Patents

Literature

40results about How to "Improve neutralization effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

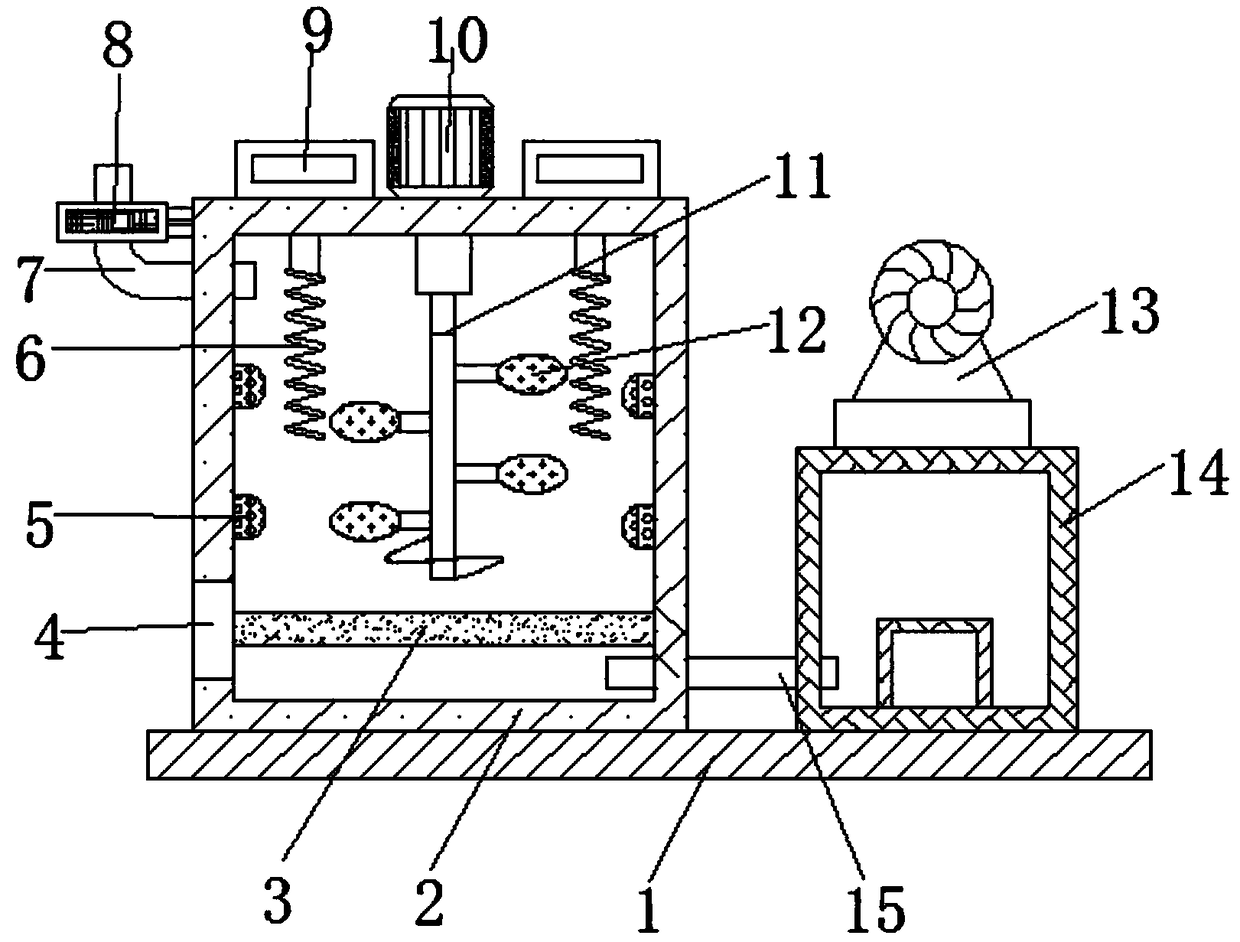

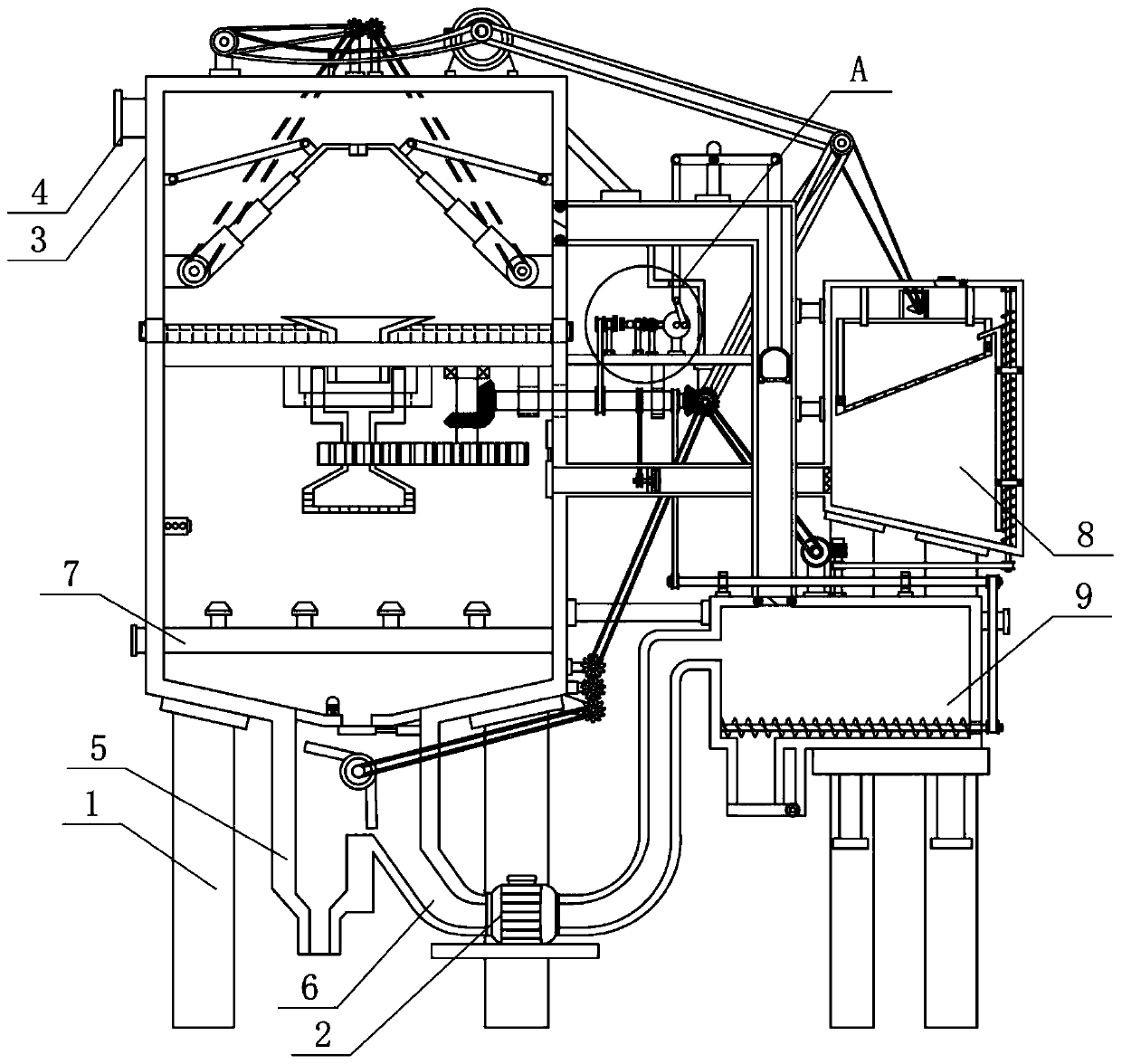

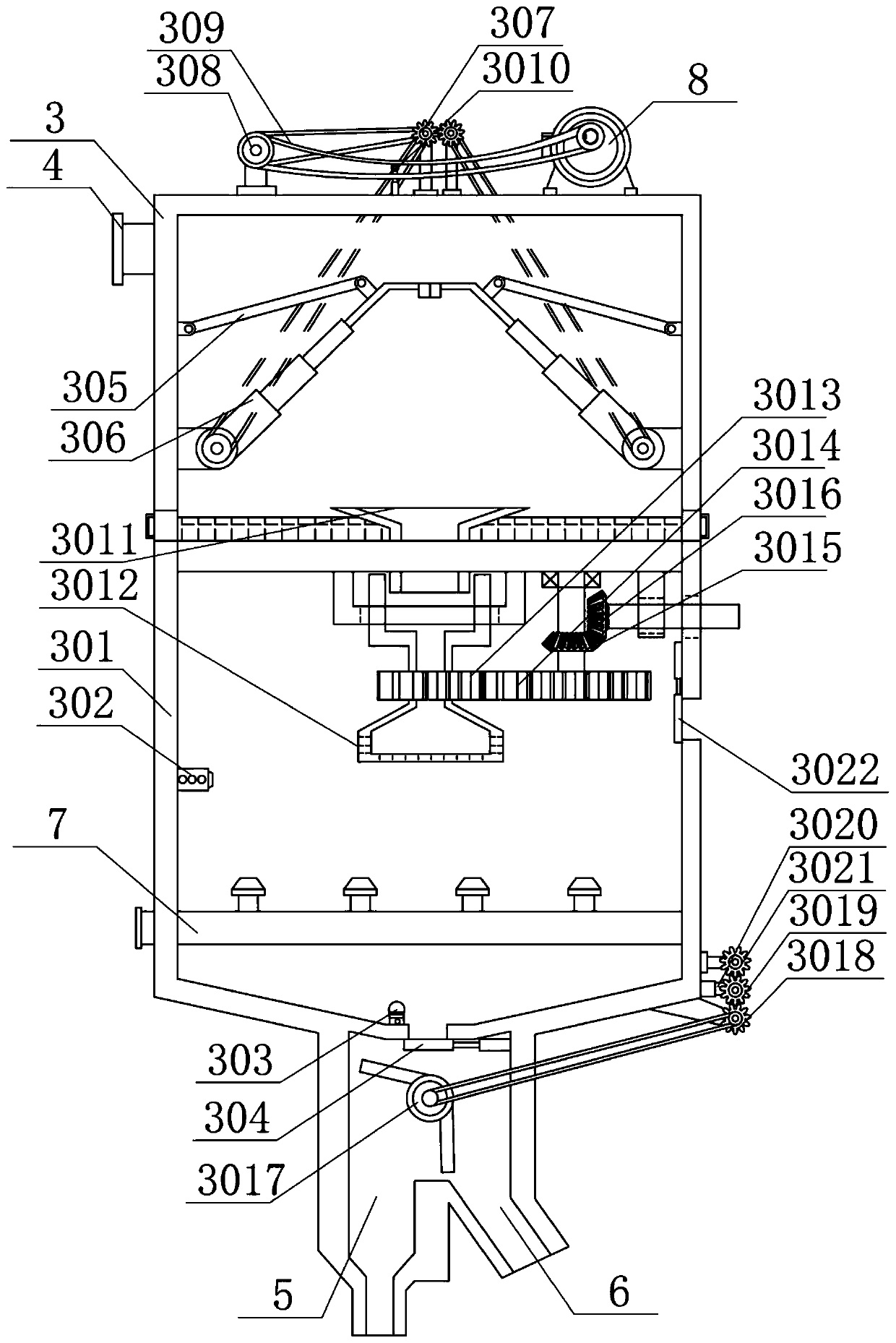

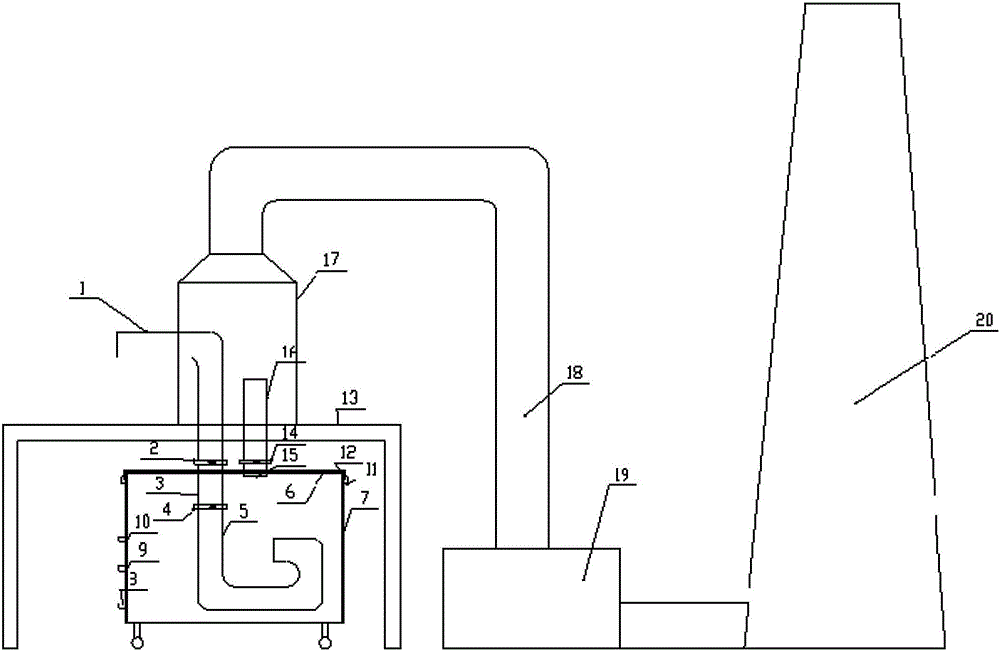

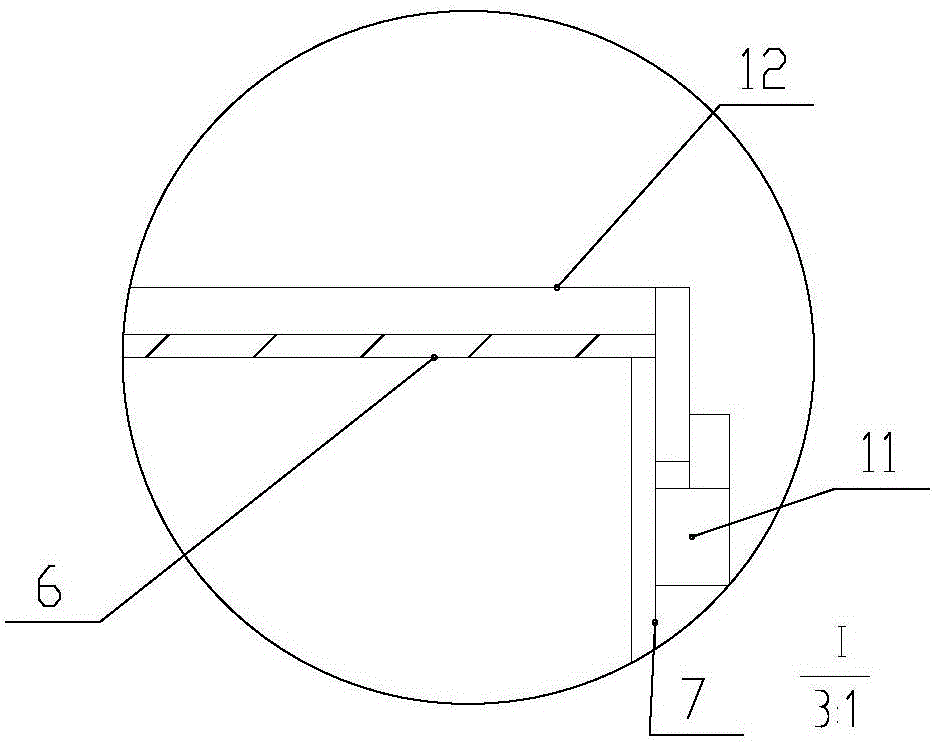

Combined type incinerating device capable of controlling toxic gases and heavy metal content in waste incineration smoke

InactiveCN103994442ARelieve pressureReduce generationIncinerator apparatusToxic gasCombustion chamber

Provided is a combined type incinerating device capable of controlling toxic gases and heavy metal content in waste incineration smoke. An incinerator hearth is composed of a first combustion chamber and a second combustion chamber, the first combustion chamber is a horizontal type combustion chamber, the second combustion chamber is a vertical type combustion chamber, heat insulation type combustion chambers are adopted by the whole first combustion chamber and the second combustion chamber of enough height, multiple primary air inlet chambers are adopted by the first combustion chamber to carry out chamber division and amount selected air supply according to needs, two rows of secondary air exhaust pipes which blow oppositely and are arranged at the connecting positions of the other two combustion chambers blow in secondary air, slaked lime adding devices are arranged out of the hearth at the horizontal height of the center of an upper boiler barrel and the hearth of the horizontal height at the center of a lower boiler barrel of a double-boiler-barrel vertical type waste heat boiler, and the slaked lime adding devices inject quantitative slaked lime into the hearth in the flow direction of the high temperature smoke between the upper boiler barrel and the lower boiler barrel. According to the combined type incinerating device capable of controlling the toxic gases and the heavy metal content in the waste incineration smoke, the structural characteristics of the combined type incinerating device is utilized, the controlling over all techniques and parameters is combined, source controlling over the toxic gases and heavy metal is achieved in an incineration process, the pressure of tail gas purification work is relieved fundamentally, and market needs are met.

