How to make waterproof skin

A production method and water-repellent technology, applied in the field of leather, can solve problems such as unfavorable long-term use, complicated coating preparation methods, and reduced waterproof performance of leather, so as to improve density and water-repellent performance, improve adsorption and cohesion performance, and improve The effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

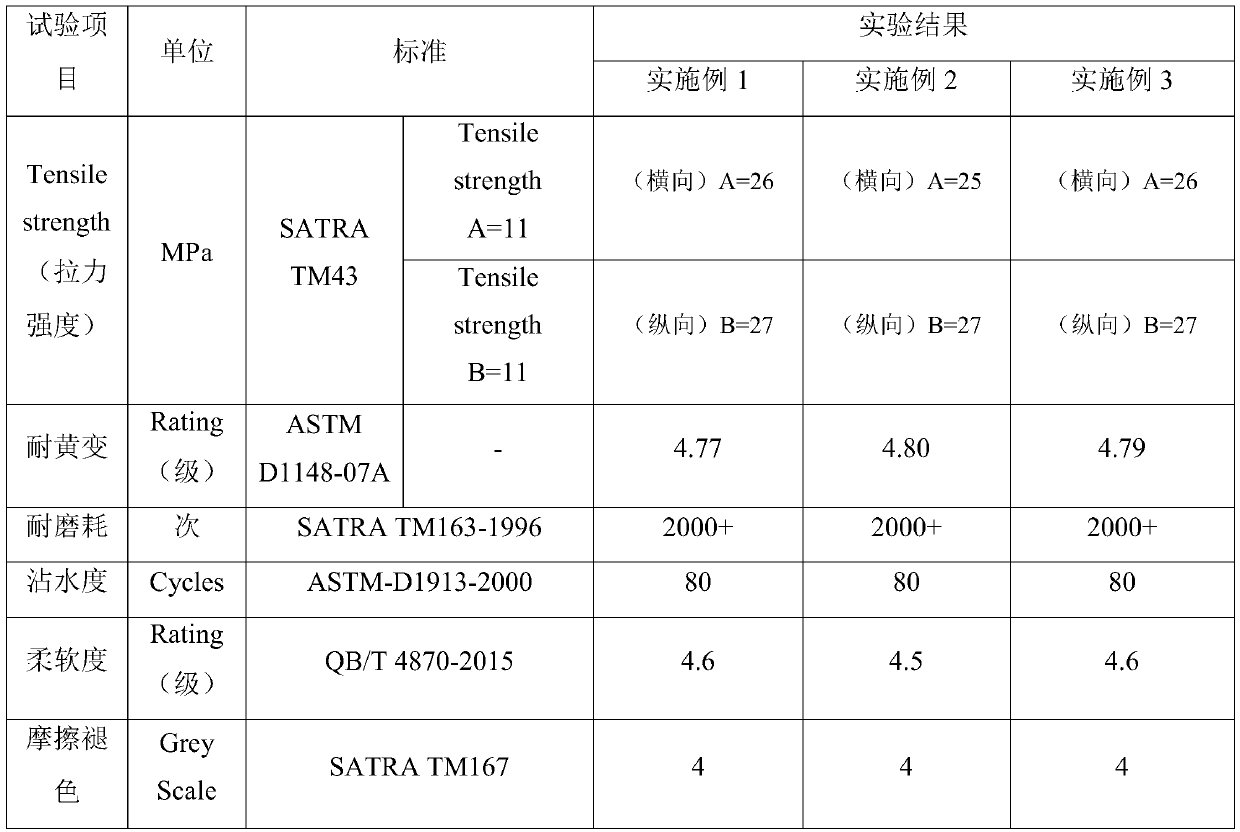

Examples

Embodiment 1

[0036] The manufacturing method of water-repellent skin comprises the following steps:

[0037] Step 1. Moisture degreasing:

[0038] The pretreated leather is placed in the drum for degreasing treatment to obtain the degreased leather; the step 1 rewetting and degreasing treatment is specifically as follows: add 120% of water accounting for the mass percentage of the pretreated leather in the drum, Polyethylene glycol ether 8%, polyaluminum chloride 5%, after the drum runs for 150 minutes, the drum is drained and washed once with water, wherein the water temperature is 45°C.

[0039] Step two, retanning:

[0040] The degreased leather material obtained in step 1 is subjected to retanning treatment to obtain retanned leather material; the retanning treatment in said step 2 is specifically as follows: add 100% of water, C5 petroleum Resin 6%, drum after 30min, then add sodium formate 2.5%, chromium trioxide 3%, drum operation 120min, then carry out once draining, then add wat...

Embodiment 2

[0055] The manufacturing method of water-repellent skin comprises the following steps:

[0056] Step 1. Moisture degreasing:

[0057] The leather is placed in the drum for degreasing treatment to obtain the degreasing leather; the step 1 rewetting and degreasing treatment is specifically as follows: add 125% of water accounting for the mass percentage of the pretreated leather in the drum, polyethylene Glycol ether 9%, polyaluminum chloride 6%, after the drum runs for 155 minutes, the drum is drained and washed once with water, wherein the water temperature is 45°C.

[0058] Step two, retanning:

[0059] The degreased leather material obtained in step 1 is retanned to obtain retanned leather material; the retanned leather material in said step 2 is specifically as follows: add 105% of water accounting for the mass percentage of the pretreated leather material in the drum, C5 petroleum Resin 7%, drum after 35min, then add sodium formate 2.5% of the mass percentage of the pret...

Embodiment 3

[0074] The manufacturing method of water-repellent skin comprises the following steps:

[0075] Step 1. Moisture degreasing:

[0076] The leather is placed in the drum for degreasing treatment to obtain the degreasing leather; the step 1 rewetting degreasing treatment is specifically as follows: add 130% of water accounting for the mass percentage of the pretreated leather in the drum, polyethylene Glycol ether 11%, polyaluminum chloride 7%, after the drum runs for 160 minutes, the drum is drained and washed once with water, wherein the water temperature is 50°C.

[0077] Step two, retanning:

[0078] The degreased leather obtained in step 1 is subjected to retanning treatment to obtain retanned leather; the retanning treatment in step 2 is specifically as follows: add 110% of water, C5 petroleum Resin 8%, drum after 40min, then add sodium formate 3.0% of the mass percentage of the pretreated leather material, chromium trioxide 4%, drum operation 130min, then perform a drain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com