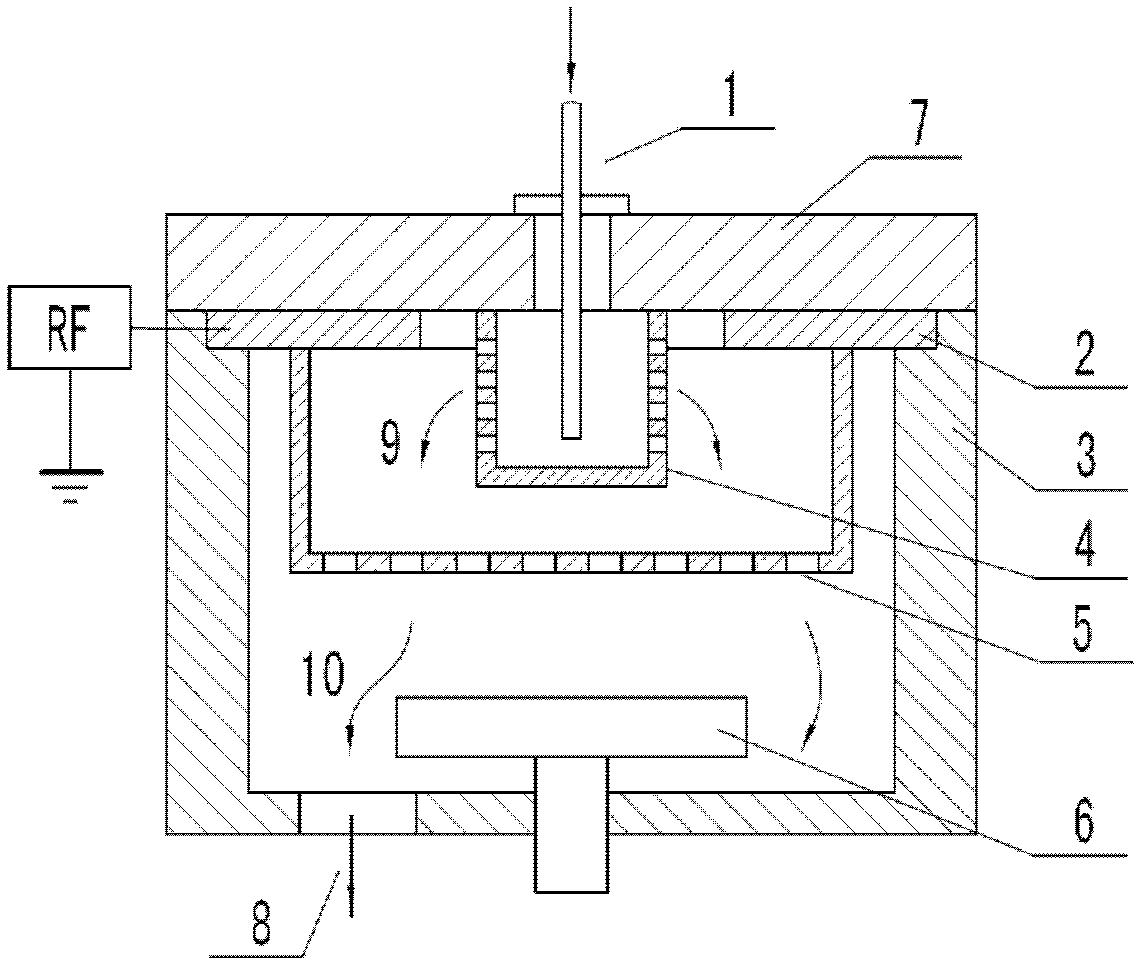

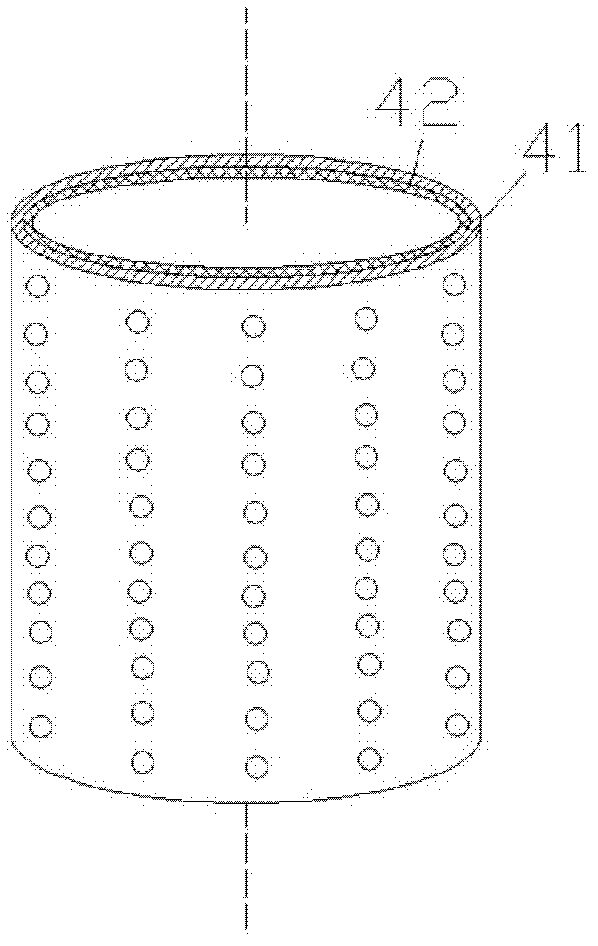

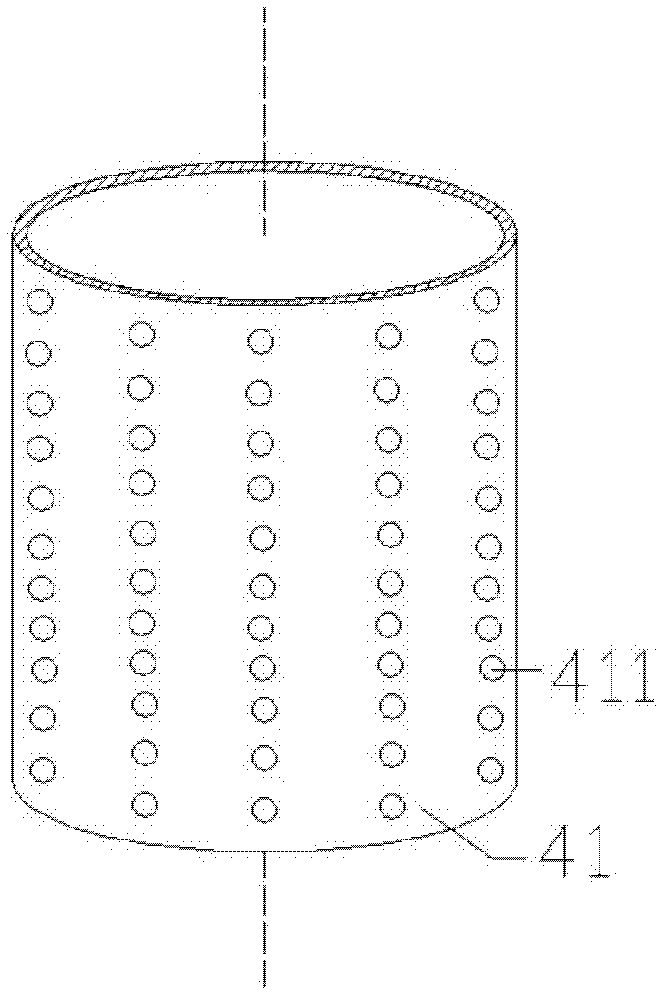

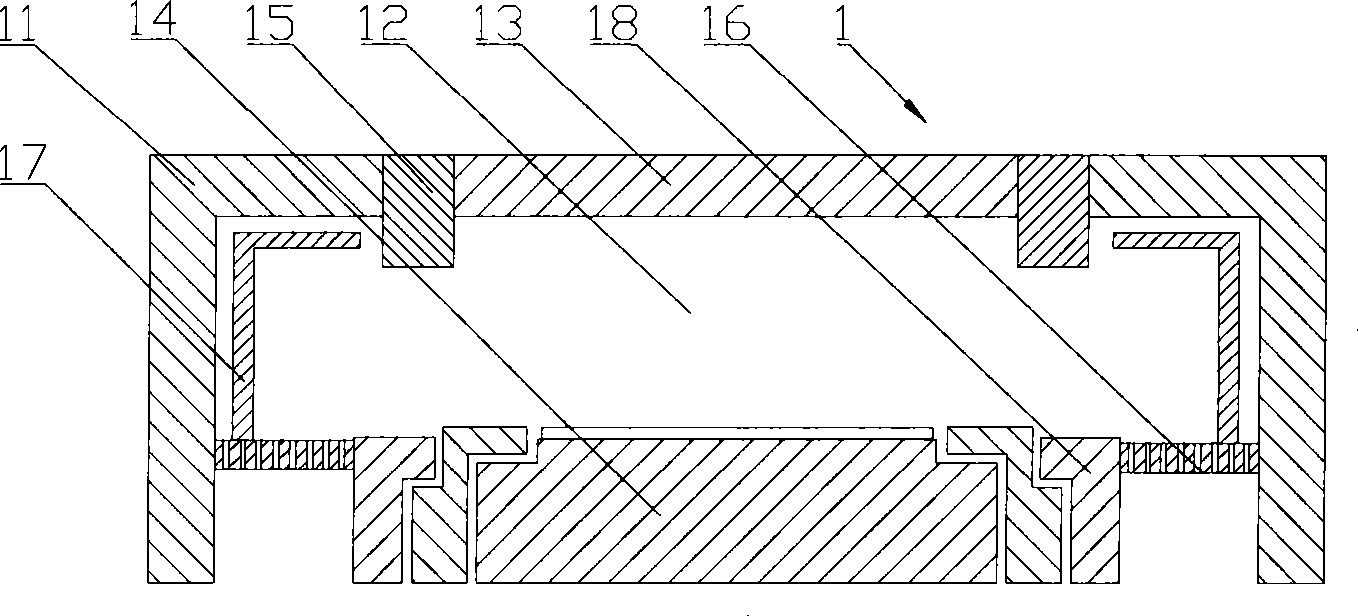

Novel gas-homogenizing structure

ActiveCN102424955AQihui benefitsImprove uniformityElectric discharge tubesChemical vapor deposition coatingEngineeringIonization

The invention relates to the technical field of plasma etching, deposition, and neutral particle etching equipment, and particularly relates to a gas-homogenizing structure applicable to plasma or neutral particle etching systems. The gas-homogenizing structure is disposed at the lower part of a gas inlet pipe of a vacuum cavity; the gas-homogenizing structure comprises a gas-homogenizing cylinder; the gas-homogenizing cylinder adopts a double-layer cylindric structure of an inner gas-homogenizing cylinder and an outer gas-homogenizing cylinder which have coaxial centers and rotate mutually; the bottom of the gas-homogenizing cylinder is closed; gas-homogenizing holes are disposed on the inner gas-homogenizing cylinder and the outer gas-homogenizing cylinder. Under a plasma striking condition, the gas-homogenizing cylinder and a gas-homogenizing disc of the invention are in a sealed state; the increase of the gas density facilitates gas ionization and gas striking, can increase the striking speed; after striking, by rotating the upper and lower layers of the inner and the outer gas-homogenizing cylinders of the gas-homogenizing cylinder and the gas-homogenizing disc, the gas-homogenizing holes are exposed; plasma passes through the gas-homogenizing holes with gas flow and etches a chip; and the uniformity of the gas on the chip surface is improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Technique for improved ion beam transport

ActiveUS20080078949A1Improved ion beam transportElectric discharge tubesSemiconductor/solid-state device manufacturingHigh energyActive cooling

A technique for improved ion implantation is provided. The technique is embodied as an electrostatic filter for an ion implantation device. The electrostatic filter is located just prior to deceleration and may be integrated with a decelerator. Electrodes are used to generate an electric field to separate neutrals from ions. Also, the filter may include active cooling to reduce background gas pressure, a precursor to neutral particle formation. Electrode geometry may also inhibit high energy neutrals from contaminating the target substrate.

