Patents

Literature

51results about How to "Improve neutralization efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

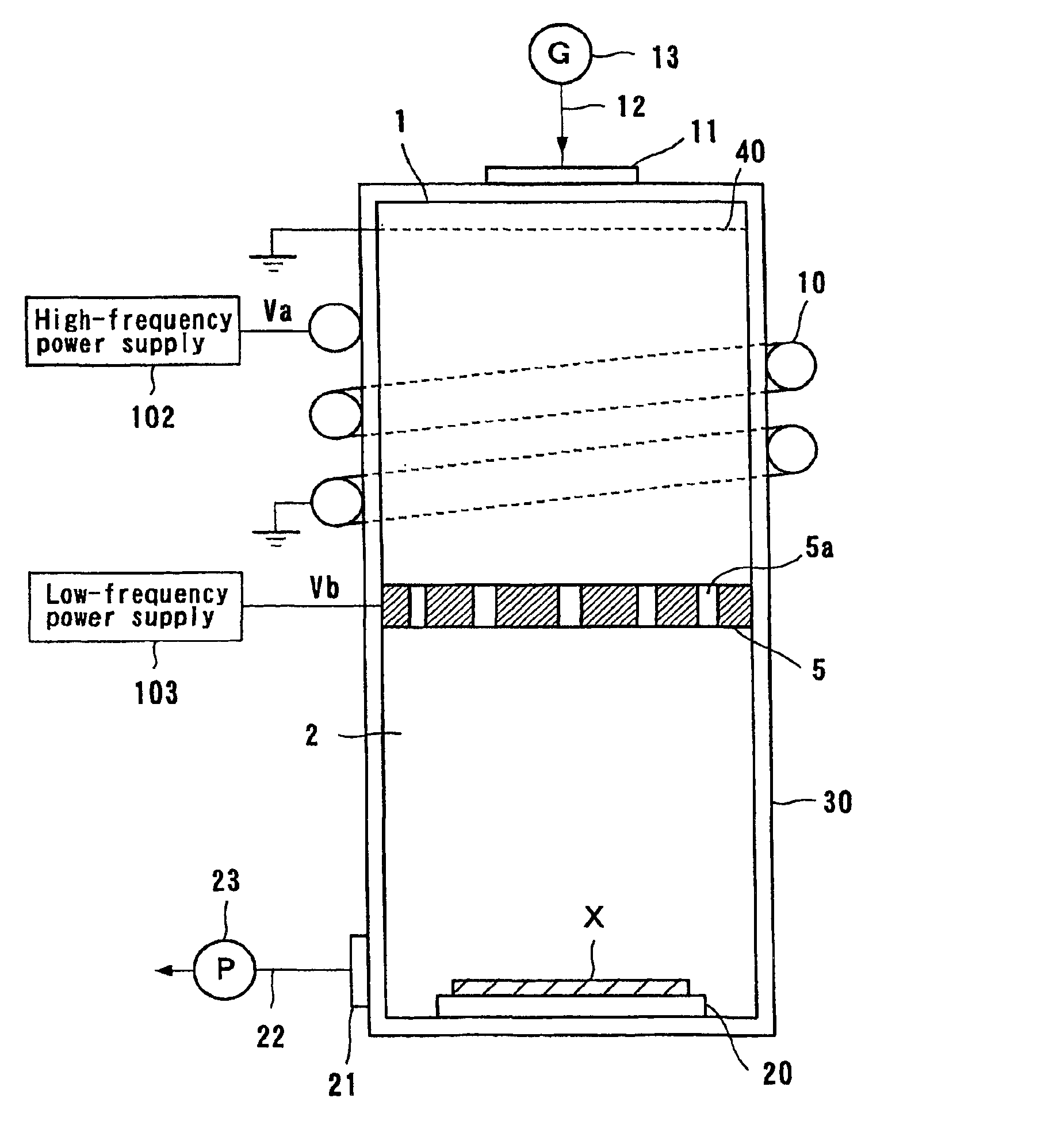

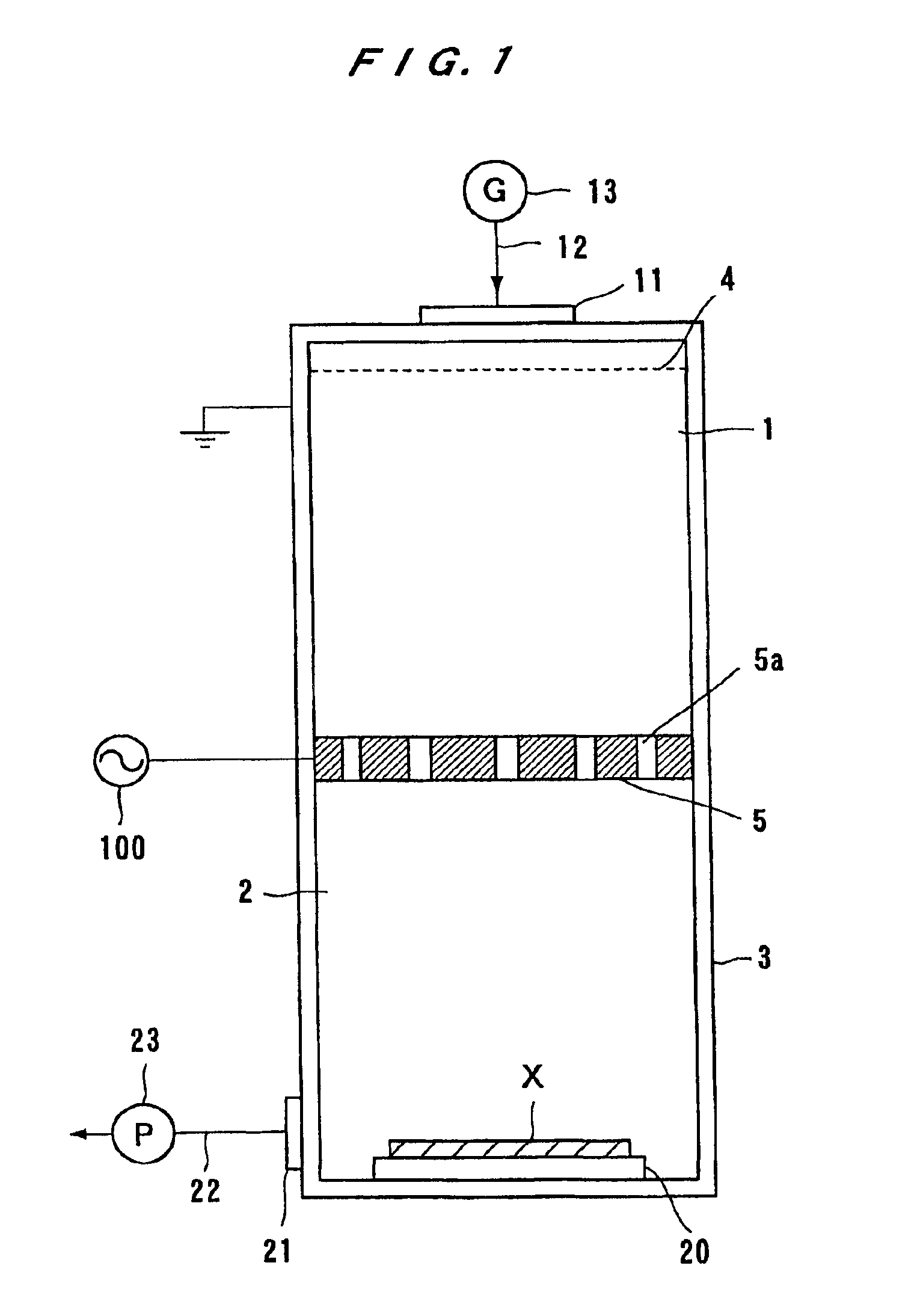

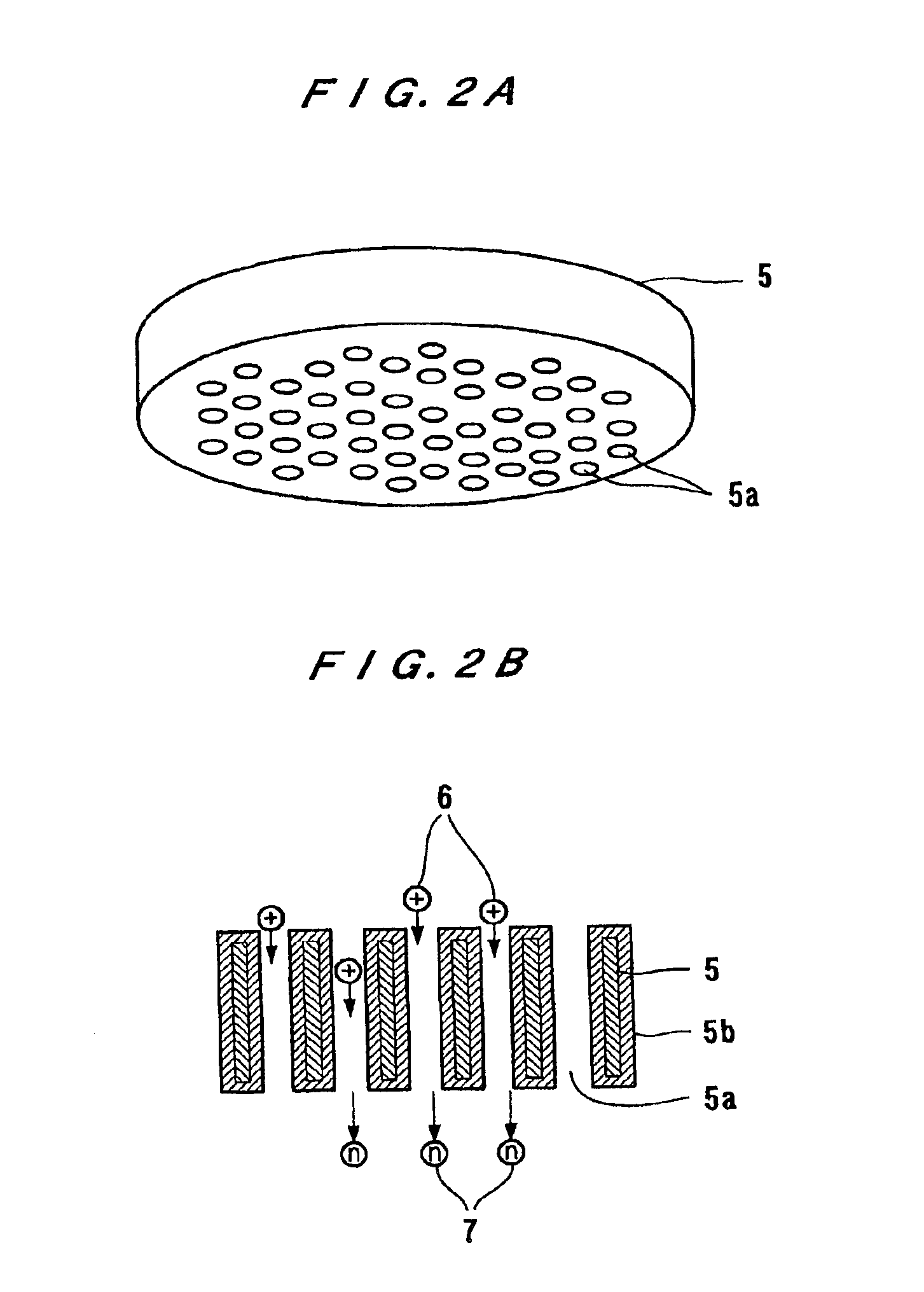

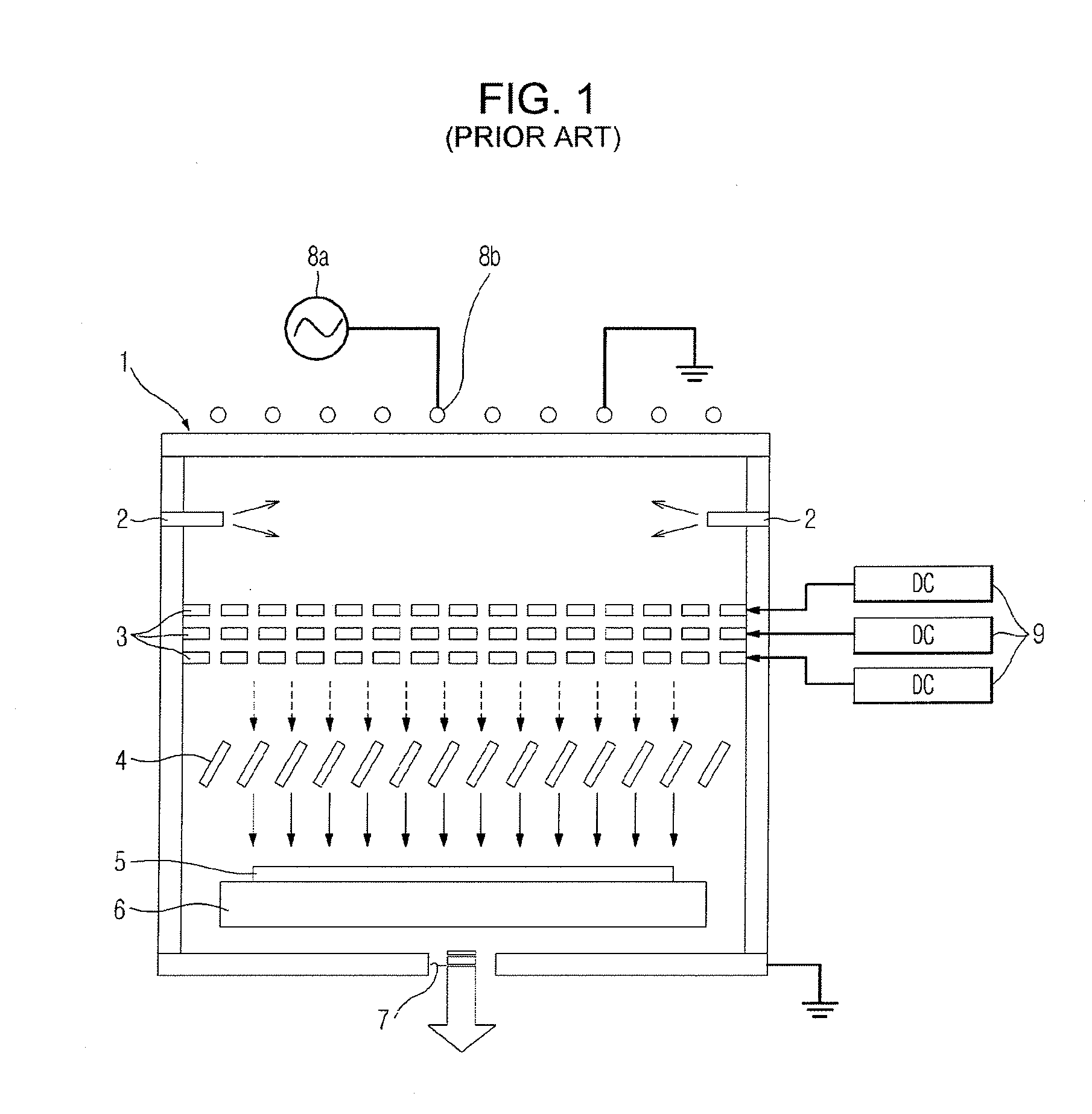

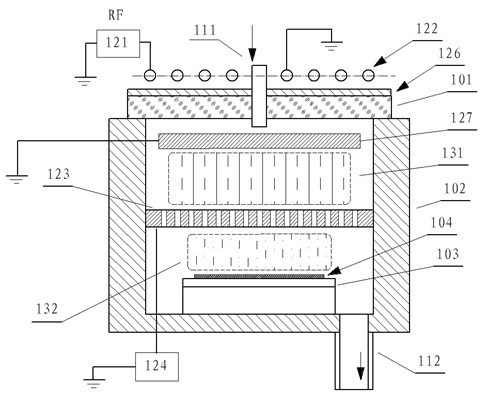

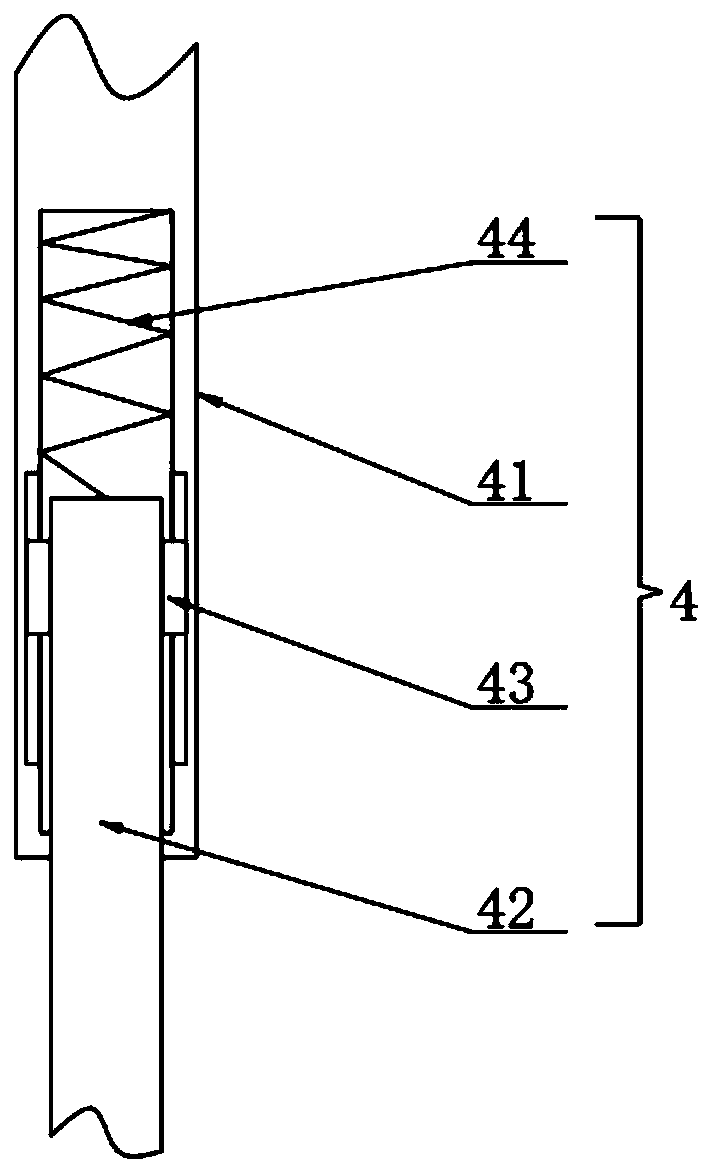

Neutral particle beam processing apparatus

InactiveUS6861642B2Inexpensive and compact structureImprove neutralization efficiencyLaser detailsVacuum evaporation coatingDielectricPlasma generator

A neutral particle beam processing apparatus comprises a workpiece holder (20) for holding a workpiece (X), a plasma generator for generating a plasma in a vacuum chamber (3), an orifice electrode (5) disposed between the workpiece holder (20) and the plasma generator, and a grid electrode (4) disposed upstream of the orifice electrode (5) in the vacuum chamber (3). The orifice electrode (5) has orifices (5a) defined therein. The neutral particle beam processing apparatus further comprises a voltage applying unit for applying a voltage between the orifice electrode (5) and the grid electrode (4) via a dielectric (5b) to extract positive ions from the plasma generated by the plasma generator and pass the extracted positive ions through the orifices (5a) in the orifice electrode (5).

