A kind of preparation method of silicone oil

A silicone oil and organosilicon technology, applied in the field of preparation of silicone oil, can solve the problems of reducing the hydrogen chloride gas efficiency of the aqueous solution, increasing the proportion of ammonia water, etc., and achieve the effects of increasing the equilibrium reaction rate, speeding up the neutralization speed, and increasing the neutralization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

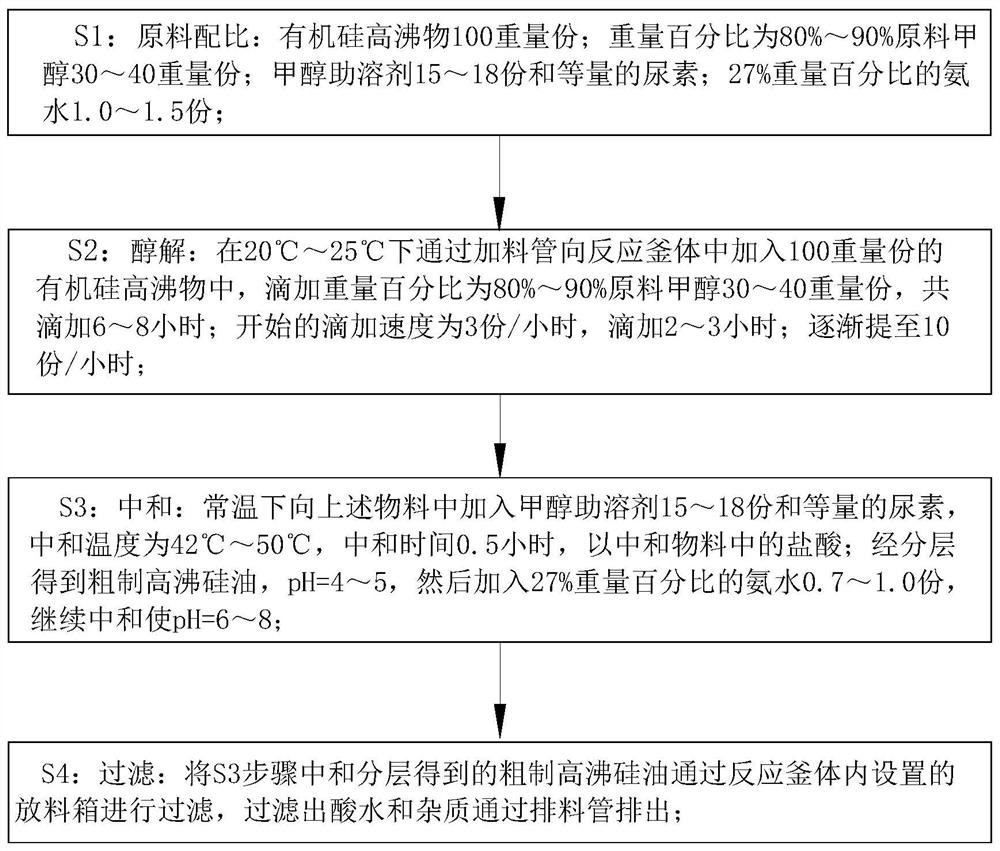

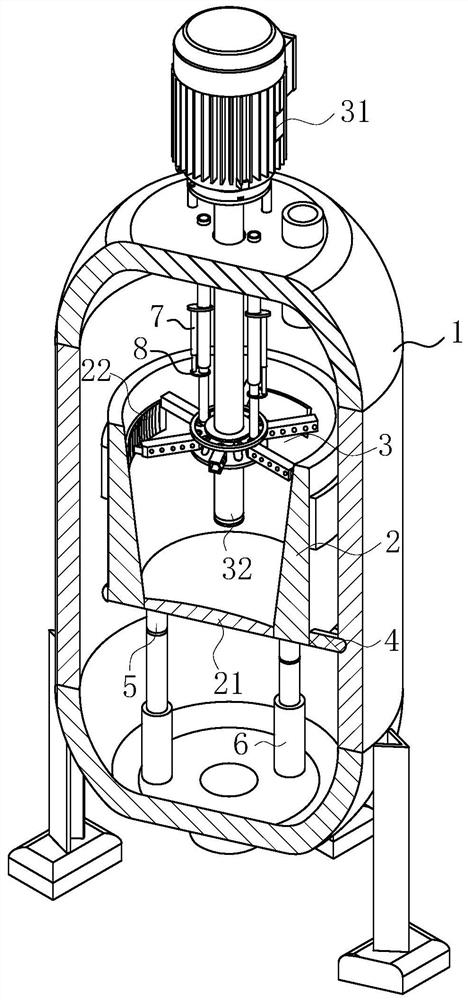

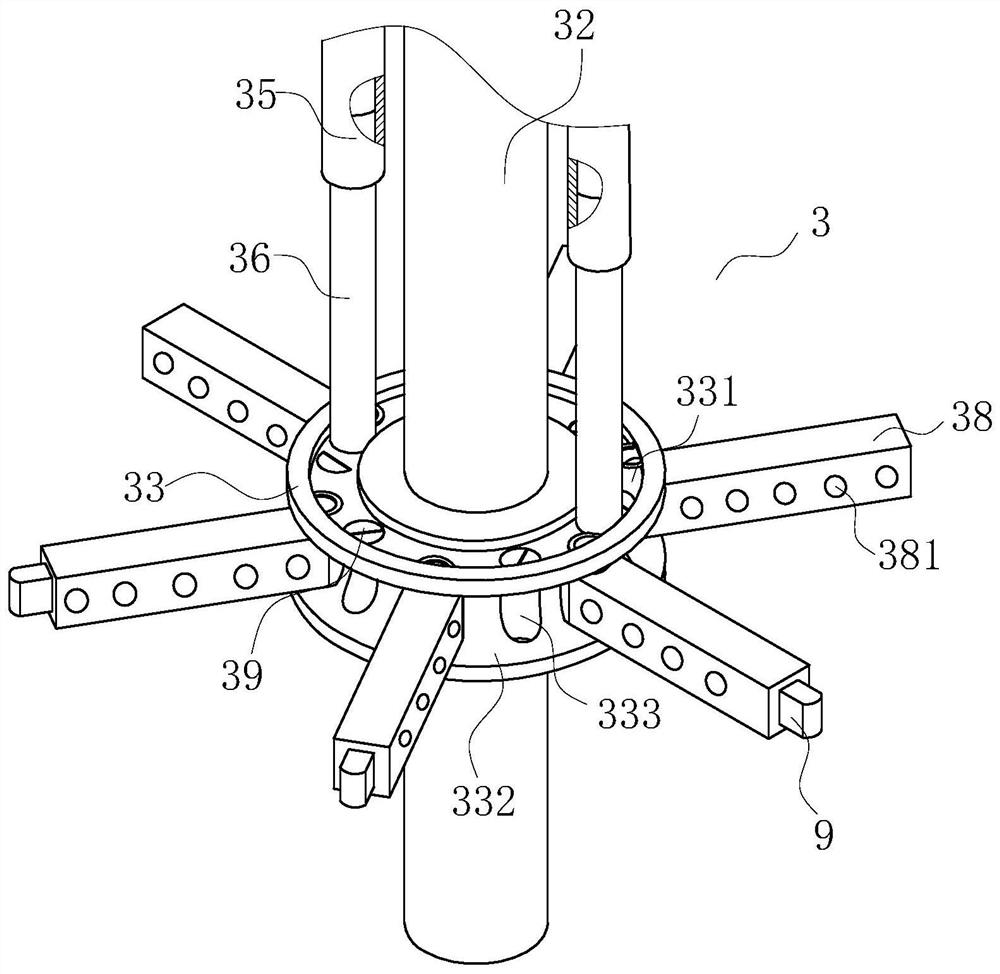

[0025] use Figure 1-Figure 4 A method for preparing a silicone oil according to an embodiment of the present invention is described as follows.

[0026] Such as Figure 1-Figure 4 Shown, the preparation method of a kind of silicone oil of the present invention, this method comprises the following steps:

[0027] S1: Raw material ratio: 100 parts by weight of organosilicon high boiler; 30-40 parts by weight of raw material methanol with 80%-90% by weight; 15-18 parts by weight of methanol co-solvent and the same amount of urea; 27% by weight of ammonia water 1.0~1.5 copies;

[0028] S2: Alcoholysis: add 100 parts by weight of organosilicon high boilers into the reaction kettle body 1 through the feeding pipe at 20°C to 25°C, and add 30 to 40 parts by weight of raw material methanol with a weight percentage of 80% to 90% dropwise , added dropwise for 6 to 8 hours; the initial drop rate was 3 parts / hour, and added dropwise for 2 to 3 hours; gradually raised to 10 parts / hour; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com