Owner:VARIAN SEMICON EQUIP ASSOC INC

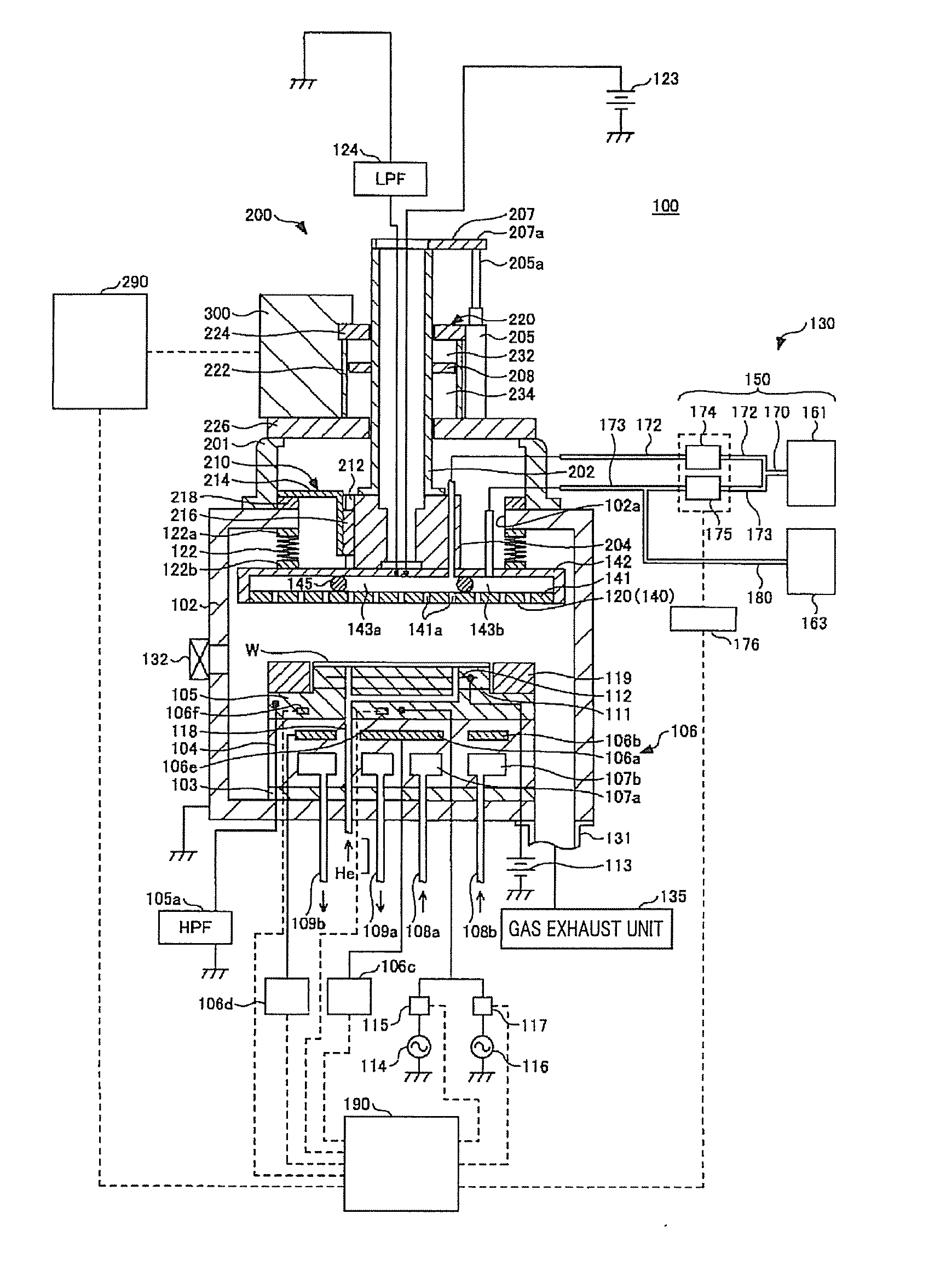

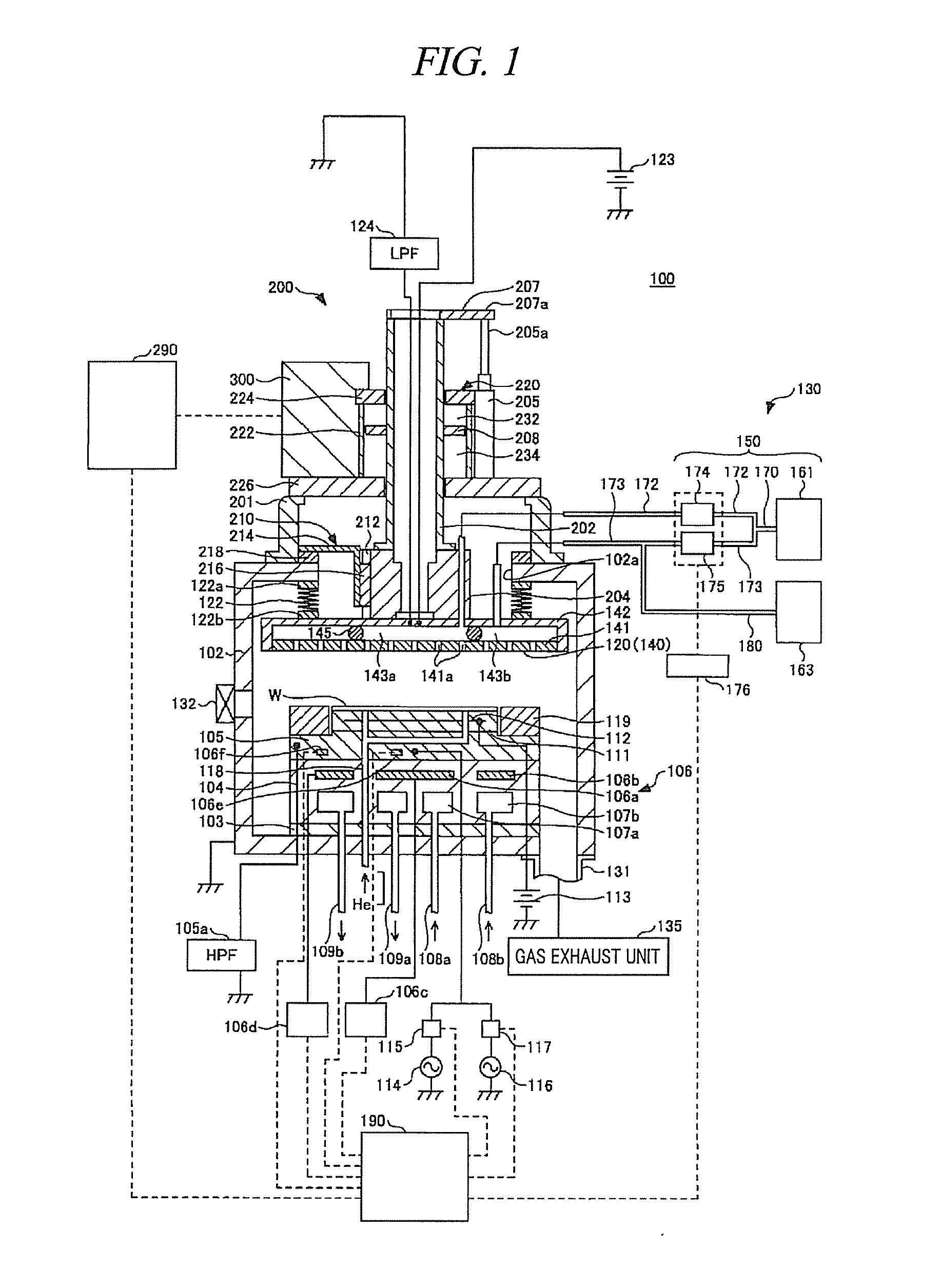

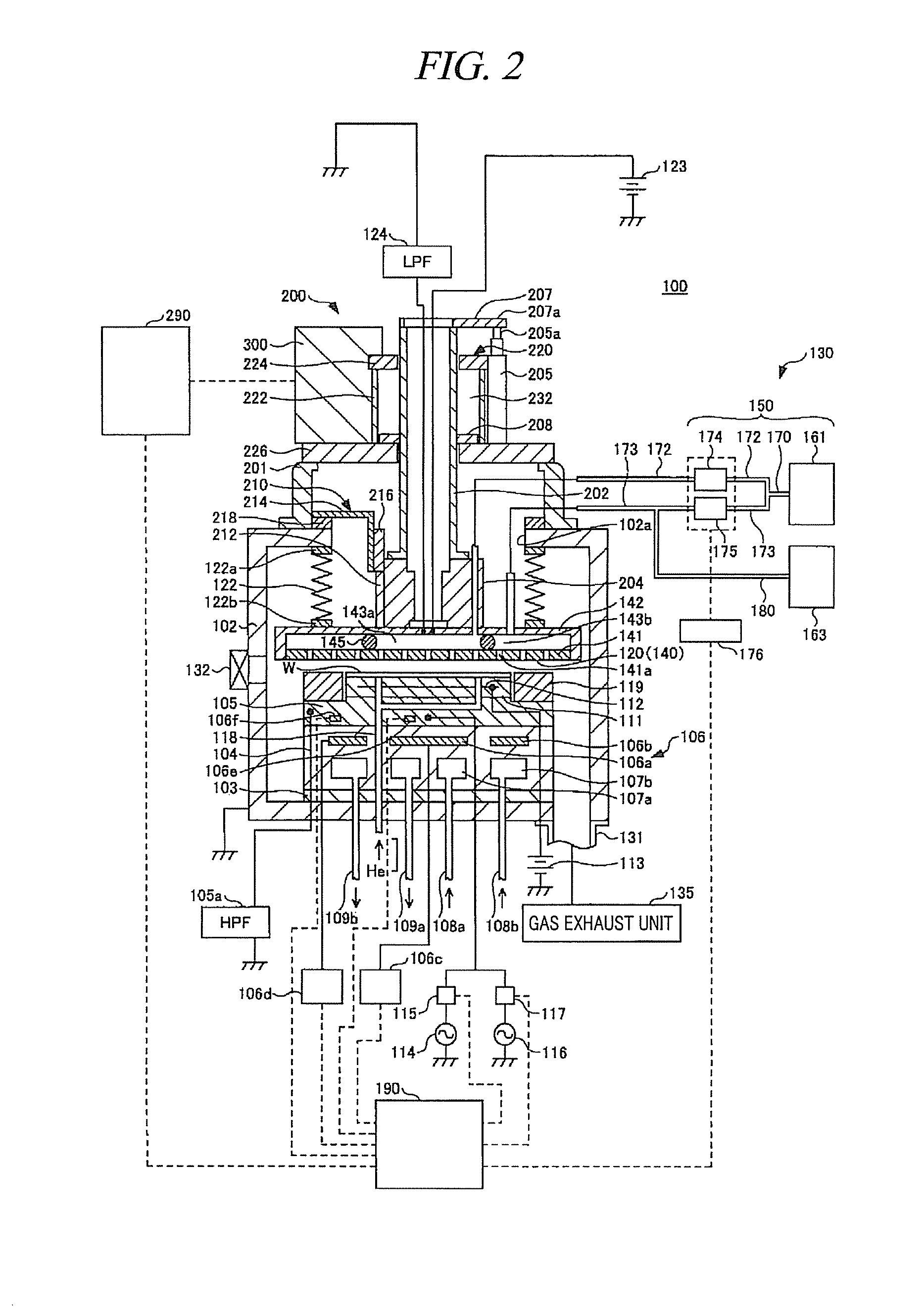

Plasma etching method and plasma etching apparatus

InactiveUS20110220609A1Improve uniformityElectric discharge tubesDecorative surface effectsIrradiationAtomic physics

Owner:TOKYO ELECTRON LTD

Extreme ultraviolet light source apparatus

ActiveUS20120091893A1Improve efficiencyEliminate the neutral particlesElectric discharge tubesPhotomechanical apparatusExtreme ultravioletIonization

In an EUV light source apparatus, a collector mirror is protected from debris damaging a mirror coating. The EUV light source apparatus includes: a chamber in which extreme ultraviolet light is generated; a target supply unit for supplying a target material into the chamber; a plasma generation laser unit for irradiating the target material within the chamber with a plasma generation laser beam to generate plasma; an ionization laser unit for irradiating neutral particles produced at plasma generation with an ionization laser beam to convert the neutral particles into ions; a collector mirror for collecting the extreme ultraviolet light radiated from the plasma; and a magnetic field or electric field forming unit for forming a magnetic field or an electric field within the chamber so as to trap the ions.

Owner:GIGAPHOTON

Ion fragmentation by reaction with neutral particles

ActiveUS20060192100A1Optical radiation measurementSugar derivativesIon trap mass spectrometryAnalyte