Owner:ASM IP HLDG BV

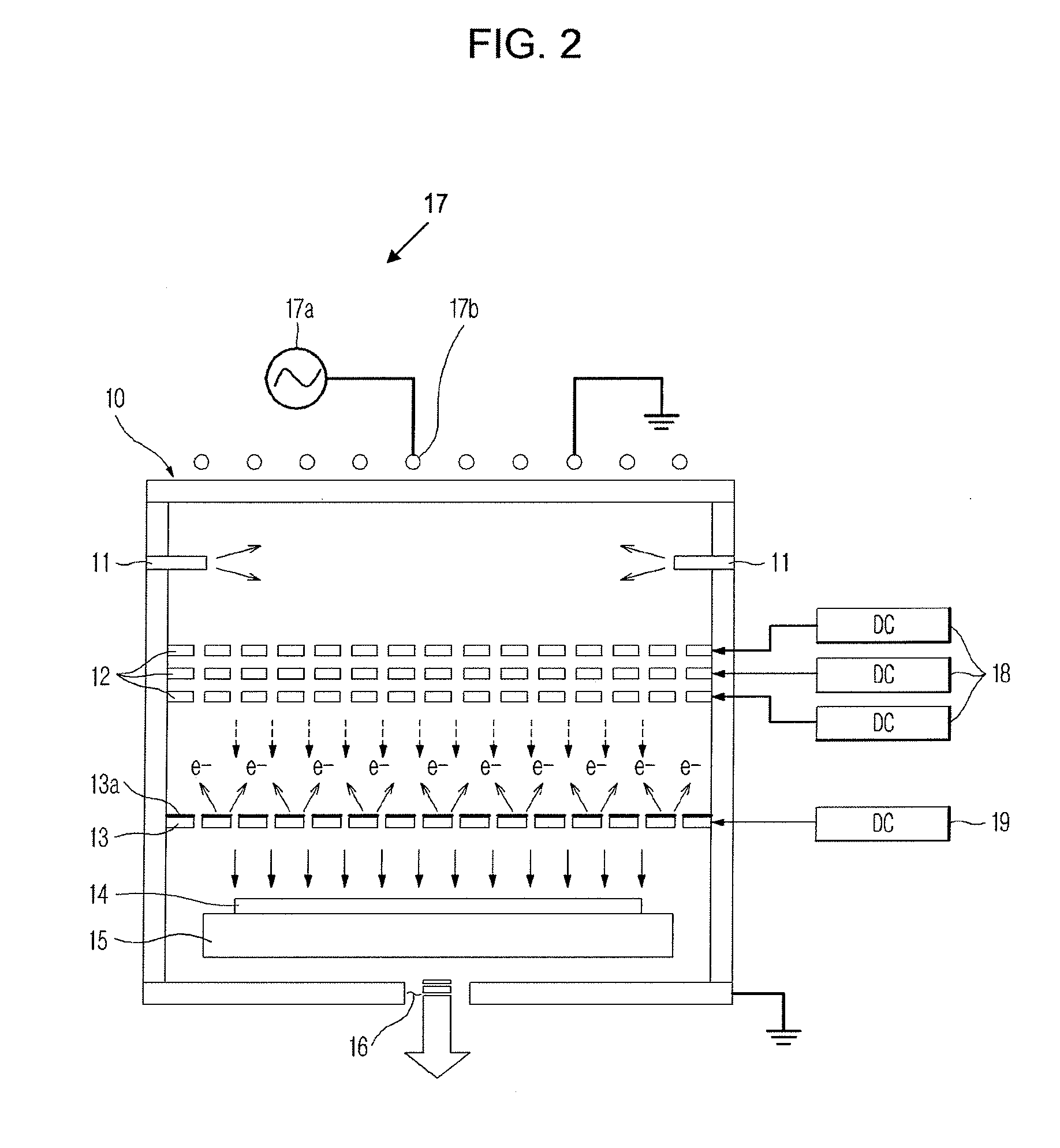

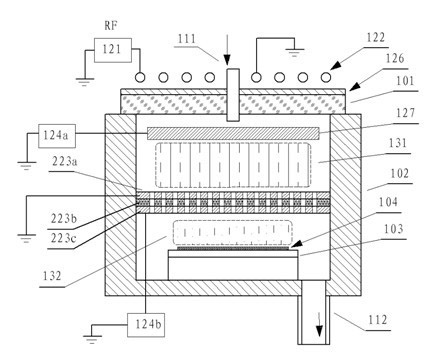

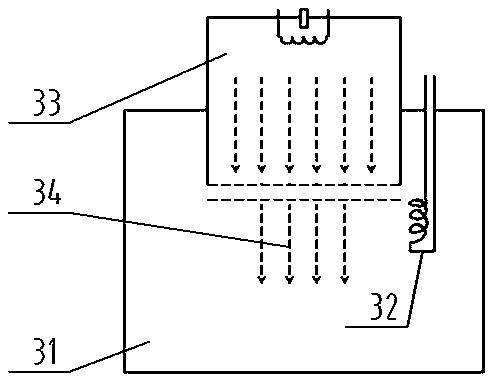

Etching apparatus using neutral beam and method thereof

InactiveUS20080156771A1Improve neutralization efficiencyCausing directionalityElectric discharge tubesDecorative surface effectsForeign matterIon beam

An etching apparatus using a neutral beam includes an electron emission unit to convert an ion beam, extracted from plasma by a plurality of grids, into a neutral beam by colliding the ion beam with electrons to prevent the ion beam from physically colliding with the electron emission unit, thus preventing the damage to a neutralization unit and generation of foreign substances with a simple structure. Further, the etching apparatus converts the ion beam into the neutral beam at a high neutralizing efficiency without causing directionality and energy losses, and generates a neutral beam having a large area, thus uniformly etching a semiconductor wafer.

Owner:SAMSUNG ELECTRONICS CO LTD

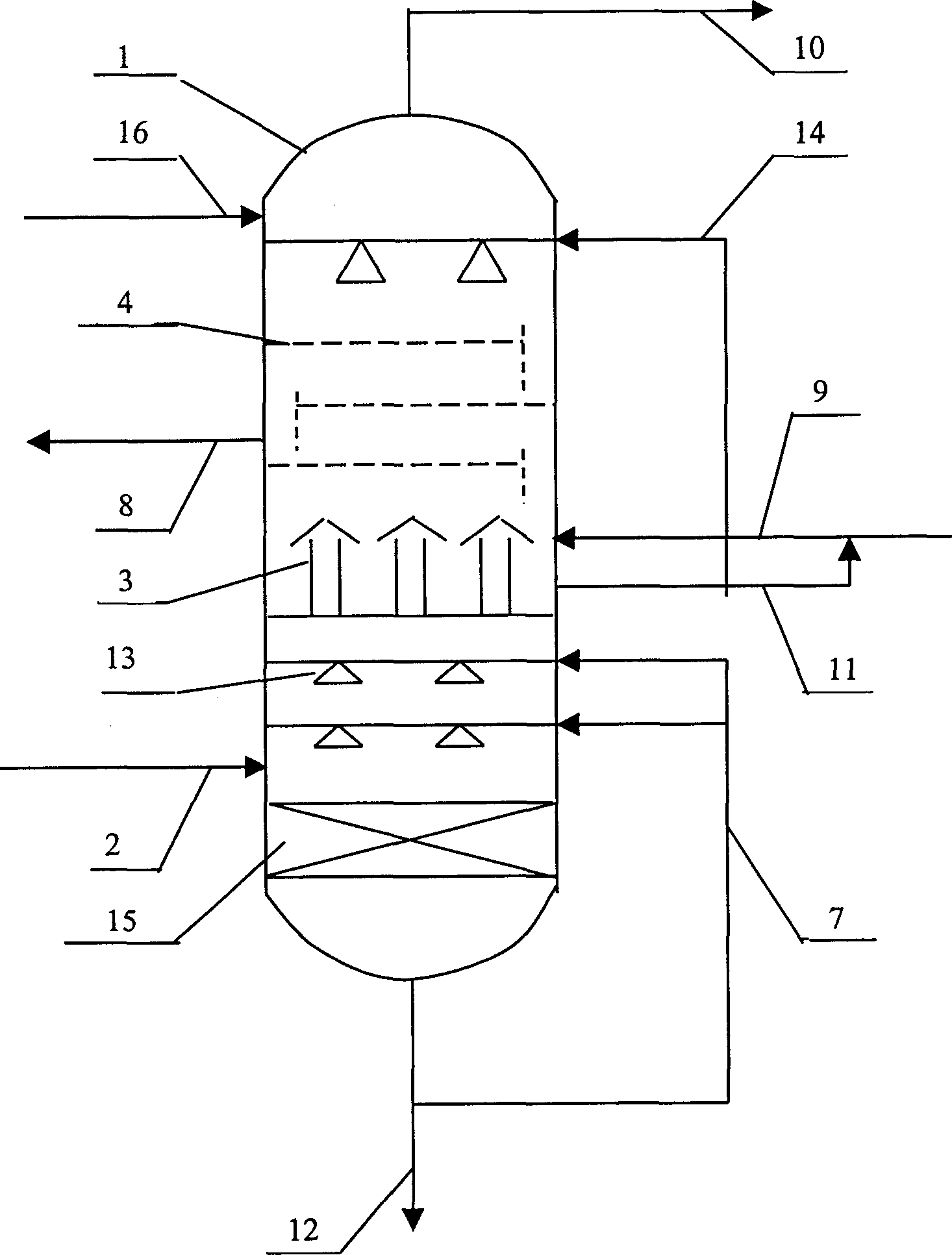

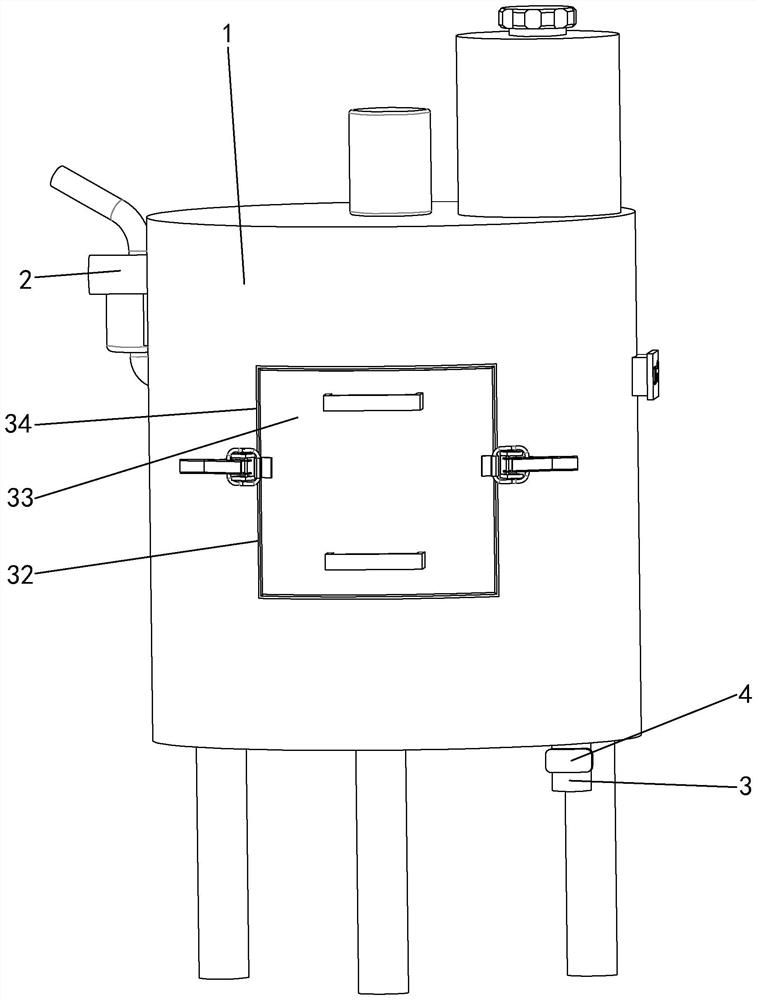

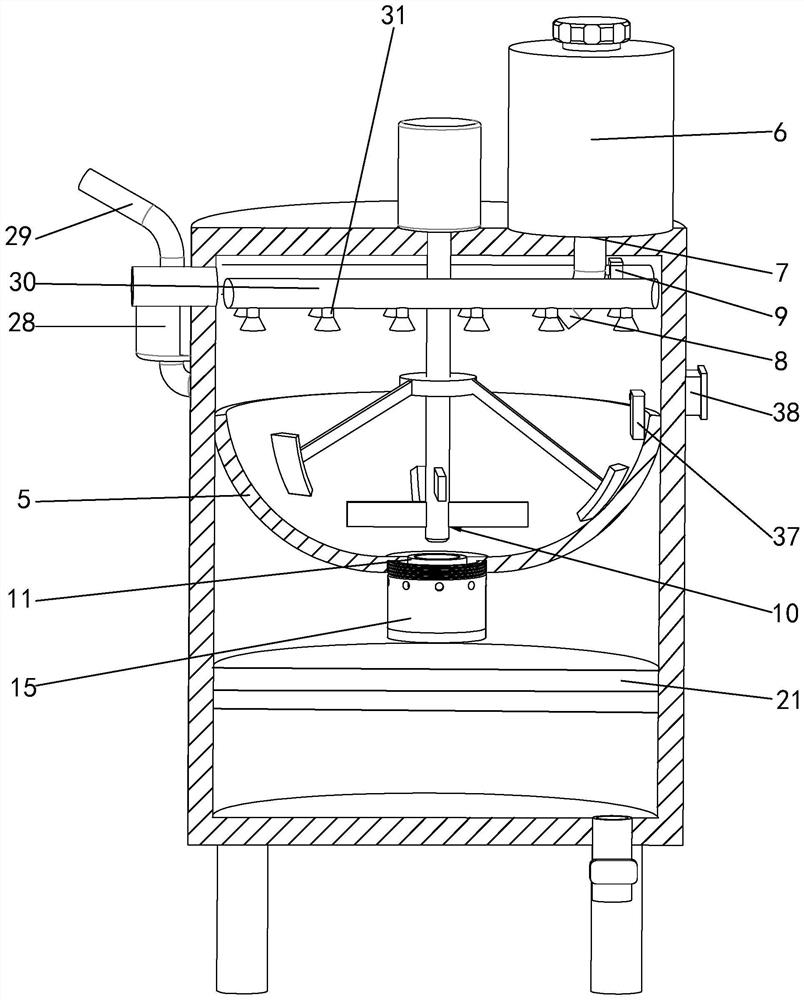

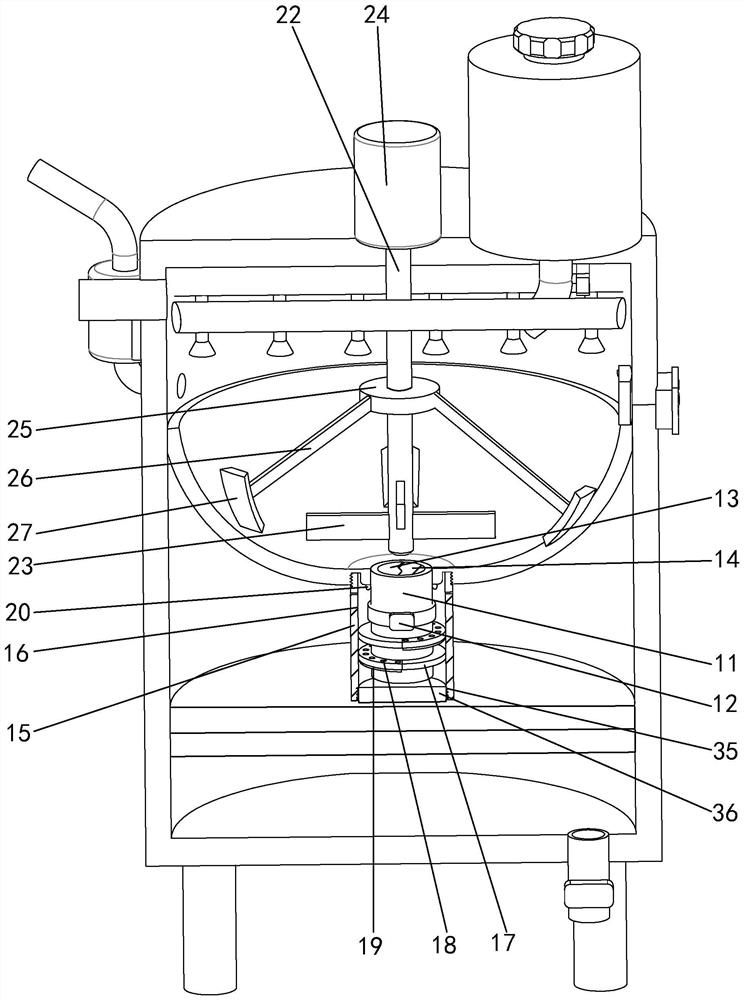

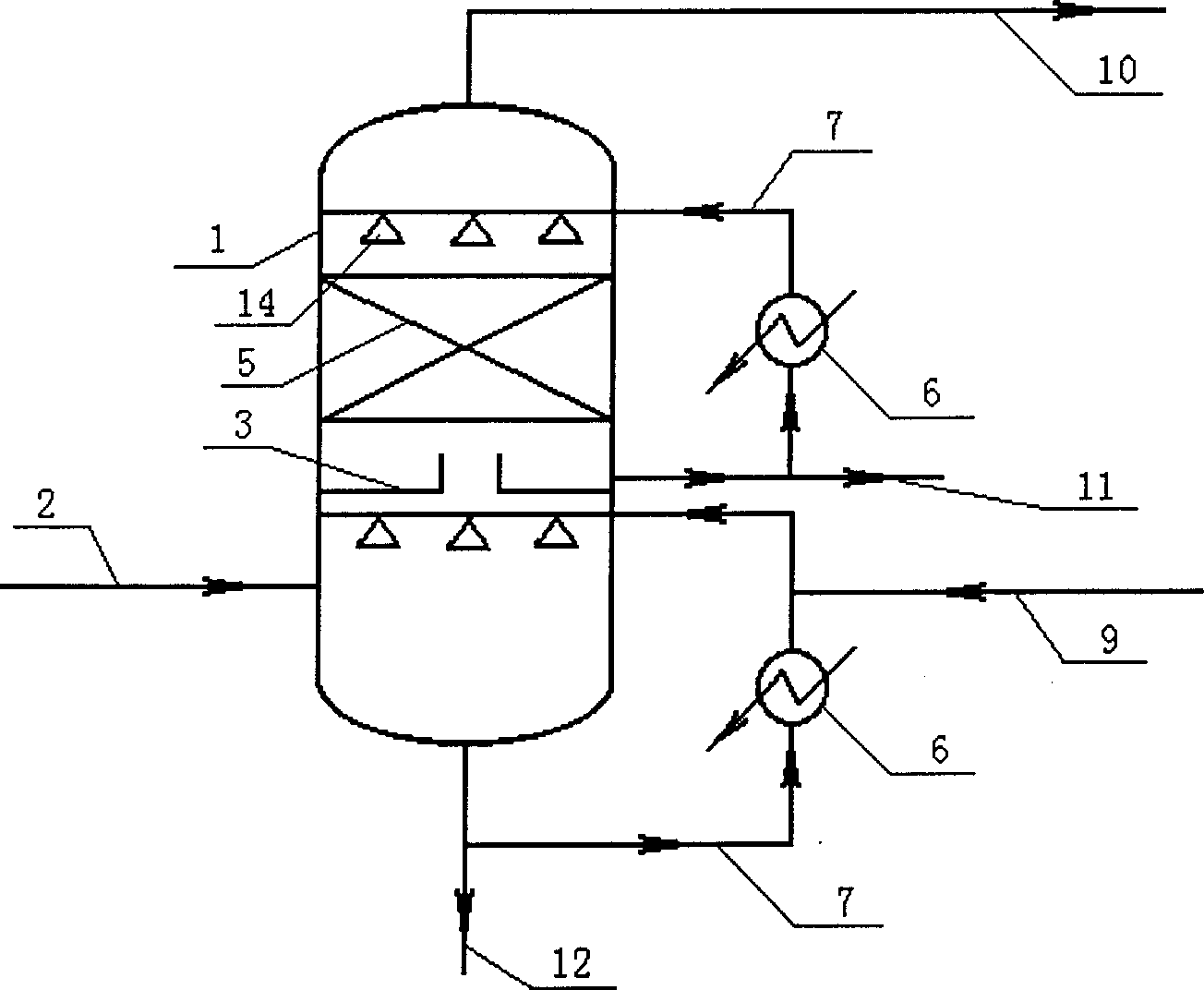

Environmentally-friendly device for waste gas treatment

InactiveCN108126496AImprove neutralization efficiencyImprove processing efficiencyMixing methodsTransportation and packagingCorrosion resistantWaste treatment

The invention discloses an environmentally-friendly device for waste gas treatment. The device is characterized in that a corrosion-resistant bearing is welded to the top part of a circular box, wherein the upper end of an outer ring of the corrosion-resistant bearing is in welded to the lower end of a waste gas inlet pipe in a sealing manner; the lower end of an inner ring of the corrosion-resistant bearing is welded to the upper end of a gas charging pipe in a sealing manner; a gas charging branched pipe communicates with the bottom part of the gas charging pipe; a gas outlet hole is formedin one sidewall of the gas charging branched pipe; a liquid draining pipe is mounted at the bottom part of the circular box, and a control valve is mounted on the liquid draining pipe; a transverse plate is welded to the inner bottom part of the circular box; a circular groove is formed in the middle part of the top part of the transverse plate; the bottom part of the gas charging pipe is insertedinto the circular groove; the outer wall of the gas charging pipe is equipped with a roller through a mounting rack in a rolling manner. With the adoption of the device, the mixing rate of the wastegas and a neutralizing solution can be effectively increased; the waste gas neutralizing efficiency can be improved; the waste gas treatment efficiency is improved; and the device is suitable for widepopularization.

