Particle separation structure and smoke dust treatment device

A particle separation and treatment device technology, applied in the direction of dispersed particle separation, combination device, separation method, etc., can solve the problems of low use value, secondary separation treatment, incomplete smoke and dust treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

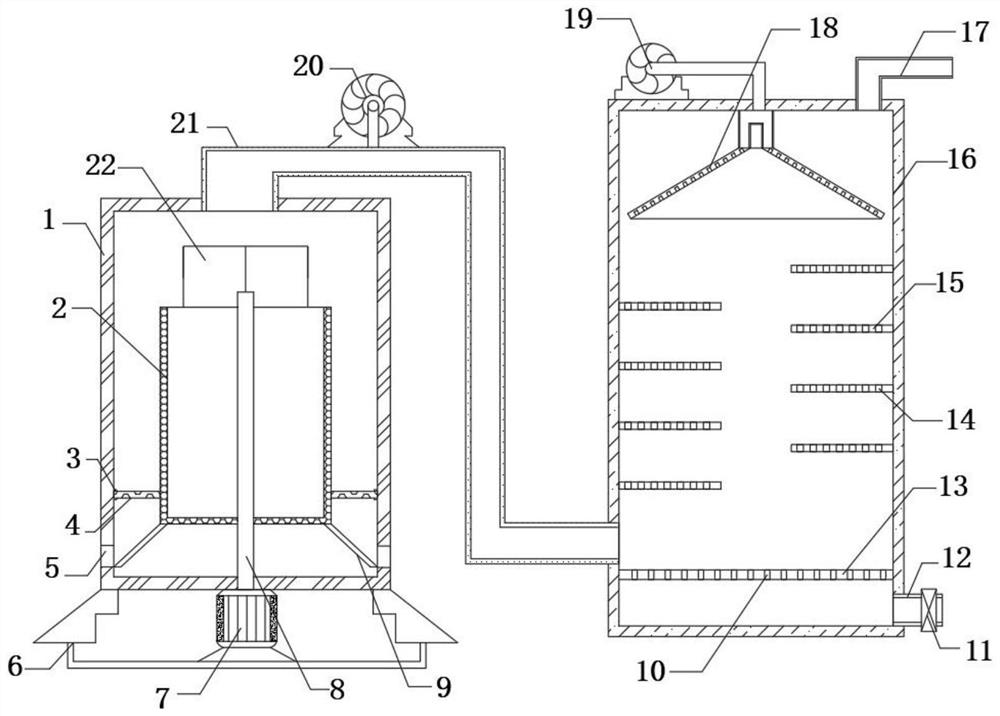

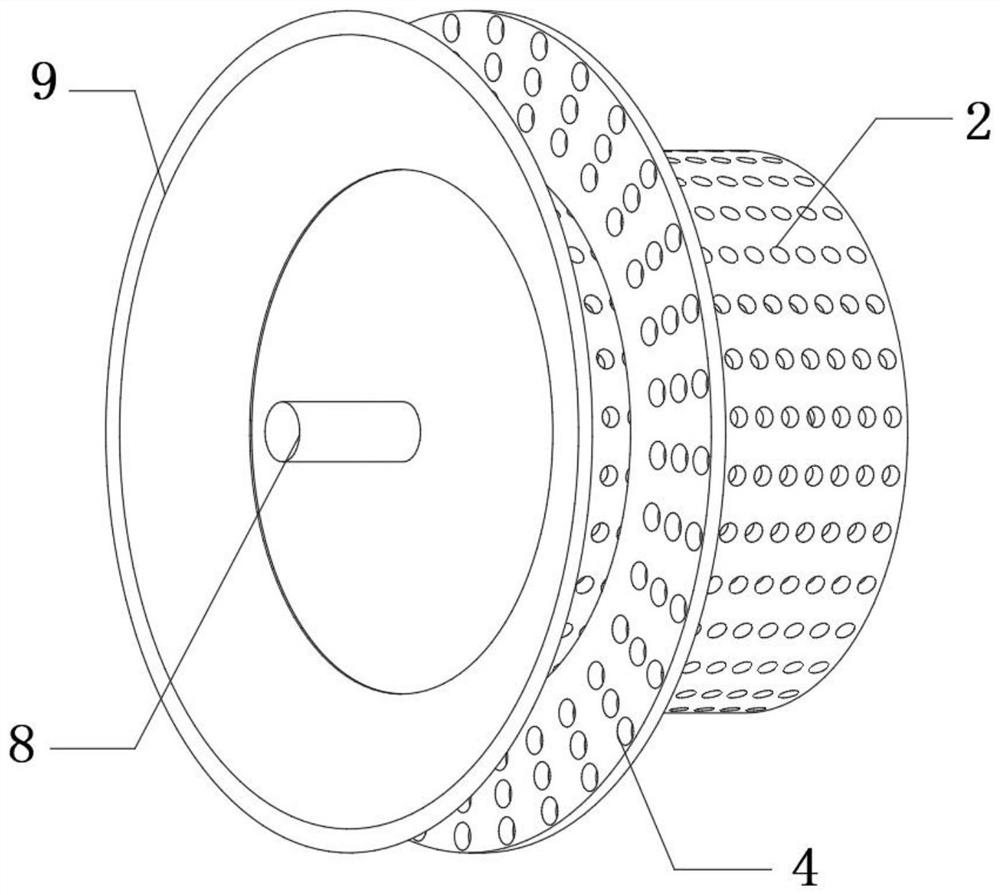

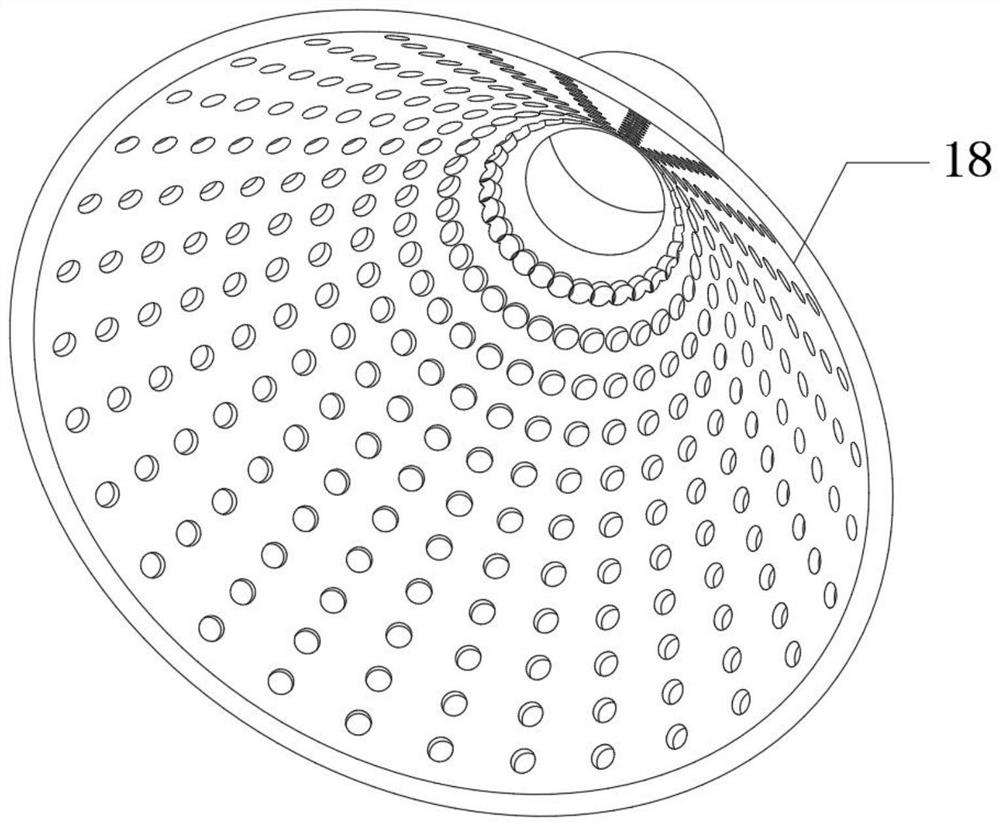

[0025] refer to Figure 1-3 , a particle separation structure and smoke treatment device, including a treatment box 1 and a spray tower 16, the bottom outer wall of the treatment box 1 is fixedly connected with a base 6, and the inner wall of the base 6 is fixedly connected with a motor 7, and the output shaft of the motor 7 passes through The shaft coupling is fixedly connected with the rotating shaft 8, and the outer wall of the rotating shaft 8 is fixedly connected with the screen cylinder 2, the outer wall of the screen cylinder 2 is fixedly connected with the sieve plate 4, and the inner wall of the processing box 1 is fixedly connected with the ring chute 3, the sieve plate 4 Slidingly connected to the inner wall of the circular chute 3, the processing box 1 is provided with a door 22 that can be opened and closed, and the sieve plate 4 can be replaced or cleaned by opening the door 22, and the bottom outer wall of the sieve drum 2 is fixedly connected with a drainage pla...

Embodiment 2

[0034] refer to Figure 1-4 , a particle separation structure and smoke treatment device, including a treatment box 1 and a spray tower 16, the bottom outer wall of the treatment box 1 is fixedly connected with a base 6, and the inner wall of the base 6 is fixedly connected with a motor 7, and the output shaft of the motor 7 passes through The shaft coupling is fixedly connected with the rotating shaft 8, and the outer wall of the rotating shaft 8 is fixedly connected with the screen cylinder 2, the outer wall of the screen cylinder 2 is fixedly connected with the sieve plate 4, and the inner wall of the processing box 1 is fixedly connected with the ring chute 3, the sieve plate 4 Slidingly connected to the inner wall of the circular chute 3, the outer wall of the bottom of the screen cylinder 2 is fixedly connected with a drainage plate 9, and the drainage plate 9 is a ring structure, and the outer wall of the treatment box 1 near the bottom of the drainage plate 9 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com