The invention relates to a method and apparatus for the fragmentation of large molecules, especially biopolymers. The invention consists in reacting analyte ions with excited or radical neutral particles, whereby, at least in the case of bombardment of analyte ions with helium atoms from an FAB generator, a new type of fragmentation occurs which strongly resembles fragmentation by electron capture (ECD). The reactions may be performed in magnetic ion traps (ion cyclotron resonance cells, ICR), in RF ion traps according to Wolfgang Paul, in RF ion guides, or in free beams of analyte ions or neutral particles.

Owner:BRUKER DALTONIK GMBH & CO KG

Extreme ultra violet light source apparatus

ActiveUS7705333B2Efficient ionizationEnergy efficiencyLaser detailsSemiconductor/solid-state device manufacturingMicrowaveElectron cyclotron resonance

In an extreme ultra violet light source apparatus that exhausts debris including fast ions and neutral particles by the effect of a magnetic field, neutral particles emitted from plasma are efficiently ionized. The extreme ultra violet light source apparatus includes a plasma generating unit that generates plasma, that radiates at least extreme ultra violet light, through pulse operation; collective optics that collects the extreme ultra violet light radiated from the plasma; a microwave generating unit that radiates microwave through pulse operation into a space in which a magnetic field is formed to cause electron cyclotron resonance, and thereby ionizes neutral particles emitted from the plasma; a magnetic field forming unit that forms the magnetic field and a magnetic field for trapping at least ionized particles; and a control unit that synchronously controls at least the plasma generating unit and the microwave generating unit.