Owner:XIAOGAN CHUANGKE ELECTRONICS TECH

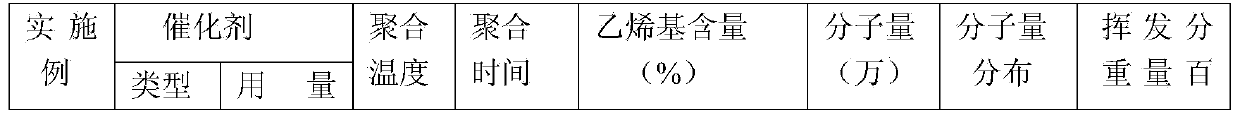

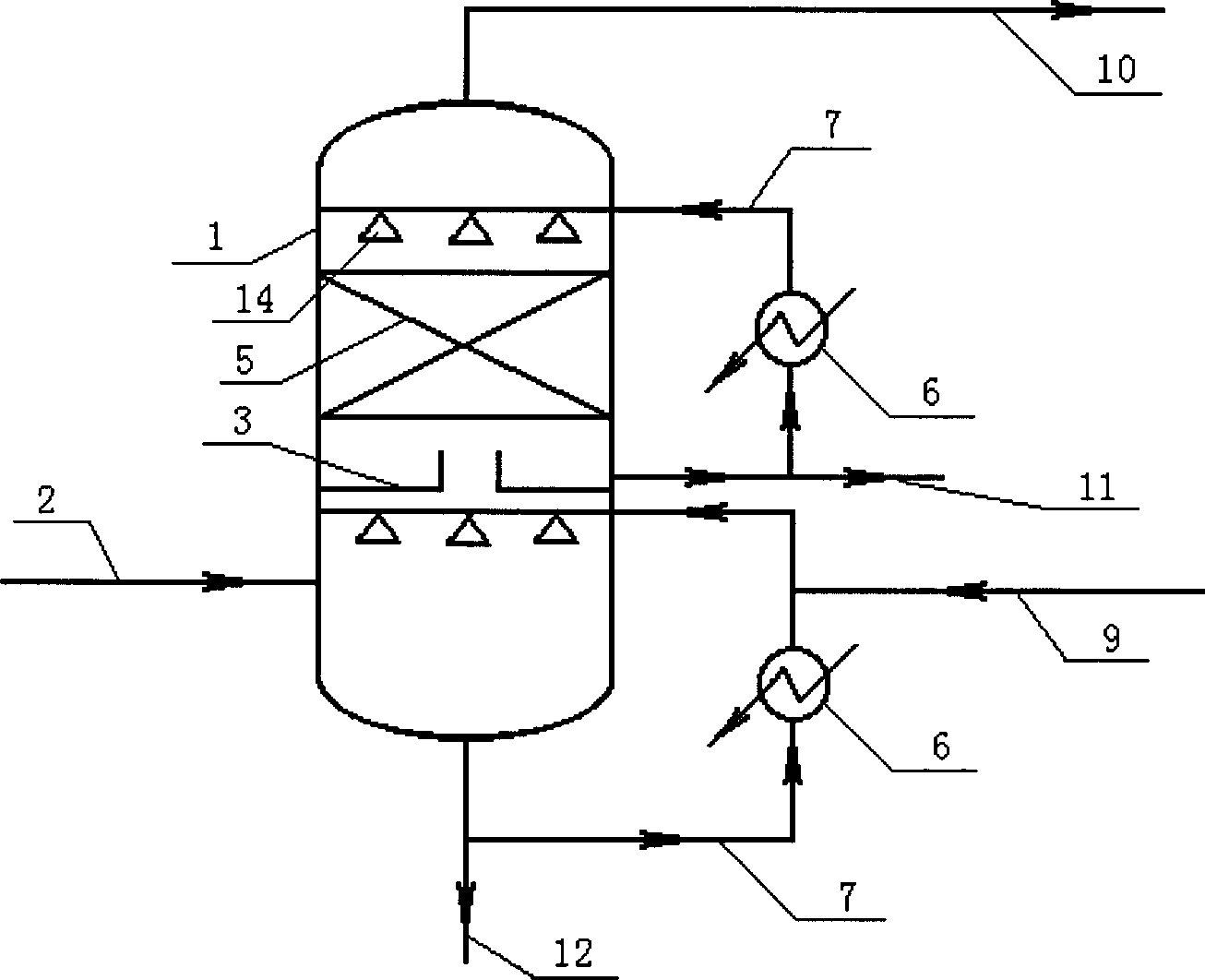

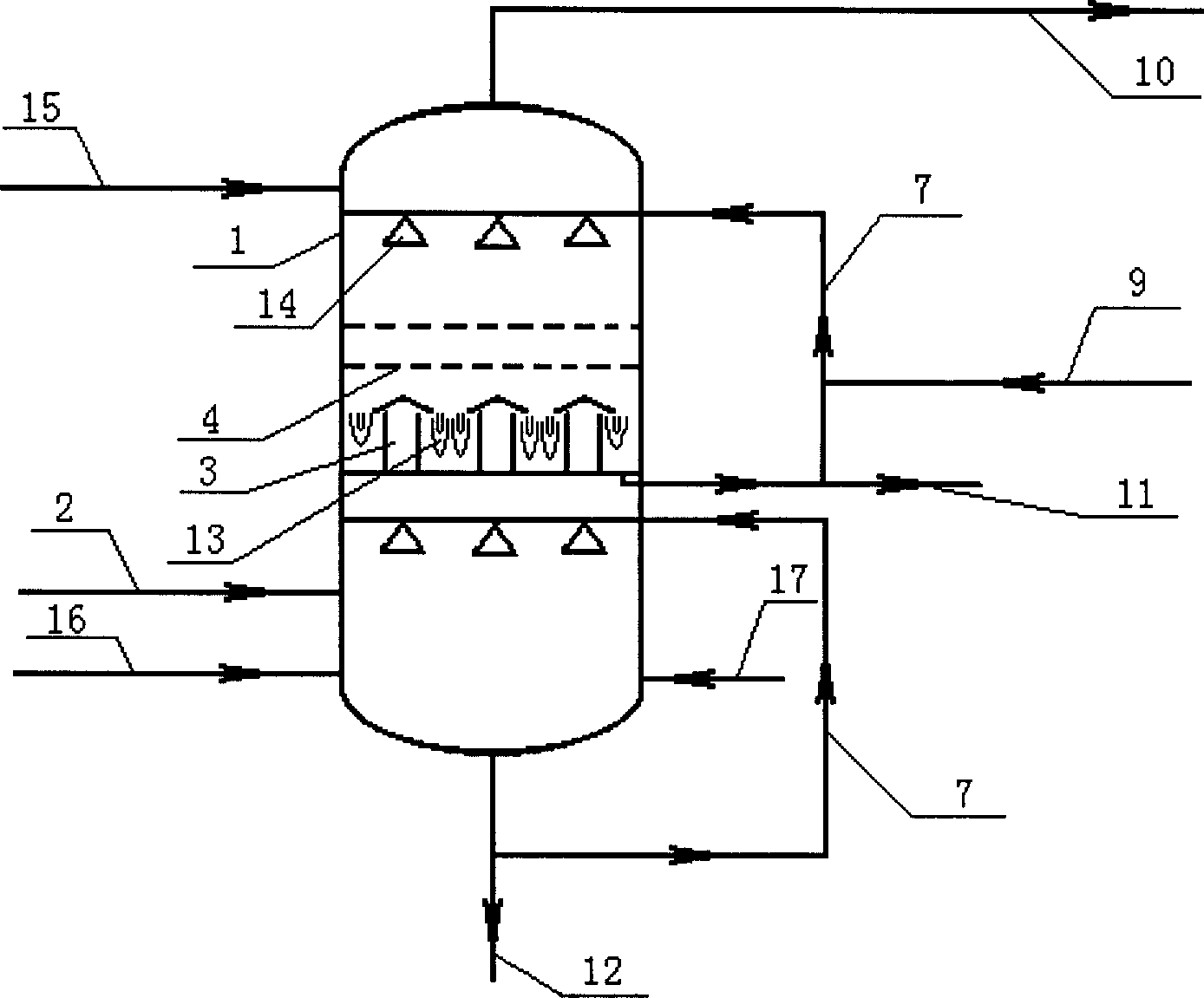

Preparation method of heat curing fluorosilicone raw rubber

The invention relates to a preparation method of heat curing fluorosilicone raw rubber. The preparation method comprises the following steps: adding D3F and D4Vi into a reactor and then dehydrating D3F and D4Vi, adding prepared potassium silanolate catalyst pre-polymer, heating, introducing nitrogen and stirring to carry out polymerization, wherein the temperature is 60-115 DEG C and the reaction time is 20-100min, neutralizing with a neutralizer until the reactant is neutral, and finally, removing small molecular substances from the material, reducing temperature and discharging. Due to the adoption of the potassium silanol catalyst pre-polymer with high activity, the reaction temperature is low, the accelerant is not required, an end-capping reagent is not required in the polymerization process, and the nitrogen purging manner is adopted in the stage of removing the small molecular substances from the material, the volatile matter of the heat curing fluorosilicone raw rubber is reduced; the prepared heat curing fluorosilicone raw rubber can be widely used in the fields of aerospace, petrochemical industry, automobiles, artificial organ, and the like, and has a good promotional value.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