Owner:上海煜工环保科技有限公司

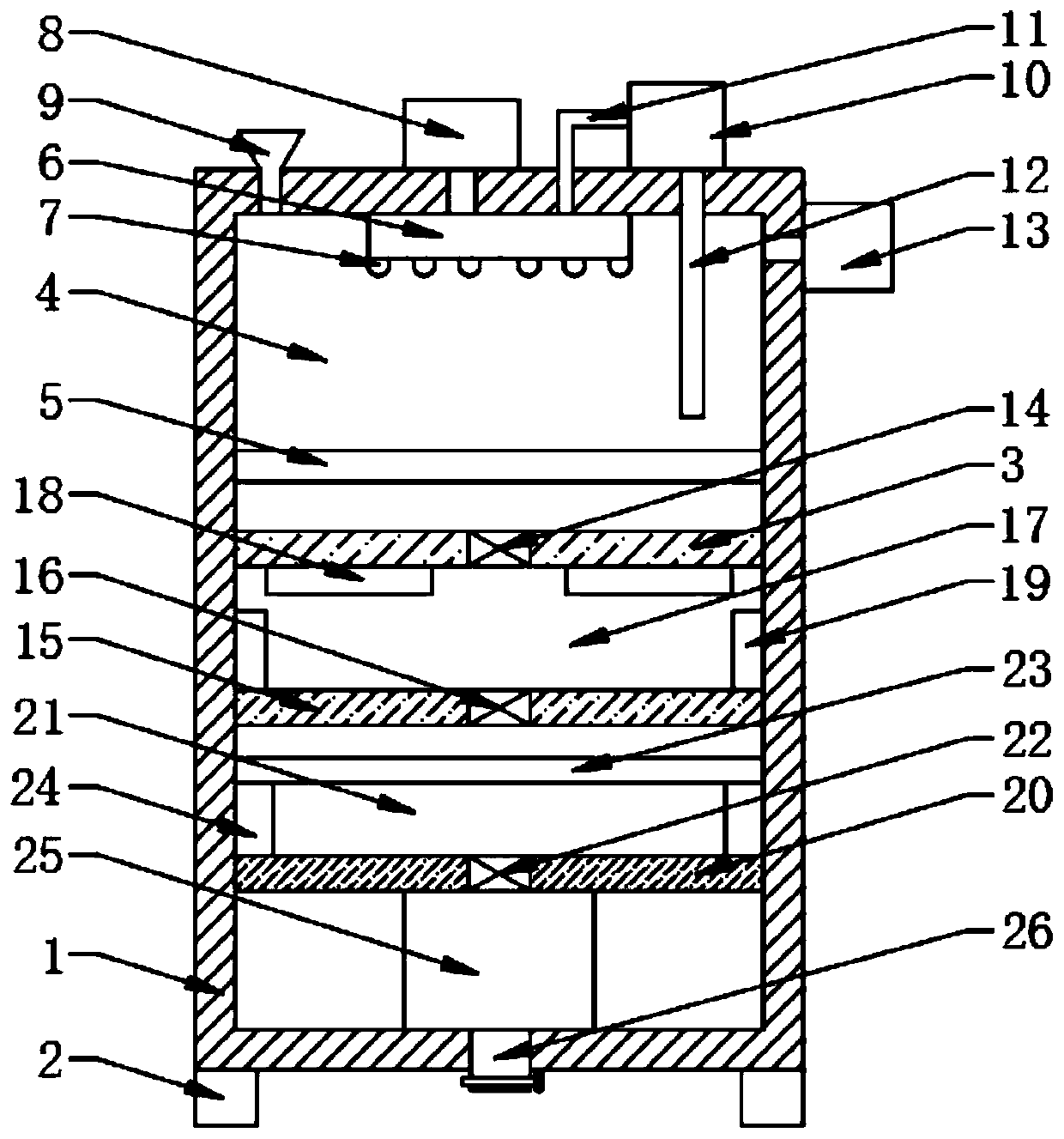

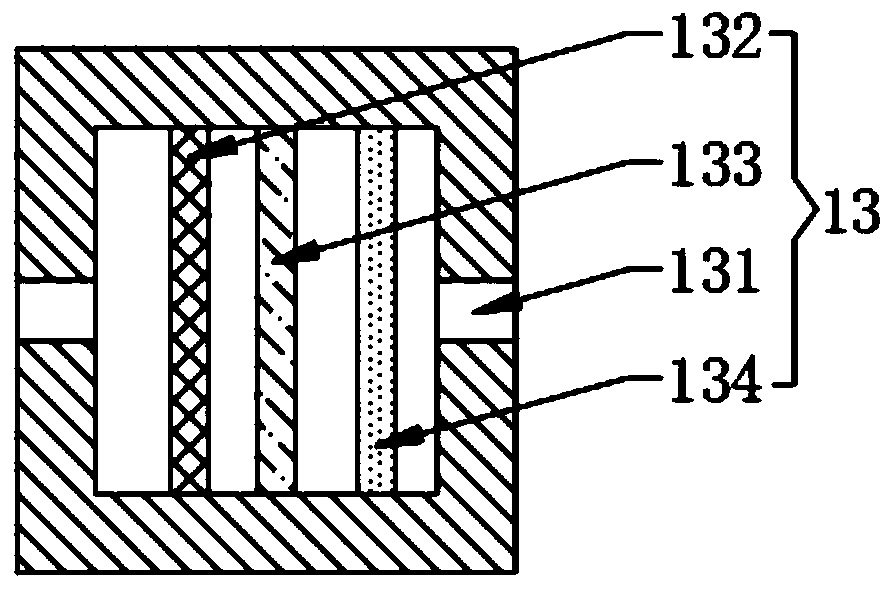

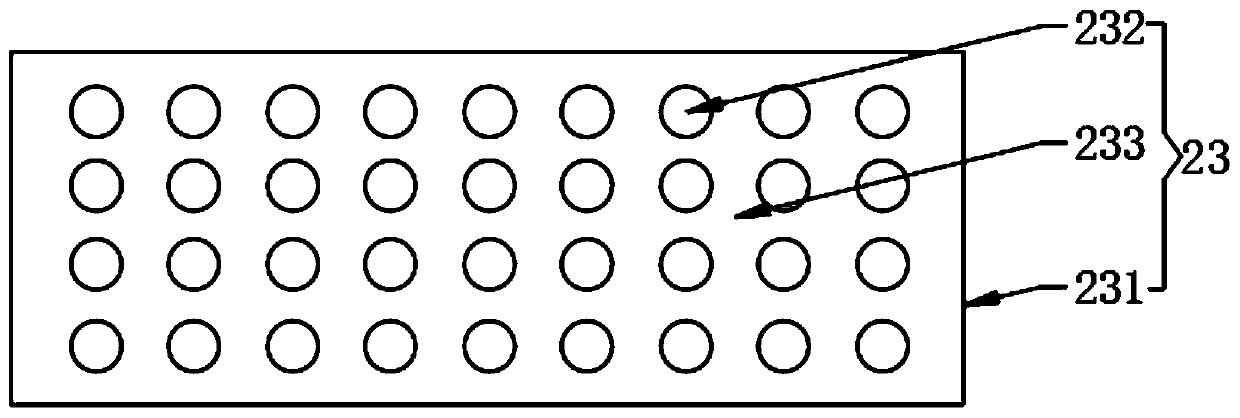

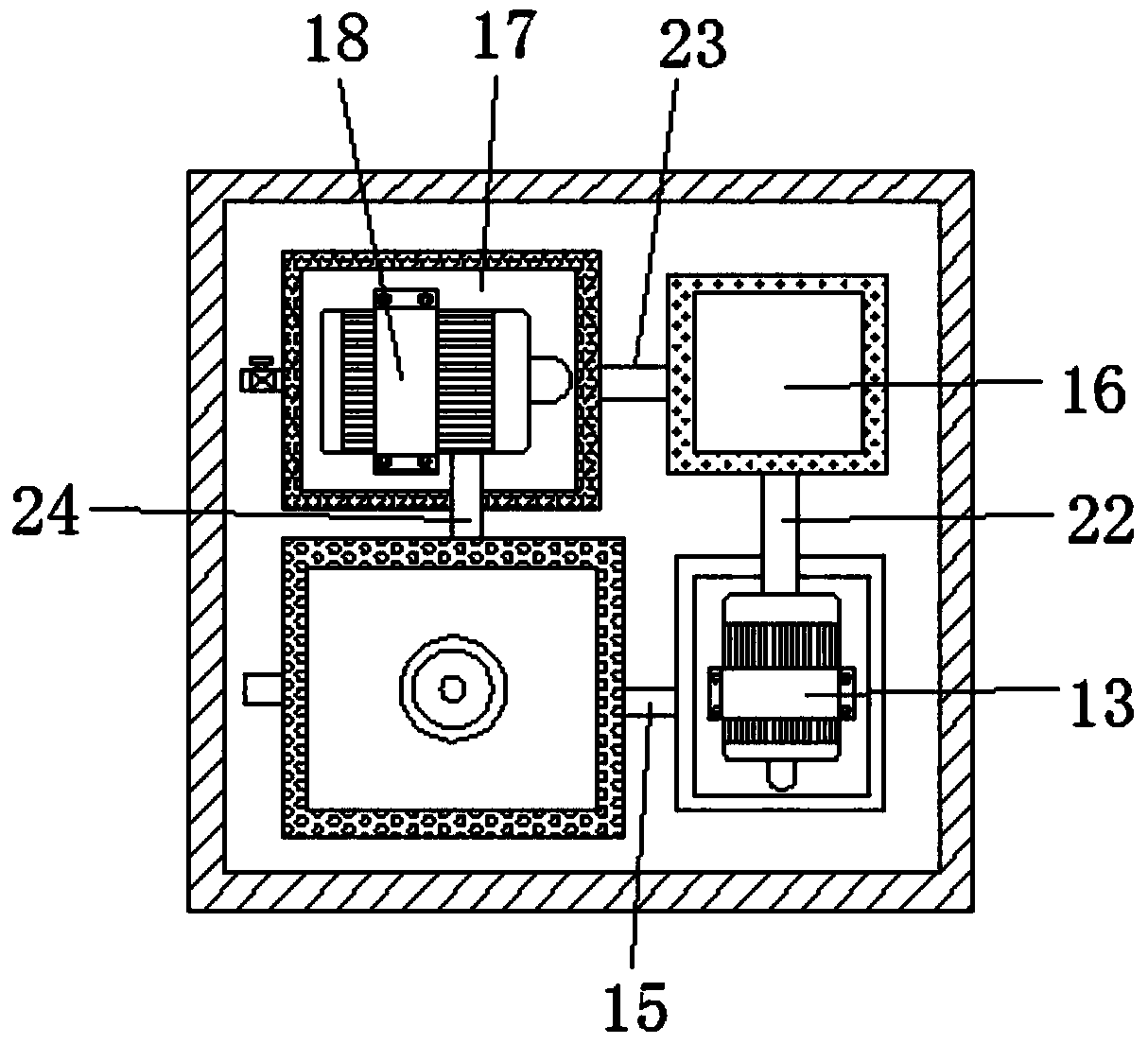

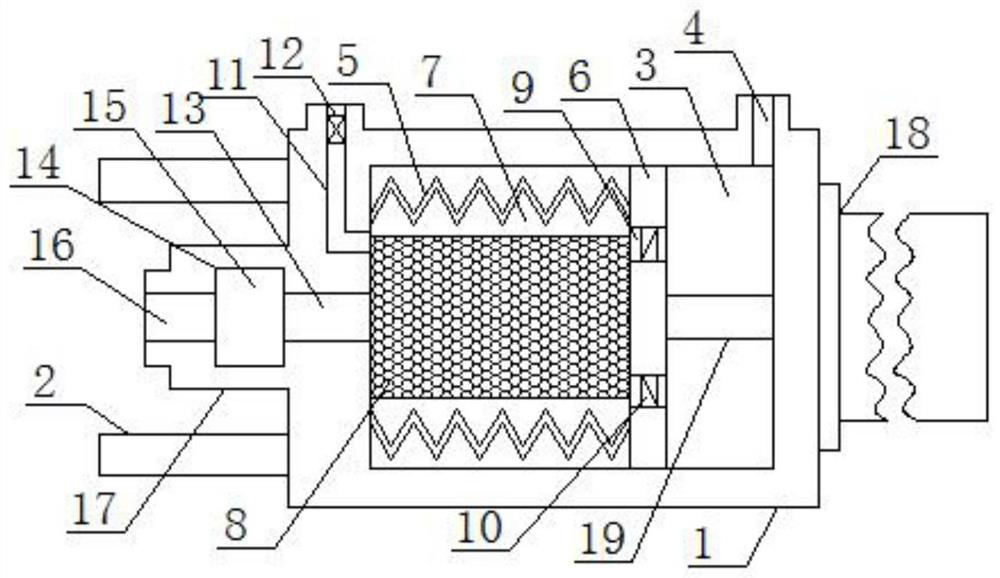

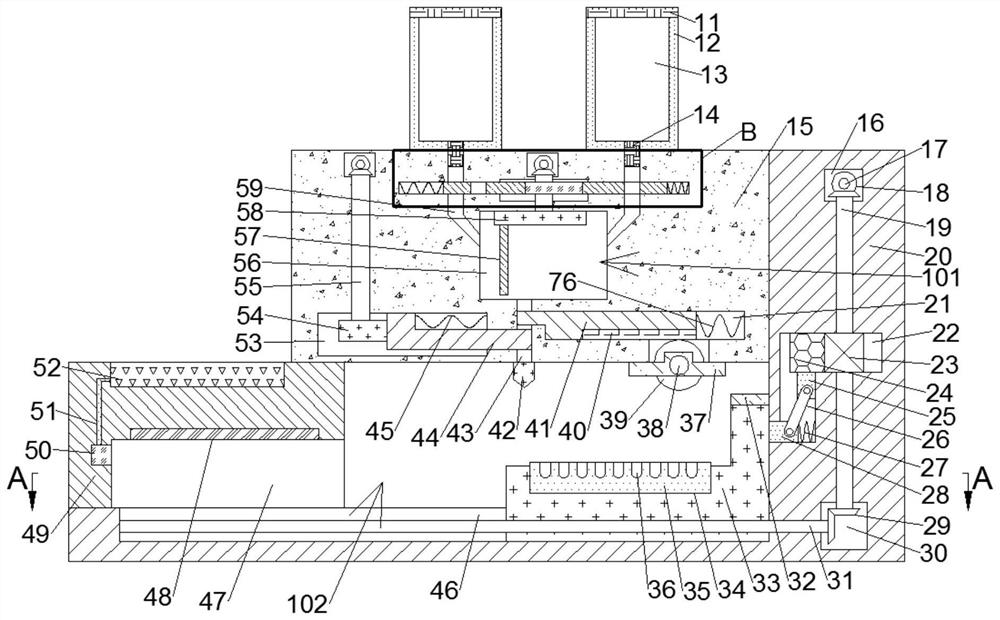

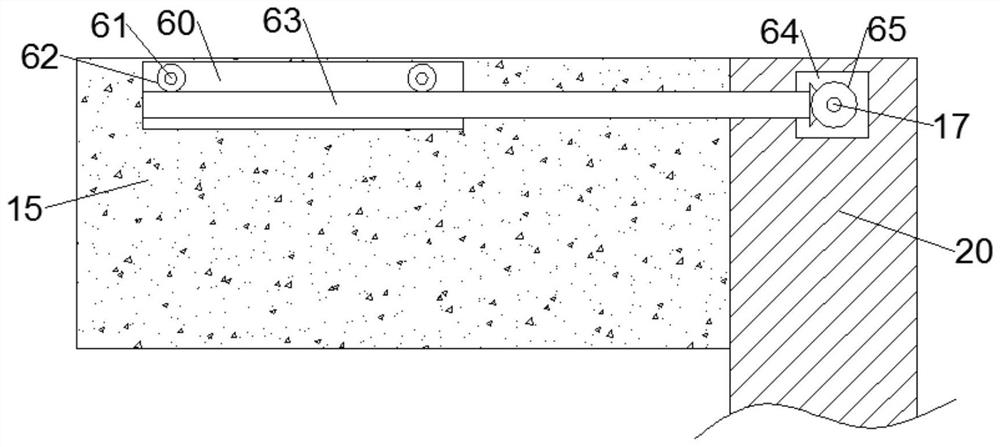

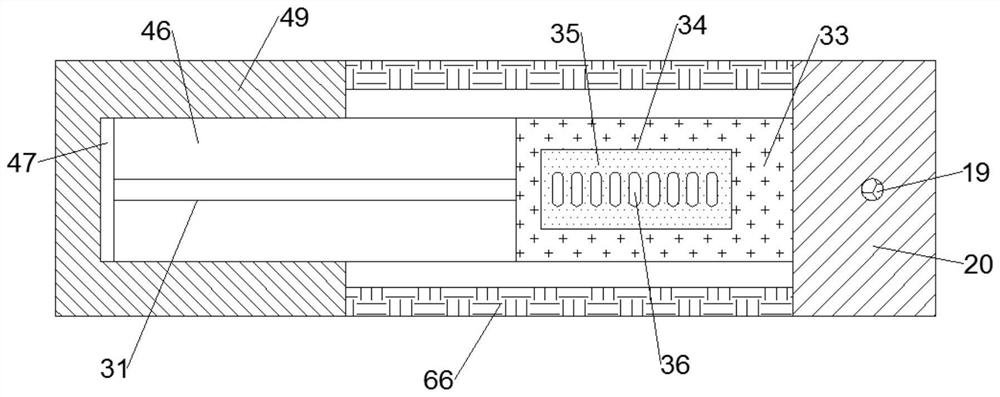

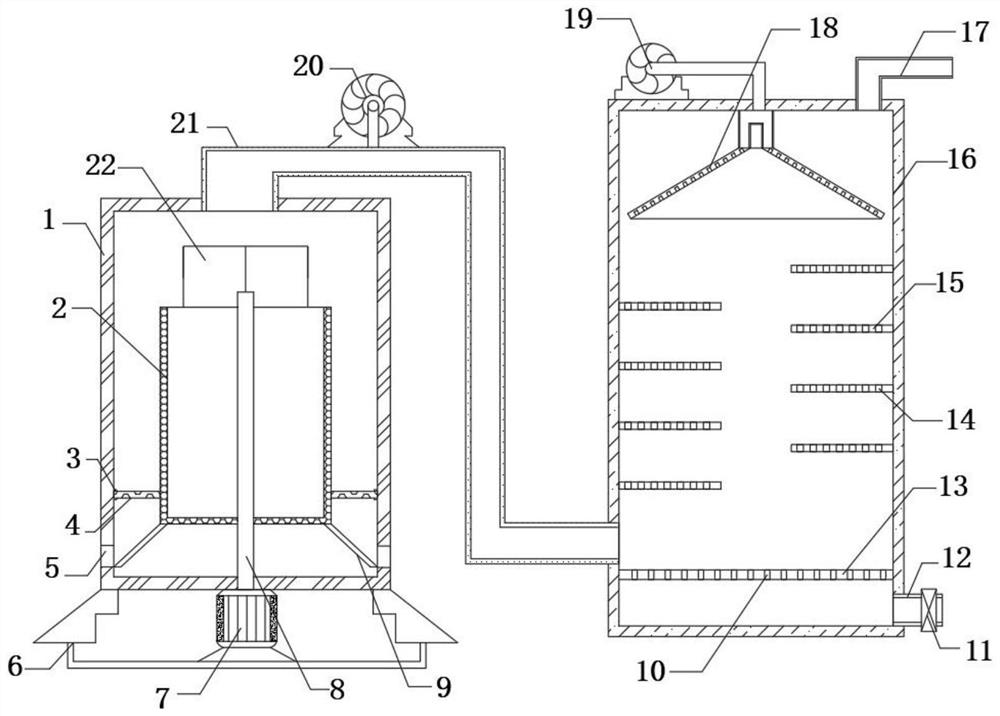

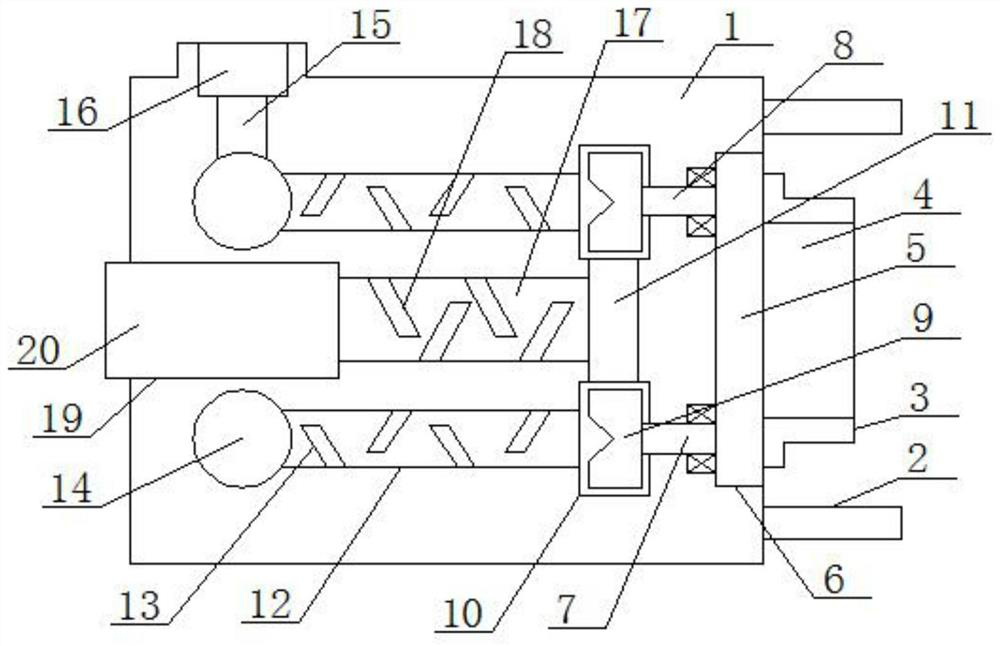

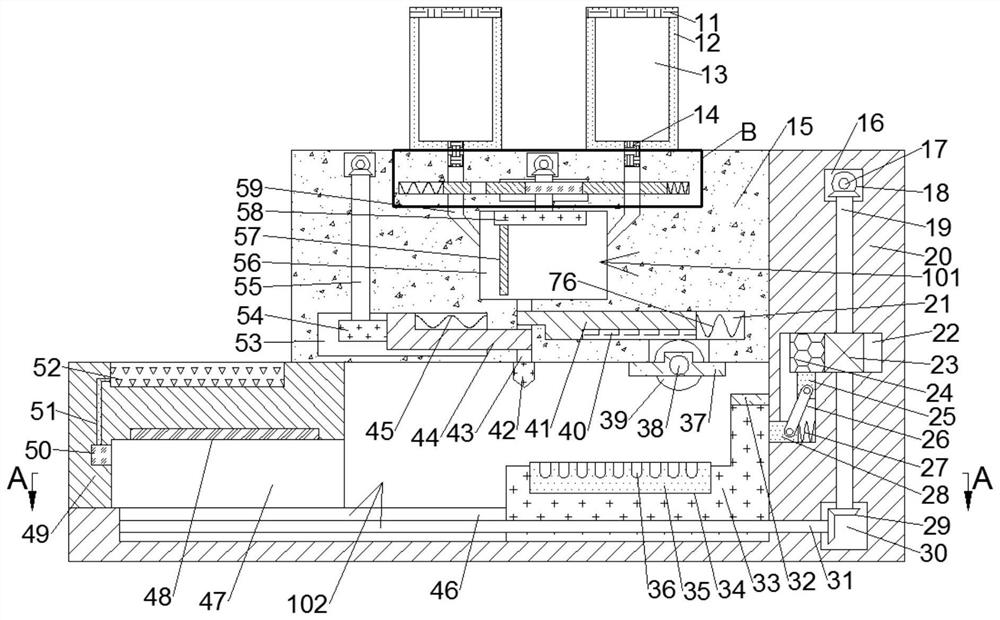

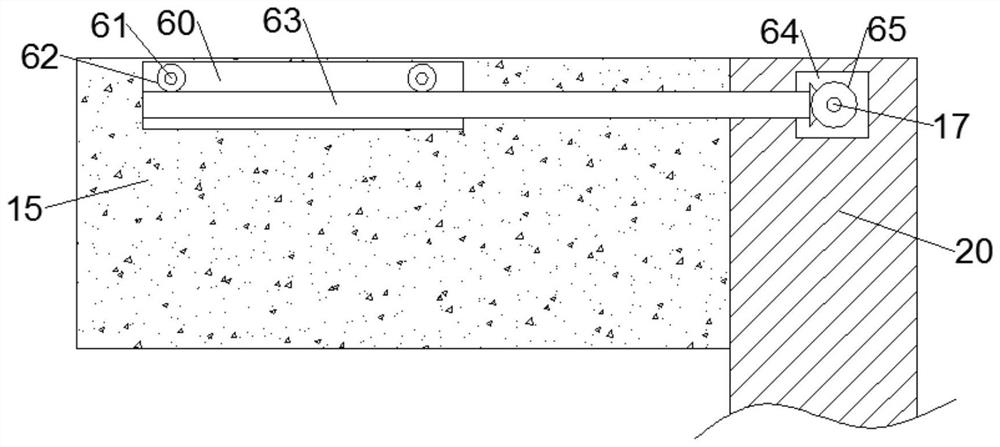

Industrial wastewater circulating treatment and purification device for ozone oxidation and use method thereof

InactiveCN110550804AAchieve secondary neutralizationImprove neutralization effectWater/sewage treatment with mechanical oscillationsWater contaminantsOzone generatorIndustrial waste water

The invention discloses an industrial wastewater circulating treatment and purification device for ozone oxidation, and belongs to the technical field of industrial wastewater circulating treatment and purification. The output end of a circulating pump is fixedly connected with a backflow pipe; the top of the right side wall of a box body is fixedly provided with a purifier; a second electromagnetic valve is assembled on a second partition plate; social free magnetic field catalysts are respectively fixed to the left side and the right side of the bottom of a first partition plate; ozone generators are fixedly arranged on the left side and the right side of the top of the second partition plate respectively; a third electromagnetic valve is assembled on a third partition plate; a photocatalytic plate fixed on the inner wall of the box body is arranged in a purification tank; ultrasonic generators are fixedly arranged on the left side and the right side of the top of the third partitionplate; and the bottom of the inner cavity of the box body is fixedly provided with an adsorber which is matched with the third baffle plate and a drain pipe. The device provided by the invention hasa better catalytic oxidation treatment effect on wastewater, is economical and practical and has low operation cost. Meanwhile, treated water is pure and has high environmental friendliness.