Owner:GIGAPHOTON

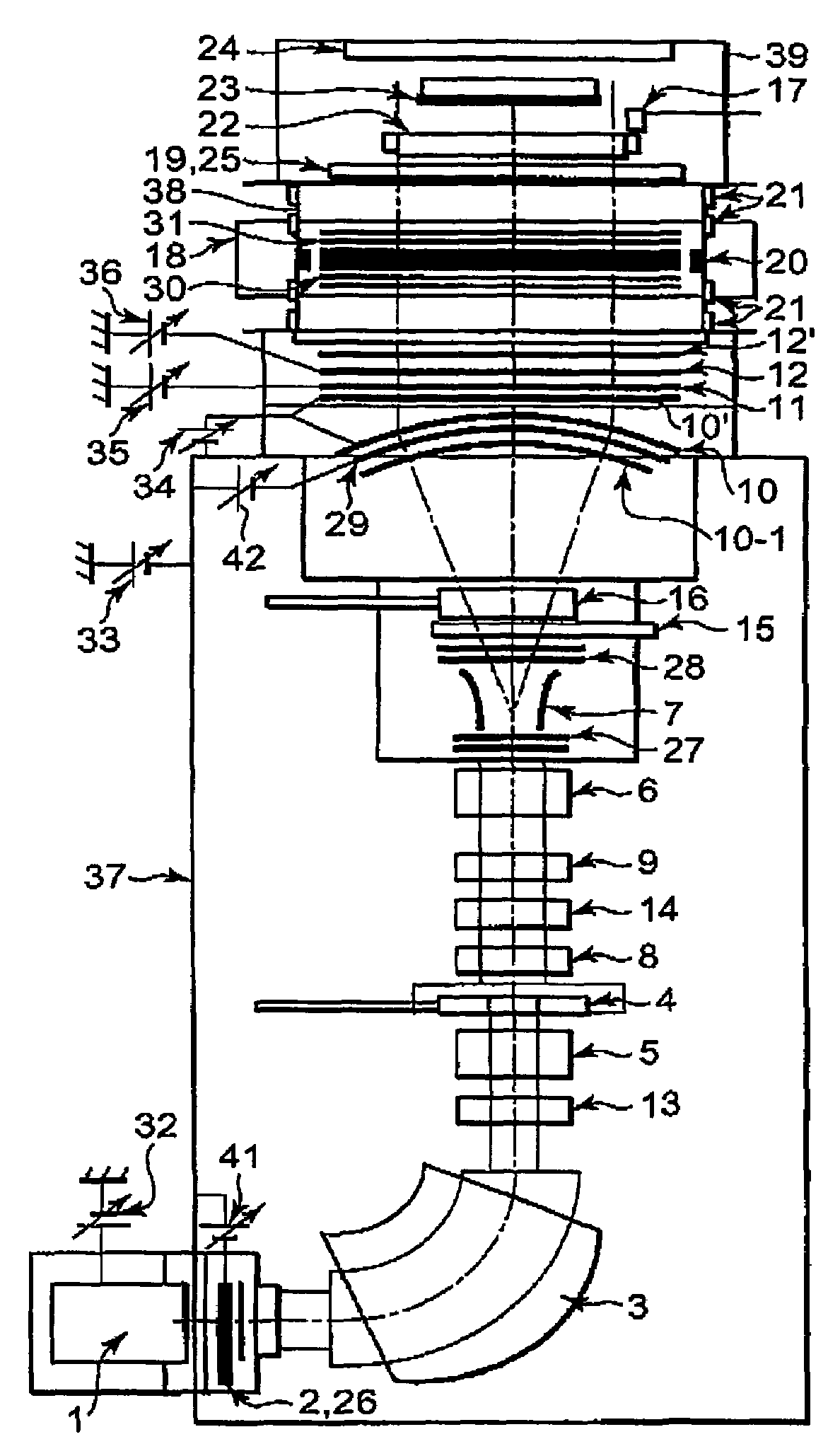

Irradiation system with ion beam

InactiveUS7351987B2Reduce pollutionSemiconductor/solid-state device manufacturingIsotope separationTransformerHigh energy

An irradiation system comprises a beam generation source, a mass analysis device, a beam transformer, a deflector for scanning which swings the beam reciprocally, a beam parallelizing device, an acceleration / deceleration device, and an energy filtering device. According to this invention, a hybrid angular energy filter generating both electric and magnetic fields to bend trajectories is provided as the energy filtering device. A pair of multi-surface energy slit units each having a plurality of energy slits that are switchable therebetween depending on an ion species for irradiation are further provided on a downstream side of the hybrid angular energy filter. It is possible to selectively irradiate a target wafer with high-current beams from low energy to high energy in the conditions where contamination such as neutral particles, different kinds of dopants, ions with different energies, metal, and dust particles is extremely small in amount.

Owner:SEN CORP AN SHI & AXCELIS

Method And Apparatus For Laser Machining

ActiveUS20120103945A1Improve micromachiningEasy to controlElectric discharge tubesElectron beam welding apparatusLaser processingMachining

Laser processing is enhanced by using endpointing or by using a charged particle beam together with a laser. End-pointing uses emissions, such as photons, electrons, ions, or neutral particles, from the substrate to determine when the material under the laser has changed or is about to change. Material removed from the sample can be deflected to avoid deposition onto the laser optics.

Owner:FEI CO

Ion transmission system for inductively coupled plasma mass spectrometry

InactiveCN103681204AEasy transferImprove transmission efficiencyElectron/ion optical arrangementsMass analyzerInductively coupled plasma

The invention belongs to the technical field of mass spectrographies, and relates to an ion transmission system for an inductively coupled plasma mass spectrometry. The ion transmission system comprises an ion sampling cone, an interception cone, an extraction lens, an ion deflecting electrode and ion focusing lenses, wherein the centers of all the parts are on coaxial horizontal lines; space electric field distribution is generated under a DC voltage; ions deflect, focus and are transmitted under the action of the electric field; photons and neutral particles in a sample are free from the action of the electric field, transmitted linearly, and blocked while meeting the ion deflecting electrode; electrified ions are guided by the electric field, bypass the ion deflecting electrode, and focus into an ion beam under the action of the electric field of the focusing lenses, and then are transmitted to a mass analyzer. The ion transmission system has the advantages that the structure is simple; the use is convenient; interference signals generated due to the entering of the photons and the neutral particles can be removed effectively; the ion transmission efficiency and the sensitivity of the inductively coupled plasma mass spectrometry are improved.