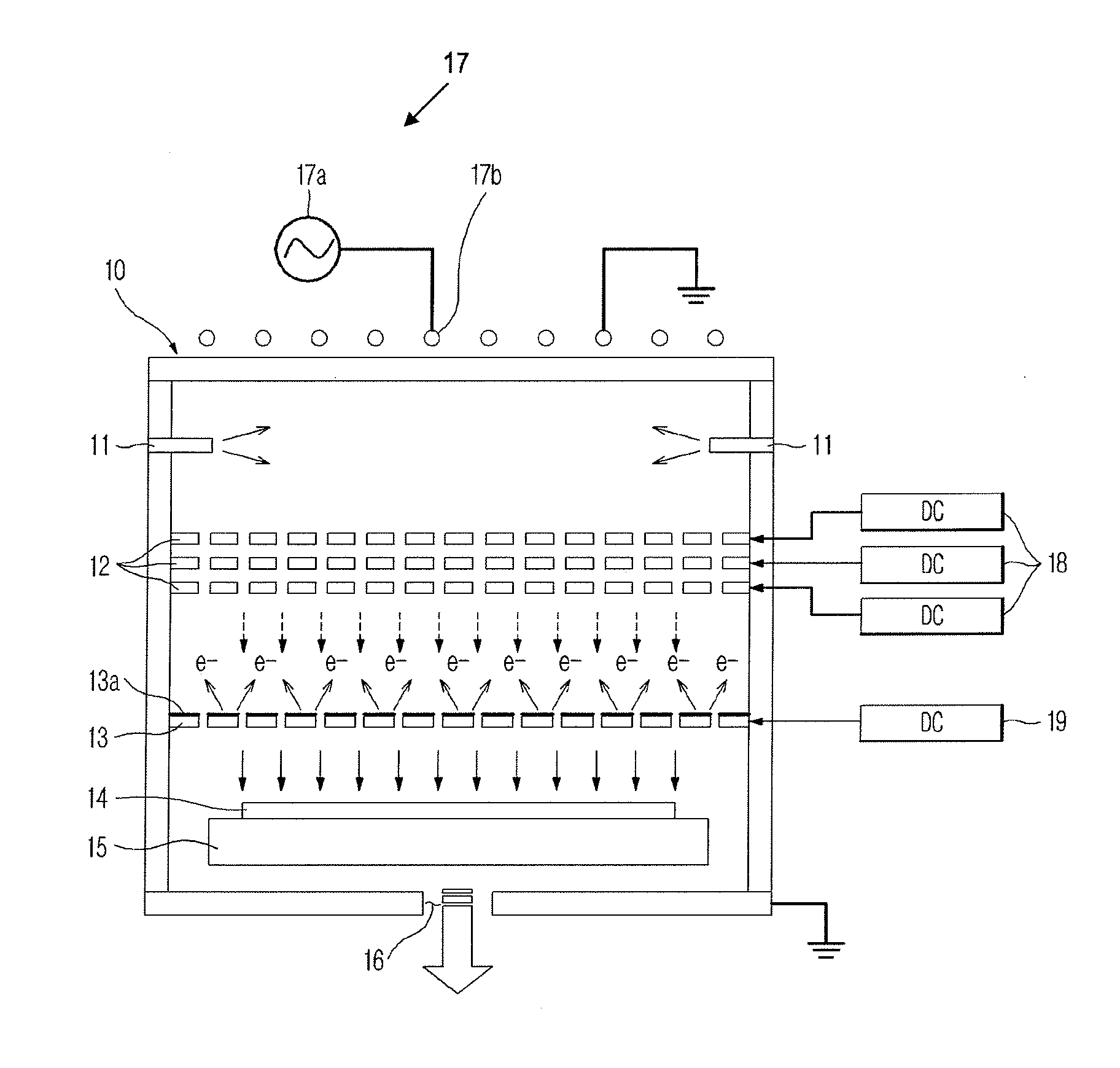

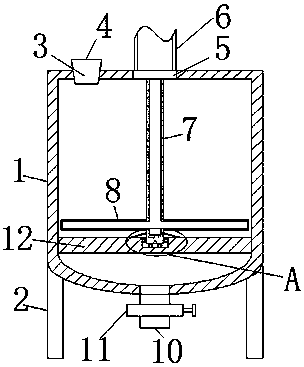

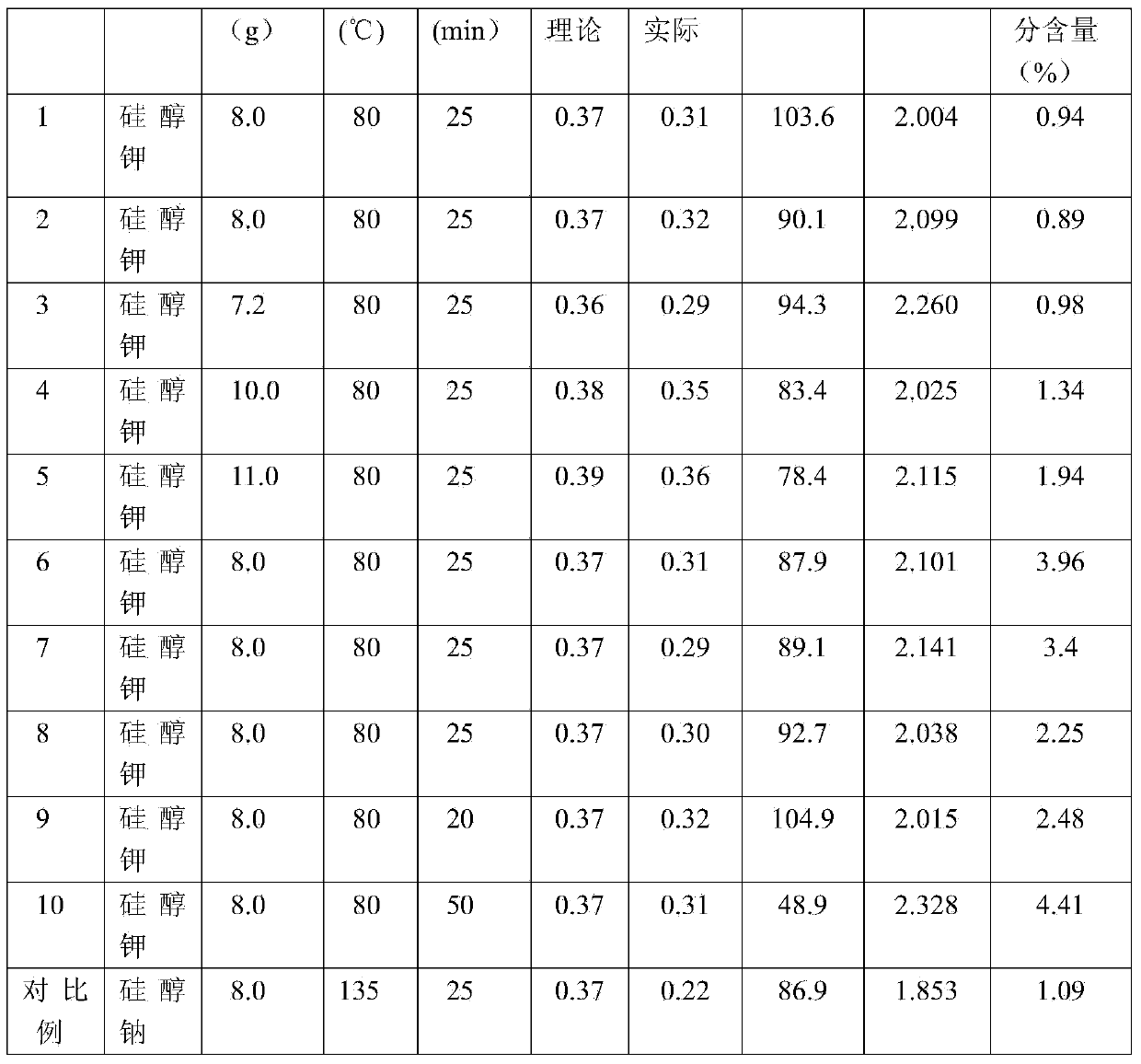

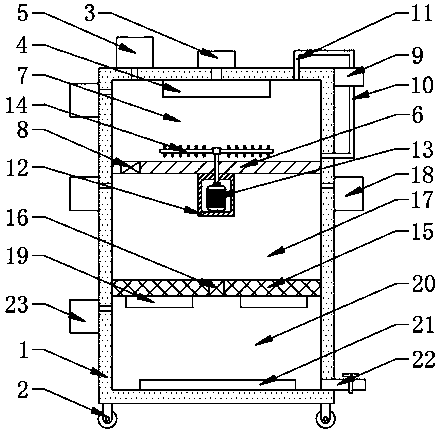

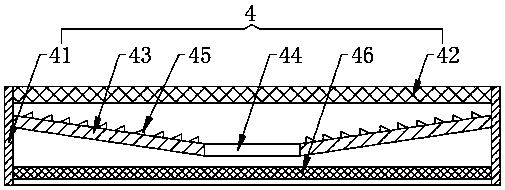

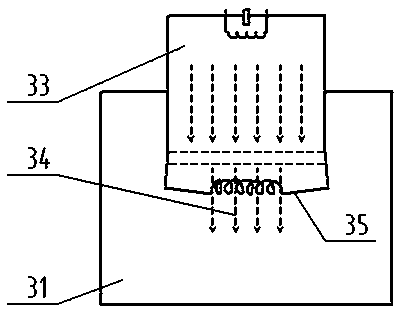

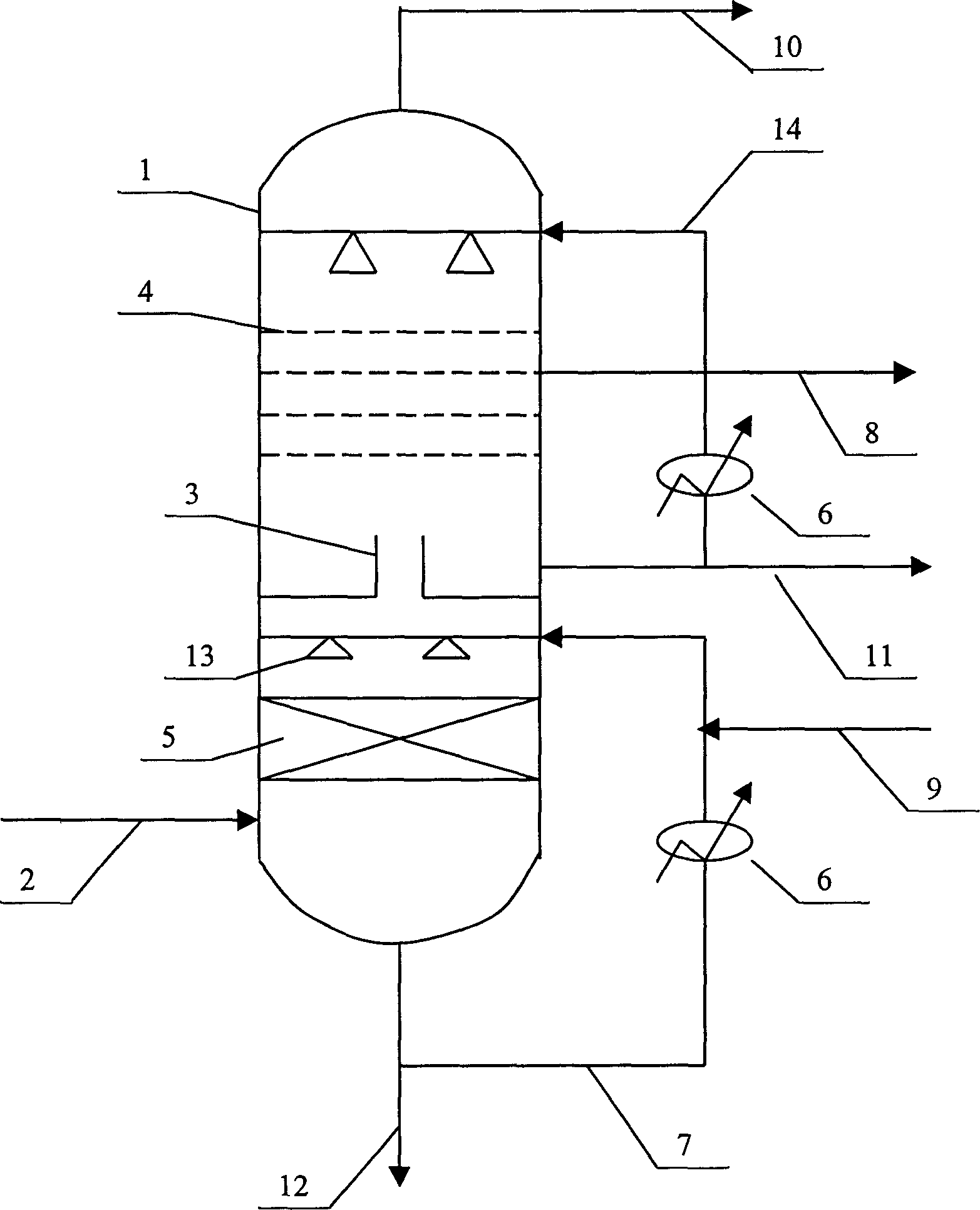

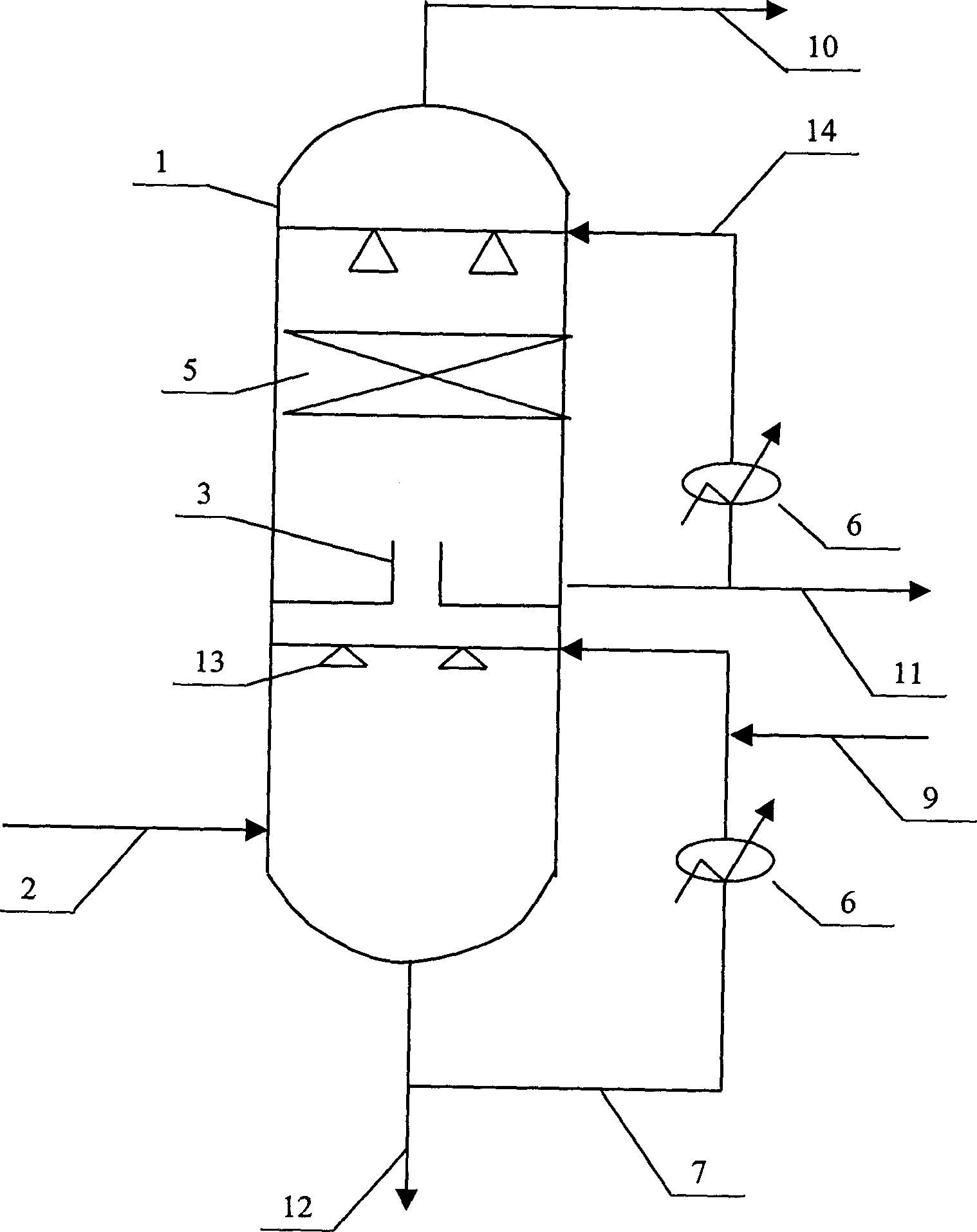

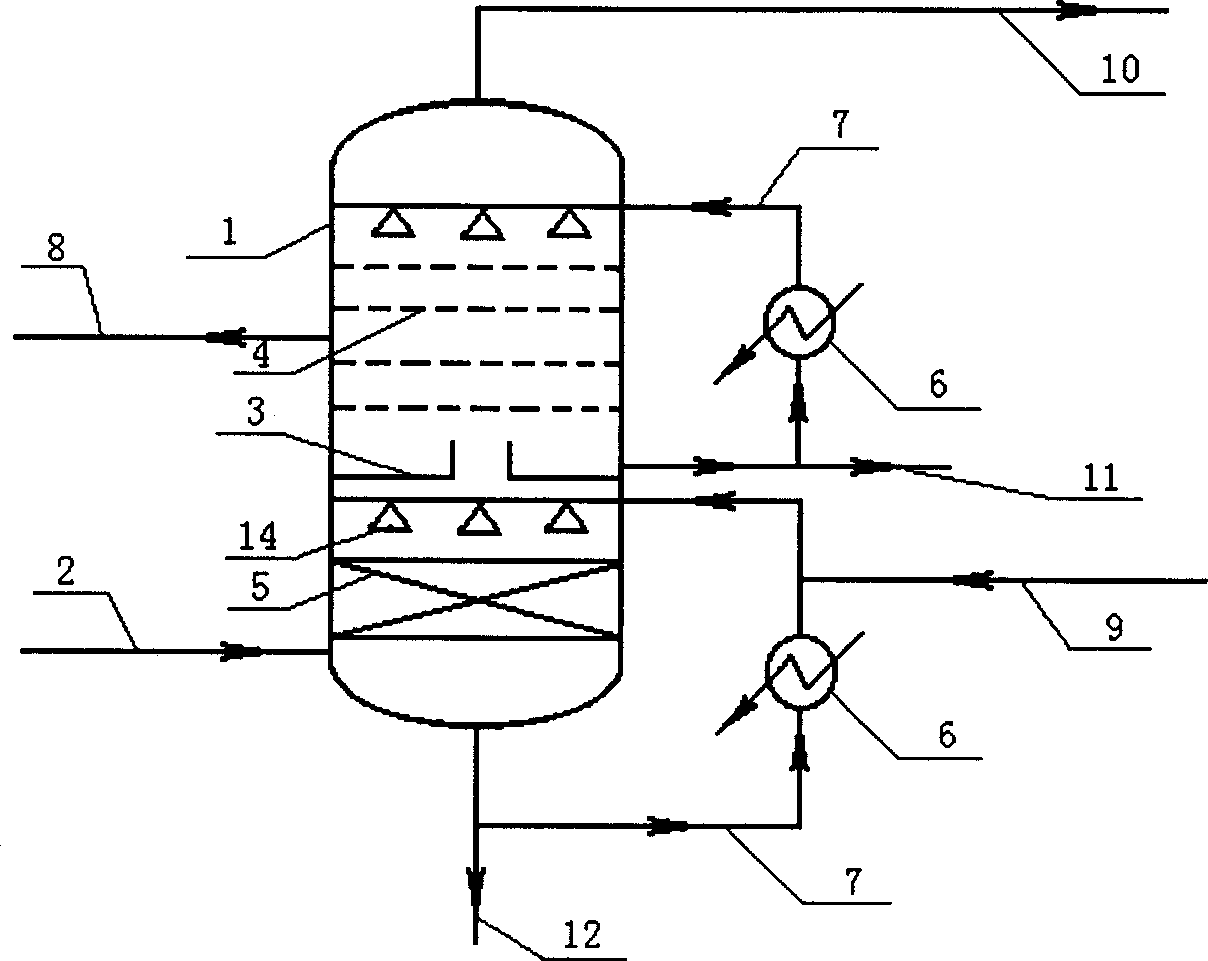

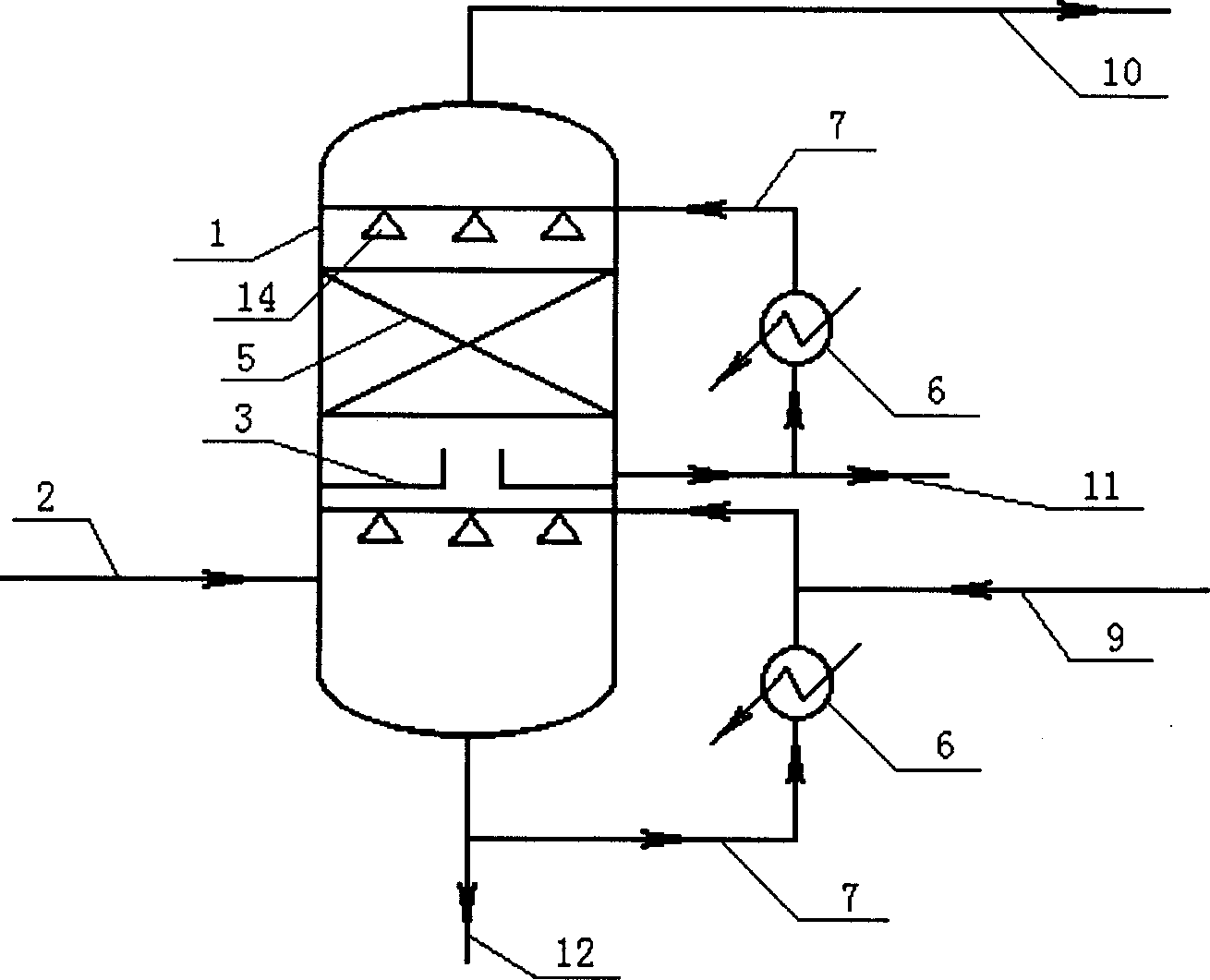

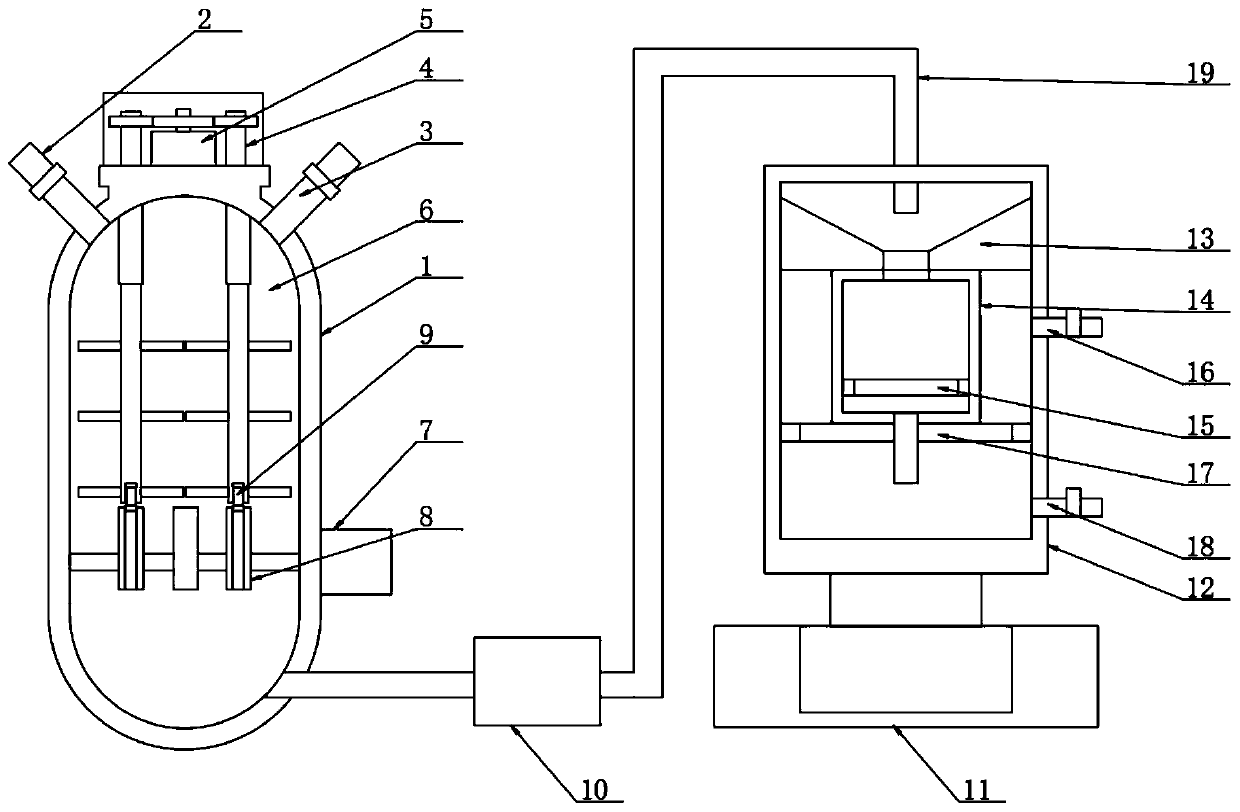

Apparatus and method for generating a beam of neutral particles

ActiveCN102290314AIncrease exerciseImprove neutralization efficiencyElectric discharge tubesAcceleratorsMixed gasDirect current

The invention discloses a device for producing a neutral particle beam, which comprises a reaction chamber, a slide glass table, a plasma source and an upper mesh plate. The slide glass table, the plasma source and the upper mesh plate are arranged on a chip and in the reaction chamber, the upper mesh plate is arranged on the plasma source, and an intermediate mesh plate, an insulating plate and a lower mesh plate are sequentially arranged between the plasma source and the slide glass table; and the upper mesh plate and the lower mesh plate are respectively connected with direct-current bias voltage, and the intermediate mesh plate is grounded. The invention also discloses a method for producing the neutral particle beam. By adopting the device for producing the neutral particle beam and the method thereof, positive ions and negative ions can be neutralized, the efficiency of ion neutralization can be improved, and different ions in mixed gases can achieve corresponding etching effects. The device and the method can adapt to different gas combinations and meet requirements of different etching processes.

Owner:AEROTECH BEIJING

Chemical laboratory drainage purifying equipment

InactiveCN111003861AImprove purification effectImprove neutralization efficiencyWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsCatalytic oxidationEngineering

The invention discloses chemical laboratorydrainage and purifying equipment, and belongs to the technical field of drainage and purifying equipment for chemical laboratories. A filter communicated with a water feeding pump is fixedly arranged at the top of an inner cavity of a purifying box; a first electromagnetic valve is fixedly assembled on the left side of a first partition plate; a second partition plate fixed on the inner wall of the purifying box is arranged below the first partition plate; a second electromagnetic valve is fixedly assembled on the second partition plate; a settling chamber is arranged between the second partition plate and the first partition plate; a precipitation medicine box matched with the settling chamber is fixedly arranged on the right side wall of the purifying box; ultrasonic generators are fixedly arranged on the left side and the right side of the bottom of the second partition plate; a photocatalysis plate is fixedly arranged at the bottom of theinner cavity of the purifying box, and a drainage pipe is fixedly assembled at the bottom of the right side wall of the purifying box, so that the catalytic oxidation treatment effect on wastewater isbetter, the chemical laboratory drainage and purifying equipment is economical and practical, the operation cost is low, and meanwhile, the treated water is relatively pure and relatively high in environmental protection property.

Owner:国家海洋局北海海洋环境监测中心站

Disinfection system of contact lens

ActiveUS20120076687A1Reduce the amount of metalEasy to neutralizeLavatory sanitoryDeodrantsMetal catalystCarboxylic acid

A disinfection system of a contact lens comprising immersing the contact lens in a disinfecting solution containing hydrogen peroxide in a concentration of 1 to 10% and neutralizing the hydrogen peroxide in the disinfecting solution through contact with a metal catalyst, where the disinfecting solution contains an organic carboxylic acid or a salt of the organic carboxylic acid, the organic carboxylic acid having a structure in which a hydroxyl group and a carboxyl group are bonded to one carbon atom; the disinfecting solution is adjusted to have a pH of 6 to 8; and the disinfecting solution after the neutralization is adjusted to have an osmotic pressure of 250 to 350 mOsm.

Owner:MENICON CO LTD

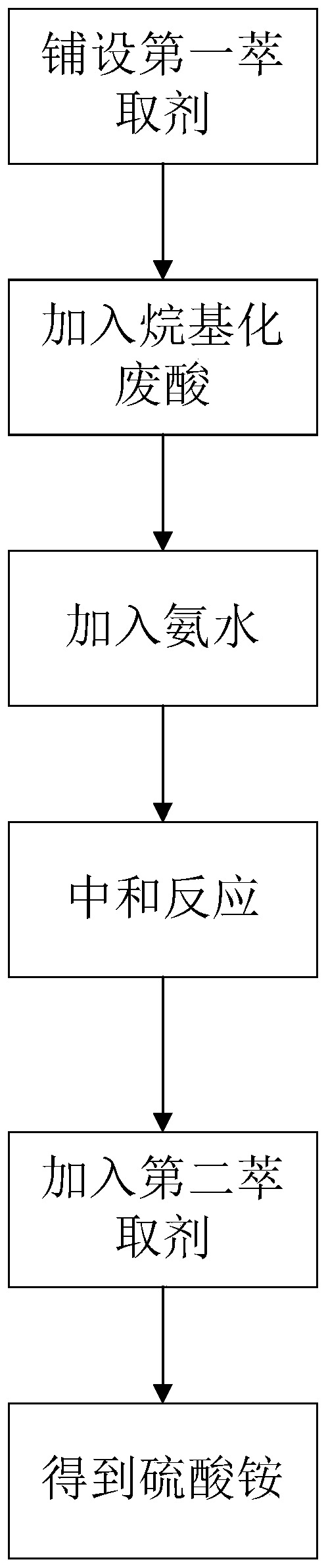

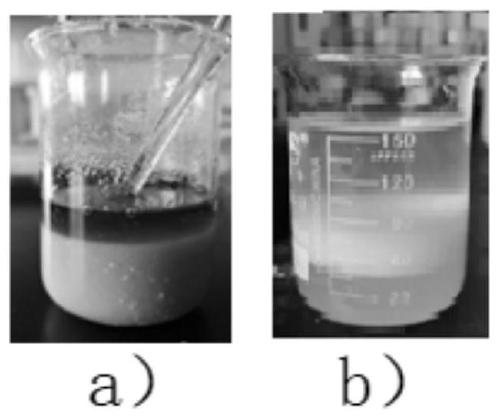

One-step impurity removal method for preparing ammonium sulfate from alkylated waste acid through

ActiveCN111302359ASuitable for large-scale industrial productionIncrease productivityAmmonium sulfatesWater chlorinationCarbon Chloride

The invention discloses a one-step impurity removal method for preparing ammonium sulfate from alkylated waste acid, which comprises the following steps: arranging a first extraction agent solution layer with the thickness of 20-30mm at the bottom of a reaction container, sequentially adding a dilute solution of alkylated waste acid and ammonia water, and carrying out neutralization reaction at normal temperature and normal pressure for 10-15 minutes; after the neutralization reaction is finished, and adding a second extraction agent, wherein the addition amount of the second extraction agentmeets the condition that the volume ratio of the second extraction agent to the dilute solution of the alkylated waste acid is 10: 1; and after standing for 10-30 minutes, enabling the mixture to enter a centrifugal machine through a pipeline to be centrifuged to obtain an ammonium sulfate solid, wherein the first extraction agent is selected from at least one of carbon tetrachloride, tetrachloroethylene, carbon trichloride, trichloromethane or dichloromethane. Through organic solvent extraction, different-color and peculiar-smell substances in a waste acid-to-ammonium sulfate product can be thoroughly extracted and separated, and it is ensured that the ammonium sulfate product is not decomposed by heating.

Owner:云南云天化石化有限公司

Disinfection system of contact lens

ActiveUS9427488B2Reduce the amount of metalEasy to neutralizeLavatory sanitoryDeodrantsMetal catalystCarboxylic acid

A disinfection system of a contact lens comprising immersing the contact lens in a disinfecting solution containing hydrogen peroxide in a concentration of 1 to 10% and neutralizing the hydrogen peroxide in the disinfecting solution through contact with a metal catalyst, where the disinfecting solution contains an organic carboxylic acid or a salt of the organic carboxylic acid, the organic carboxylic acid having a structure in which a hydroxyl group and a carboxyl group are bonded to one carbon atom; the disinfecting solution is adjusted to have a pH of 6 to 8; and the disinfecting solution after the neutralization is adjusted to have an osmotic pressure of 250 to 350 mOsm.