Owner:XUZHOU TIANLAN OZONE EQUIP CO LTD

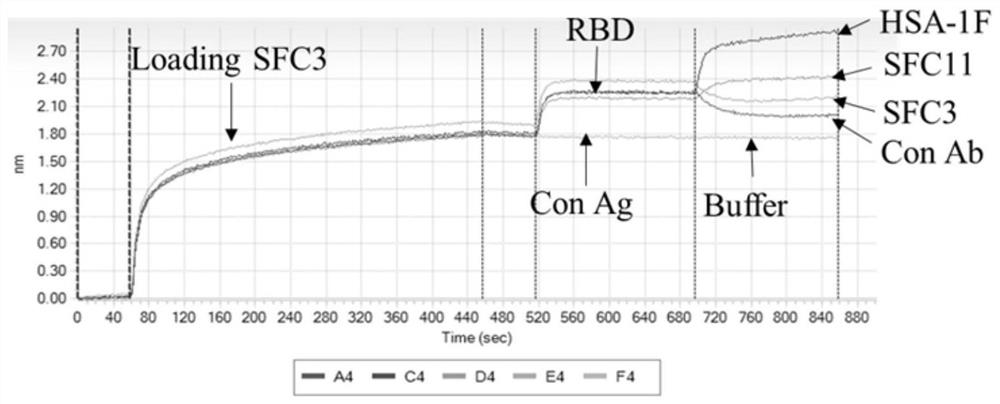

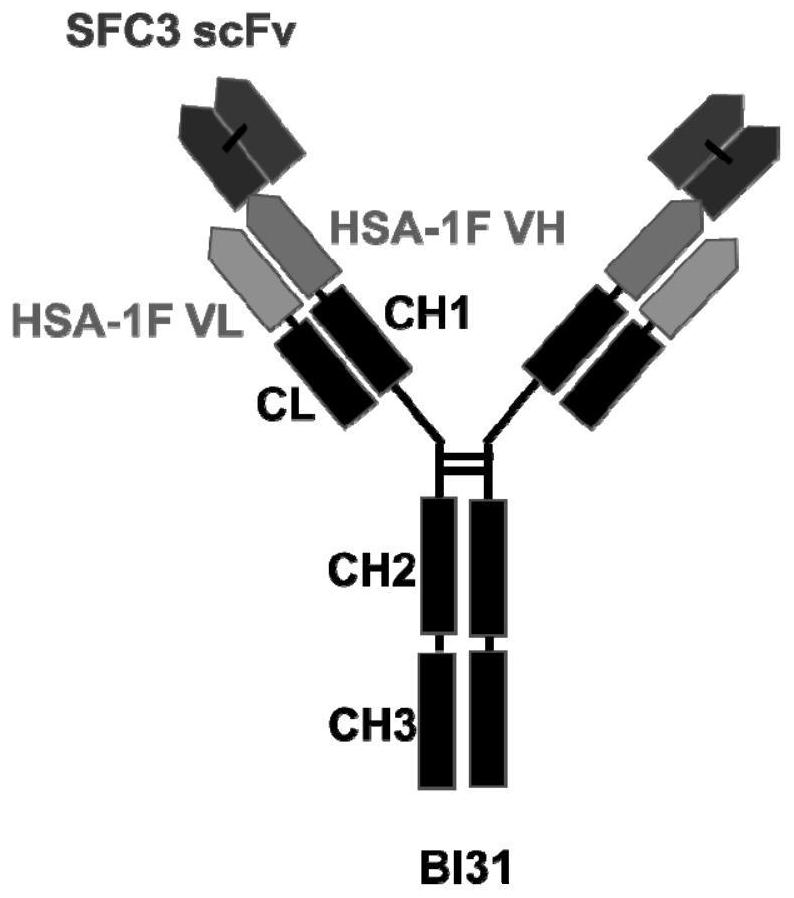

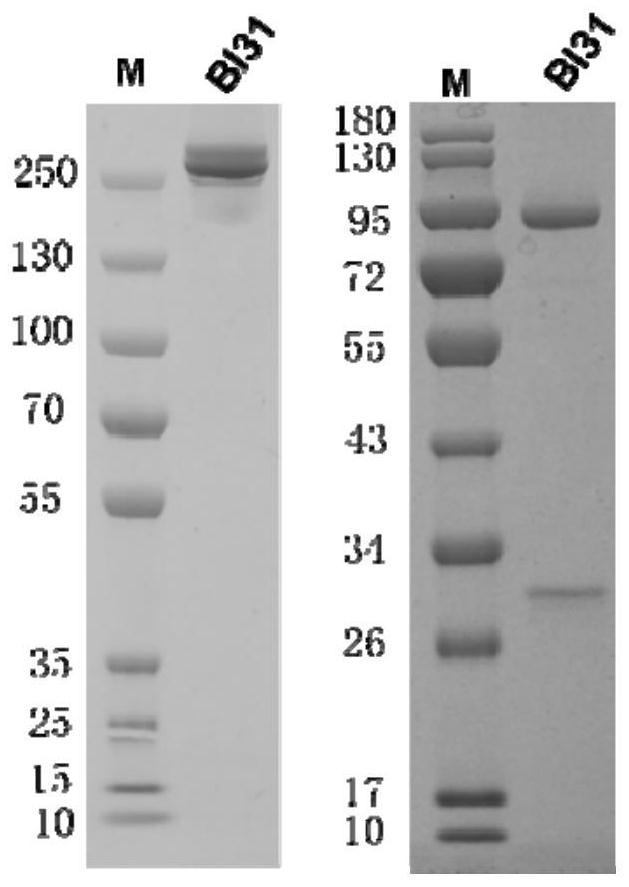

Anti-coronavirus bispecific neutralizing antibody and application

ActiveCN114149509AHigh affinityGood neutralizing activityHybrid immunoglobulinsImmunoglobulins against virusesEpitopeSingle-Chain Antibodies

The invention discloses an anti-coronavirus bispecific neutralizing antibody and application thereof. Specifically, the invention discloses a bispecific antibody specifically combined with different epitopes of a novel coronavirus S protein receptor binding domain and application thereof. The bispecific antibody comprises a single-chain antibody SFC3scFv and a complete humanized antibody HSA-1F structure, has a highly stable symmetric structure, shows better neutralizing activity compared with a parent antibody and when the bispecific antibody is combined with the parent antibody, and also shows better neutralizing activity on an SARS-CoV-2 variant strain, an SARS-CoV virus and an MERS-CoV virus. According to the bispecific antibody, the neutralizing effect of the novel coronavirus is remarkably improved, the probability of generation of virus escape mutation is reduced, the treatment and prevention means of COVID-19 are enriched, and the bispecific antibody has a huge prospect of becoming a broad-spectrum antibody drug aiming at the coronavirus and has important significance on prevention and treatment of coronavirus infection.

Owner:ACADEMY OF MILITARY MEDICAL SCI

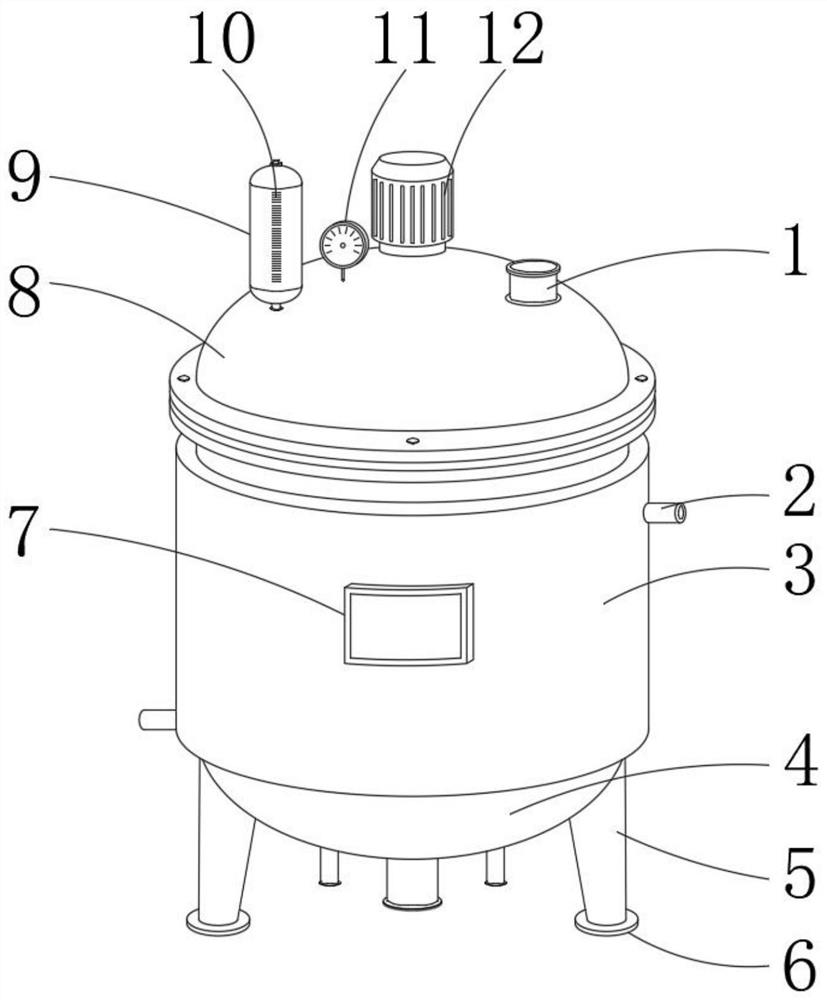

Pharmaceutical wastewater treatment and recovery device

InactiveCN108840498AImprove neutralization effectImprove neutralization abilityWater treatment parameter controlWater/sewage treatment by irradiationActivated carbonWastewater

The invention discloses a pharmaceutical wastewater treatment and recovery device which comprises a bottom plate and a neutralization device, wherein a reaction tank is fixed on the outer wall of thetop of the bottom plate by virtue of bolts; an activated carbon adsorption net is welded on the inner wall of one side of the reaction tank; a motor is welded on the inner wall at the top of the reaction tank; a transmission bar is welded at the bottom end of the output shaft of the motor; screw blades are welded on the outer walls of the bottom of the transmission bar; horizontally arranged stirring blades are welded on the outer walls of one side of the transmission bar; heaters distributed in equal distance are fixed on the outer walls on the top of the reaction tank by virtue of bolts; vertically arranged heating pipes are fixed at heating ports of the heaters by virtue of bolts; and the heating pipes are positioned inside the reaction tank. According to the pharmaceutical wastewater treatment and recovery device disclosed by the invention, the wastewater is heated, acidic-basic materials in the wastewater are completely neutralized, the neutralizing capacity of the device is improved, standing cooling can be performed, the content and pH value of microbes can be detected after the wastewater is restored to a normal state, the detection ability of the device is improved, and the detection accuracy of the device is improved.

Owner:郑州莉迪亚医药科技有限公司

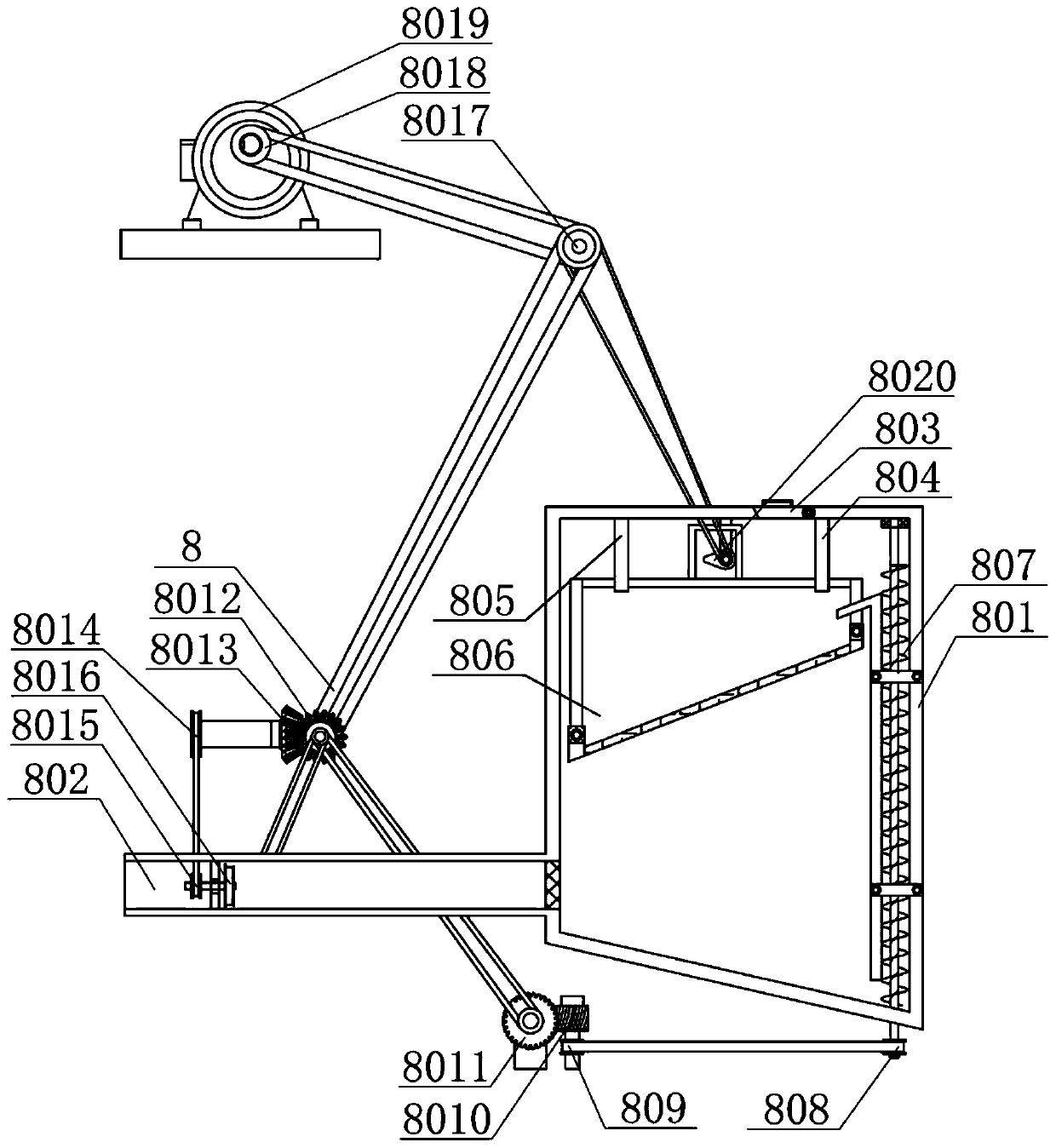

Tungsten production waste water convection purification device

InactiveCN110759536AControl mixing speedImprove neutralization effectGas treatmentWater contaminantsSulfate radicalsNitrogen dioxide

The invention relates to a waste water treatment device, in particular to a tungsten production waste water convection purification device. The invention aims to provide the tungsten production wastewater convection purification device. The tungsten production waste water convection purification device comprises a high-efficiency atomizing and neutralizing device, a nitrogen dioxide purificationdevice and a well type purification device; and the high-efficiency atomizing and neutralizing device is arranged on the left side of the top end of a bottom frame. The problem that sulfur dioxide inwaste gas generally needs to be utilized as well as in a container, alkaline waste water is sprayed from top and waste gas containing the sulfur dioxide is blown from bottom when an existing waste water purification device treats waste water of tungsten production. The flowing speed of the waste gas and the waste water is controlled, the purification effect is improved, the waste water which cannot be purified completely is recovered and sulfate ions in the waste water are settled, so that the fact that the dissolving capacity of the sulfur dioxide is not reduced during secondary purificationis guaranteed; and sodium peroxide solid is thrown circularly and the nitrogen dioxide is completely absorbed, so that the aim of completely purifying the waste gas and the waste water is finally fulfilled.

Owner:郭慧珍

PH value neutralization method of mercerized dyed shell fabric

InactiveCN109252409AImprove neutralization effectReduce neutralization costsDyeing processHigh pressureNeutralization method

The invention discloses a pH value neutralization method of a mercerized dyed shell fabric. The method comprises the following steps of firstly, charging water with carbon dioxide at the rate of 15m<3> / h to 30m<3> / h so as to subject carbon dioxide and water to a reaction in a high-pressure environment of 1MPa to 4MPa to produce carbonic acid and enable a pH value of the produced carbonic acid to be 4 to 6, then, charging a rinsing bath with the carbonic acid so as to completely submerge a fabric into the carbonic acid for neutralization, thereby obtaining the finished fabric, wherein the temperature of the carbonic acid during neutralization is 25 DEG C to 40 DEG C, and the neutralization time is 25 to 35 seconds. According to the method, the neutralization cost of the fabric can be reduced while surface off odors are removed from the fabric.

Owner:ZHEJIANG MIZUDA TEXTILE PRINTING & DYEING TECH CO LTD

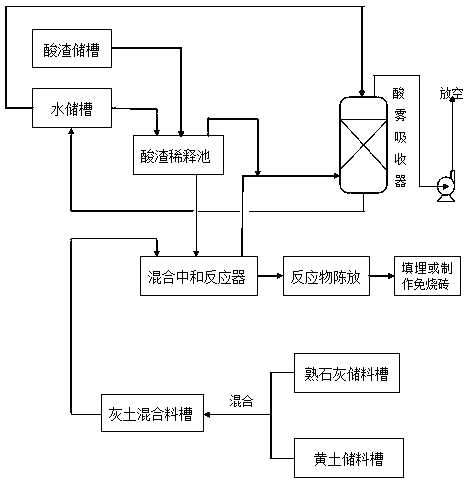

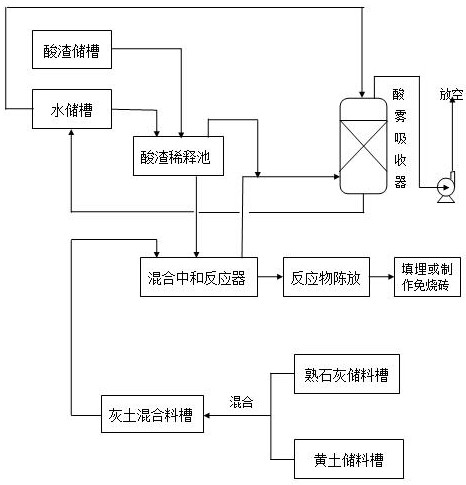

Chemical acid slag neutralization method

ActiveCN108405552ARaw materials are easy to getSimple methodSolid waste disposalChemical/physical/physico-chemical processesBrickSlag

The invention relates to a chemical acid slag neutralization method, in particular to a treatment method of alkylated acid slag discharged by an alkylating production device. When acid liquid is neutralized by slaked lime, soil is introduced to uniformly mix with the slaked lime as dust; under the stirring condition, the dust is reacted with chemical acid slag; and a reacted product is aged untila pH value reaches 7-8. The neutralized product after aging can be directly filled or used as preparation raw materials of baking-free bricks. The chemical acid slag neutralization method is particular suitable for treatment of the alkylated acid slag discharged by the alkylating production device, and is easy to obtain raw materials, simple and feasible, obvious and quick in neutralization effect, low in treatment cost and incapable of causing secondary pollution.

Owner:LANZHOU KANGSHUN PETROCHEM

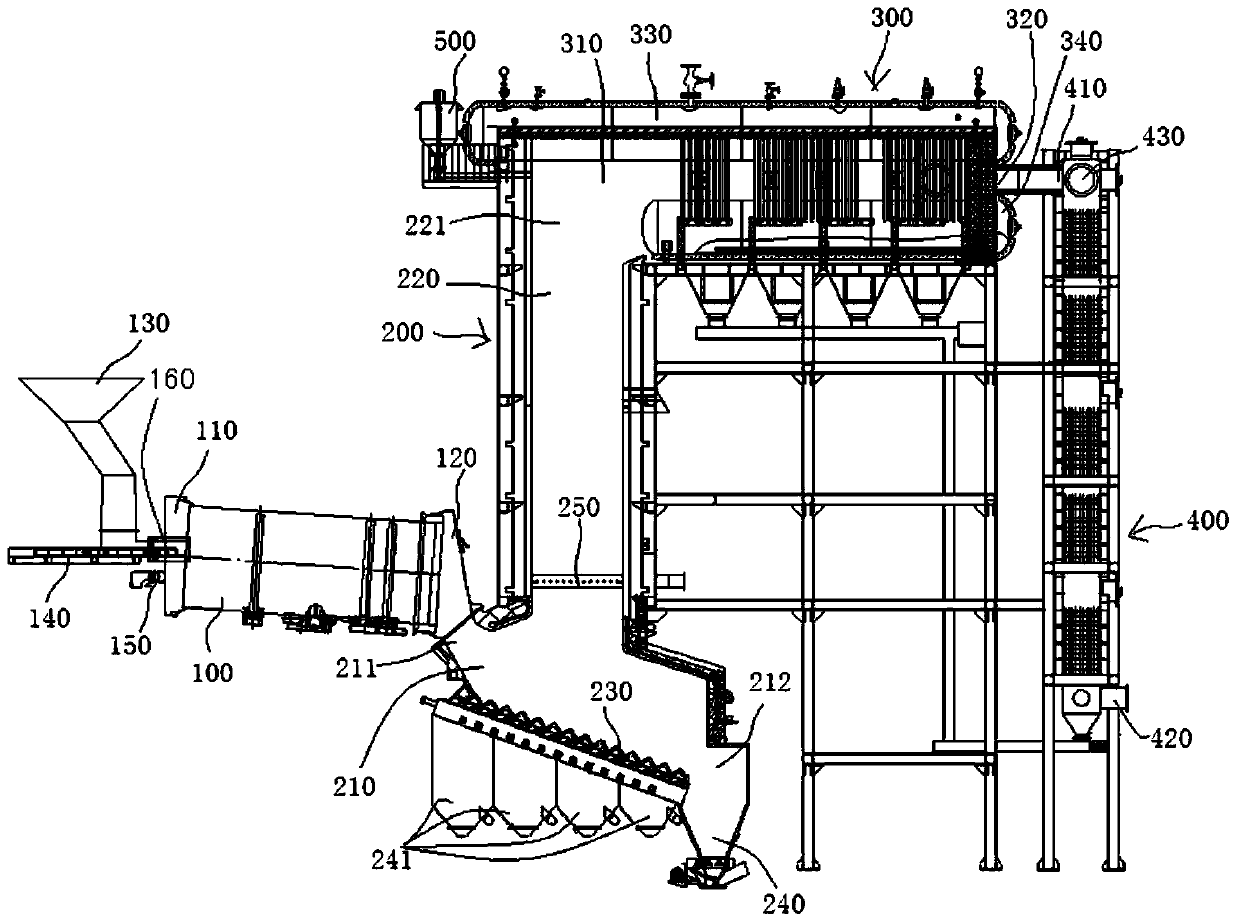

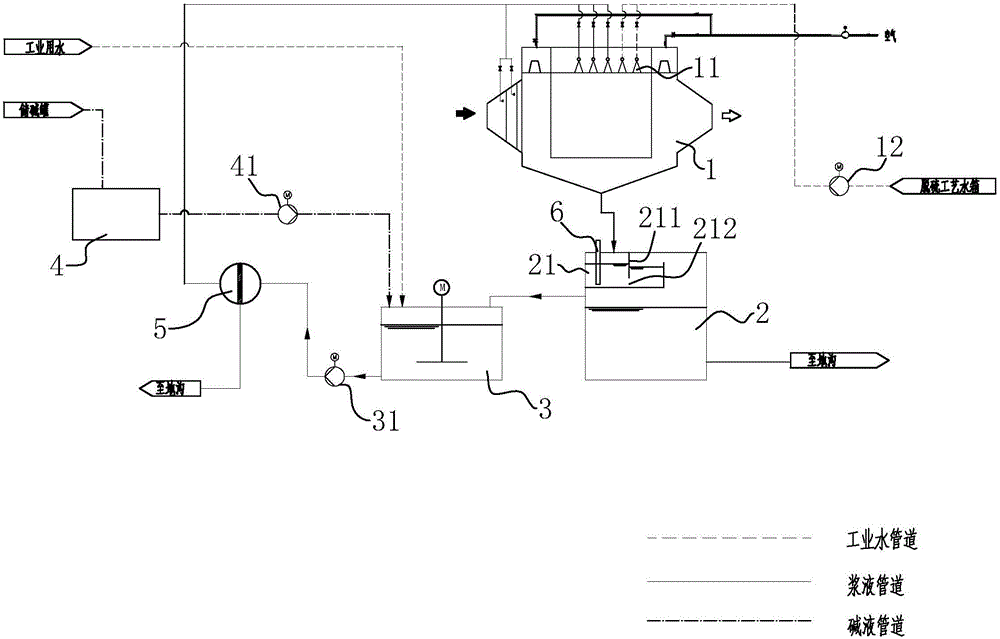

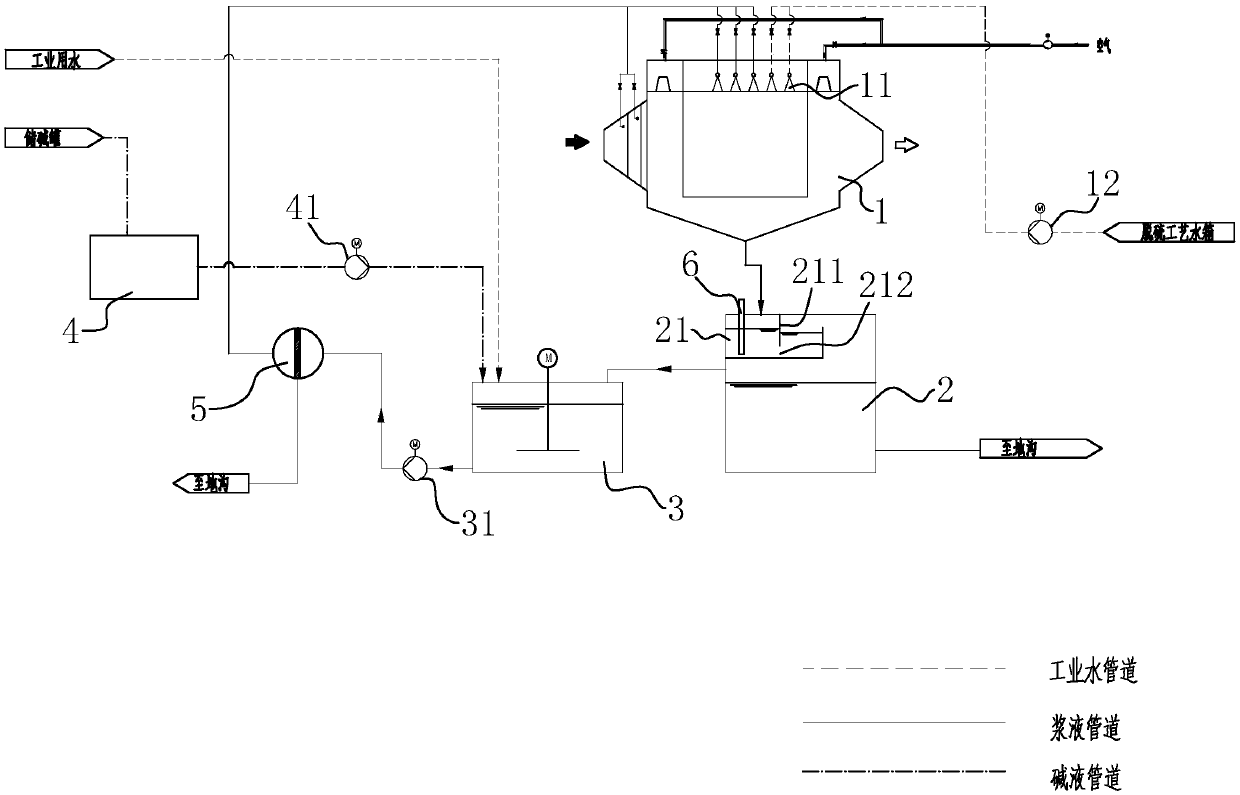

Boiler dust removing and conveying system

ActiveCN106391311AAchieve recyclingSolve secondary pollutionTreatment involving filtrationMultistage water/sewage treatmentFlue gasWater flow

The invention discloses a boiler dust removing and conveying system which comprises a wet type electric dust remover, a circulation water tank and an alkali liquor tank. Spraying mechanisms are arranged on the top of the wet type electric dust remover and sequentially fall into a front portion and a rear portion in the flue gas circulation direction. The boiler dust removing and conveying system is characterized by further comprising a drainage tank and a washing water tank. A sewage outlet of the wet type electric dust remover is connected with the drainage tank through a sewage drainage pipeline. The drainage tank is connected with the circulation water tank, and water flows into the circulation water tank in an overflow mode. The bottom of the drainage tank is connected to a trench through a pipeline. The alkali liquor tank is connected with the circulation water tank through an alkali liquor metering pump. The circulation water tank is connected with the spraying mechanisms on the front portion through a circulation water pump, and the washing water tank is connected with the spraying mechanisms on the rear portion through a washing water pump. A PH sensor is arranged in the drainage tank. The alkali liquor metering pump is controlled by the PH sensor. By arranging a feedback system, the effect of improving corrosion resistance of the wet type electric dust remover is achieved.

