Chemical acid residue neutralization treatment method

A treatment method and acid slag technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc., can solve the problem of affecting the neutralization effect of acid slag and Ca, increasing operating costs, and the number of product stacks It can't achieve neutrality and other problems in a month, and achieve the effect of obvious and rapid neutralization effect, simple and easy method, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

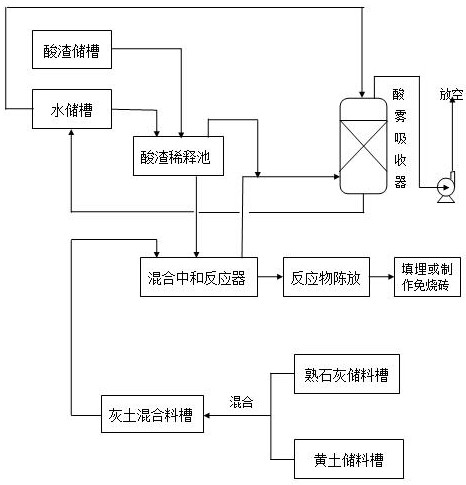

Method used

Image

Examples

Embodiment 1

[0026] Alkylation acid residue 100g in a refinery, Ca(OH) 2 (slaked lime) 90g, loess 150g, water 100g. Dilute the alkylated acid slag with water first, and the Ca(OH) 2 (slaked lime) and loess evenly mixed into lime soil. Slowly add the mixed lime soil into the alkylated acid slag solution while stirring, react for 30 minutes, and age for 3 hours after the reaction, the pH value of the reaction product is 7.17. The neutralized product after aging can be made into unfired brick according to the method of CN1955141A.

Embodiment 2

[0030] Chemical waste water, composed of: 90g of mixed aqueous solution of hydrochloric acid and sulfuric acid, containing 4.6% (mass) of HCl, H 2 SO 4 30% (mass), water content 62.1% (mass). Take Ca(OH) 2 (slaked lime) 36g, loess 63g, Ca(OH) 2 (slaked lime) is evenly mixed with loess to form lime soil. Slowly add mixed lime soil into the mixed acid solution while stirring, stir and react for 30 minutes, and age for 360 minutes after the reaction, the pH value of the reaction product is 7.11. According to the method of CN103172334 A, the neutralized product after aging can be made into unfired bricks.

Embodiment 3

[0032] 26 tons of alkylation acid slag in a factory, Ca(OH) 2 (slaked lime) 26 tons, loess 40 tons, water 26 tons. Dissolve the alkylated acid residue in water and dilute the Ca(OH) 2(slaked lime) and loess are mixed evenly into lime soil. Under the condition of stirring, lime soil was slowly added to the alkylated acid slag solution to react for 40 minutes, and aged for 2 days after the reaction, and the pH value of the reaction product was 7.85. According to the method of CN102659376 A, the neutralized product after aging can be made into unfired bricks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com