Owner:MENICON CO LTD

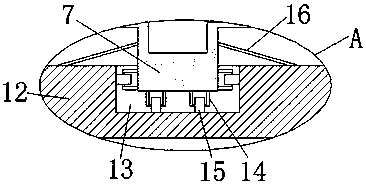

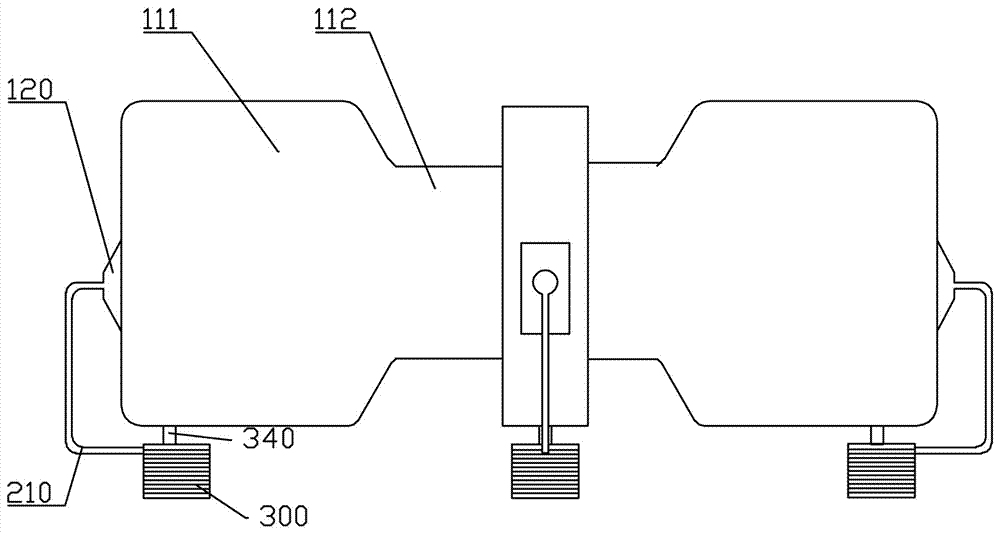

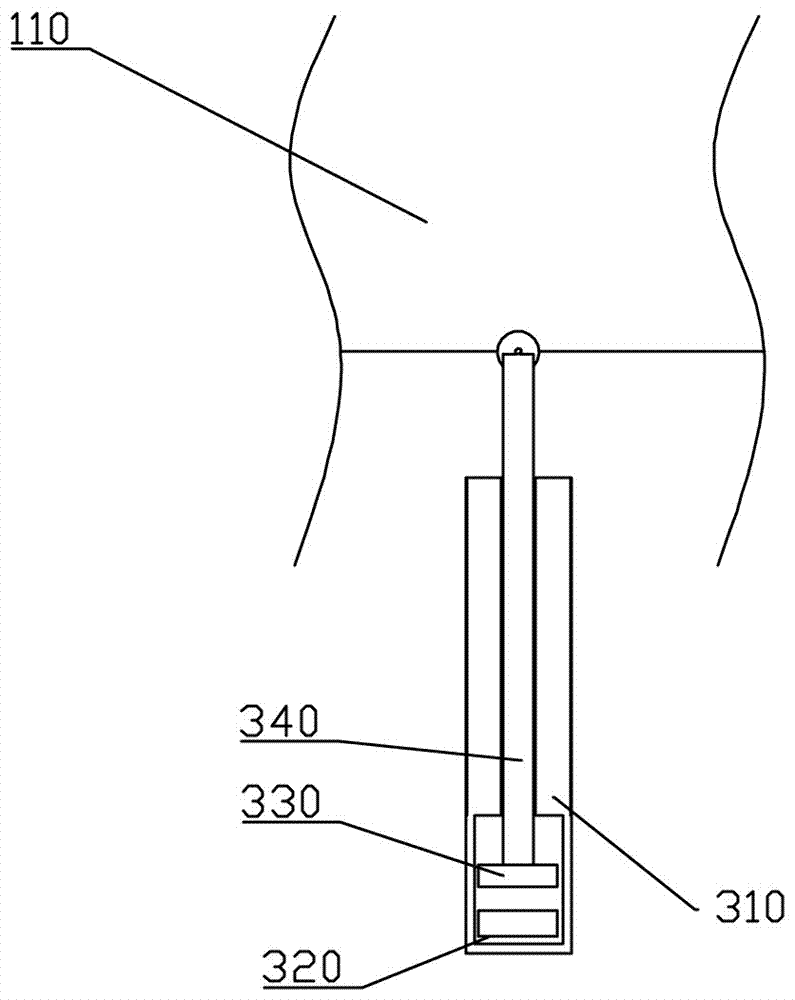

Fingerling transport device

InactiveCN107372288AImprove neutralization efficiencyGood steady water flowPisciculture and aquariaEngineeringPower regulation

The invention relates to fingerling long-distance transport and transfer devices, in particular to a fingerling transport device which comprises a transport tank, a triggering mechanism and a jacking mechanism. The transport tank comprises a tank and a plurality of connectors, the tank is at least provided with four side surfaces including a front surface, a rear surface, a left surface and a right surface, and at least one connector is arranged on each side surface; the triggering mechanism comprises connecting pipes, hydraulic pressure sensors, a power regulator and a control panel, the connecting pipes are communicated with the connectors, the internal hydraulic pressures of the connecting pipes can be sensed by the hydraulic pressure sensors, power of the jacking mechanism can be controlled by the power regulator, hydraulic pressure information of the hydraulic pressure sensors can be received by the control panel, and the power regulator can be controlled by the control panel; magnetic blocks are fixed to the bottoms of jacking rods, and the magnetic pole of the end, which faces a corresponding electromagnet, of each magnetic block is identical to the magnetic pole of an end of the electromagnet. The fingerling transport device has the advantages that the problem of easiness in collision between existing fingerlings due to turbulence of water flow when the existing fingerlings are transported can be solved by the aid of the fingerling transport device, and collision between fingerlings can be relieved by the fingerling transport device.

Owner:重庆市长寿区精英渔业股份合作社

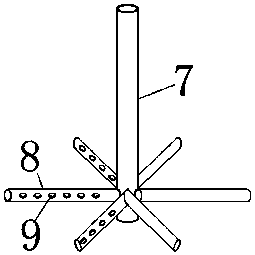

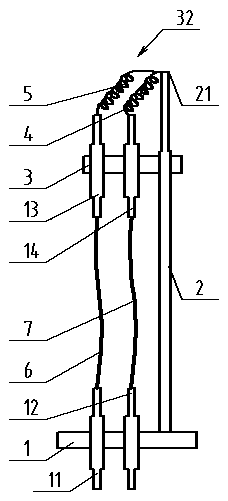

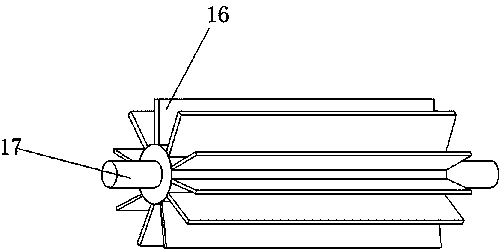

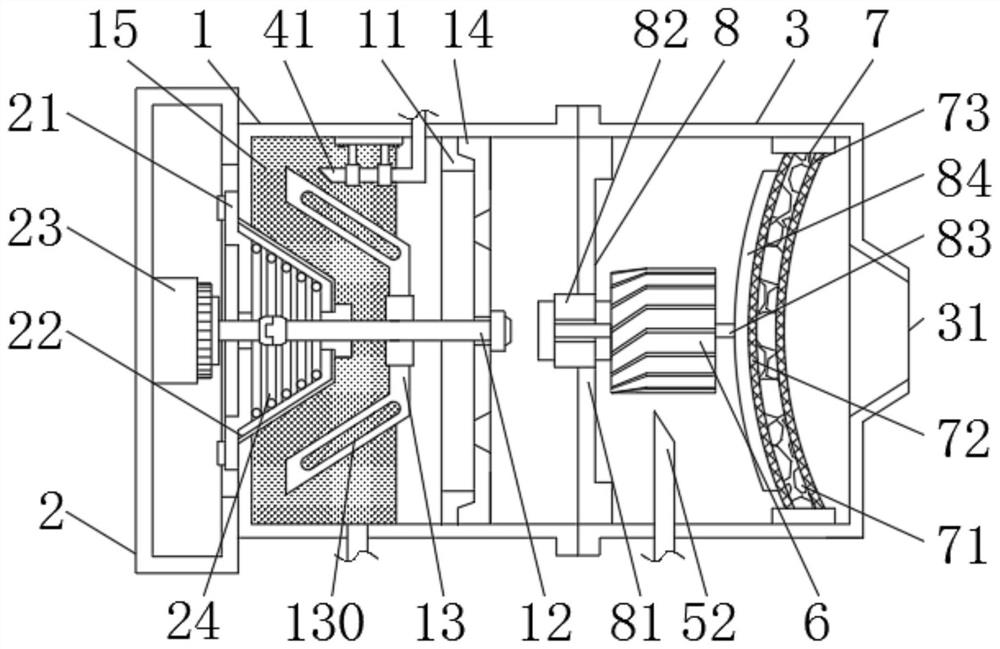

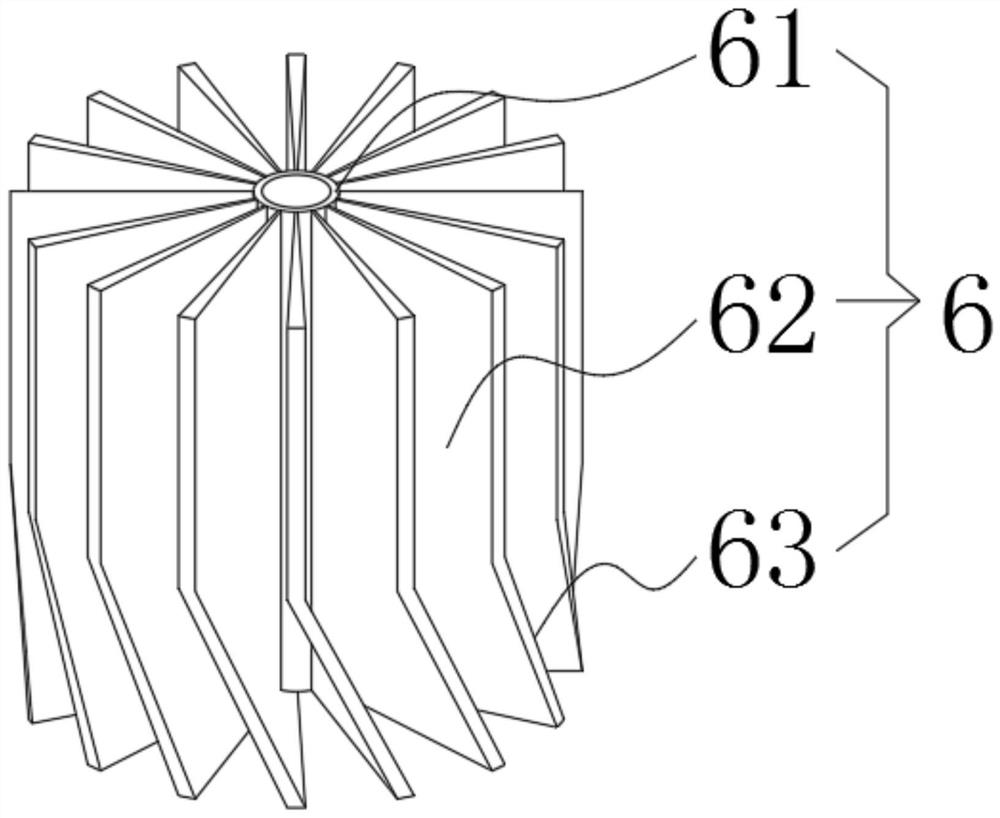

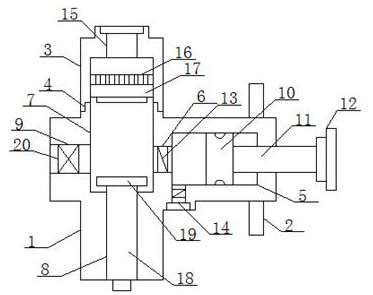

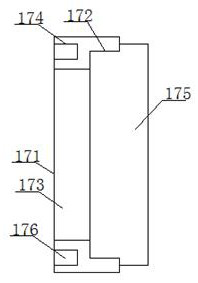

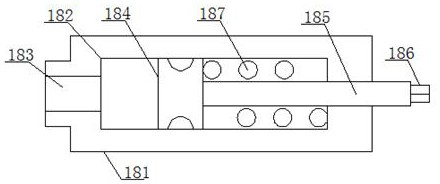

Double lamp filament neutralizer for ion beam equipment

PendingCN109881174AImprove neutralization efficiencySolution to short lifeElectric discharge tubesVacuum evaporation coatingIon beamEngineering

The invention discloses a double lamp filament neutralizer for ion beam equipment. The double lamp filament neutralizer for the ion beam equipment comprises a flange, a supporting rod, a bracket, a lamp filament A, a lamp filament B, a wire A, a wire B and four electrodes. As a mode of the neutralizer independent of an ion source is adopted, two lamp filaments are arranged, the neutralizing efficiency of the neutralizer is high, the lamp filaments are not directly bombarded by an ion beam, the service life of the lamp filaments is long, the working efficiency of the complete machine equipmentis high, lamp filament material atoms are not prone to polluting a vacuum chamber and workpieces, and mounting and maintenance are convenient.

Owner:BEIJING CHUANGDENENG TECH

Quench process for recovery of acrylonitrile

InactiveCN1413981AAvoid it happening againAvoid secondary pollutionCarboxylic acid nitrile purification/separationCooling towerAcrylonitrile

A suddenly cooling process for recovering acrylonitrile features that the stay time of suddenly cooling liquid in tower still at lower segment of suddenly cooling tower is controlled, the acid is directly added to said tower still, the pH value of liquid in tower still is controlled to 7-7.5, water is supplemented at lower segment and the concentration of heavy component in liquid of tower stil is controlled. Its advantage is high recovery rate of acrylonitrile.

Owner:CHINA PETROLEUM & CHEM CORP +1

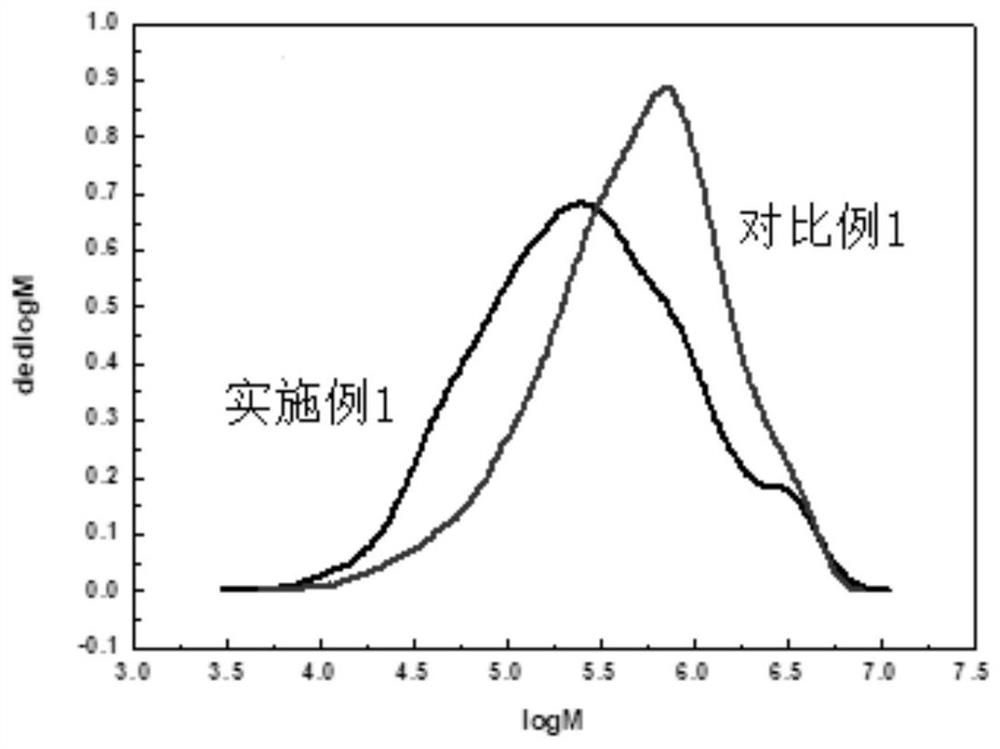

Preparation method of branched halogenated butyl rubber

The invention provides a preparation method of branched halogenated butyl rubber. Compared with the prior art, the molecular weight of the synthesized branched butyl rubber is in bimodal distribution, the molecular weight distribution is widened, and the mechanical properties such as tensile strength are obviously improved, so that the processability of the butyl rubber is effectively improved; according to the branched butyl rubber halogenation method provided by the invention, the neutralization efficiency is improved, the possibility of incomplete neutralization is reduced, the conversion from a secondary allyl bromide substitution product to a primary allyl bromide substitution product is effectively inhibited, and the obtained brominated butyl rubber is excellent in various indexes and more stable in structure; meanwhile, the preparation method is easy to operate, easy in condition control and low in cost, and has a wide application prospect.

Owner:山东京博中聚新材料有限公司

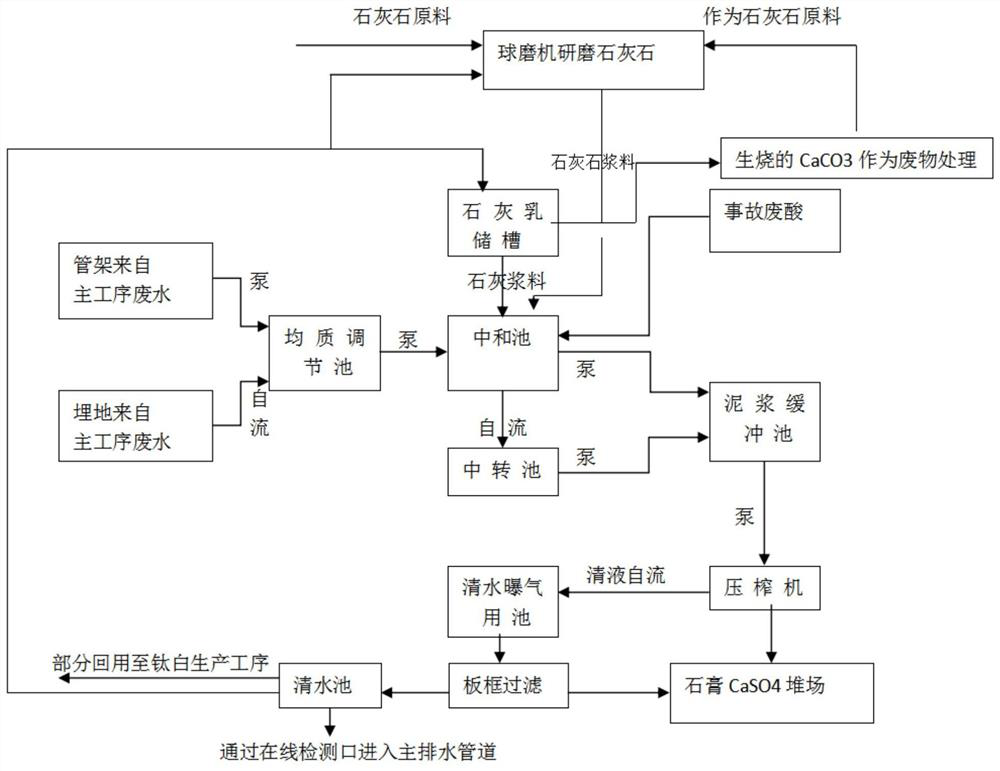

Treatment method of sulfuric acid method titanium dioxide acid wastewater

InactiveCN112441676AImprove neutralization efficiencyEffective cost controlCalcium/strontium/barium sulfatesWater aerationPhysical chemistrySlurry

The invention relates to the technical field of titanium dioxide acidic wastewater treatment, and provides a treatment method of sulfuric acid method titanium dioxide acid wastewater. The method comprises the following steps that: S1, under stirring treatment, a mixed solution of acidic wastewater and clear white water containing 3-8% of sulfuric acid automatically flows into a neutralization poolthrough height difference, limestone slurry is pumped into the neutralization pool, and first-stage neutralization is carried out, the pH value ranges from 4.0 to 5.0 at the reaction end point ; S2,stirring is continued, the digested lime slurry is pumped, and second-stage neutralization is carried out until the pH value is 7.0-8.5 at the reaction end point to obtain reaction slurry; S3, the qualified reaction slurry obtained after the neutralization is pumped into a filter press for filter pressing, the pH value of the reaction slurry is 6.5-8.5; and S4, a filter cake obtained after filterpressing is naturally dried, filtrate obtained after filter pressing is aerated and filtered, qualified water which is detected to reach the standard is discharged or is used as process water. The method of the invention has the advantages of high neutralization efficiency, good aeration effect and low cost.