Owner:杭州红山热电有限公司

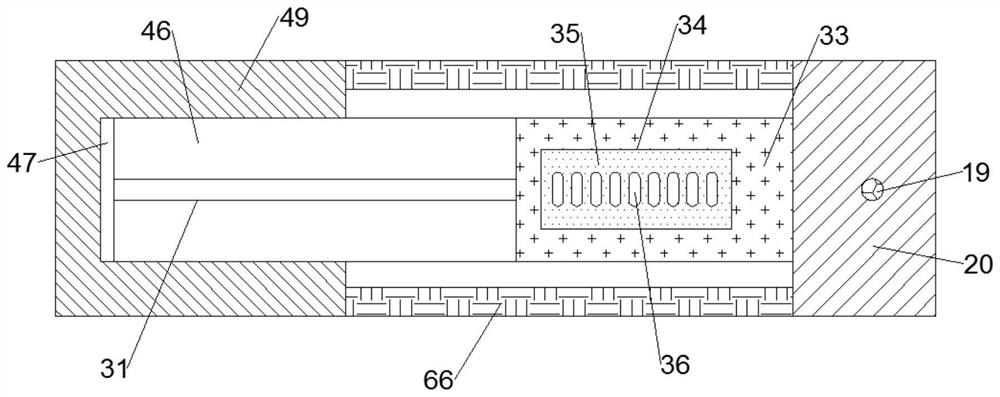

Liquid neutralization treatment device for industrial waste gas

InactiveCN112058060AIncrease neutralization rangeImprove efficiencyDispersed particle separationReciprocating motionEnvironmental engineering

The invention discloses a liquid neutralization treatment device for industrial waste gas. The liquid neutralization treatment device comprises a vertical columnar shell of which the bottom is provided with supporting legs, liquid is used for neutralizing waste gas, so that the whole waste gas flows upwards under the action of the liquid, then the fluffy sponge is used for integrally separating the flowing-in waste gas into fine bubbles, meanwhile, the fluffy sponge can enter the neutralizing liquid after being compressed each time, and after the fluffy sponge shrinks; a large amount of neutralizing liquid can be adsorbed on the surface of the fluffy sponge; in addition, when passing through a gap structure in the fluffy sponge, tiny bubbles can make full contact with the neutralizing liquid attached to the surface of the fluffy sponge, the neutralizing range is widened, and therefore the neutralizing effect is improved, and meanwhile waste gas sucked each time can be fully and rapidlysubjected to neutralizing treatment through reciprocating motion; therefore, the working efficiency is improved.

Owner:米佳

Exosome RNA detection device based on tumor diagnosis and prediction

ActiveCN112246140AUltraviolet light detection effect is accurateImprove neutralization effectRotary stirring mixersTransportation and packagingNeoplasm diagnosisExosome

The invention discloses an exosome RNA detection device based on tumor diagnosis and prediction, which comprises a power body, a detection box and a neutralizing body; the detection box is fixedly arranged on the top surface of the left side of the power body, the neutralizing body is fixedly arranged on the left side surface of the power body, the bottom surface of the neutralizing body is fixedly connected with the top surface of the detection box, and the neutralizing body is fixedly connected with the top surface of the detection box. The neutralizing body is internally provided with a neutralizing mechanism capable of neutralizing and blending an RNA sample, and the neutralizing mechanism comprises two solution tanks fixedly arranged on the top surface of the neutralizing body. The neutralization effect of the final detection liquid can be greatly improved, and the purple light detection effect of RNA is more accurate; meanwhile, the moving block can be controlled to drive the detection mold to move left and right to enter and exit the detection cavity only by using one motor.

Owner:广州爱索达生物医药技术有限公司

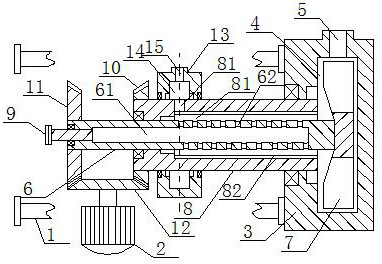

Double-neutralization system in circuit board electroless plating copper production line

ActiveCN105228361AImprove neutralization effectReduce open cylinderConductive pattern polishing/cleaningElectroless platingPotassium permanganate

The invention relates to the technical field of circuit board manufacturing, and specifically relates to a double-neutralization system in the circuit board electroless plating copper production line. A first overflow mouth is arranged in a neutralization tank, so that liquid medicine can overflow into a pre-neutralization tank, the concentration of the liquid medicine in the tank can be stabilized, the effect of neutralization can be improved, and residual potassium permanganate and other impurities in a production plate can be better removed. The liquid medicine in the neutralization tank can be reused after filtered by a filter pump. The liquid medicine can also flow into the pre-neutralization tank through a pre-neutralization pipe, so that the number of opening times of the pre-neutralization tank is reduced, the liquid medicine is utilized better, and waste is reduced. By overflowing the water in a first washing tank after neutralization into a second washing tank before neutralization, the dosage is reduced, and the cost is lowered. Through the structure improvement, the pollution of potassium permanganate to the neutralization tank is improved significantly, the service life of the neutralization tank is prolonged, and the pollution of potassium permanganate to hole forming and activating is improved effectively.

Owner:大连崇达电子有限公司

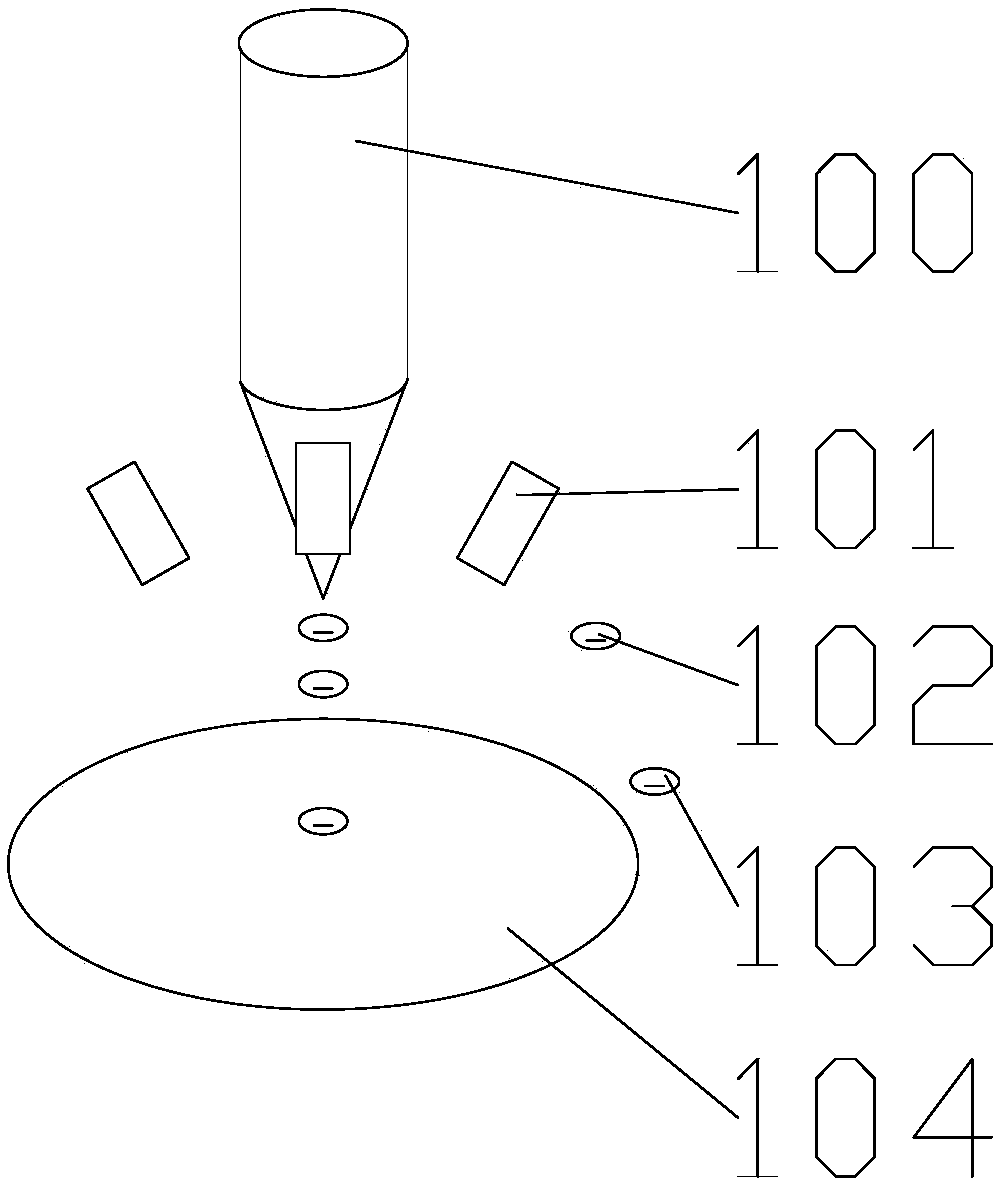

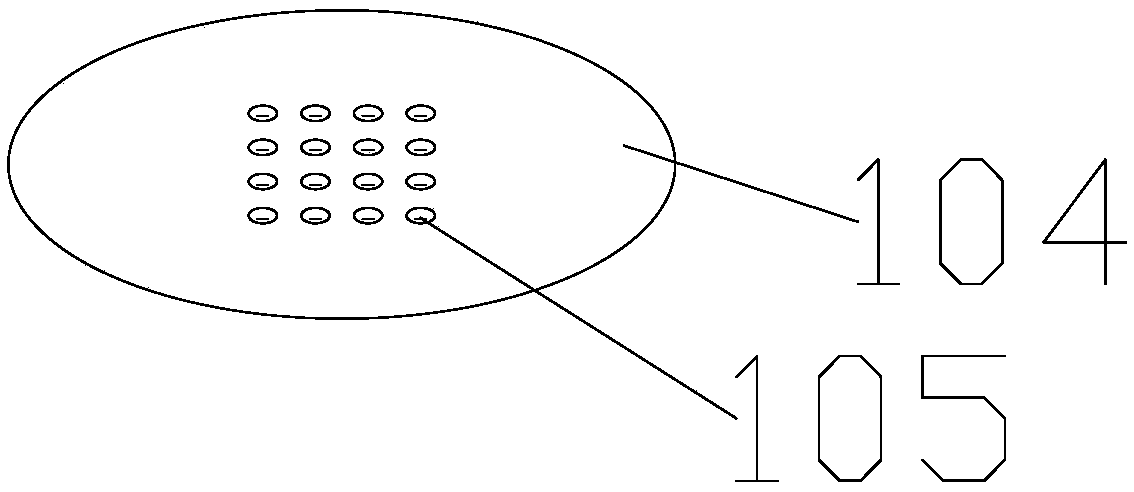

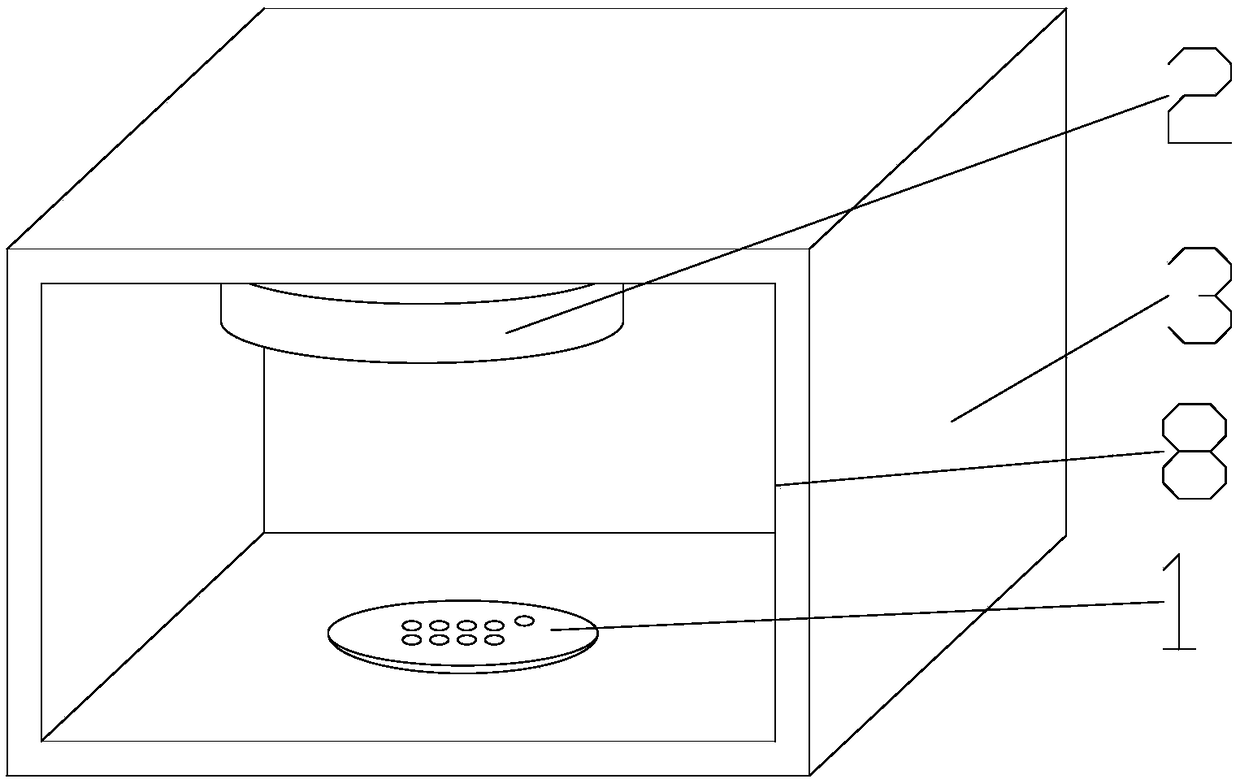

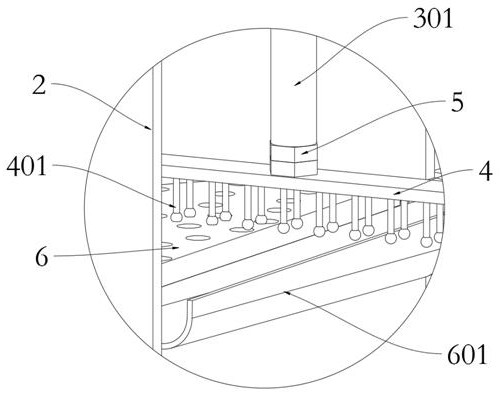

Static elimination device and method for reducing static residue on surface of wafer

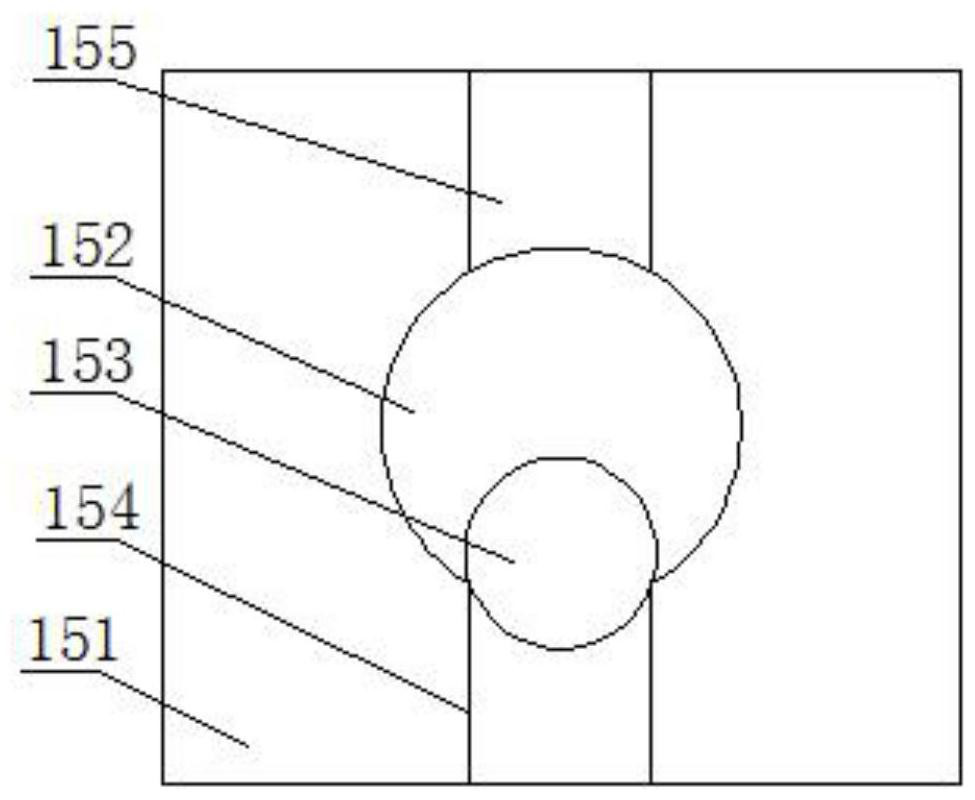

InactiveCN109451642AEliminate static electricityImprove product yieldElectrostatic chargesIonizationEngineering

The invention provides a static elimination device and a method for reducing electrostatic residue on the surface of a wafer, for eliminating static residue on the surface of the wafer. The static elimination device comprises a static elimination unit and a receiving unit, wherein the receiving unit is internally provided with a receiving cavity for receiving the wafer and provided with at least one opening communicated with the receiving cavity; the static elimination unit is fixedly connected to the receiving cavity, and configured to perform static elimination on the wafer by providing ionized positive and negative ions in a non-vacuum environment. By neutralizing the static electricity remaining on the surface of the wafer through the positive and negative charge ions formed by ionization of the static elimination unit, the purpose of eliminating static electricity remaining on the surface of the wafer is realized, and the electrostatic residue on the surface of the wafer is effectively prevented from affecting subsequent processes, thereby improving the product yield.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

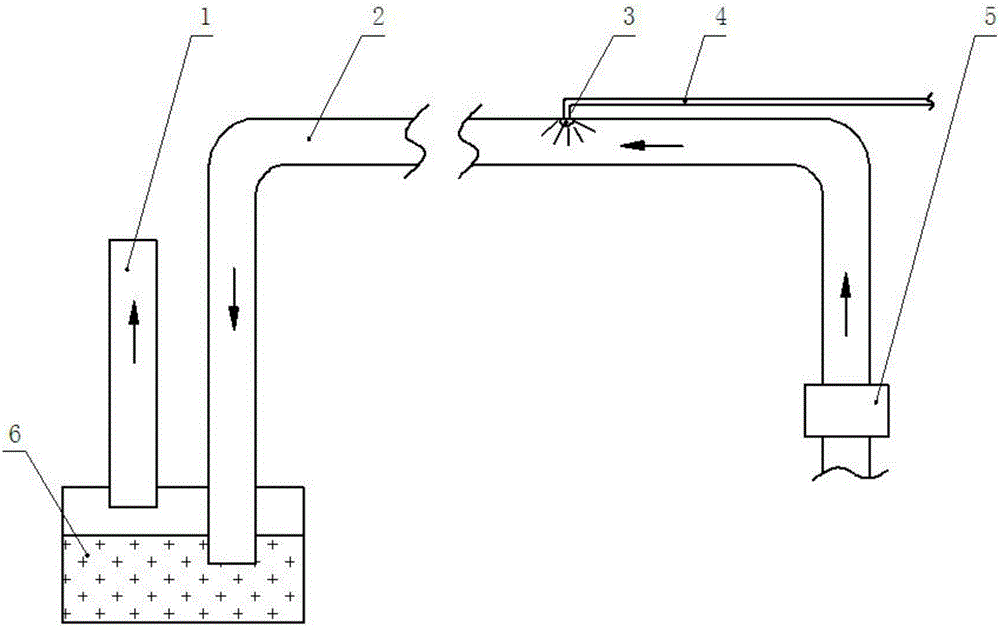

Exhausting structure of papermaking workshop

PendingCN106552495AFresh breathImprove neutralization effectDispersed particle separationPulp and paper industry

The invention relates to an exhausting structure of a papermaking workshop. The exhausting structure comprises an alkali liquor tank, a first exhausting pipeline, a second exhausting pipeline and an exhauster. The input end of the first exhausting pipeline is connected with the workshop, the output end of the first exhausting pipeline is connected with the alkali liquor tank, and the exhauster is installed on the position, located at the input end of the first exhausting pipeline, of the first exhausting pipeline. Rancid gas in the workshop is discharged into the alkali liquor tank through the exhauster. The top of the alkali liquor tank on one side of the output end of the first exhausting pipeline vertically communicates with the second exhausting pipeline in a sealed mode. Acid in the rancid gas is effectively neutralized through the alkali liquor tank, and the purpose that people breathe fresh air is ensured. Through an alkali liquor spraying head in the first exhausting pipeline, the rancid gas is subjected to two-time neutralization, and the neutralizing effect is improved. The exhausting structure of the papermaking workshop is simple in structure, scientific and reasonable in design, fantastic in conception and low in cost, and has the value of wide application and promotion.