Owner:FUDAN UNIV

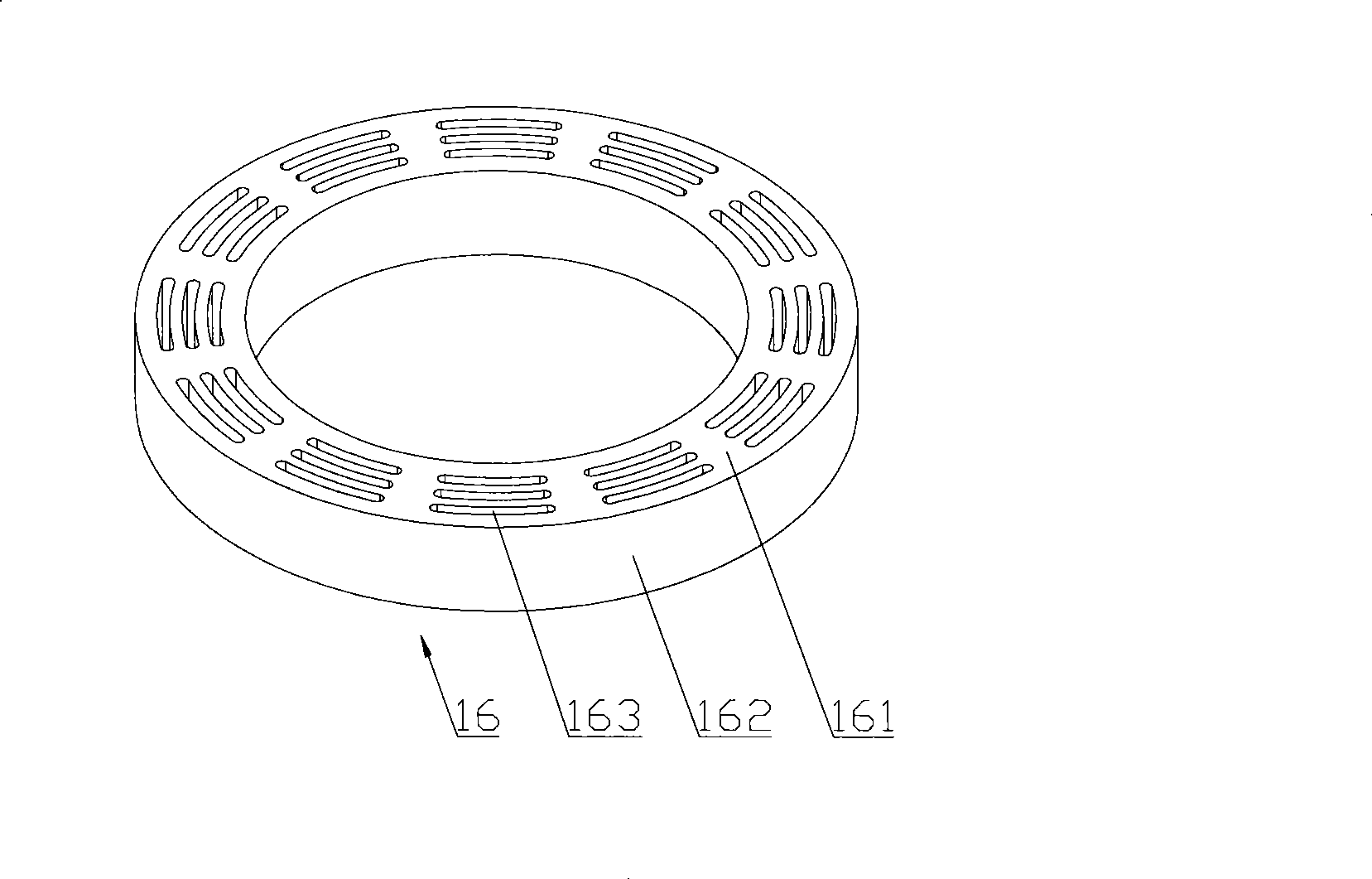

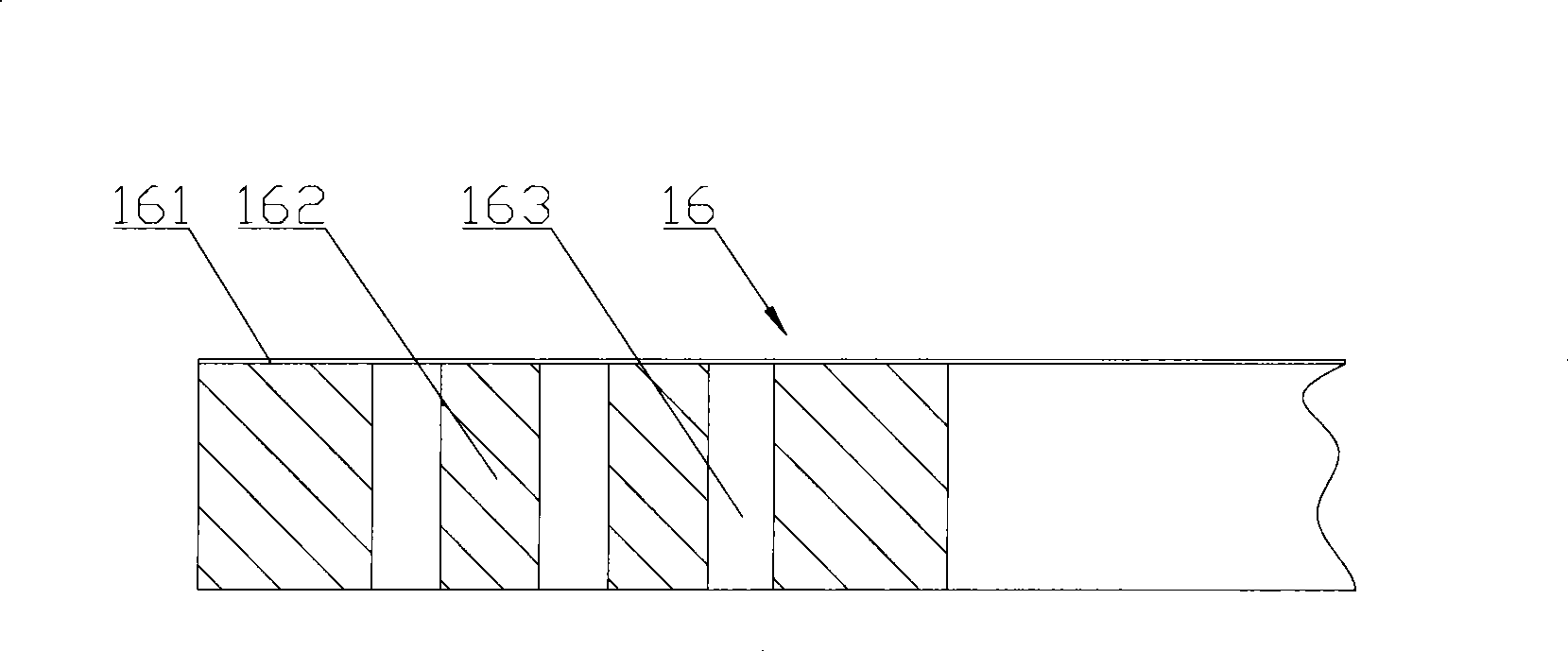

Plasma treatment apparatus and shield ring thereof

ActiveCN101452821AImprove restraintExtended service lifeElectric discharge tubesSemiconductor/solid-state device manufacturingElectrical conductorPlasma processing

