Novel sulfur dioxide removing device

A new type of sulfur dioxide technology, applied in chemical instruments and methods, gas treatment, membrane technology, etc., can solve problems such as unsatisfactory treatment effect, and achieve the effect of enhancing neutralization effect, convenient use, and preventing excessive airflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

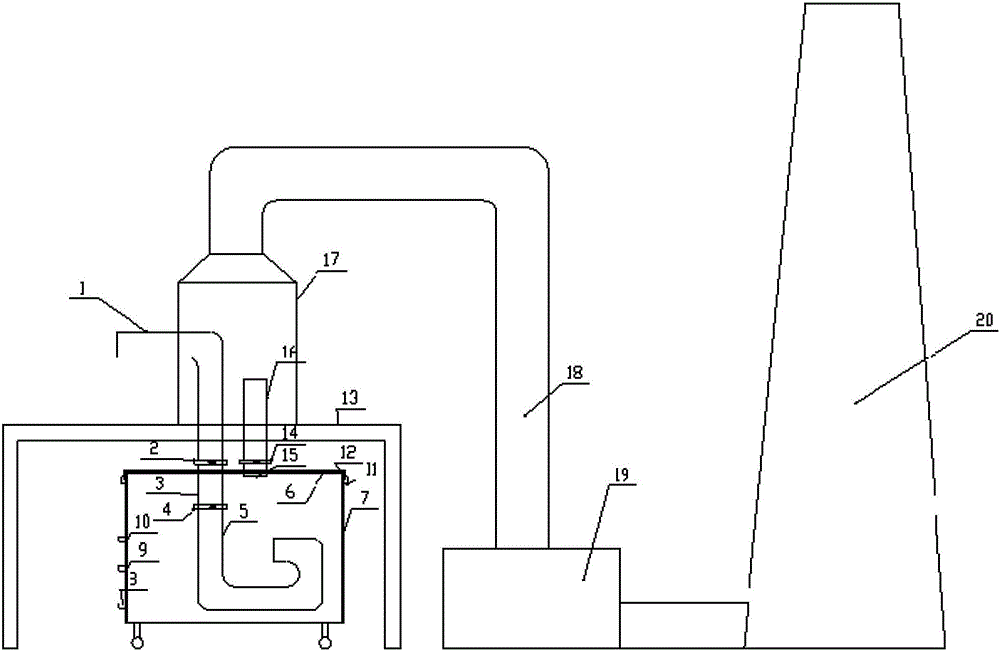

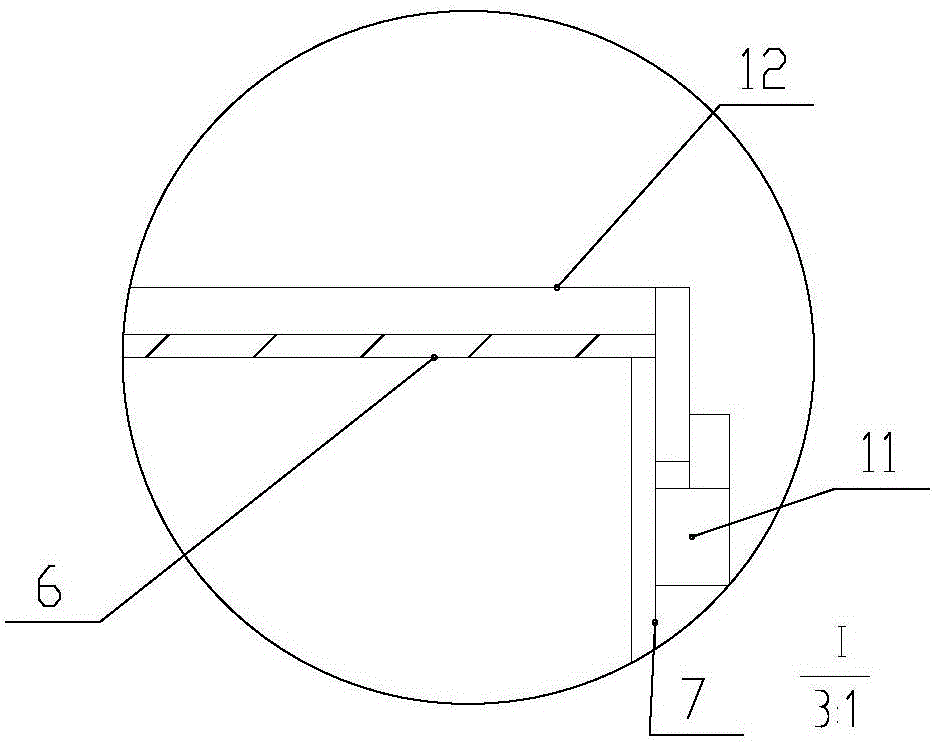

[0015] Such as figure 1 As shown, a novel sulfur dioxide removal device includes a base 13, a water tank 7, a blower 19, a chimney 20, and a ventilation tank 17. The base 13 is provided with a ventilation tank 17, and the ventilation tank 17 and the ventilation pipe-1 are welded connection, the vent pipe one 1 is connected with the vent pipe two 3 through the clamp one 2, the vent pipe two 3 is connected with the box cover 12 by welding, and the vent pipe two 3 and the vent pipe three 5 are connected through the clamp two 4 Connection, the box cover 12 is connected with the vent pipe four 15 by welding, the vent pipe four 15 is connected with the vent pipe five 16 through the clamp three 14, the passage pipe five is connected with the vent tank 17 by welding, and the vent pipe five is connected with the vent tank 17 by welding. The upper end of the tank 17 is provided with a ventilation pipe 6 18, and the lower end of the ventilation pipe 6 18 is provided with a blower 19. Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com