Owner:TIANJIN GUANGJUYUAN PAPER IND GRP

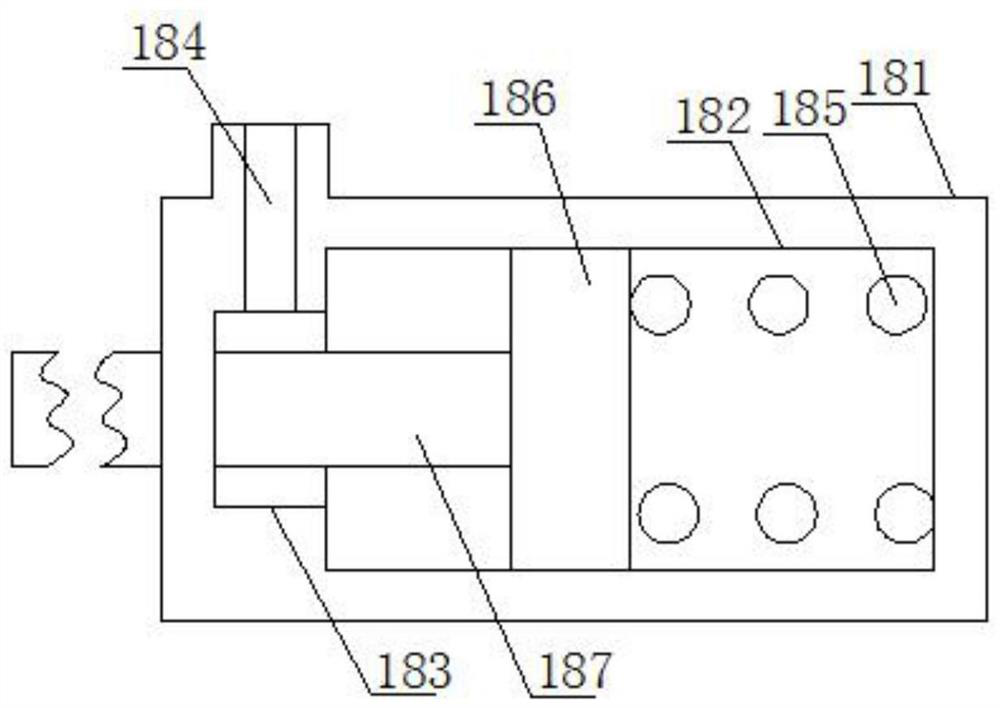

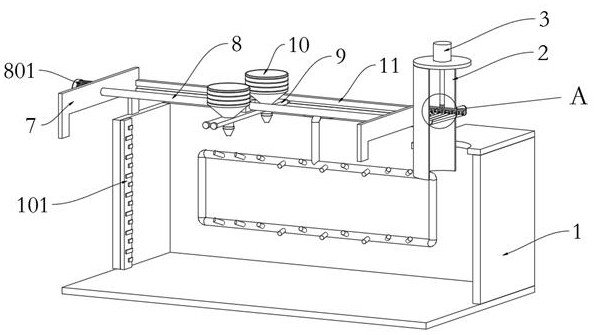

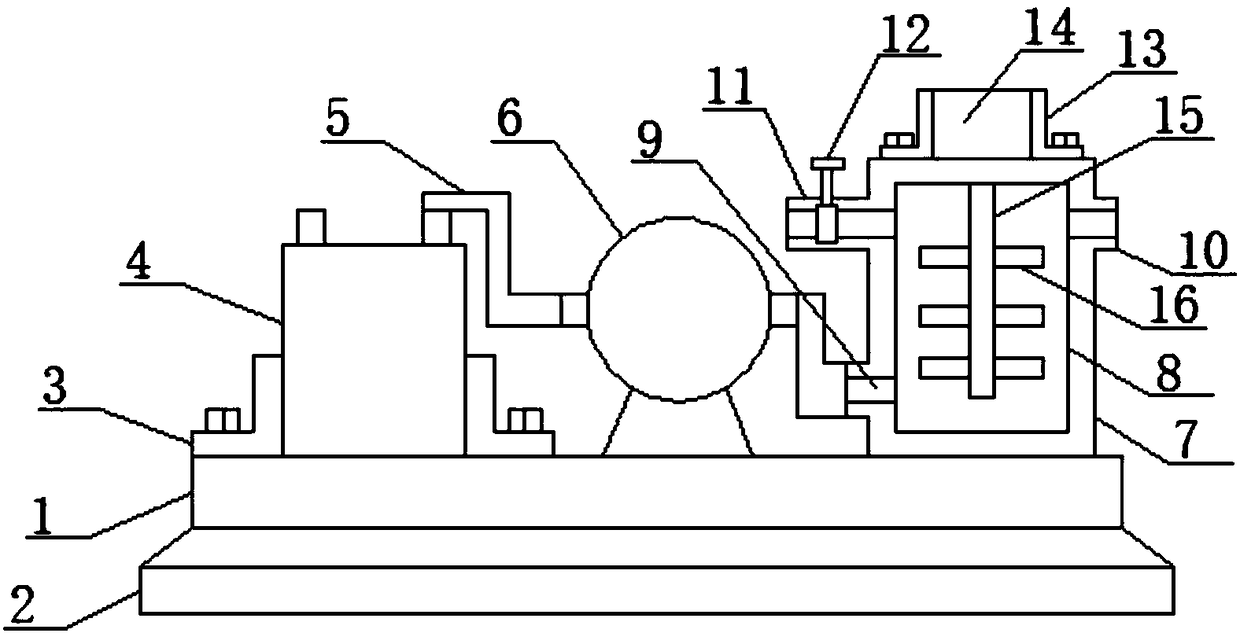

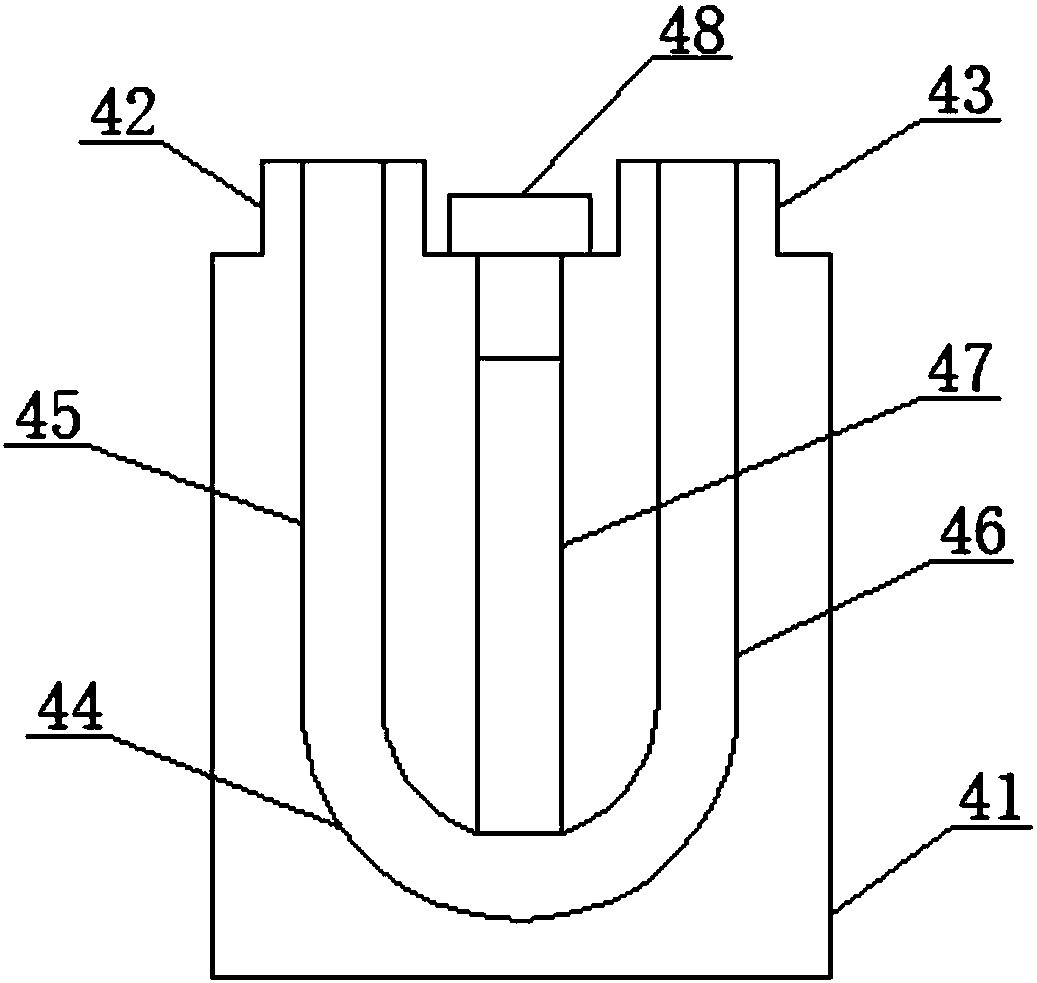

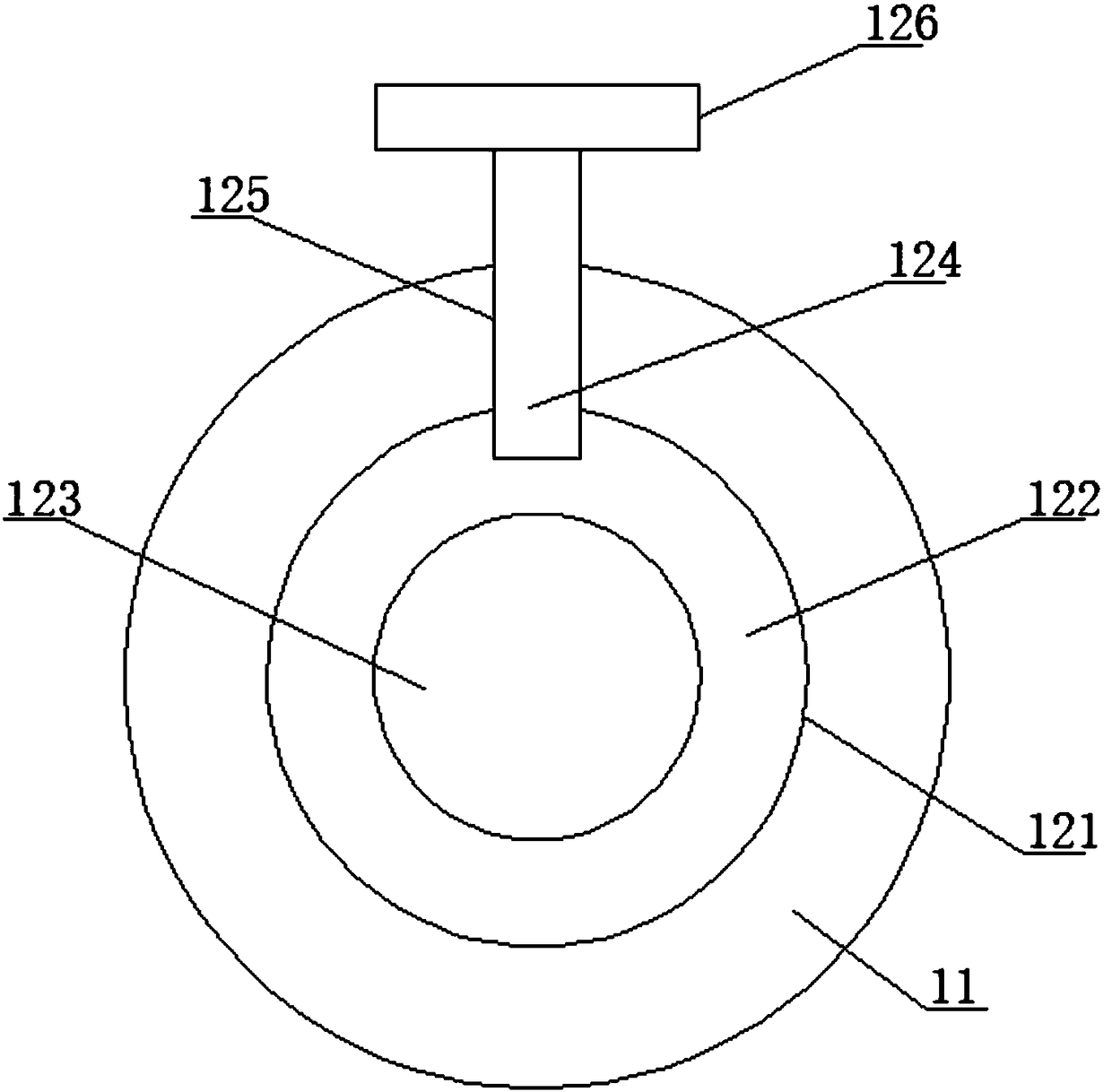

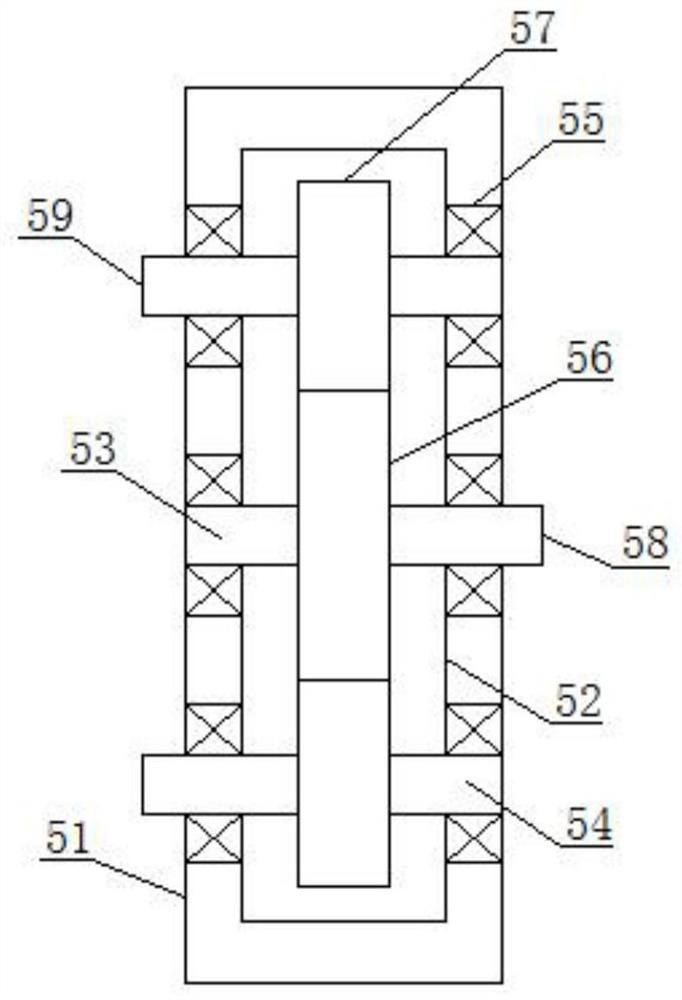

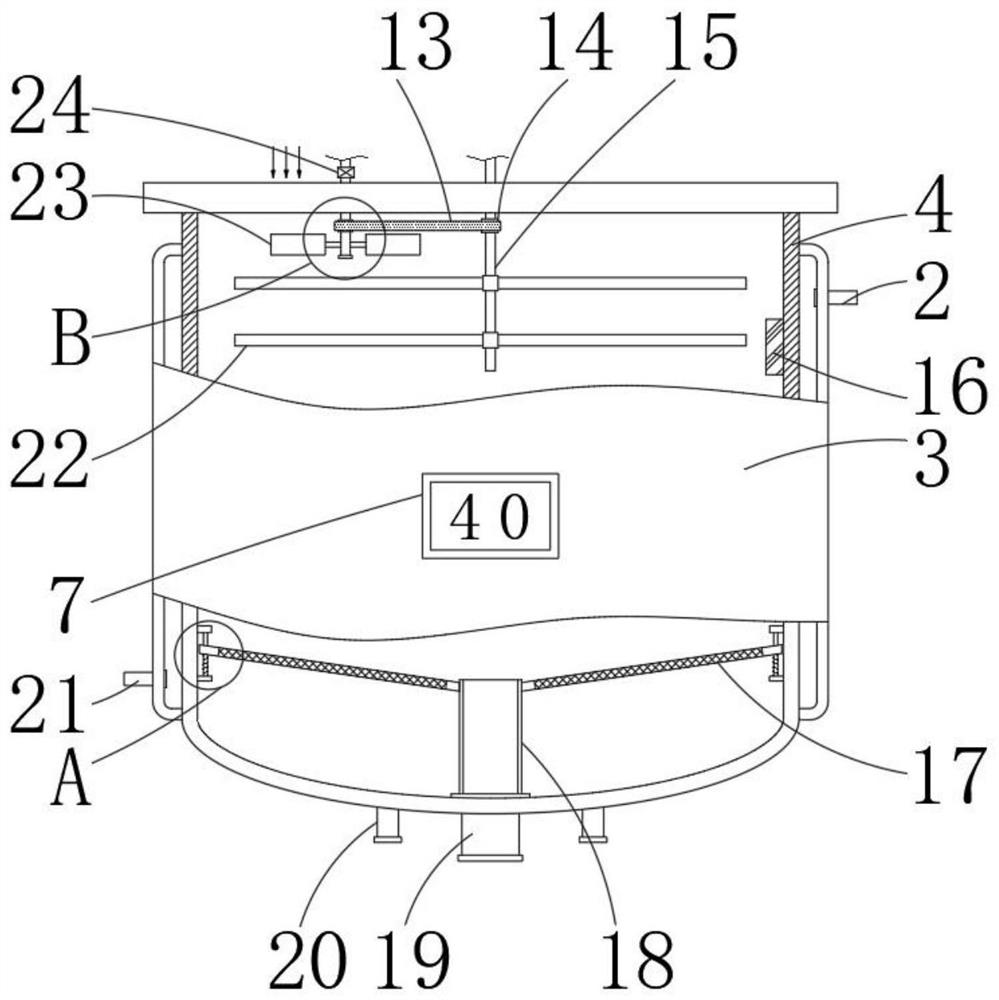

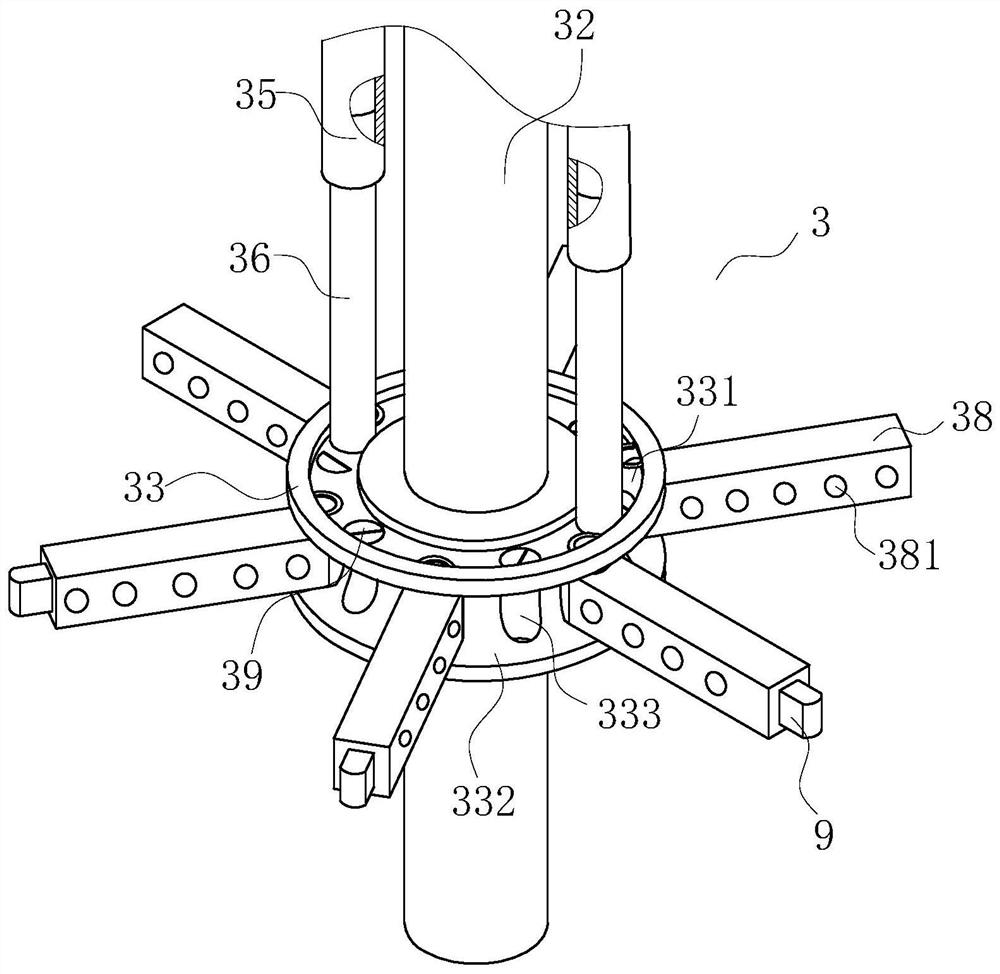

Neutralizing treatment device for pickling wastewater of hot-rolled nickel-based alloy stainless steel medium plate

PendingCN112811674AAvoid blockingEasy to replace and maintainSpecific water treatment objectivesTreatment involving filtrationWastewaterElectric machinery

The invention provides a neutralizing treatment device for pickling wastewater of a hot-rolled nickel-based alloy stainless steel medium plate. The neutralizing treatment device comprises a purification tank, a cleaning plate, a reciprocating lead screw, a sliding plate and air inlet pipes; two groups of U-shaped support frames are symmetrically arranged on the upper end surface of the purification tank, and two groups of transverse rails are arranged between the U-shaped support frames; a threaded rod is arranged at the upper end of the cleaning plate, and a brush is arranged at the lower end of the cleaning plate; the sliding plate is clamped in sliding grooves in the transverse rails in a sliding mode, and a fixed block is arranged at the upper end of the sliding plate; two groups of feeding bins are symmetrically arranged on the upper end surface of the sliding plate; and the air inlet pipes are fixedly connected with air conveying pipes, and the two air conveying pipes are arranged in a vertically symmetrical mode. According to the device, the reciprocating lead screw is in threaded connection with the fixed block, so that in the process that a driving motor drives the reciprocating lead screw to rotate, the sliding plate can move back and forth in a sliding groove in the transverse rails, lime in the feeding bins can be uniformly scattered into the purification tank, and the neutralizing effect of the lime on acidic substances in the purification tank is improved.

