Neutralizing treatment device for pickling wastewater of hot-rolled nickel-based alloy stainless steel medium plate

A technology for nickel-based alloys and pickling wastewater, which is used in metallurgical wastewater treatment, neutralization water/sewage treatment, and water/sewage multi-stage treatment. It can solve problems such as waste, inability to accurately calculate the amount of lime, and excessive lime input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

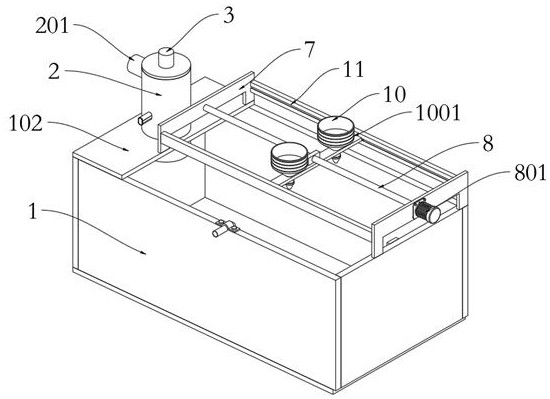

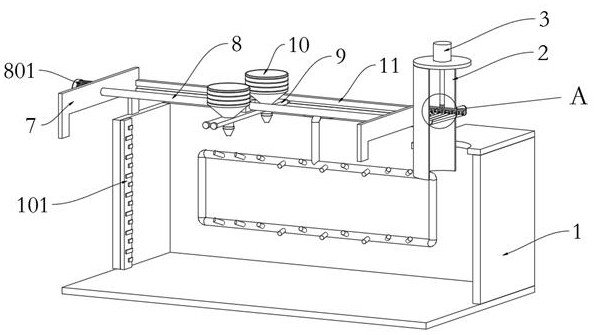

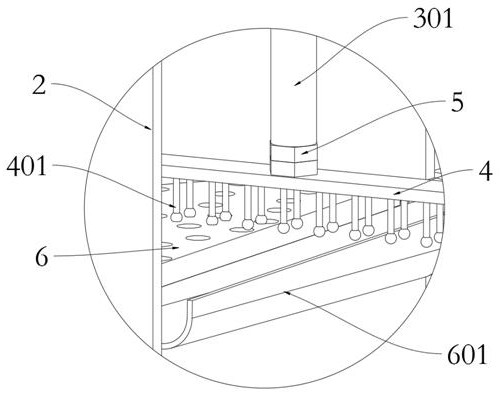

[0035] as attached figure 1 to attach Figure 9 Shown:

[0036] The invention provides a pickling wastewater neutralization treatment device for hot-rolled nickel-based alloy stainless steel plate, which comprises a purification tank 1, a cleaning plate 4, a reciprocating screw 8, a sliding plate 9 and an air intake pipe 12; the upper end surface of the purification tank 1 There are two sets of U-shaped support frames 7 symmetrically, and two sets of horizontal rails 11 are arranged between the U-shaped support frames 7; a fixed plate 102 is provided on the left side of the upper end of the purification pool 1, and a filter bucket is provided on the upper surface of the fixed plate 102 2. The outer end of the filter barrel 2 is provided with a water inlet pipe 201; the top of the filter barrel 2 is provided with a rotating motor 3, and the rotating shaft 301 passes through the top plate of the filter barrel 2 and is connected to the rotating motor 3, and the inside of the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com