Owner:攀枝花大互通钛业有限公司

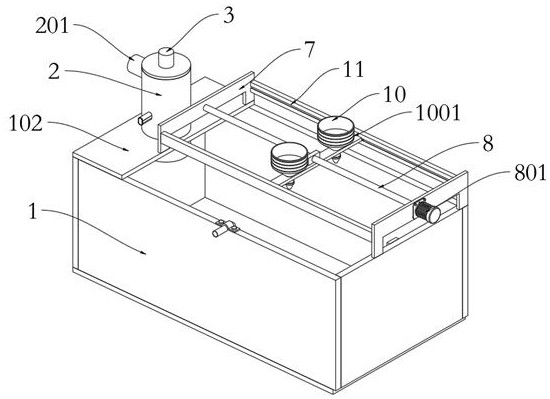

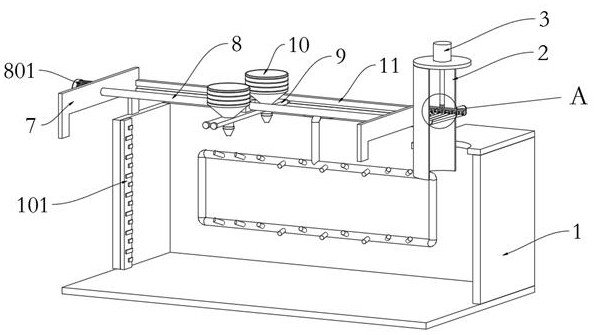

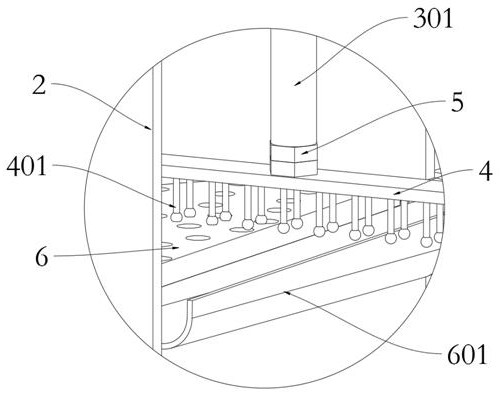

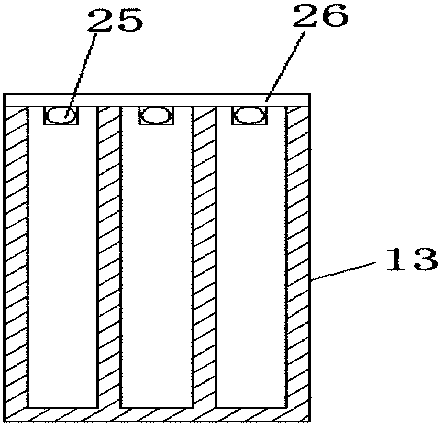

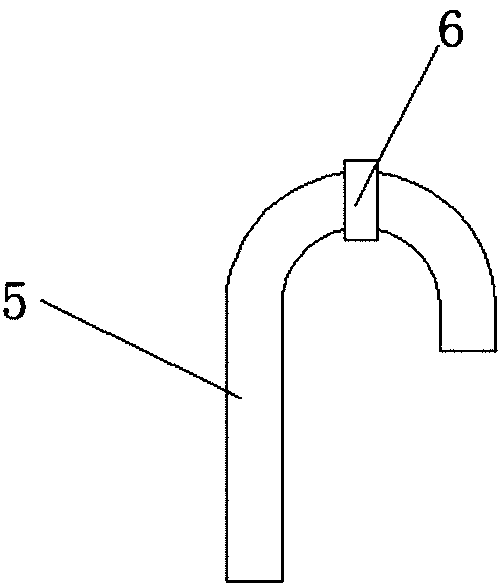

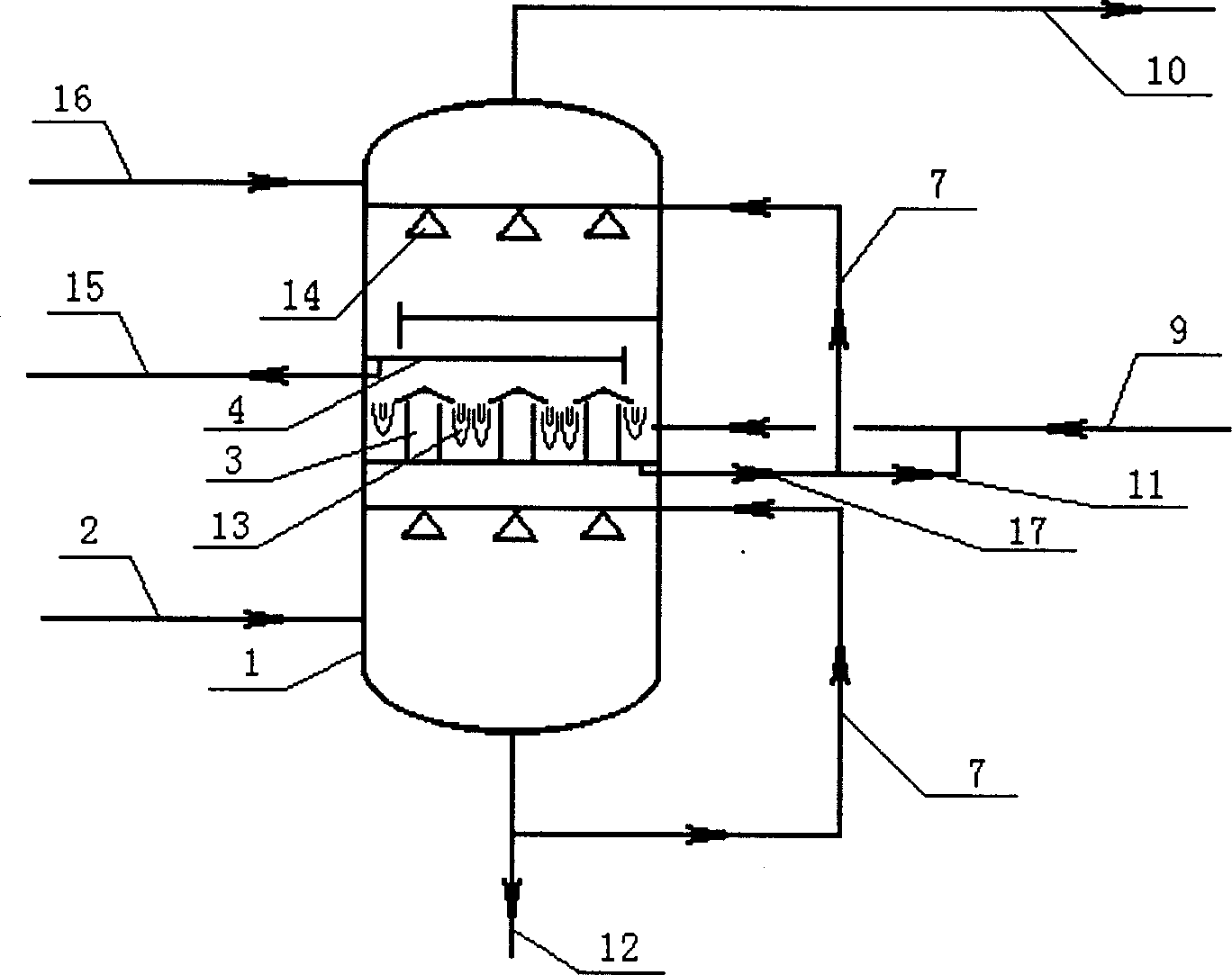

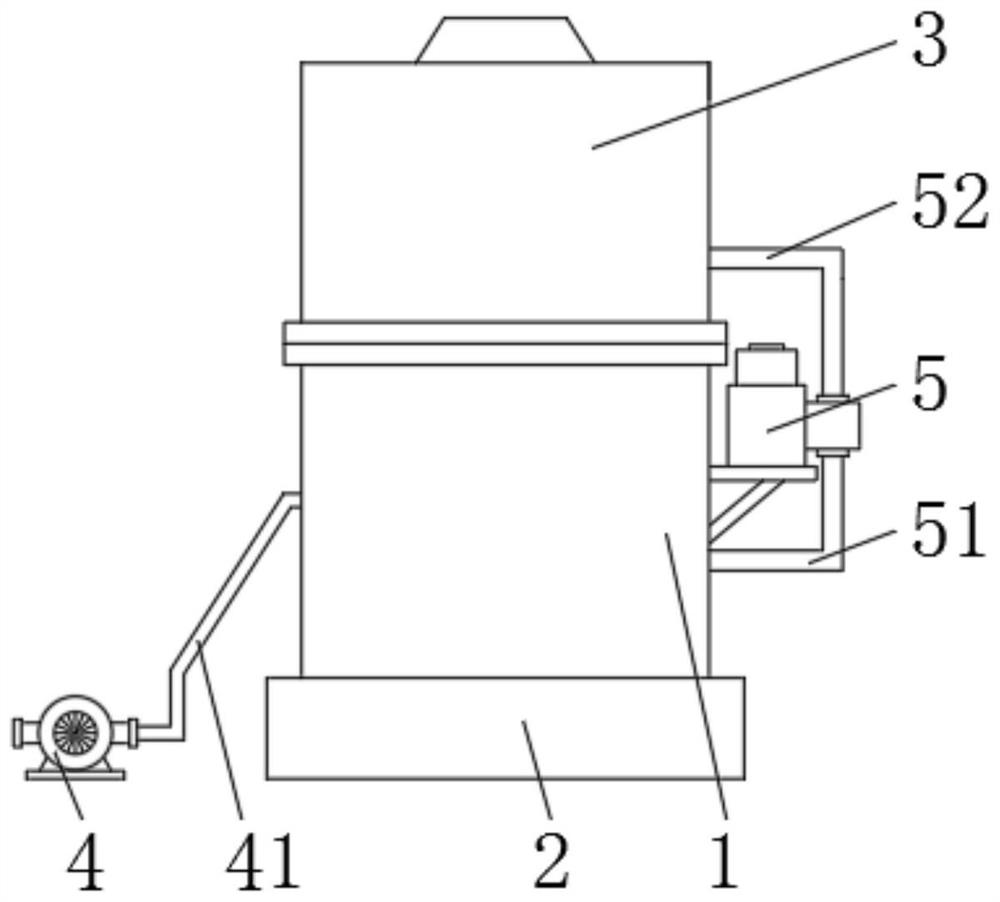

Neutralizing treatment device for pickling wastewater of hot-rolled nickel-based alloy stainless steel medium plate

PendingCN112811674AAvoid blockingEasy to replace and maintainSpecific water treatment objectivesTreatment involving filtrationWastewaterElectric machinery

The invention provides a neutralizing treatment device for pickling wastewater of a hot-rolled nickel-based alloy stainless steel medium plate. The neutralizing treatment device comprises a purification tank, a cleaning plate, a reciprocating lead screw, a sliding plate and air inlet pipes; two groups of U-shaped support frames are symmetrically arranged on the upper end surface of the purification tank, and two groups of transverse rails are arranged between the U-shaped support frames; a threaded rod is arranged at the upper end of the cleaning plate, and a brush is arranged at the lower end of the cleaning plate; the sliding plate is clamped in sliding grooves in the transverse rails in a sliding mode, and a fixed block is arranged at the upper end of the sliding plate; two groups of feeding bins are symmetrically arranged on the upper end surface of the sliding plate; and the air inlet pipes are fixedly connected with air conveying pipes, and the two air conveying pipes are arranged in a vertically symmetrical mode. According to the device, the reciprocating lead screw is in threaded connection with the fixed block, so that in the process that a driving motor drives the reciprocating lead screw to rotate, the sliding plate can move back and forth in a sliding groove in the transverse rails, lime in the feeding bins can be uniformly scattered into the purification tank, and the neutralizing effect of the lime on acidic substances in the purification tank is improved.

Owner:武文青

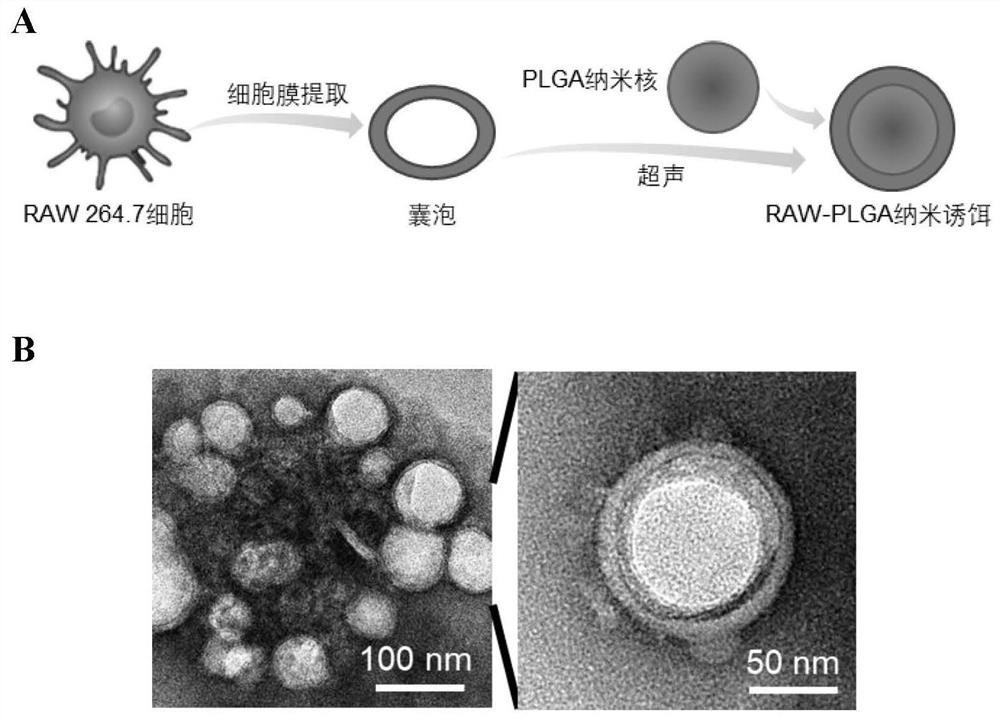

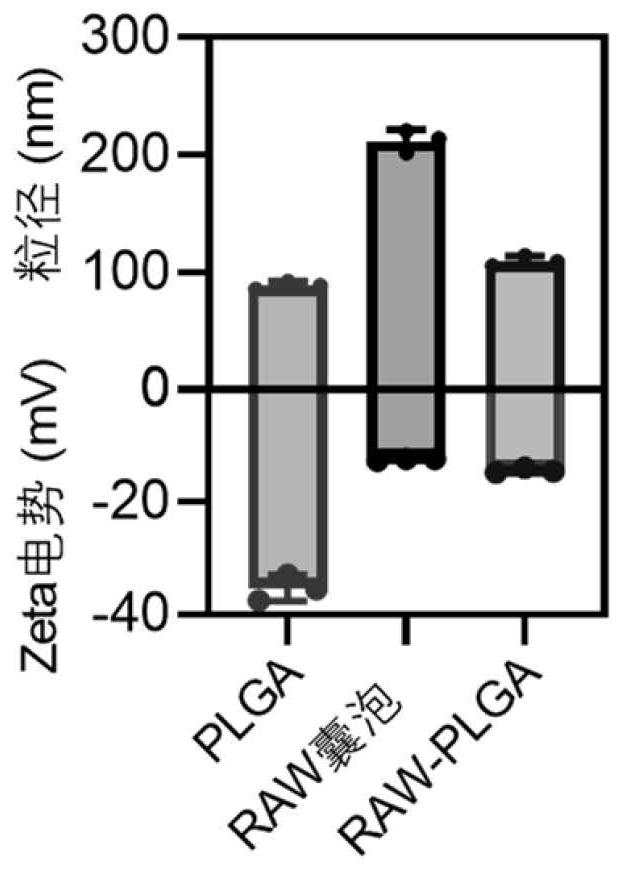

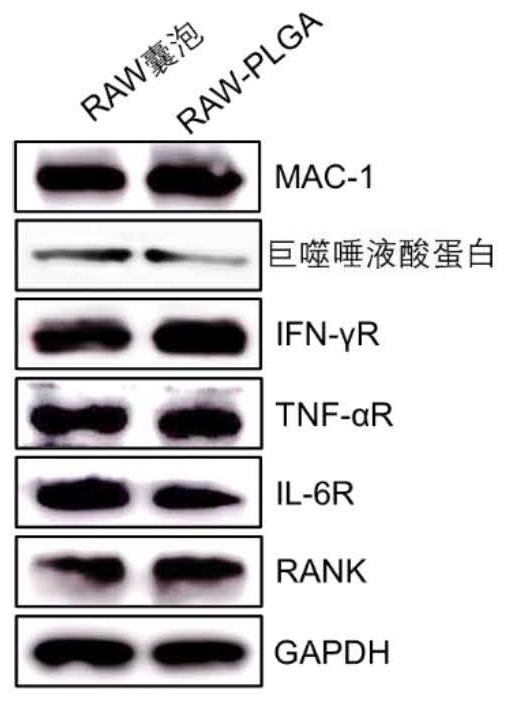

Cell membrane coated nano bait for removing RANKL, preparation and application thereof

PendingCN113925836AAvoid adverse reactionsIncrease serum stabilityDigestive systemInorganic non-active ingredientsDiseaseCell membrane

The invention provides a cell membrane coated nano bait for removing a nuclear factor kappa B receptor activation factor ligand (RANKL), preparation and application thereof. Specifically, the invention provides a nano bait, which comprises: (a) a nano core; and (b) a osteoclast precursor cell membrane coated with the nano core. The nano bait can be RAW-PLGA, wherein the RAW cell membrane is a cell membrane of osteoclast precursor cells, and PLGA is a nano core. The invention also provides a preparation method and application of the nano bait, especially application in treatment of osteoclast excess or hyperfunction related diseases (like osteoporosis). The nano bait provided by the invention can effectively remove highly expressed RANKL in osteoporosis, at the same time can escape from macrophage capture and has long-term blood circulation after systemic application, thus having great potential in clinical treatment of osteoporosis.

Owner:SUZHOU UNIV

Acrylonitrile quench method

InactiveCN1193008CAvoid direct deep burialEnhanced mass transferPreparation by hydrocarbon ammoxidationAcrylonitrileQuenching

The present invention relates to a quenching method of acrylonitrile, it is characterized by that in the upper section of quenching tower the acid or mixture of the acid and upper section partial external circulation liquid phase can be directly added on the liquid-collecting disk of its upper section, and the pH value of external circulation liquid can be controlled to 2-5, and in the lower section of the quenching tower a reasonable member is added and the gas-liquid distribution in the tower can be optimized so as to raise recovery rate of acrylonitrile by 4-5%. Said invention can be used in industrial production equipment of acrylonitrile.

Owner:CHINA PETROLEUM & CHEM CORP +1

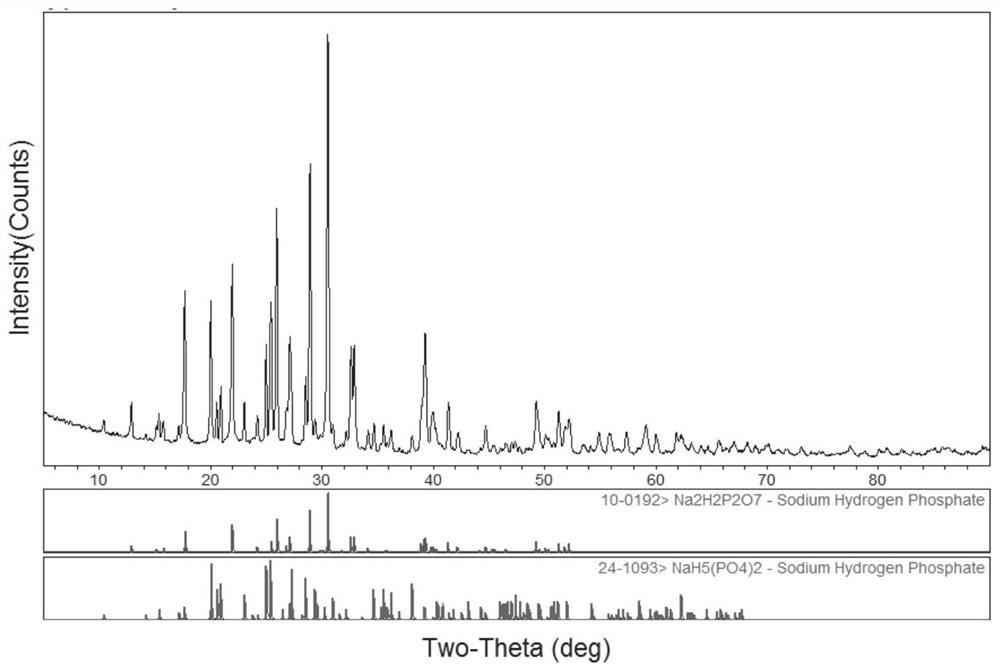

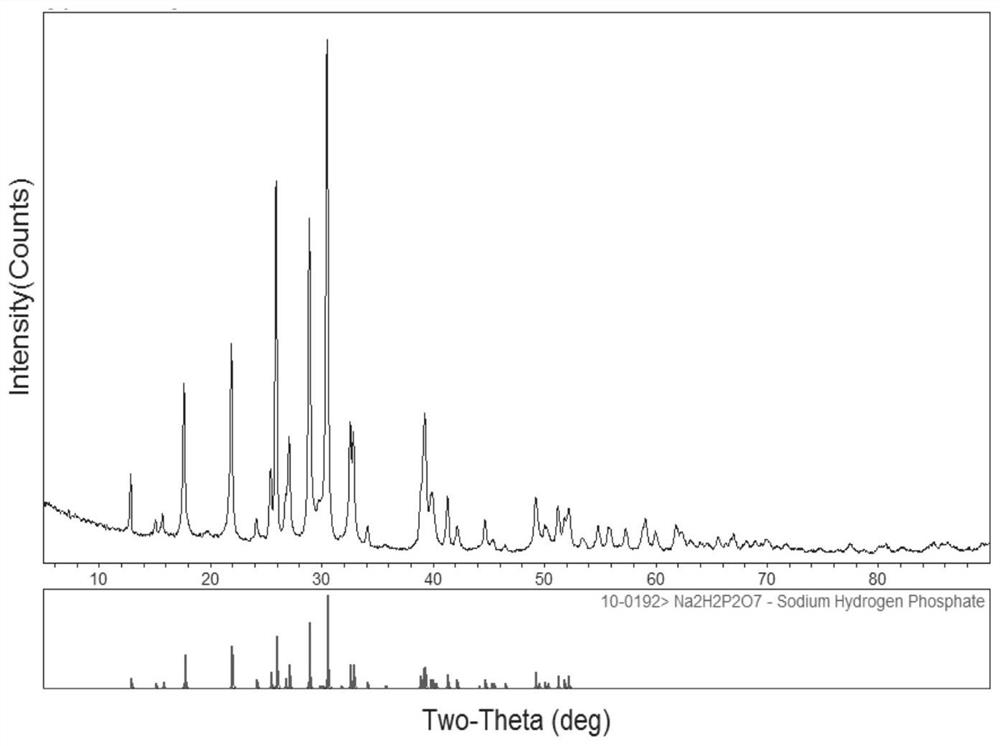

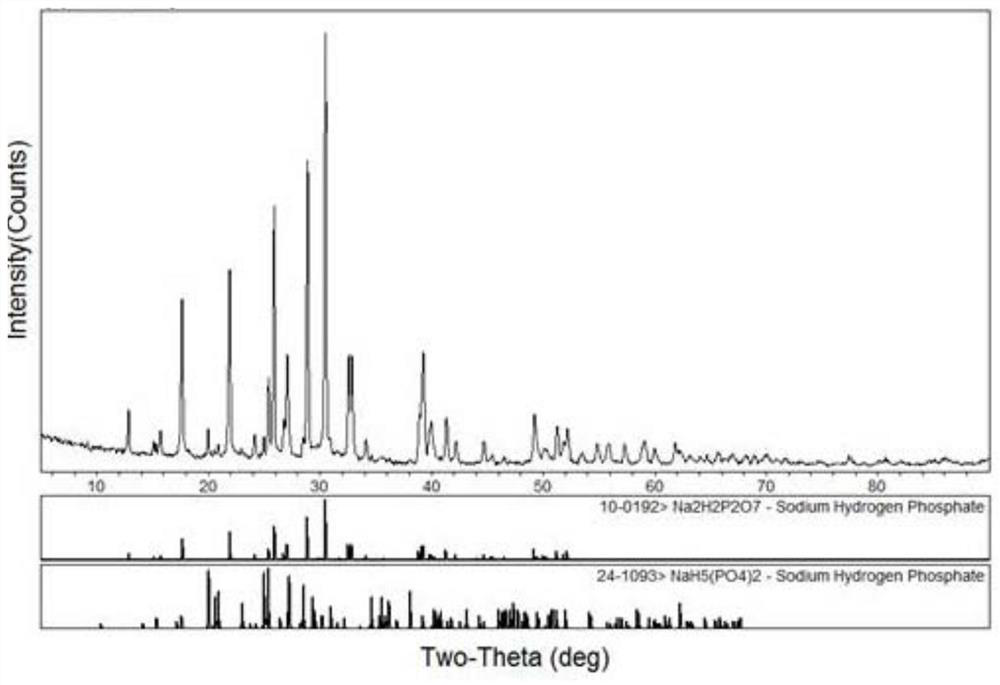

Acidic leavening agent with high neutralization value and preparation method and application thereof

ActiveCN113080222AImprove neutralization efficiencyReduce intakeDough treatmentClimate change adaptationLeavening agentSodium bicarbonate

The invention relates to the technical field of fermentation, in particular to an acidic leavening agent with a high neutralization value and a preparation method and application thereof. The acidic leavening agent is mainly composed of disodium dihydrogen pyrophosphate, the neutralization value of the acidic leavening agent is larger than or equal to 100, and the pH value of an aqueous solution with the mass fraction of the acidic leavening agent being 1.0% is 2.5-3.5. The acidic swelling agent has the advantages of secondary swelling, secondary processing, controllable and adjustable reaction speed and the like. More prominently, the neutralization value of the acidic leavening agent is high, and the neutralization efficiency can be remarkably improved when the acidic leavening agent is matched with sodium bicarbonate for use. Therefore, compared with the conventional disodium dihydrogen pyrophosphate, by using the acidic leavening agent, the sodium intake can be reduced by about 40%, the fermentation efficiency is greatly improved, and the food is safer and more beneficial to the health of a human body.