Owner:武文青

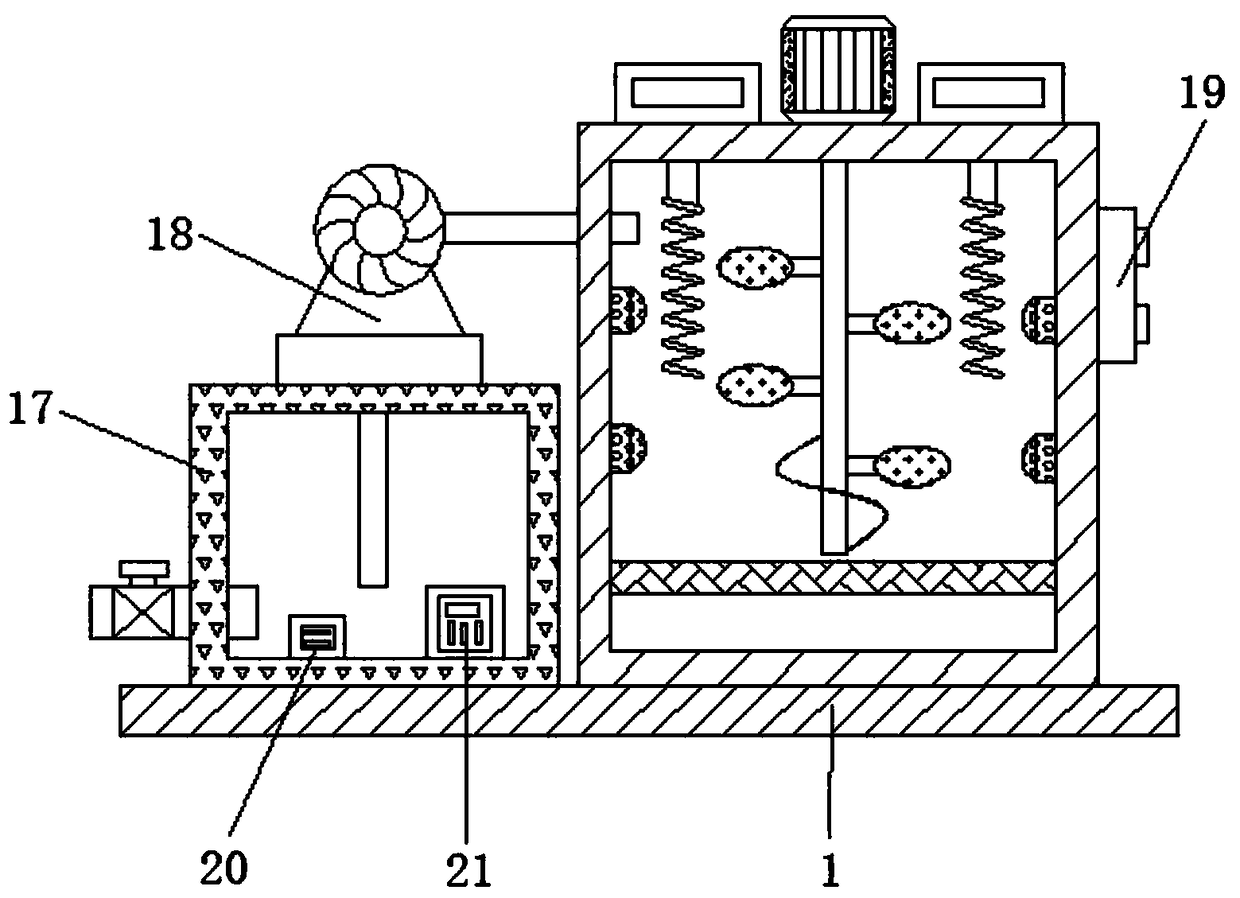

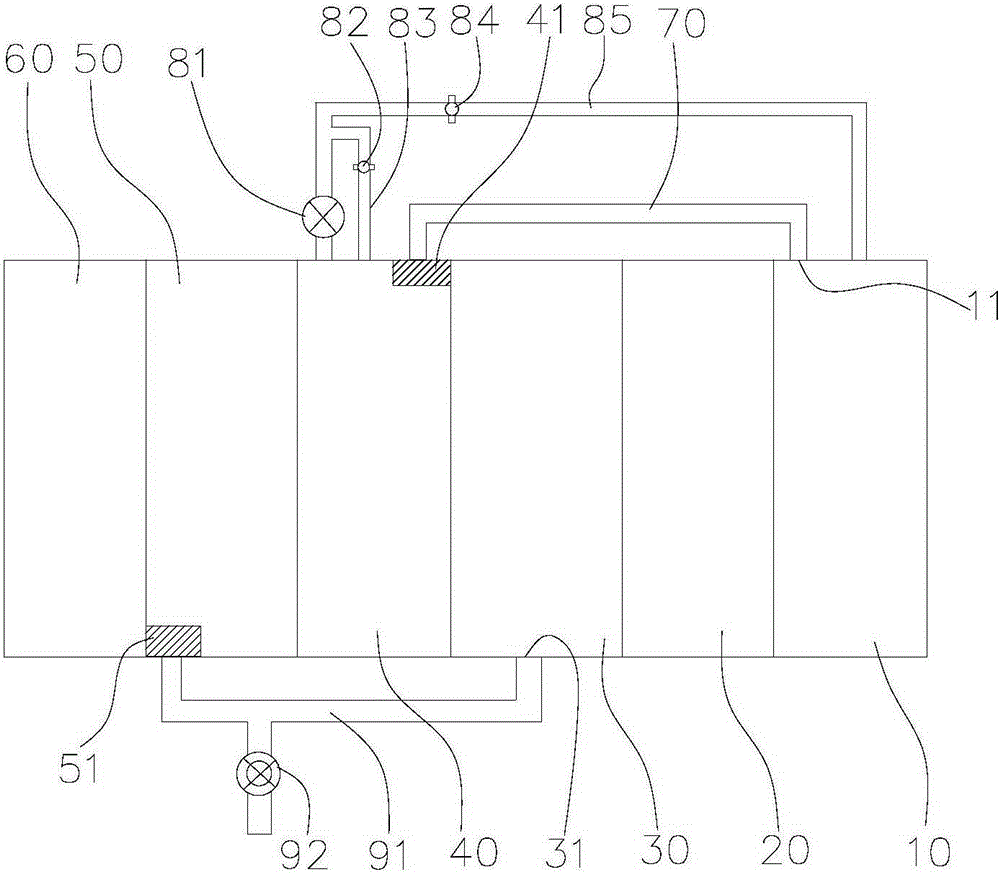

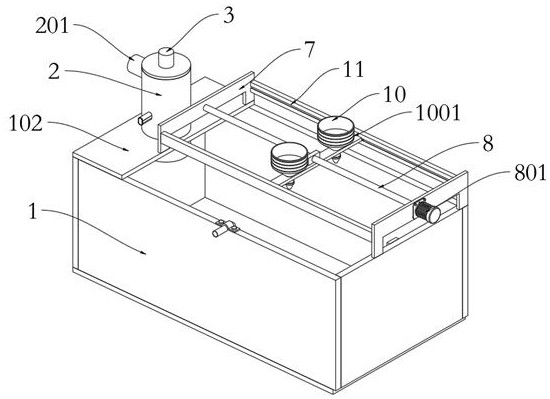

Laboratory wastewater treatment device

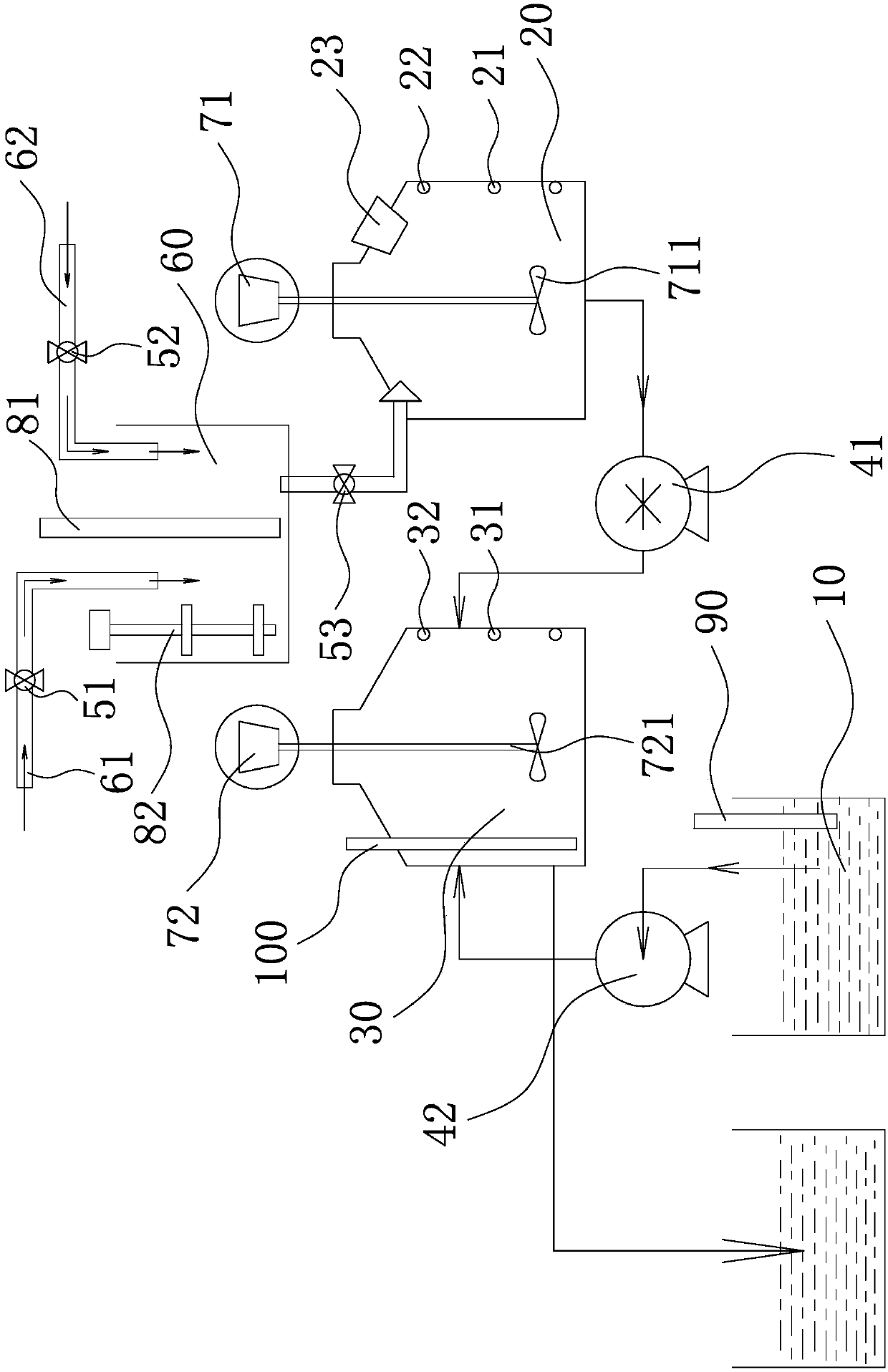

InactiveCN108178275AHarm reductionImprove neutralization effectTreatment of wastewater with pathogenic microorganismsWater/sewage treatment by neutralisationEngineeringCirculating pump

The invention discloses a laboratory wastewater treatment device. The device includes a bottom mounting substrate, a bottom support base plate is installed at the bottom of the bottom mounting substrate, a mounting shell is fixed to one side of the bottom mounting substrate upper surface through bolts, a U-shaped drainage pipeline shell mechanism is mounted inside the mounting shell, a circulatingpump is mounted at the center on the bottom mounting substrate upper surface, and a liquid inlet port of the circulating pump is communicated with the U-shaped drainage pipeline shell mechanism through a first hose. The device provided by the invention can realize mixing of wastewater generated by experiments in a laboratory with a neutralizing liquid, and accordingly achieves a neutralizing dilution effect on harmful substances in wastewater and lowers the hazardous degree of wastewater. In addition, the device has the U-shaped drainage pipeline shell mechanism, and does not enable neutralization generated waste gas to enter the laboratory. The device has a spherical liquid flow control valve mechanism, can achieve effective control of the amount of the accessing neutralizing liquid andimprove the neutralization effect.

Owner:李志浩

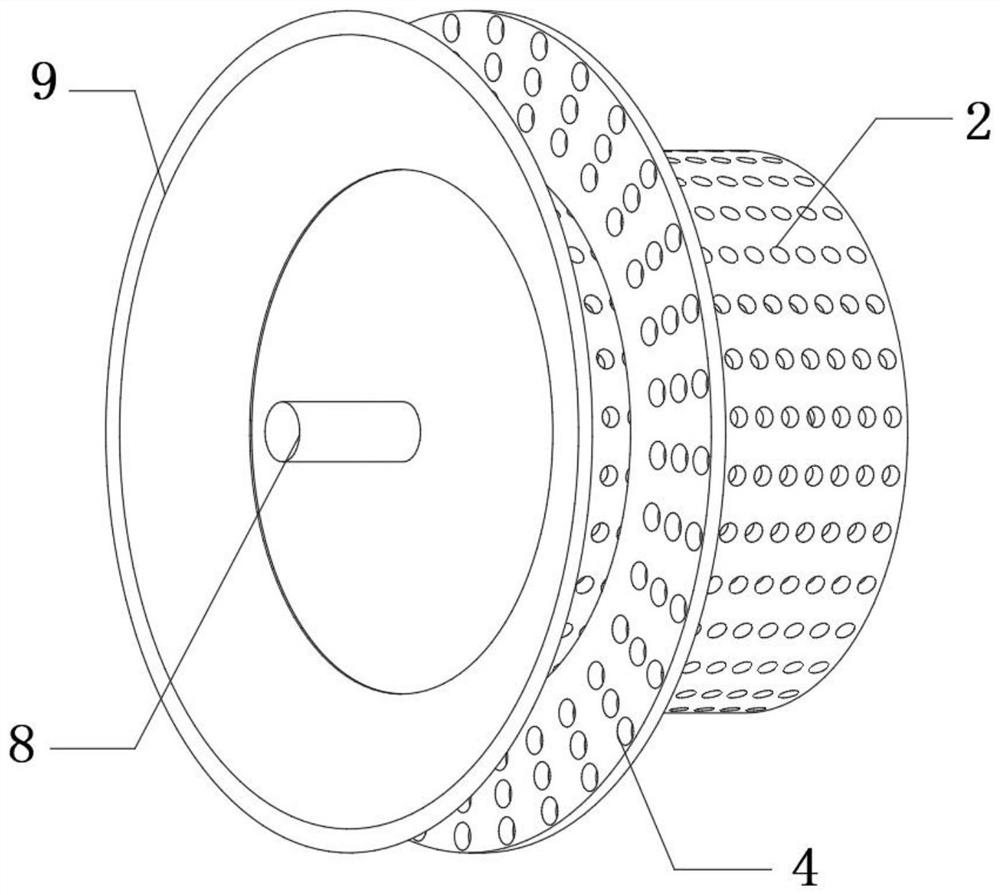

Industrial acidic wastewater treatment device

InactiveCN111233236AEasy to controlSmall footprintTransportation and packagingMixing methodsHeater RodElectric machinery

The invention discloses an industrial acidic wastewater treatment device. The device comprises a shell, a plurality of supporting legs are evenly and fixedly connected to the bottom of the shell, an exhaust port is formed in the top of the shell, liquid inlet pipes are fixedly connected to the upper left corner and the upper right corner of the shell, a plurality of first through holes are evenlyformed in a baffle, and second through holes are formed in the positions, corresponding to the first through holes of the baffle, of a rotary drum. According to the industrial acidic wastewater treatment device, the transpiration device and a neutralization chamber are combined into a whole, the occupied area is greatly reduced and a cost is reduced, the baffle plate, the rotary drum, the first through holes and the second through holes are matched so that on-off control over a partition layer is achieved, through cooperation of an electric heating rod, a connecting base, a conducting ring anda power line, so that concentration of acid wastewater in the transpiration chamber is achieved, through cooperation of a main shaft and a stirring rod, neutralization treatment in the neutralizationchamber is accelerated, and through cooperation of a second motor, a fourth gear and a fifth gear, power supply of the stirring mechanism is achieved.

Owner:王浩

Particle separation structure and smoke dust treatment device

InactiveCN112516775AImprove use valueImprove stabilityCombination devicesElectric machineEngineering

The invention belongs to the technical field of smoke dust treatment, particularly relates to a particle separation structure and a smoke dust treatment device, and aims to solve the problems of incomplete smoke dust treatment and relatively low use value due to the fact that only smoke and particles are separated and then smoke is treated during existing smoke dust treatment, but separated particles cannot be subjected to secondary separation treatment. According to the scheme, the device comprises a treatment box and a spray tower, a base is fixedly connected to the outer wall of the bottomof the treatment box, and a motor is fixedly connected to the inner wall of the base. By arranging the motor, a screen drum, a screen plate and a drainage plate, when smoke and particles of smoke areseparated, the motor is started and drives the screen drum to rotate at a high speed through the rotating shaft, so that the particles in the smoke are discharged from the screen holes, the smoke rises, the thrown-out particles fall on the screen plate, and the screen plate rotating at a high speed conducts secondary separation on the particles; and the separated particles are directly guided to an annular discharge hole through the drainage plate to be discharged, so that the use value of the smoke dust treatment device is improved.

Owner:金保财

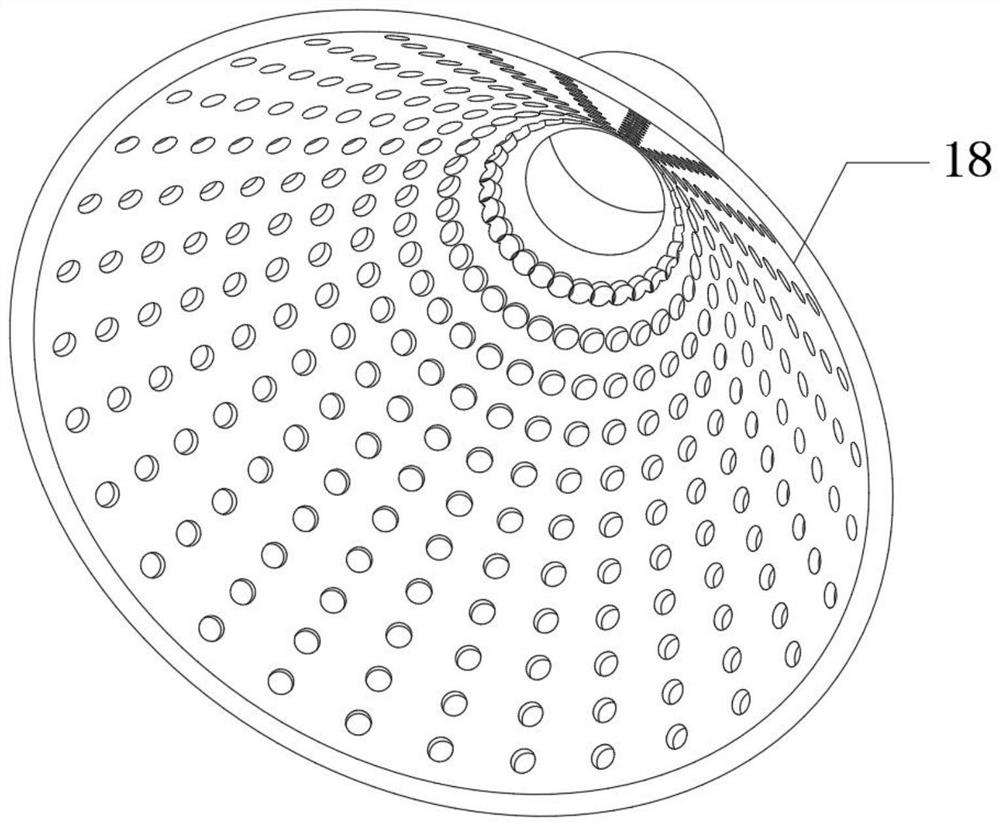

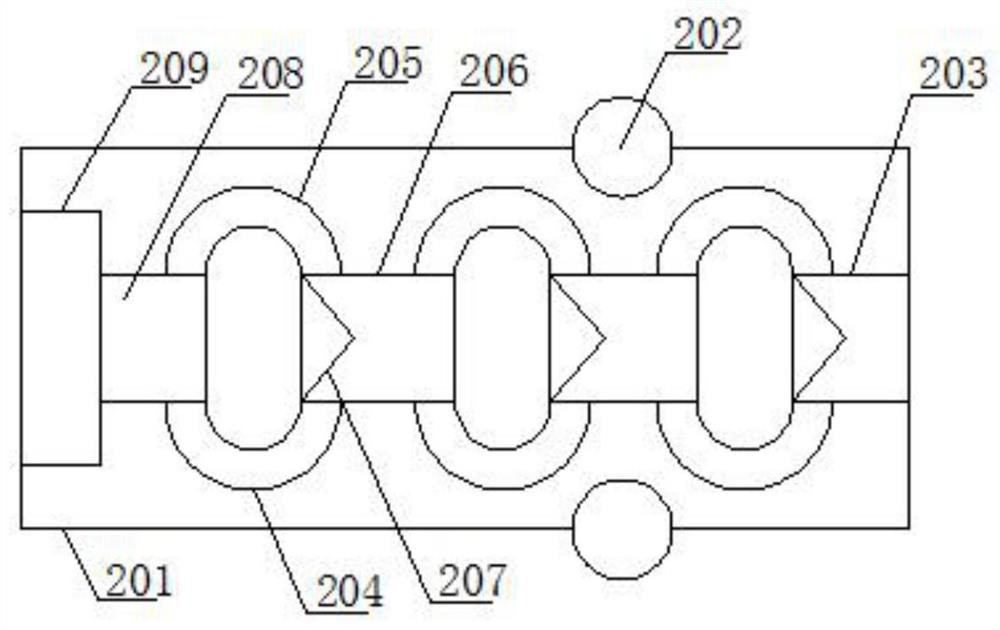

Gas mixing device for industrial waste gas treatment

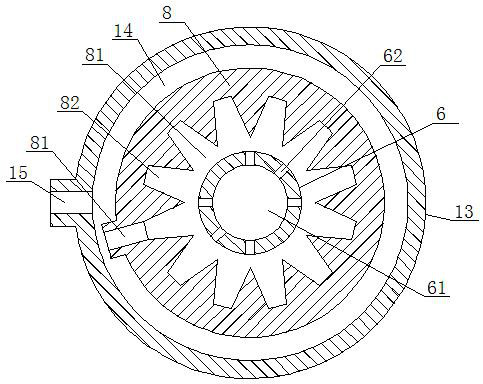

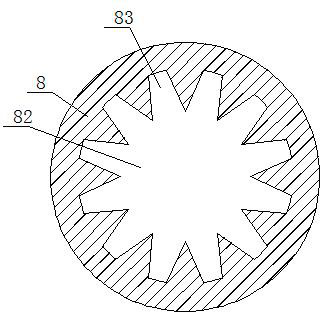

InactiveCN112090256AImprove neutralization effectChange shapeGas treatmentFlow mixersThermodynamicsExhaust fumes

The invention discloses a gas mixing device for industrial waste gas treatment. The gas mixing device comprises a vertical hollow shell of which the bottom is provided with supporting legs. Centralized entering of a neutralizing gas and waste gas is achieved through multiple annular array type air inlet holes, due to the size of air exhaust holes, when air enters, the air flowing speed can be decreased, the mixing time can be prolonged, meanwhile, when the air enters, multiple inclined plates which are inclined upwards can conduct space limiting on the mixed gas, when the mixed gas flows, theform of the gas entering is continuously changed, the mixing degree is improved, meanwhile, when the mixed air passes through a discharging part, the form of the gas during discharging can also be continuously changed through multiple inclined plates inclining downwards, the mixing degree is improved, meanwhile, the mixed gas enters a convection type gas mixing mechanism and is collided by a convection gas, the mixing degree can be further deepened, and the neutralizing effect between the neutralizing gas and the waste gas is effectively improved.