The invention discloses a plasma shielding ring, which comprises an upper layer and a lower layer connected fixedly and integrally, wherein the upper layer is a plasma-proof insulating layer (21), and the lower layer is a conductor layer (22). At least one axially extended exhaust passage (23) penetrates the insulating layer (23) and the conductor layer (21), and the exhaust passage (23) is a bent passage. The invention also discloses a plasma processing device comprising the plasma shielding ring (2). Under the condition that the exhaust passage (23) is the bent passage, most of charged particles inevitably collide with the bent inner wall of the bent passage, so as to lose carried electric charge, and be converted into harmless neutral particles. Therefore, the plasma shielding ring (2) improves inhibiting effect on plasma remarkably; and the internal structure of the plasma processing device is not easy to be damaged, so the service life of the plasma processing device is remarkably prolonged.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

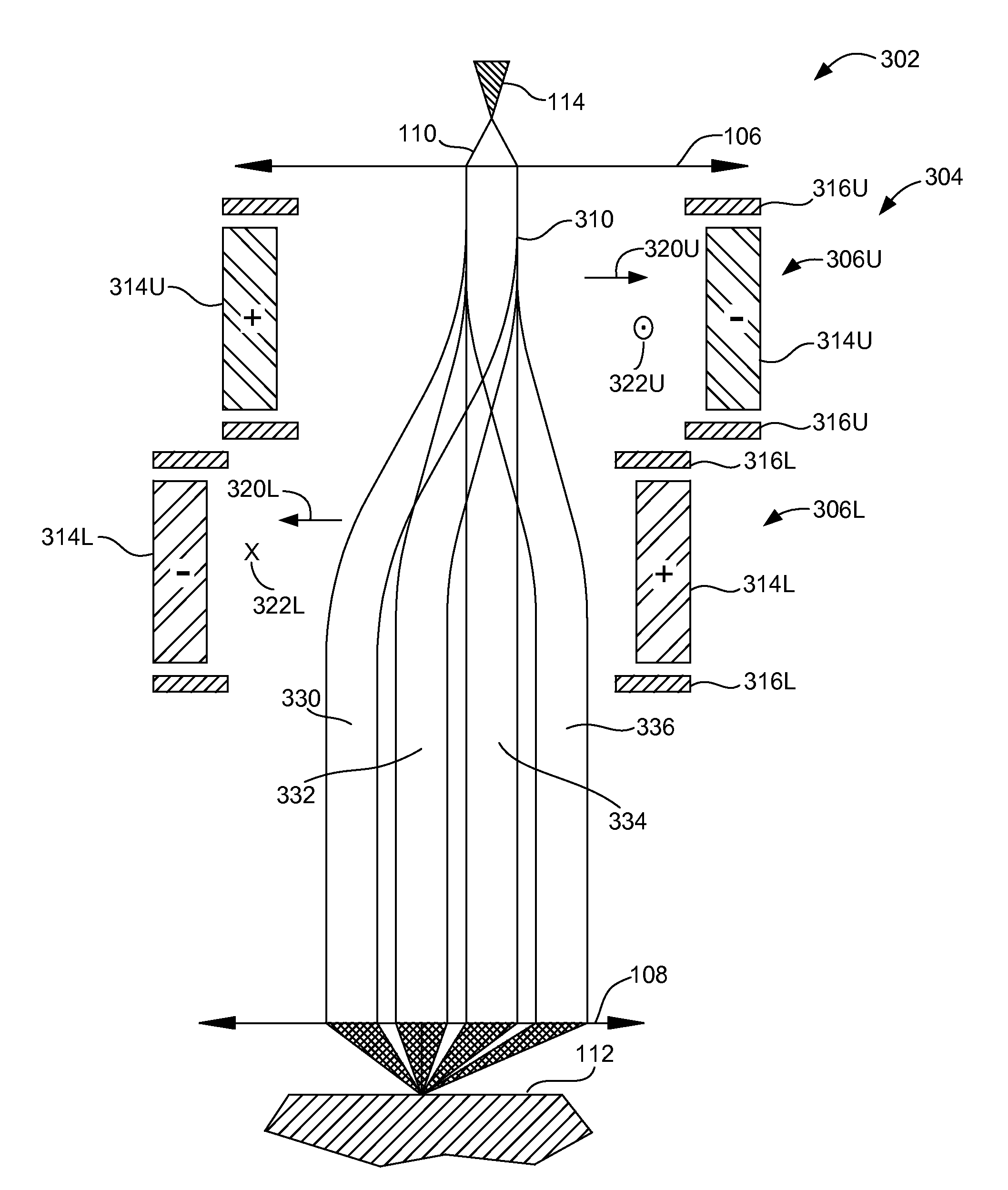

