Double-neutralization system in circuit board electroless plating copper production line

A production line and circuit board technology, applied in printed circuit, printed circuit manufacturing, printed circuit secondary treatment, etc., can solve the problems of strong oxidants and redox products, poor backlighting of production boards, and easy contamination of potions, etc. Achieve the effects of reducing the risk of contamination, stabilizing the backlight of copper sinking, and reducing the scrap rate of copper-free holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

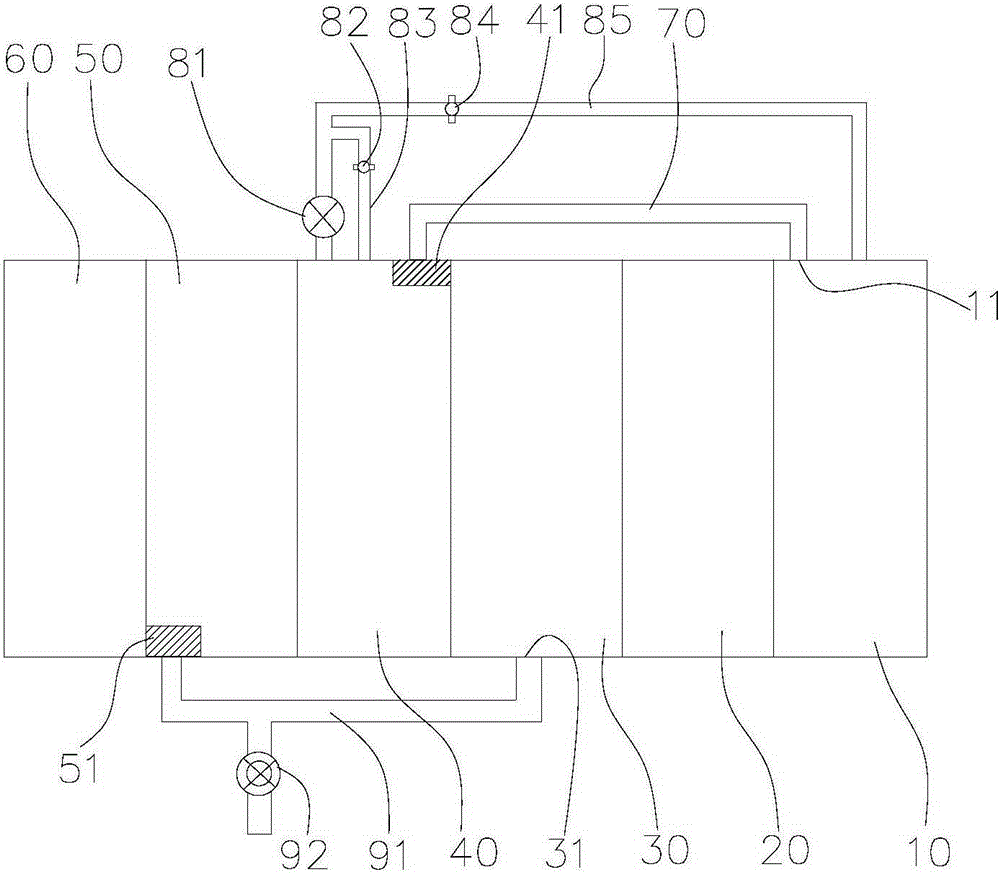

[0018] This embodiment provides a dual neutralization system in a circuit board copper sinking production line, including a pre-neutralization cylinder 10, a first water washing cylinder 20 before neutralization, a second water washing cylinder 30 before neutralization, a neutralization cylinder 40, a neutralization After the first water washing cylinder 50, after neutralization, the second water washing cylinder 60, filter pump 81 and air pump 92.

[0019] The pre-neutralization cylinder 10, the first water washing cylinder 20 before neutralization, the second water washing cylinder 30 before neutralization, the neutralization cylinder 40, the first water washing cylinder 50 after neutralization and the second water washing cylinder 60 after neutralization are arranged in sequence, When neutralizing the production plate, the production plate passes through the pre-neutralization tank 10, the first water washing tank 20 before neutralization, the second water washing tank 30 be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com