Owner:刘 杨

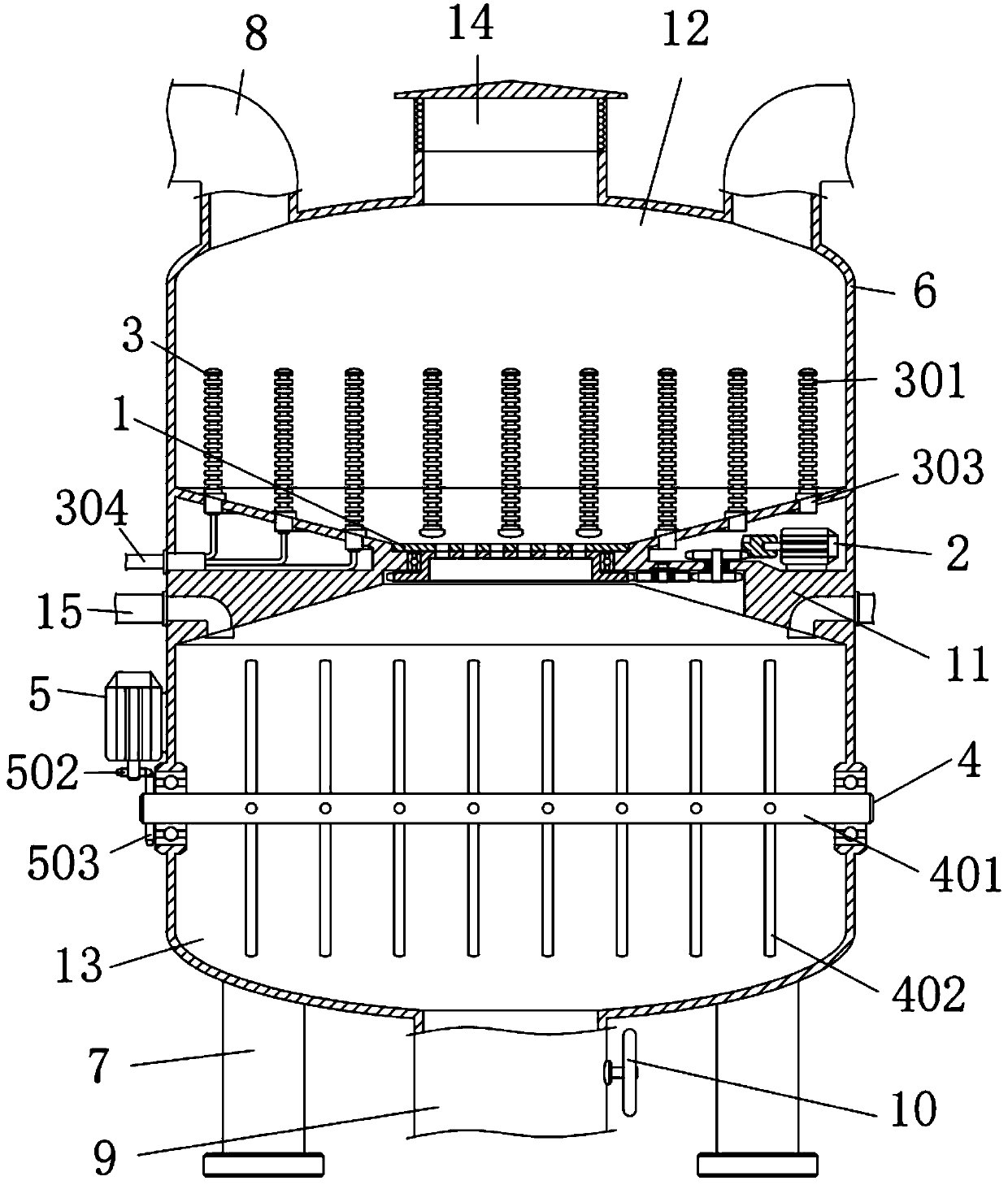

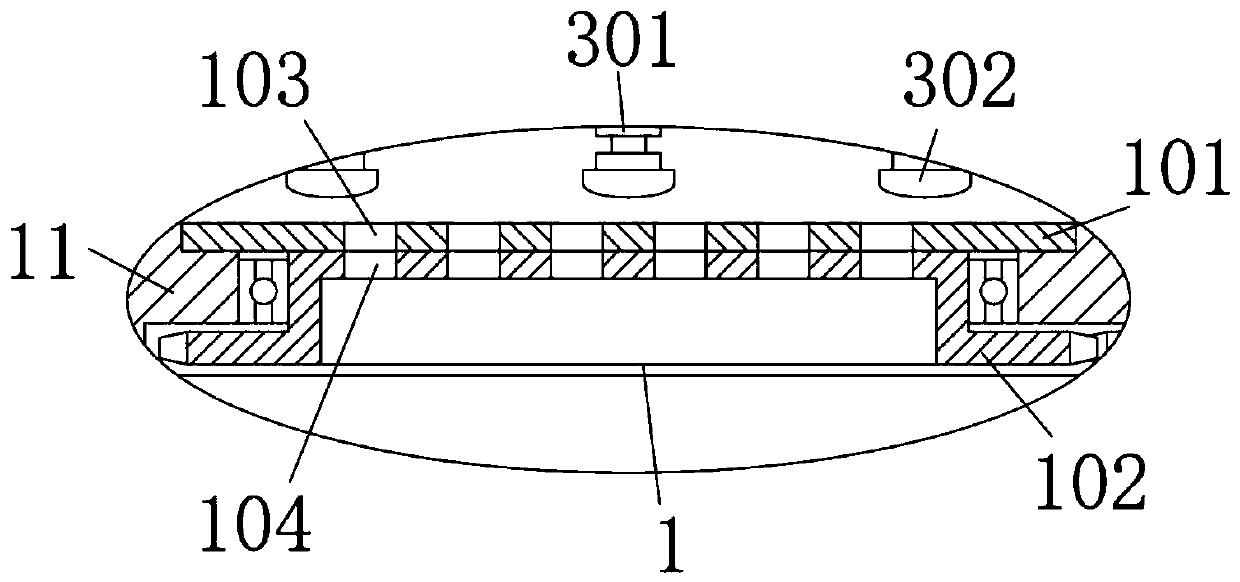

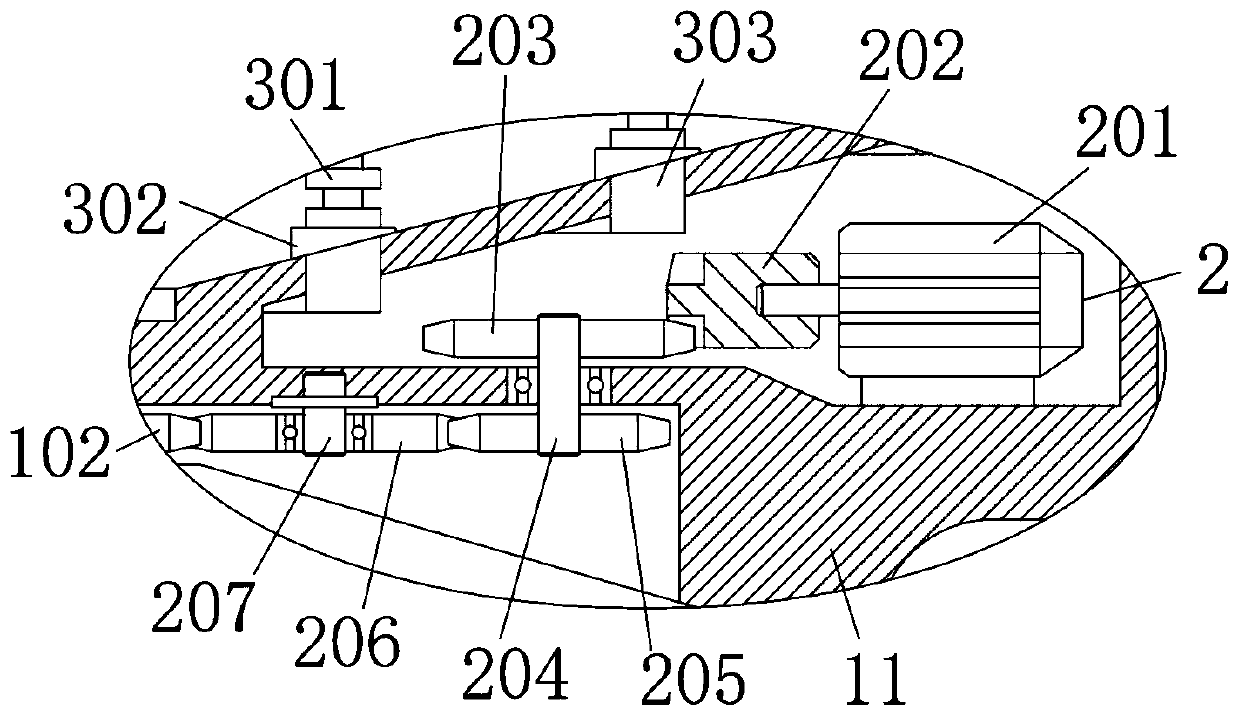

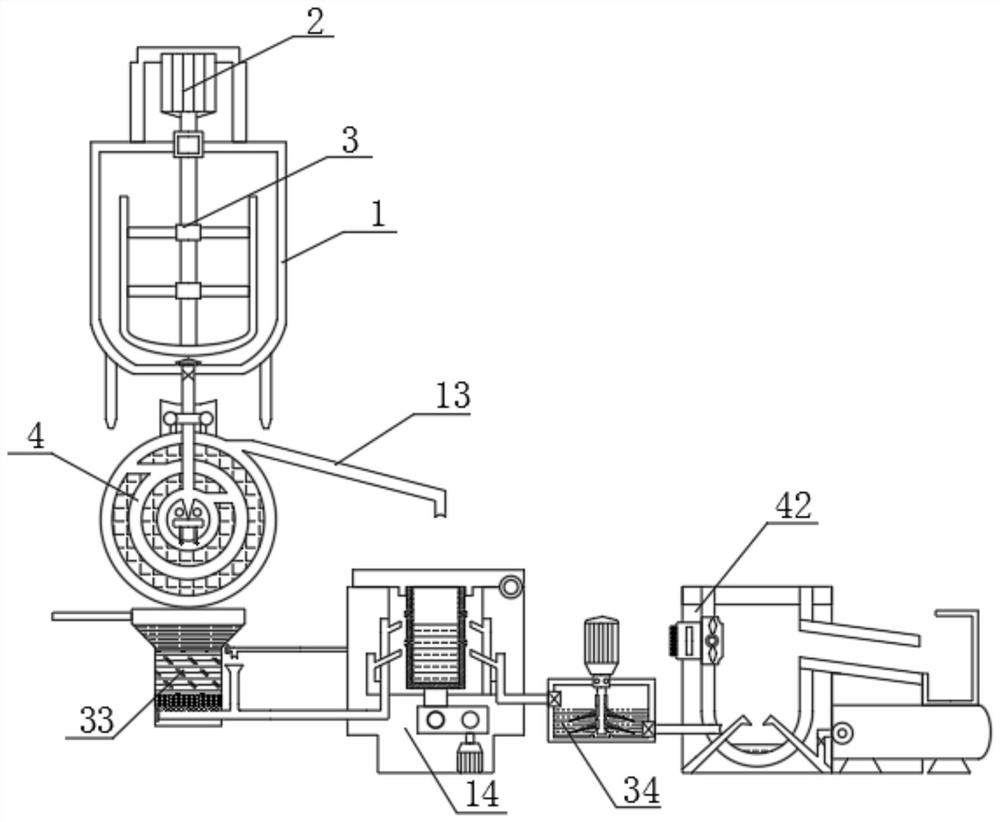

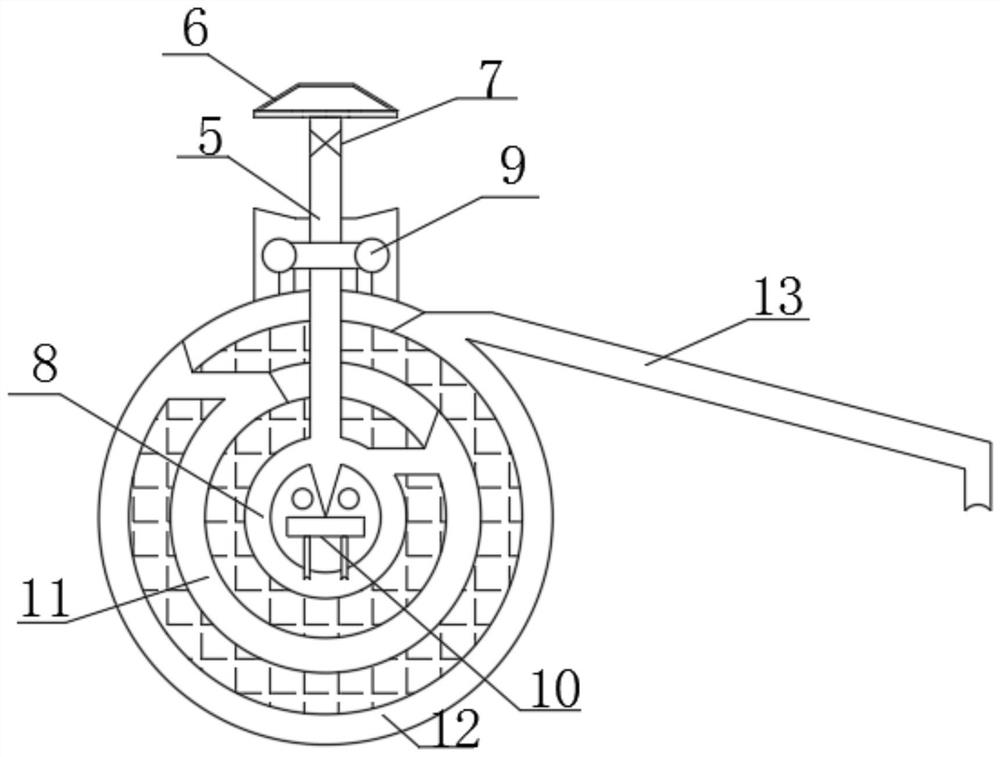

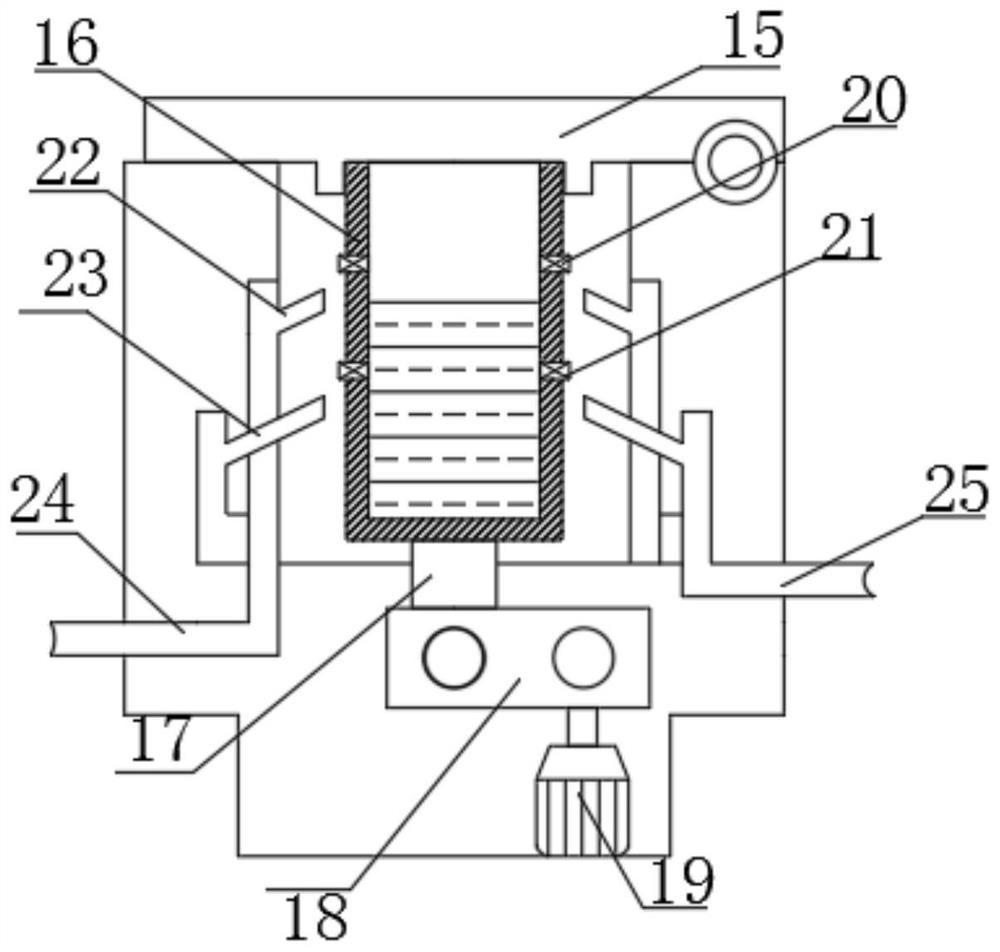

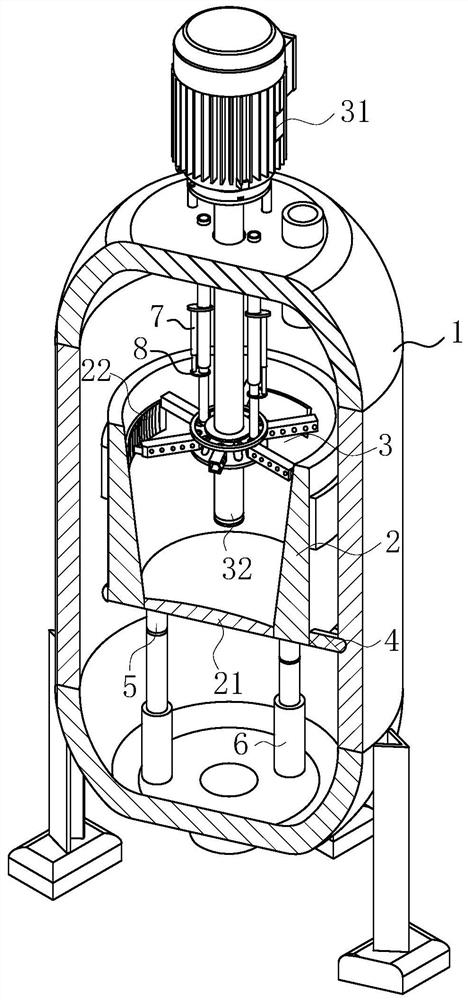

Reaction kettle acid treatment system for diamond production

InactiveCN112403420AWell mixedImprove the breaking effectSievingScreeningElectric machineryEngineering

The invention discloses a reaction kettle acid treatment system for diamond production, which relates to the technical field of diamond production. The reaction kettle acid treatment system comprisesa reaction kettle and a cover plate arranged at the upper end of the reaction kettle, the lower surface of the reaction kettle is fixedly connected with a plurality of uniformly distributed support legs, the outer side of the reaction kettle is connected with a heat exchange mechanism, a feeding pipe is fixedly communicated to the upper surface of the cover plate, and a driving motor is fixedly arranged in the center of the upper surface of the cover plate. The system is provided with a scattering mechanism, under the work of the driving motor, a driving chain wheel is driven to rotate througha rotating shaft, the driving chain wheel drives a driven chain wheel to rotate through a chain, then a shifting plate is driven to rotate through the scattering shaft, thefalling neutralizer is dispersed, the neutralizer is more uniformly mixed, and the product production speed is enhanced; the stirring plate is located under the liquid outlet pipe, so that the dispersing effect on the neutralizer is improved, and the neutralizing effect on the solution is further improved.

Owner:湖北汇尚钻石有限公司

Treatment system for dreg organic fertilizer fermentation waste liquid

InactiveCN114084988ASolve pollutionWell mixedWater/sewage treatment by centrifugal separationSpecific water treatment objectivesCentrifugationStraight tube

The invention relates to a treatment system for dreg organic fertilizer fermentation waste liquid, which comprises a fermentation tank, a deodorization mechanism, a centrifugal mechanism, a neutralization reactor, a temporary storage device and an atomization drying mechanism, the top of the fermentation tank is provided with a first motor, the first motor is downwards connected with a frame type stirrer, the bottom of the fermentation tank is communicated with a waste liquid straight pipe, a filter screen is arranged at the top of the waste liquid straight pipe, and a first electromagnetic valve is arranged in the upper end part of the waste liquid straight pipe. The whole treatment system is simple in design, a plurality of processes of fermentation, stirring, deodorization, centrifugation, neutralization, re-stirring and atomization drying are included, the processes are combined layer by layer and fed back mutually, a complete circulating type fermentation waste liquid treatment system is achieved, the actual use standard is met, the production cost is reduced, the working efficiency is improved, the using effect is better than that of a traditional mode, the device is suitable for different working conditions, and better using prospects are brought.

Owner:BOZHOU UNIV

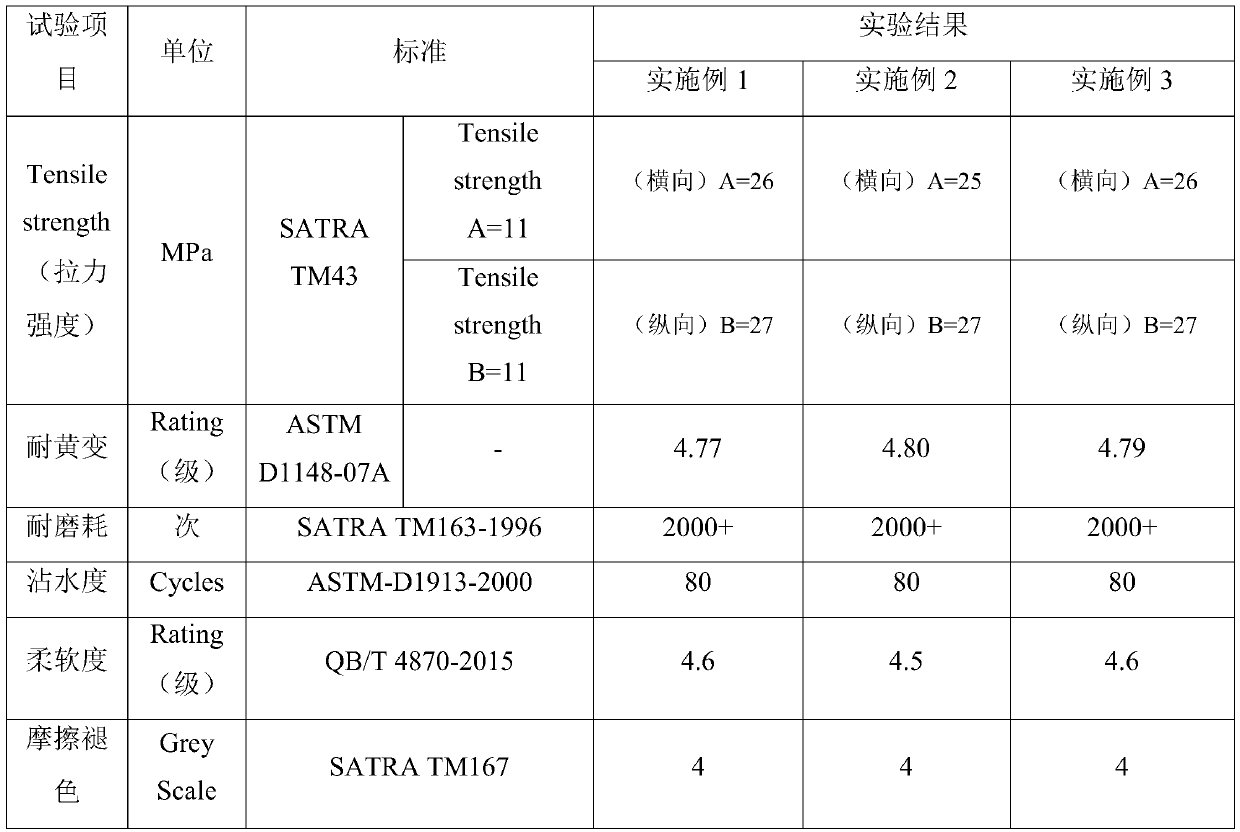

How to make waterproof skin

ActiveCN108998593BImprove stabilityImprove wetting abilityTanning treatmentPre-tanning chemical treatmentSolid acidPulp and paper industry

The invention discloses a preparation method of water-resistant leather, and belongs to the technical field of leather. The preparation method of water-resistant leather comprises the following stepsof rewetting and degreasing, retanning, neutralizing, filling, dyeing, solid acid treatment and post-treatment. The preparation method of the water-resistant leather has the advantages of being suitable for different leather materials, and producing the water-resistant leather with high strength and strong bending resistance.