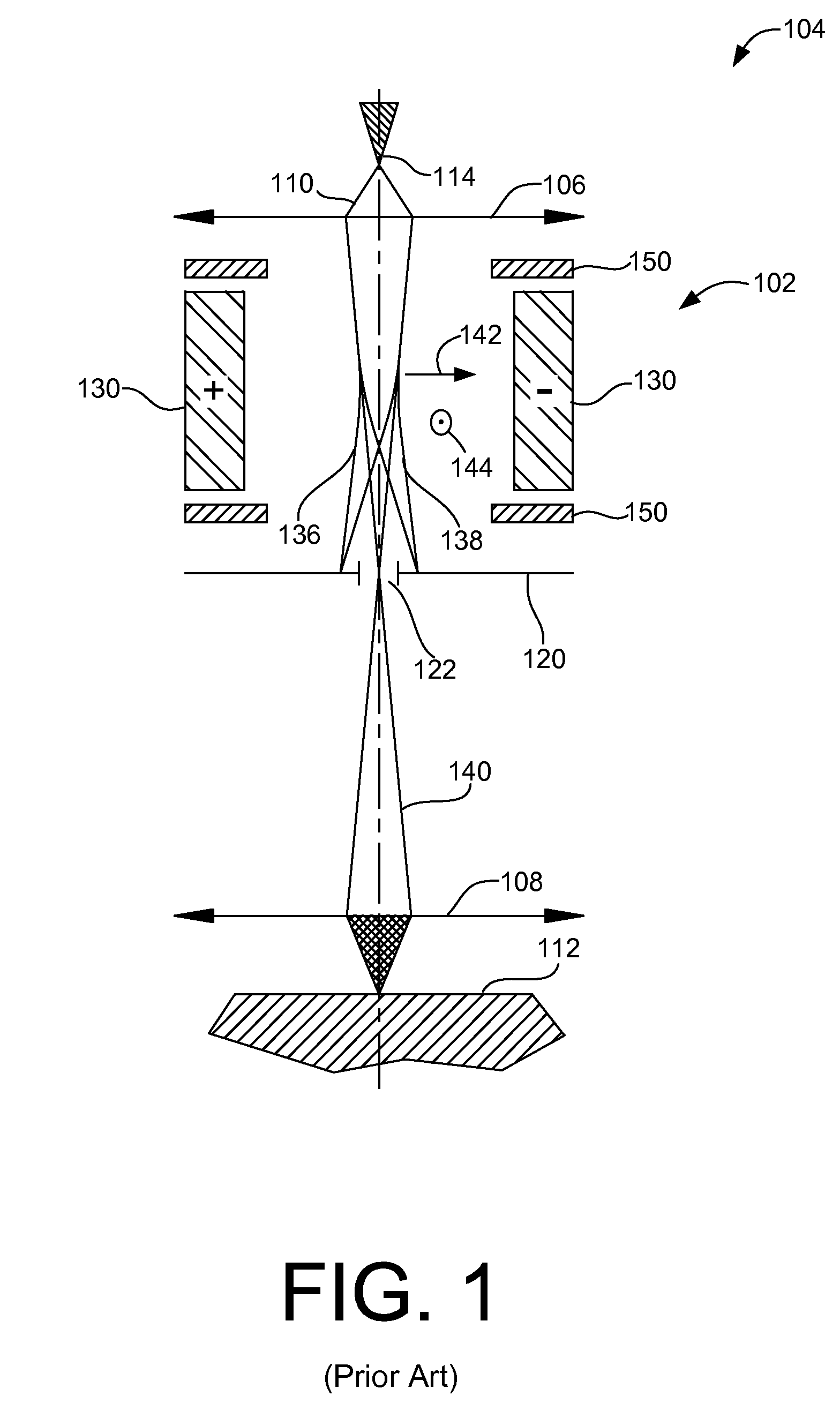

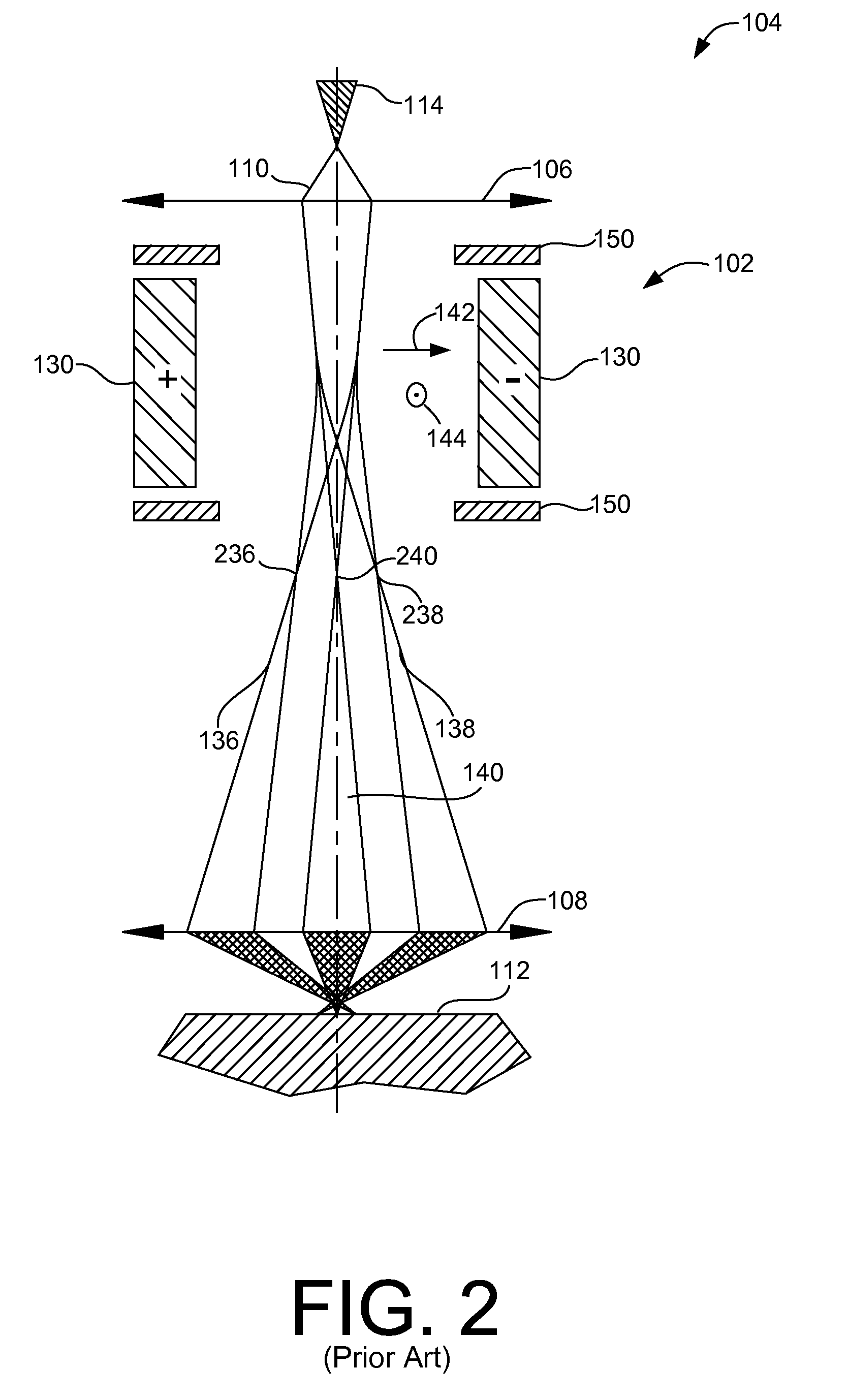

Aberration-corrected wien ExB mass filter with removal of neutrals from the Beam

ActiveUS8283629B1Reduce overall chromatic aberrationReduce and eliminate chromatic aberrationStability-of-path spectrometersMaterial analysis using wave/particle radiationLight beamIon beam

A mass filter for an ion beam system includes at least two stages and reduces chromatic aberration. One embodiment includes two symmetrical mass filter stages, the combination of which reduces or eliminates chromatic aberration, and entrance and exit fringing field errors. Embodiments can also prevent neutral particles from reaching the sample surface and avoid crossovers in the beam path. In one embodiment, the filter can pass a single species of ion from a source that produces multiple species. In other embodiments, the filter can pass a single ion species with a range of energies and focus the multi-energetic ions at the same point on the substrate surface.

Owner:FEI CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com