Owner:YUNNAN ADDIPHOS TECH CO LTD

Disinfection system of contact lens

ActiveUS20160361457A1Reduce the amount of metalEasy to neutralizeChemicalsMetal catalystCarboxylic acid

Owner:MENICON CO LTD

Acidic and alkaline industrial sewage treatment system

InactiveCN109467258ATo achieve the purpose of stirring and mixingAvoid corrosionWater treatment parameter controlWater/sewage treatment by irradiationSewageSewage treatment

The invention discloses an industrial sewage treatment system. The industrial sewage treatment system comprises a first sewage pool, wherein a first swage tube which communicates with the cavity of the first sewage pool is mounted on the left side surface of the first sewage pool; a first PH tester is mounted on the first sewage tube; a first sewage pump is mounted on the right side of the cavityof the first sewage pool; a first spraying tube is mounted on a water outlet tube of the first sewage pump; a first flowmeter is mounted on the first spraying tube; and a second sewage pool is arranged in the front of the first sewage pool. According to the industrial sewage treatment system, by the first PH tester and a second PH tester, the PH value of acidic sewage and the PH value of alkalinesewage are measured, according to a measurement result, the ratio of the acidic sewage to the alkaline sewage during neutralizing can be calculated, the sewage in the first sewage pool and the sewagein the second sewage pool are pumped into a neutralizing pool by the first sewage pump and a second sewage pump according to a calculated proportion and then are neutralized, and a purpose of neutralizing the acidic sewage and the alkaline sewage is achieved.

Owner:南京恒嘉坤科技有限公司

New energy automobile battery recovery environment-friendly sewage treatment device

PendingCN114105362AStable chemical propertiesImprove adsorption capacityTreatment involving filtrationMultistage water/sewage treatmentChemical storageWater storage

The invention discloses a new energy automobile battery recovery environment-friendly sewage treatment device which is characterized in that a water storage tank is fixed in a treatment box, a chemical storage box is fixed at the top of the treatment box, a chemical feeding hole communicated with the interior of the treatment box is formed in the bottom of the chemical storage box, the chemical feeding hole is connected with a chemical conveying pipe, and one end of the chemical conveying pipe is arranged above the chemical storage box; a drainage pipe is connected to the bottom of the water storage pond and penetrates through the water storage pond, a mesh screen is arranged at the top of the drainage pipe, first screen cloth is arranged in the mesh screen, a collecting column is in threaded fit with the bottom of the water storage pond, a circular groove is formed in the collecting column, and the end, away from the water storage pond, of the drainage pipe is arranged in the circular groove. A plurality of staggered first drainage holes are formed in the two baffles, second screen cloth is fixed to the first drainage holes, a plurality of second drainage holes communicated with the circular groove are formed in the side wall of the top of the collecting column, and the problems that a large number of metal precipitates and impurities are carried in sewage, and the sewage is acidic and cannot be directly discharged are solved.

Owner:杭州光明汽车有限公司

Quick cooling method for allyl nitrile

InactiveCN1173936CAvoid direct deep burialReduce consumptionPreparation by hydrocarbon ammoxidationCarboxylic acid nitrile purification/separationAcrylonitrileTower

The present invention relates to an acrylonitrile quenching method. It is characterized by that in the upper portion of quench tower the acid or acid after which is mixed with external circulating liquor of upper portion can be directly added on the liquor-collecting disk of the upper portion, and the pH value of the external circulating liquor is controlled at 2-5 so as to solve the problem of raising acrylonitrile yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

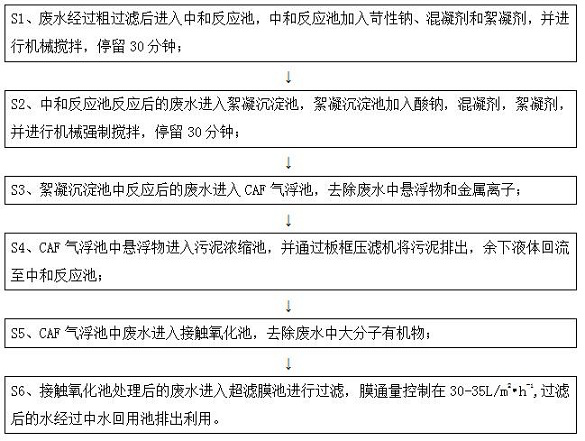

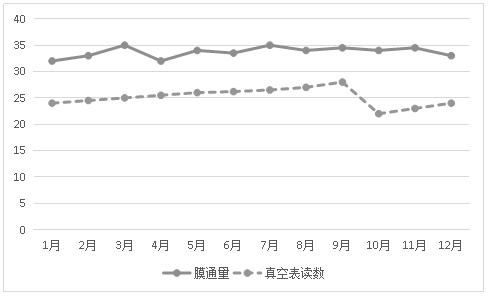

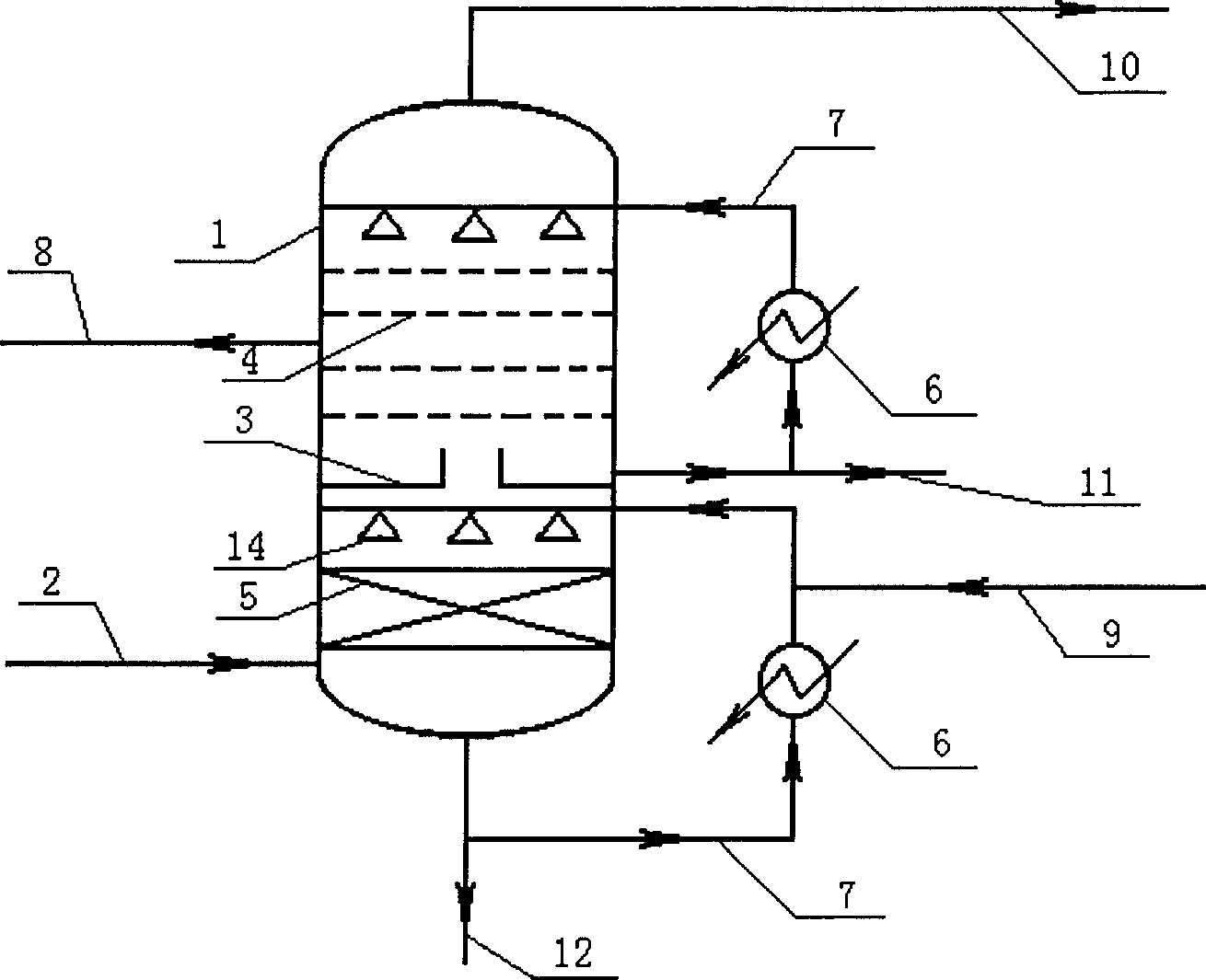

Iron and steel enterprise wastewater advanced treatment and recycling process

PendingCN113754187AImprove cleanlinessReduce processing loadFatty/oily/floating substances removal devicesTreatment involving filtrationFlocculationUltrafiltration

The invention discloses an iron and steel enterprise wastewater advanced treatment and recycling process, which comprises the following steps that wastewater enters a neutralization reaction tank after being subjected to coarse filtration, and caustic soda, a coagulant and a flocculant are added into the neutralization reaction tank; the wastewater reacted in the neutralization reaction tank enters a flocculation sedimentation tank; the reacted wastewater in the flocculation sedimentation tank enters a CAF air floatation tank; suspended matter in the CAF flotation tank enters a sludge concentration tank; the wastewater in the CAF flotation tank enters a contact oxidation tank, and macromolecular organic matter in the wastewater is removed; and the wastewater treated by the contact oxidation tank enters an ultrafiltration membrane tank to be filtered. An air flotation machine in the CAF flotation tank can remove grease, suspended solids and metal ions in water, wastewater in the CAF flotation tank enters the contact oxidation tank, macromolecular organic matter in the wastewater is removed through the contact oxidation tank, so that the water quality is further improved, the purposes of purification and separation are achieved, and the recycled water is relatively high in cleanliness and can be utilized to most areas of a factory, so that the cost is saved.

Owner:SHANDONG SHIHENG SPECIAL STEEL GROUP

Quench process for recovery of acrylonitrile

InactiveCN1161327CAvoid it happening againAvoid secondary pollutionCarboxylic acid nitrile purification/separationCooling towerAcrylonitrile

A suddenly cooling process for recovering acrylonitrile features that the stay time of suddenly cooling liquid in tower still at lower segment of suddenly cooling tower is controlled, the acid is directly added to said tower still, the pH value of liquid in tower still is controlled to 7-7.5, water is supplemented at lower segment and the concentration of heavy component in liquid of tower stil is controlled. Its advantage is high recovery rate of acrylonitrile.

Owner:CHINA PETROLEUM & CHEM CORP +1

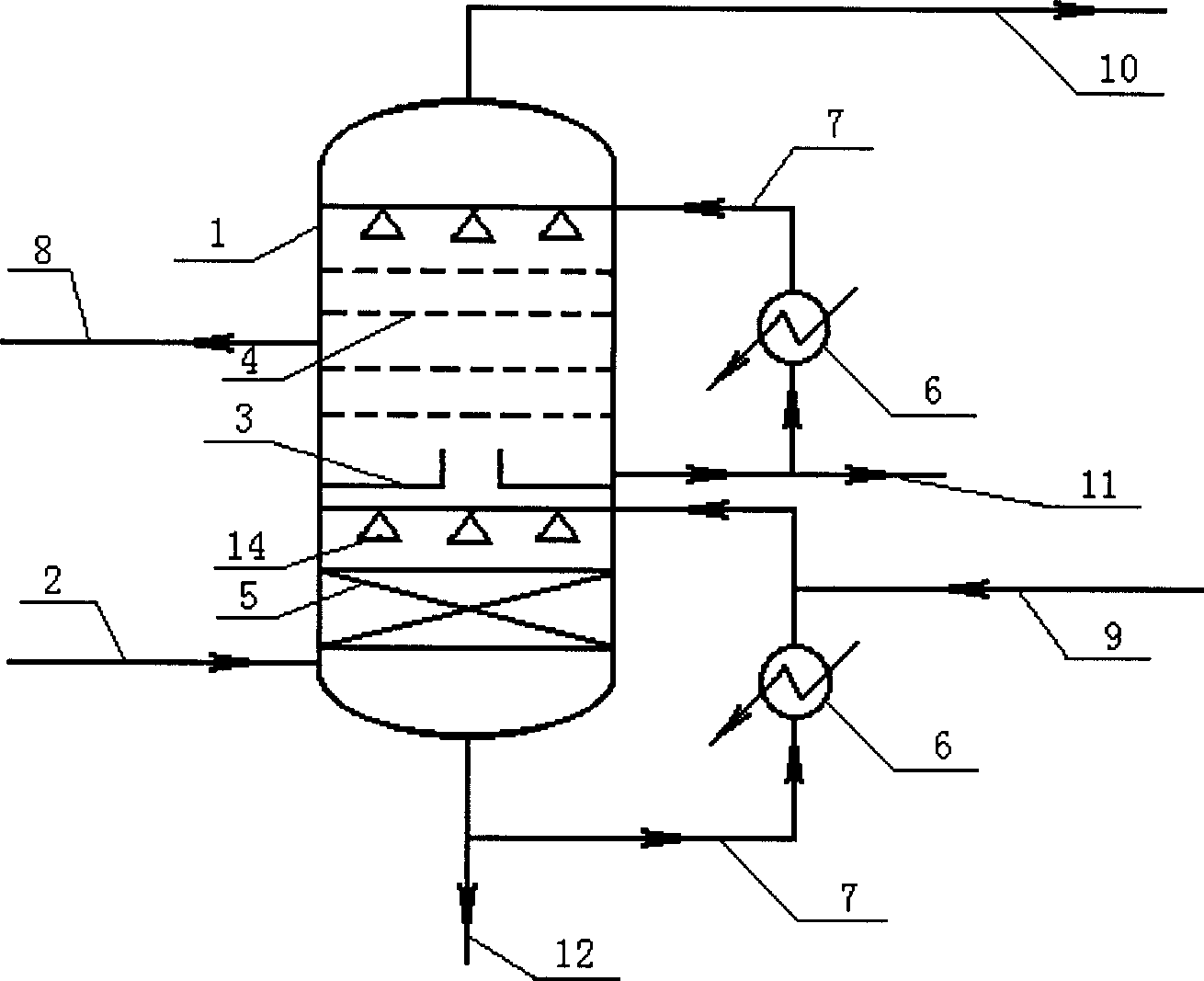

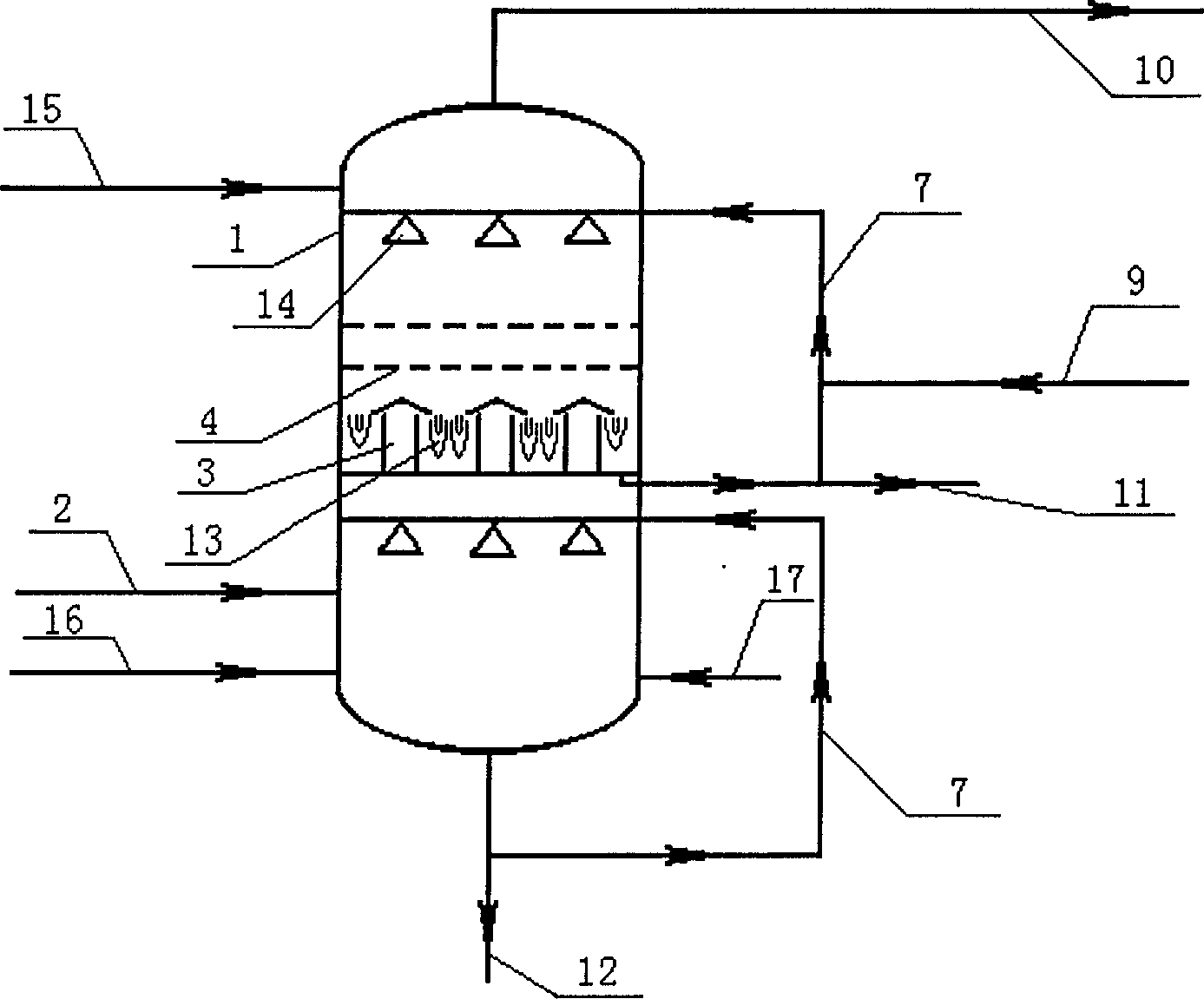

Tail gas treatment device for domestic waste incineration

ActiveCN109647162BEnsure normal dischargePromote neutralizationGas treatmentDispersed particle separationEnvironmental engineeringMechanical engineering

The invention discloses a tail gas treatment device for domestic garbage incineration, which relates to the technical field of environmental protection equipment, and specifically comprises a neutralization chamber, a driving chamber fixedly installed at the bottom of the neutralization chamber, a clean room fixedly connected to the top of the neutralization chamber, and fixedly installed on the purification chamber. The transmission wheel, the purification device and the cleaning device inside the chamber. An axial flow fan is fixedly installed outside the neutralization chamber. Inside the neutralization chamber, a fixing ring is fixedly connected to the inner side wall of the neutralization chamber. The baffle is set to cooperate with the gas outlet to ensure that the exhaust gas can be discharged while effectively reducing the outlet area, so that part of the exhaust gas can flow back into the neutralization liquid again, and prevent part of the tail gas from escaping due to incomplete reaction in the neutralization liquid. It is pointed out that the acidic or alkaline substances cannot be completely neutralized, resulting in the problem that the discharge does not meet the standard.