Owner:漳州香洲皮革有限公司

Novel sulfur dioxide removing device

InactiveCN106076098AIncrease contact areaPrevents fast neutralizationGas treatmentDispersed particle separationAgricultural engineeringAir blower

The invention discloses a novel sulfur dioxide removing device which comprises a base, a water tank, an air blower, a chimney and a ventilation tank. The ventilation tank is arranged on the base and connected with a first ventilation pipe in a welded manner, the first ventilation pipe is connected with a second ventilation pipe through a first clamp, the second ventilation pipe is connected with a tank cover in a welded manner and connected with a third ventilation pipe through a second clamp, the tank cover is connected with a fourth ventilation pipe in a welded manner, the fourth ventilation pipe is connected with a fifth ventilation pipe through a third clamp, the fifth ventilation pipe is connected with the ventilation tank in a welded manner, a sixth ventilation pipe is arranged at the upper end of the ventilation tank, the air blower is arranged at the lower end of the sixth ventilation pipe, an air outlet pipe of the air blower is fixedly connected with the chimney, and the water tank and the tank cover are respectively connected with a hook-and-loop fastener component in a welded manner. The novel sulfur dioxide removing device is simple in structure and convenient to use, the staying time of gas in a container is prolonged by the aid of the ventilation pipes with meshes, and incapability of timely removing the gas due to too fast airflow is prevented.

Owner:南京润屹电子科技有限公司

Viscose fiber production wastewater pretreatment neutralization process method

InactiveCN111825234AReduce suspended solidsLow running costMultistage water/sewage treatmentWater/sewage treatment by neutralisationAcid waterPulp and paper industry

The invention relates to a viscose fiber production wastewater pretreatment neutralization process method which comprises the following steps: (1) centrally collecting viscose fiber acidic wastewater,and stirring; collecting the alkaline wastewater in a centralized manner, and stirring; (2) pumping the acidic wastewater into a reaction tank I, and adding calcium carbonate slurry into the reactiontank; (3) feeding the reacted acidic water into a reaction tank II, mixing the alkaline wastewater with the acidic water, and then adding lime slurry; and (4) after the reaction, allowing the wastewater to enter a reaction tank III, and supplementing sodium hydroxide alkali liquor to neutralize and adjust the pH value. According to the method, the viscose fiber production wastewater is pretreatedand neutralized in a multi-stage neutralizing and settling mode, suspended solids in the wastewater can be reduced, the neutralizing effect can be improved, the operation cost can be reduced, and themethod has guiding significance in viscose fiber production wastewater treatment correspondingly.

Owner:山东雅美科技有限公司

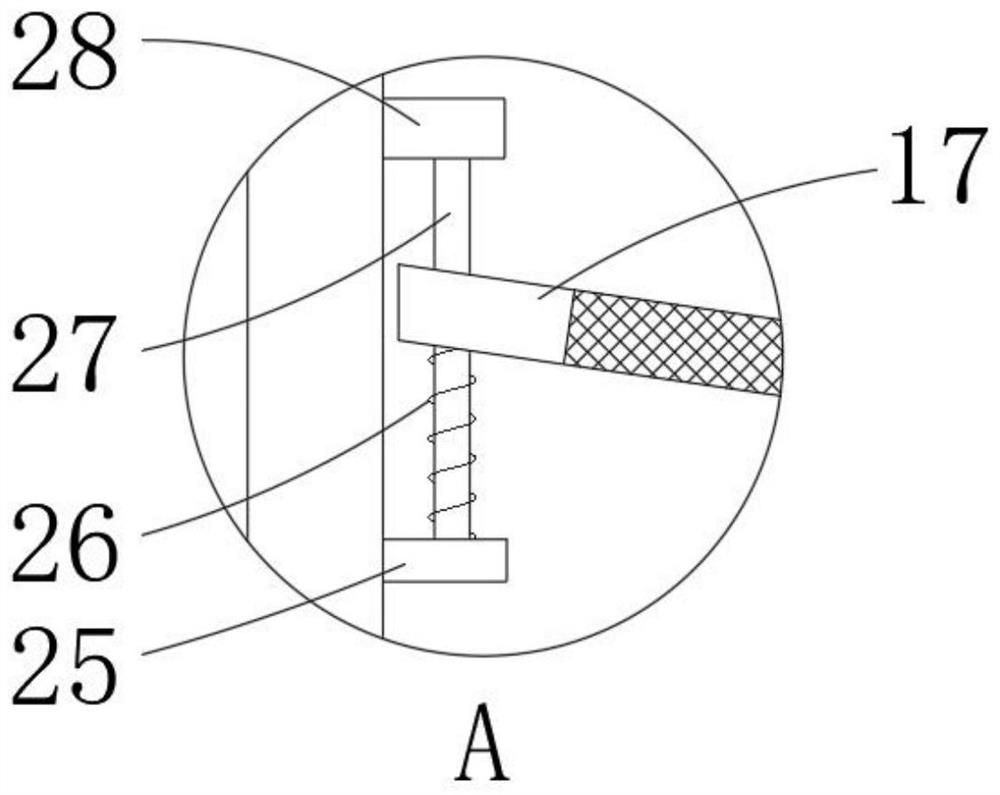

Casting waste water neutralization device

PendingCN107555572AIncrease concentrationReasonable structural designWaste water treatment from metallurgical processWaste water treatment from gaseous effluentsWastewaterMaterials science

The invention provides a casting waste water neutralization device, and belongs to the technical field of machinery. The casting waste water neutralization device solves a problem that an existing casting waste water neutralization device is not in place in monitoring. The casting waste water neutralization device comprises a waste water tank which contains acidic waste water, a dissolving barrelwhich dissolves alkaline substances to form an alkaline solution, a neutralization barrel which performs neutralization after absorbing the acidic waste water and the alkaline solution respectively from the waste water tank and the dissolving barrel and discharge a solution after neutralization outwards, and a control unit which is connected with a PH detector and can control the acidic waste water and the alkaline solution to enter the neutralization barrel, wherein a pH detector for detecting a pH value is arranged in the neutralization barrel. The device has the advantages of real-time detection and automatic neutralization.

Owner:宁波视线软件科技有限公司

Wastewater neutralization treatment device for environmental protection

InactiveCN114715996AExtension of timeImprove mix qualityWater treatment parameter controlRotary stirring mixersWastewaterElectric machinery

The invention relates to the technical field of environmental protection, and discloses a wastewater neutralization treatment device for environmental protection. According to the environment-friendly wastewater neutralization treatment device, through the rotating mechanism, after wastewater and neutralization liquid are mixed, the fusion stroke of the wastewater and the neutralization liquid is also converted into a spiral line advancing mode, the neutralization time of the wastewater and the neutralization liquid can be effectively prolonged, and due to the fact that the wastewater and the neutralization liquid are in a high-speed rotating state, the mixing efficiency can be effectively improved, and the mixing quality can be improved; by means of the driving motor, the function of conveying the waste water can be achieved, rotation driving of the waste water can be achieved, the high-speed centrifugal state is generated, meanwhile, rotation driving of neutralization liquid and the waste water in the opposite direction can be achieved, one machine has multiple purposes, and each function is progressive in relation. And therefore, the kinetic energy utilization rate is effectively improved.

Owner:韩成伍

A device for detecting RNA in exosomes based on tumor diagnosis and prediction

ActiveCN112246140BUltraviolet light detection effect is accurateImprove neutralization effectRotary stirring mixersTransportation and packagingNeoplasm diagnosisBiomedical engineering

Owner:广州爱索达生物医药技术有限公司

Chemical acid residue neutralization treatment method

ActiveCN108405552BRaw materials are easy to getSimple methodSolid waste disposalChemical/physical/physico-chemical processesEnvironmental engineeringAlkylation

The invention relates to a method for neutralizing chemical acid slag, in particular to a method for treating alkylated acid slag discharged from an alkylation production device. When using slaked lime to neutralize the acid solution, soil is introduced and uniformly mixed with slaked lime in advance. Lime soil is reacted with chemical acid slag under stirring conditions, and the reacted product is aged until the pH value reaches 7‑8. The products of the neutralization reaction after aging can be directly landfilled or utilized as raw materials for unburned bricks. The invention is especially suitable for the treatment of the alkylation acid slag discharged from the alkylation production device, the raw material is easy to obtain, the method is simple and easy, the neutralization effect is obvious and rapid, the treatment cost is low, and no secondary pollution is caused.

Owner:LANZHOU KANGSHUN PETROCHEM

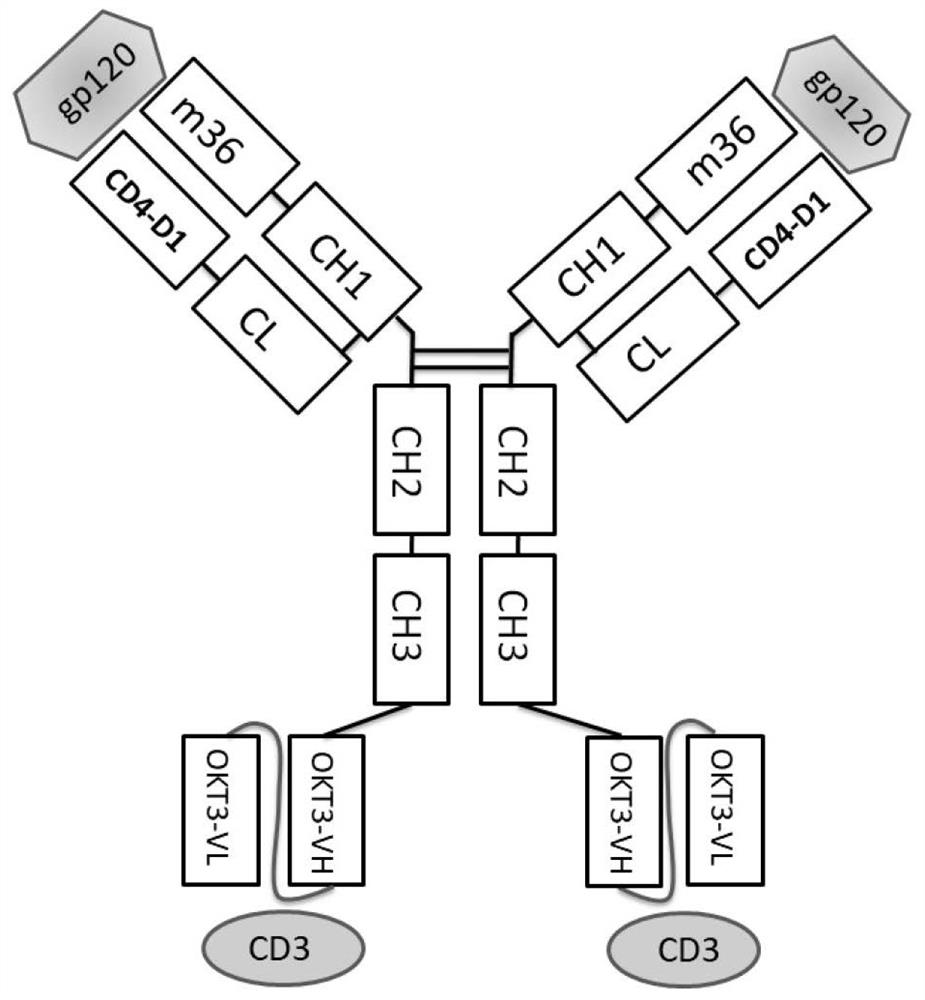

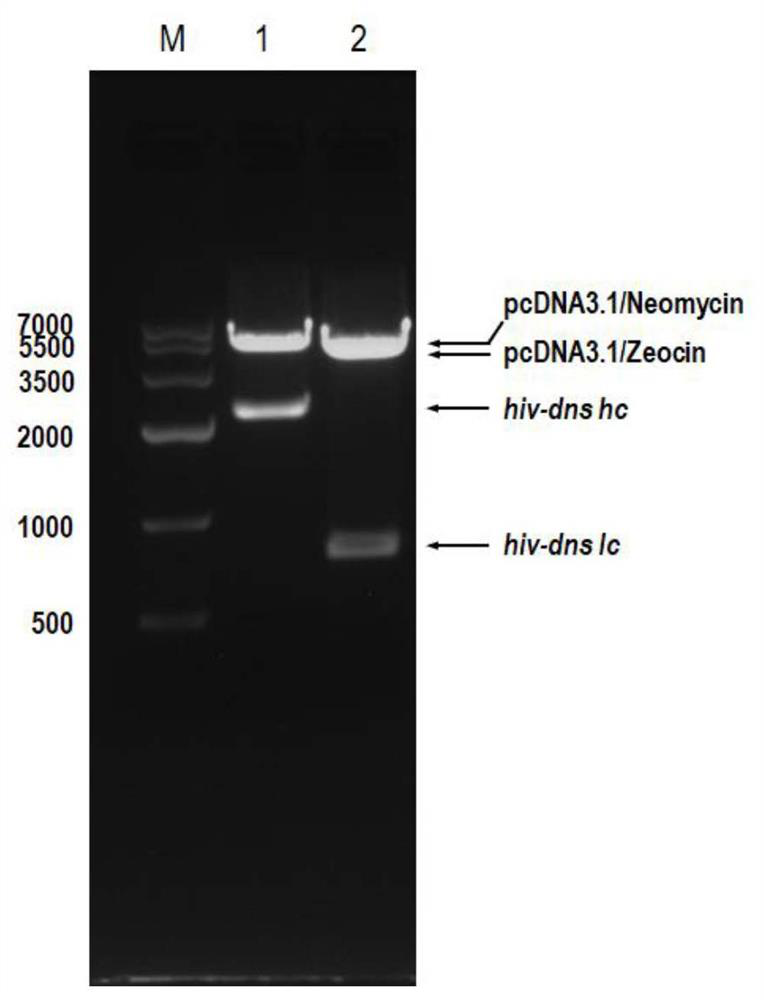

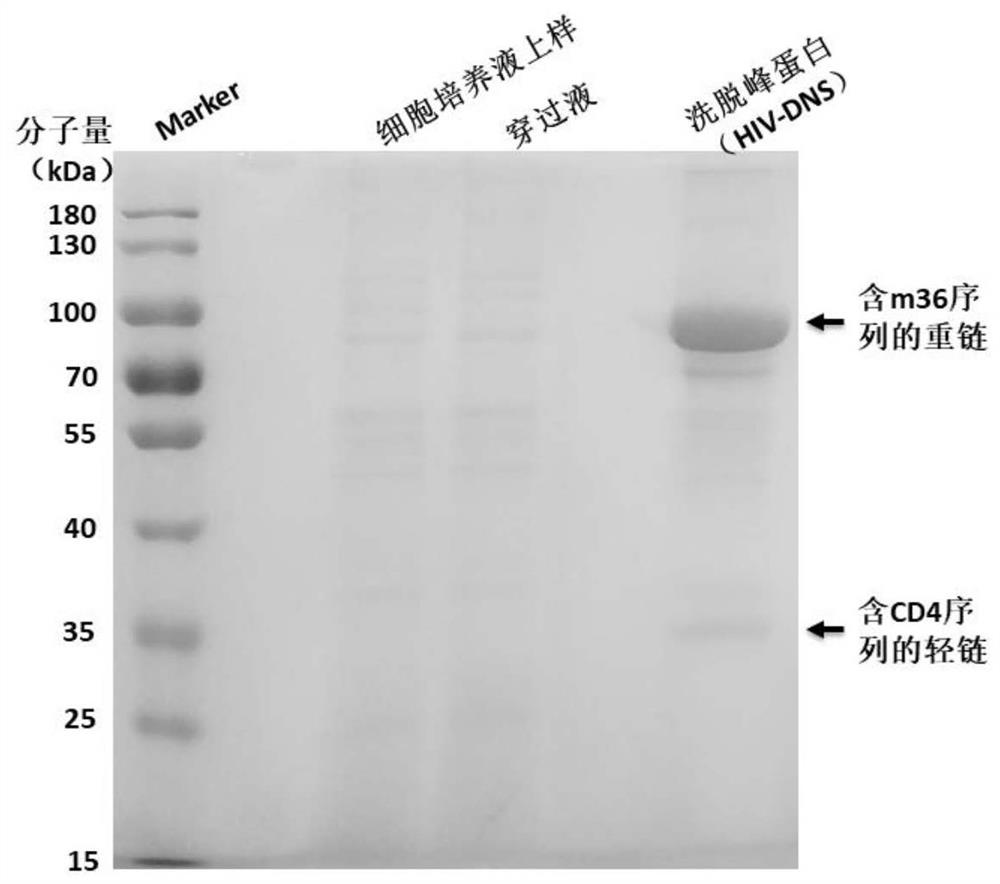

Multispecific antibody targeting HIV gp120 protein and human CD3 molecule and application thereof

ActiveCN114316062BEasy to eliminateReduce loadHybrid immunoglobulinsAntiviralsSingle-Chain AntibodiesClinical efficacy

The invention discloses a multispecific antibody targeting HIV gp120 protein and human CD3 molecule and application thereof. The multispecific antibody includes an antibody specifically binding to gp120 and a single-chain antibody specifically binding to CD3 whose amino acid sequence is 471-710 of sequence 1, and the antibody specifically binding to gp120 includes an amino acid sequence of 1-710 of sequence 1. The heavy chain variable region at position 136 and the amino acid sequence are the light chain variable region at positions 1-125 of Sequence 3, and the single-chain antibody is fused to the C-terminus of the heavy chain of an antibody specifically binding to gp120. The multispecific antibody targets different epitopes of gp120, which can significantly improve the neutralization effect of HIV virus, reduce the probability of virus escape mutation, and target CD3 molecules to better eliminate the virus and improve the clinical efficacy of antibody therapy.

Owner:珠海臻谱基因科技有限公司

Boiler dust removal and ash conveying system

ActiveCN106391311BAchieve recyclingSolve secondary pollutionTreatment involving filtrationMultistage water/sewage treatmentFlue gasWater flow

The invention discloses a boiler dust removing and conveying system which comprises a wet type electric dust remover, a circulation water tank and an alkali liquor tank. Spraying mechanisms are arranged on the top of the wet type electric dust remover and sequentially fall into a front portion and a rear portion in the flue gas circulation direction. The boiler dust removing and conveying system is characterized by further comprising a drainage tank and a washing water tank. A sewage outlet of the wet type electric dust remover is connected with the drainage tank through a sewage drainage pipeline. The drainage tank is connected with the circulation water tank, and water flows into the circulation water tank in an overflow mode. The bottom of the drainage tank is connected to a trench through a pipeline. The alkali liquor tank is connected with the circulation water tank through an alkali liquor metering pump. The circulation water tank is connected with the spraying mechanisms on the front portion through a circulation water pump, and the washing water tank is connected with the spraying mechanisms on the rear portion through a washing water pump. A PH sensor is arranged in the drainage tank. The alkali liquor metering pump is controlled by the PH sensor. By arranging a feedback system, the effect of improving corrosion resistance of the wet type electric dust remover is achieved.

Owner:杭州红山热电有限公司

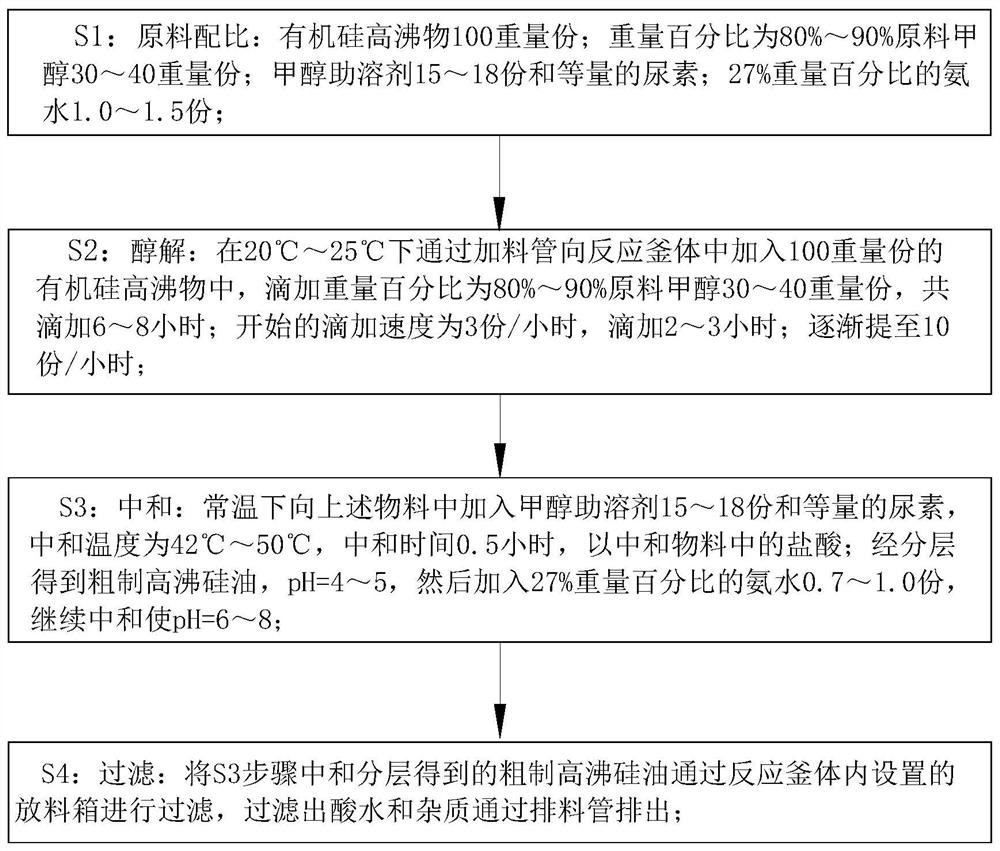

A kind of preparation method of silicone oil

Owner:山东盛宇新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com