Owner:湖南美中环境生态科技有限公司

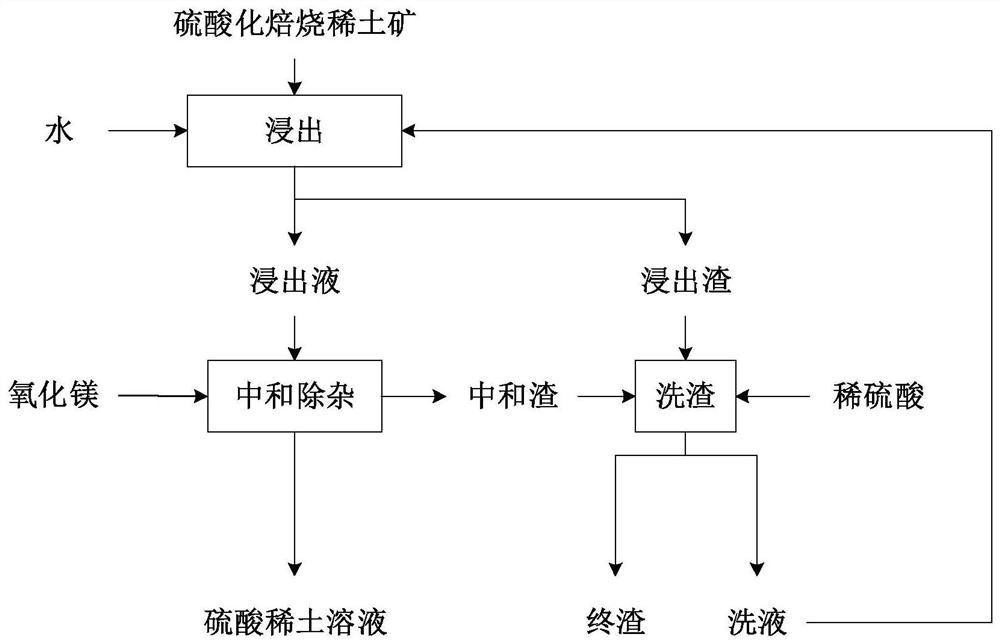

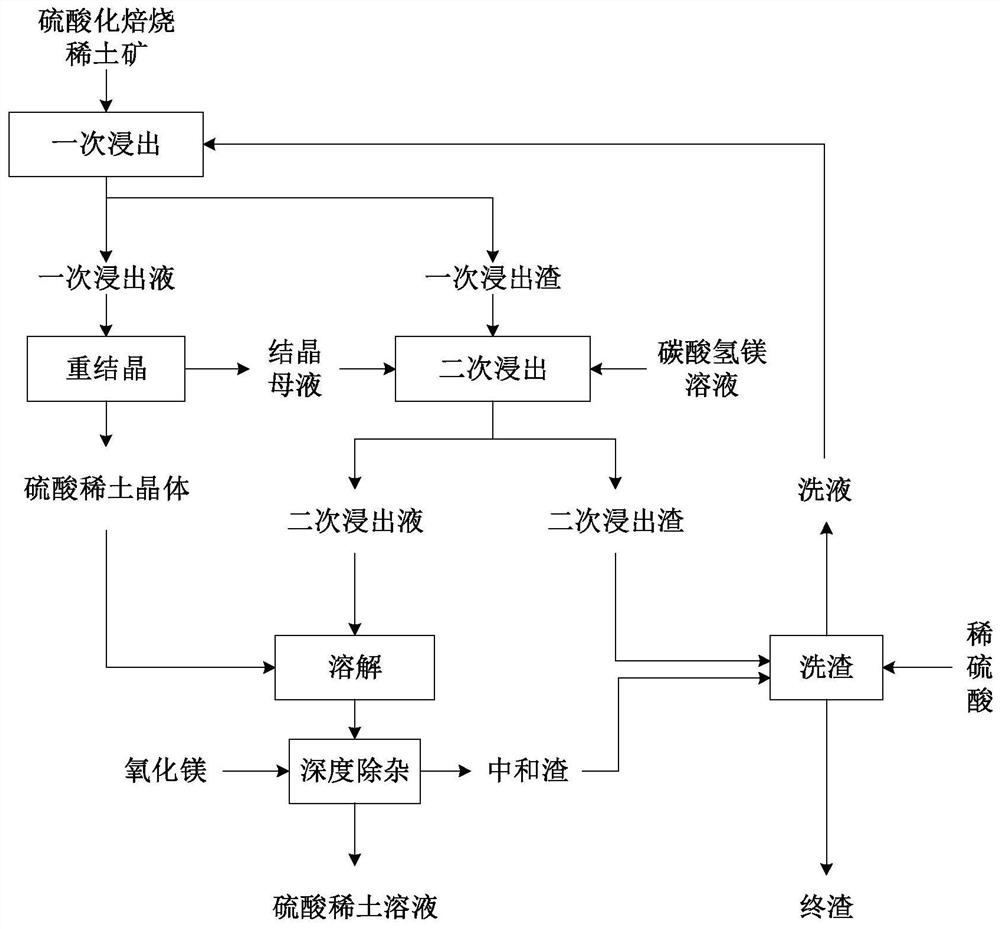

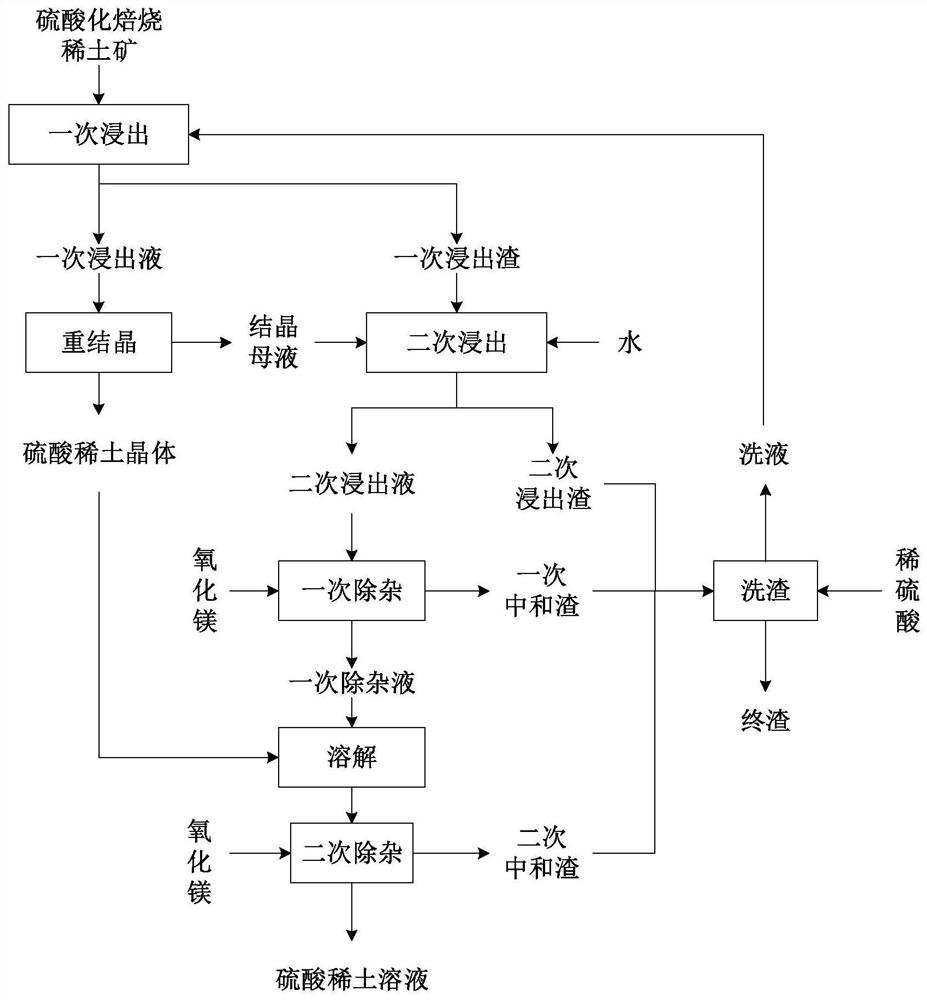

Method for preparing pure sulfuric acid rare earth solution

ActiveCN113373326AHigh recovery rateReduce consumptionProcess efficiency improvementSlagPhysical chemistry

The invention relates to a method for preparing a pure sulfuric acid rare earth solution from sulfating roasting rare earth ore. Rare earth is recovered step by step through two phases, so that the rare earth recovery rate is improved. According to the dynamic characteristics of rare earth dissolution in the rare earth sulfuric acid roasted ore leaching process and the law of the influence of temperature on the solubility of sulfuric acid rare earth, and through low-liquid-solid-ratio rapid leaching and then heating recrystallization, 50% or above of rare earth is separated out in a high-purity sulfuric acid rare earth recrystallization phase, and preliminary separation of the rare earth and impurities is achieved; and the remaining rare earth can be separated from the impurities again by means of neutralization and impurity removal, specifically, (1) one-step impurity removal of magnesium oxide in a traditional process can be replaced by a magnesium bicarbonate solution, so that the total consumption of solid magnesium oxide is reduced by 90%, magnesium recycling is realized, and the impurities introduced by magnesium oxide and the amount of slag generated by incomplete reaction are also reduced; and (2) magnesium oxide two-step impurity removal is adopted, and the total consumption of solid magnesium oxide is reduced by about 10% compared with a traditional process. According to the preparation method, the total recovery rate of the rare earth is increased by 1-3%.

Owner:GRIREM ADVANCED MATERIALS CO LTD +1

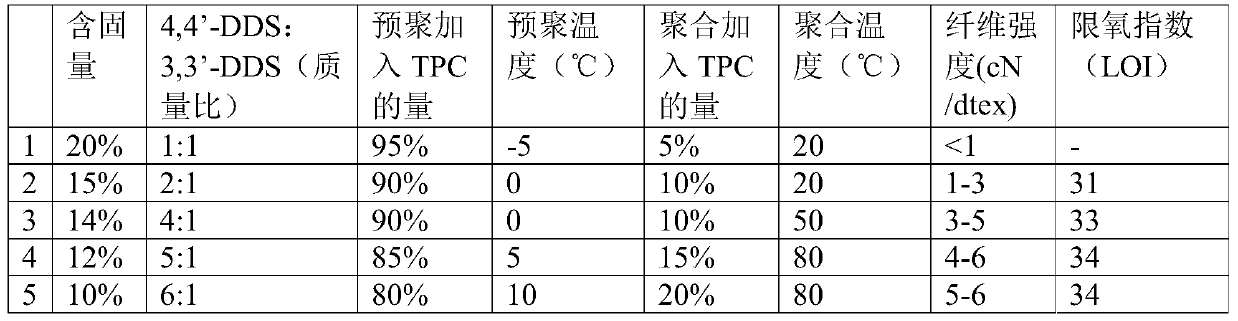

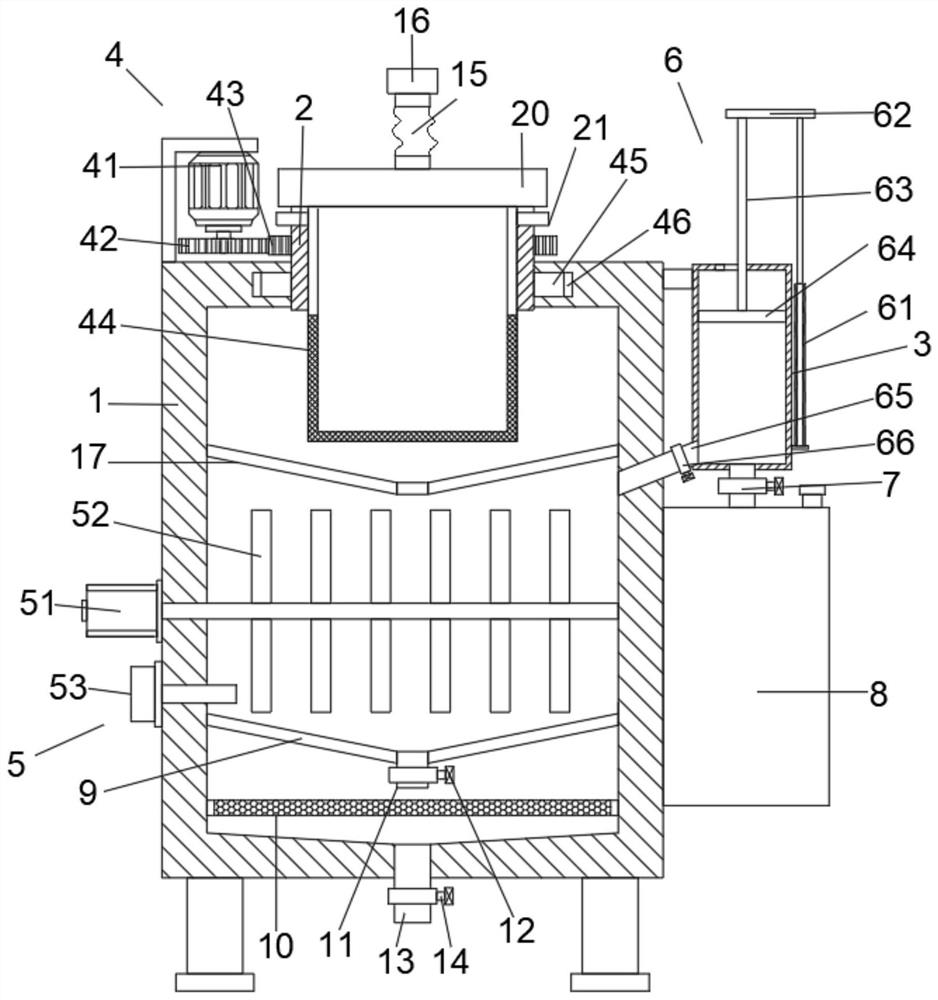

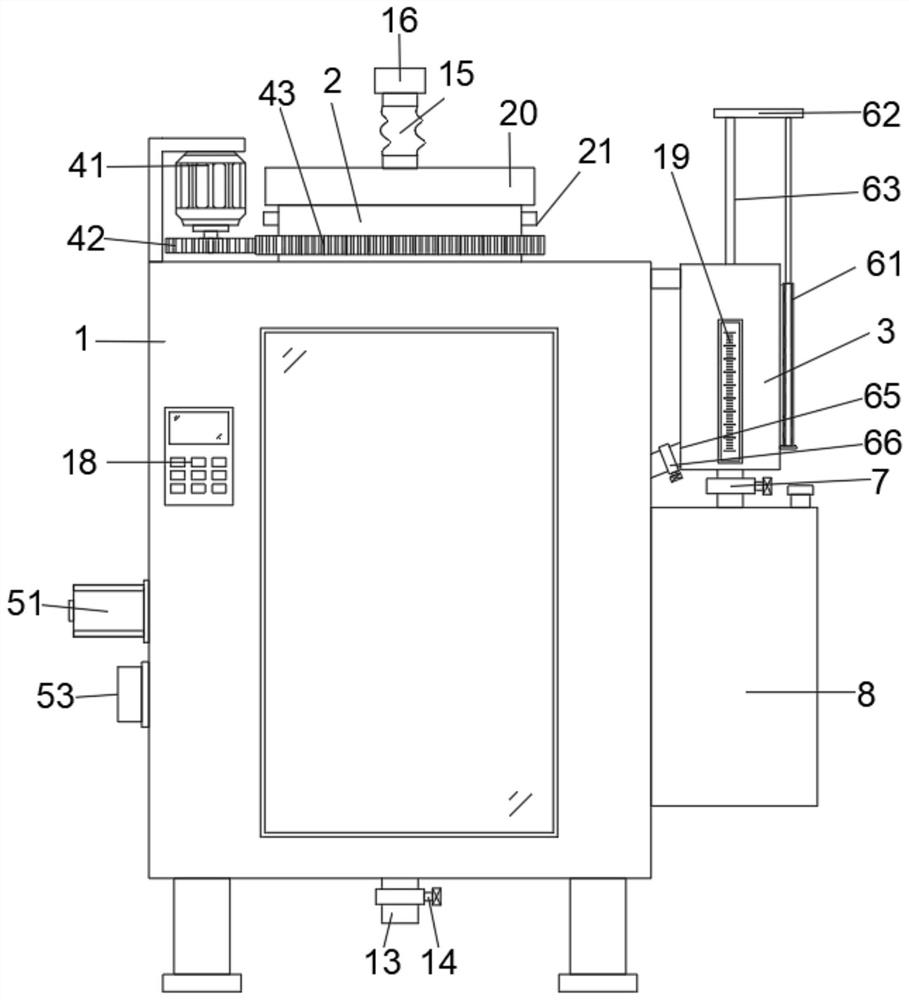

A kind of polysulfone aramid fiber, slurry to be spun and manufacturing method thereof

ActiveCN106519220BHigh solid contentHigh breaking strengthArtificial filament washing/dryingMonocomponent copolyamides artificial filamentPolymer scienceSpinning

The invention discloses a polysulfone aramid fiber, a to-be-spun slurry and a preparation method thereof. The method includes the steps of: 1. in a solvent, subjecting 4, 4'-diaminodiphenyl sulfone, 3, 3'-diaminodiphenyl sulfone and terephthaloyl chloride to prepolymerization reaction at a temperature ranging from -20DEG C to 25DEG C, with 4, 4'-diaminodiphenyl sulfone and 3, 3'-diaminodiphenyl sulfone being in a mass ratio of 2-6; 2. subjecting the prepolymerization product and paraphthaloyl chloride to polymerization reaction at a temperature of 30-100DEG C; and 3. mixing the polymerization product with organic alkali to carry out neutralization reaction, thus obtaining the to-be-spun slurry. The method provided by the invention maintains a high spinning slurry solid content, acquires polysulfone amide fiber with high breaking strength and good heat resistant and flame retardant performance, enhances the neutralization efficiency, and is non corrosive to follow-up spinning equipment; the generated salt has no need of filtration for removal, the high equipment cost caused by corrosion is saved, and the fiber production efficiency is improved.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI +1

Cleaning liquid recovery device for pickling processing and use method of cleaning liquid recovery device

InactiveCN114053785AHEPA filterWell mixedFiltration circuitsProcess engineeringIndustrial engineering

The invention discloses a cleaning liquid recovery device for pickling processing and a using method thereof. The cleaning liquid recovery device comprises a recovery box, a rotating ring, a filtering mechanism, a treatment mechanism and a liquid adding mechanism, wherein one side of the recovery box is fixedly connected with a liquid adding box, the liquid adding mechanism is arranged in the liquid adding box, the rotating ring is arranged in the recovery box, the filtering mechanism is arranged on one side of the rotating ring, and the treatment mechanism is arranged below the filtering mechanism and located in the recovery box. The cleaning liquid recovery device has the beneficial effects that by adding the filtering mechanism, impurities in cleaning liquid can be efficiently filtered, and filtering efficiency is improved; by adding the treatment mechanism, the cleaning liquid and an alkaline solution are fully mixed, and neutralization efficiency is improved; the recovery box can be accurately filled with the alkaline solution by adding the liquid adding mechanism, so neutralization effect is improved; and a filter cartridge can be rapidly taken out by adding a cover plate and a limiting rod, so impurities can be removed, and the labor intensity of workers is reduced.

Owner:SICHUAN HUIYUAN STEEL CONSTR SCI & TECH

Isooctyl acrylate production process with oil phase and water phase separation device

InactiveCN110540502AAvoid stirring vortexImprove the quality of neutralizationOrganic compound preparationCarboxylic acid esters separation/purificationIsooctyl acrylateOil and grease

The invention discloses an isooctyl acrylate production process with an oil phase and water phase separation device, and belongs to the technical field of isooctyl acrylate production processes. The device comprises a neutralization kettle; elastic telescopic rods with the same structure are inserted into the left side and the right side of the top of the neutralization kettle; an oil-water separation net film I is arranged at the bottom of an inner cavity of a coalescing filter element; and an oil-water separation net film II is arranged at the bottom of the coalescing filter element. In theproduction process, a separation barrel is adopted after neutralization; a solution enters the coalescing filter element through the influence of a guide block; a step motor is started and drives theseparation cylinder to rotate; under the action of centrifugal force, water in the solution flows downwards through the oil-water separation net film I and then flows to a water storage cavity througha water outlet pipe; and grease in the solution is adsorbed into a grease cavity by the coalescing filter element, so that oil phase and water phase separation is rapidly realized, the separation error and the labor intensity are reduced, and the overall work efficiency and the subsequent processing quality are greatly improved.

Owner:JIANGSU GUOJIAO CHEM TECH

Breathing type treatment device for industrial wastewater treatment

InactiveCN114477557AModerate and even flowImprove neutralization efficiencyMultistage water/sewage treatmentWater/sewage treatment by neutralisationIndustrial equipmentEngineering

The invention relates to the technical field of industrial equipment, and discloses a breathing type treatment device for industrial wastewater treatment. According to the breathing type treatment device for industrial wastewater treatment, a main body shell with a mounting plate is fixed to the outer side, a longitudinal sealing cover is screwed to the top of the main body shell through a thread structure, and a transverse main piston cavity is formed in the main body shell; a longitudinal liquid flowing cavity is formed in the position, located on one side of the main piston cavity, in the main body shell and the sealing cover, one end of the main piston cavity communicates with the side face of the liquid flowing cavity through a first liquid flowing hole, and an equipment mounting hole located below the liquid flowing cavity is formed in the main body shell. By combining catalytic treatment and neutralization treatment, on one hand, the requirement on equipment can be reduced, and the cost can be reduced; on the other hand, the working process can be accelerated, and the working efficiency is improved.

Owner:檀德水

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com