Casting waste water neutralization device

A technology for waste water and waste water pools, applied in the field of machinery, can solve the problems of substandard discharge, lack of real-time performance, inaccurate pH value, etc., and achieve the effect of increasing concentration, reasonable structure design, and increasing neutralization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

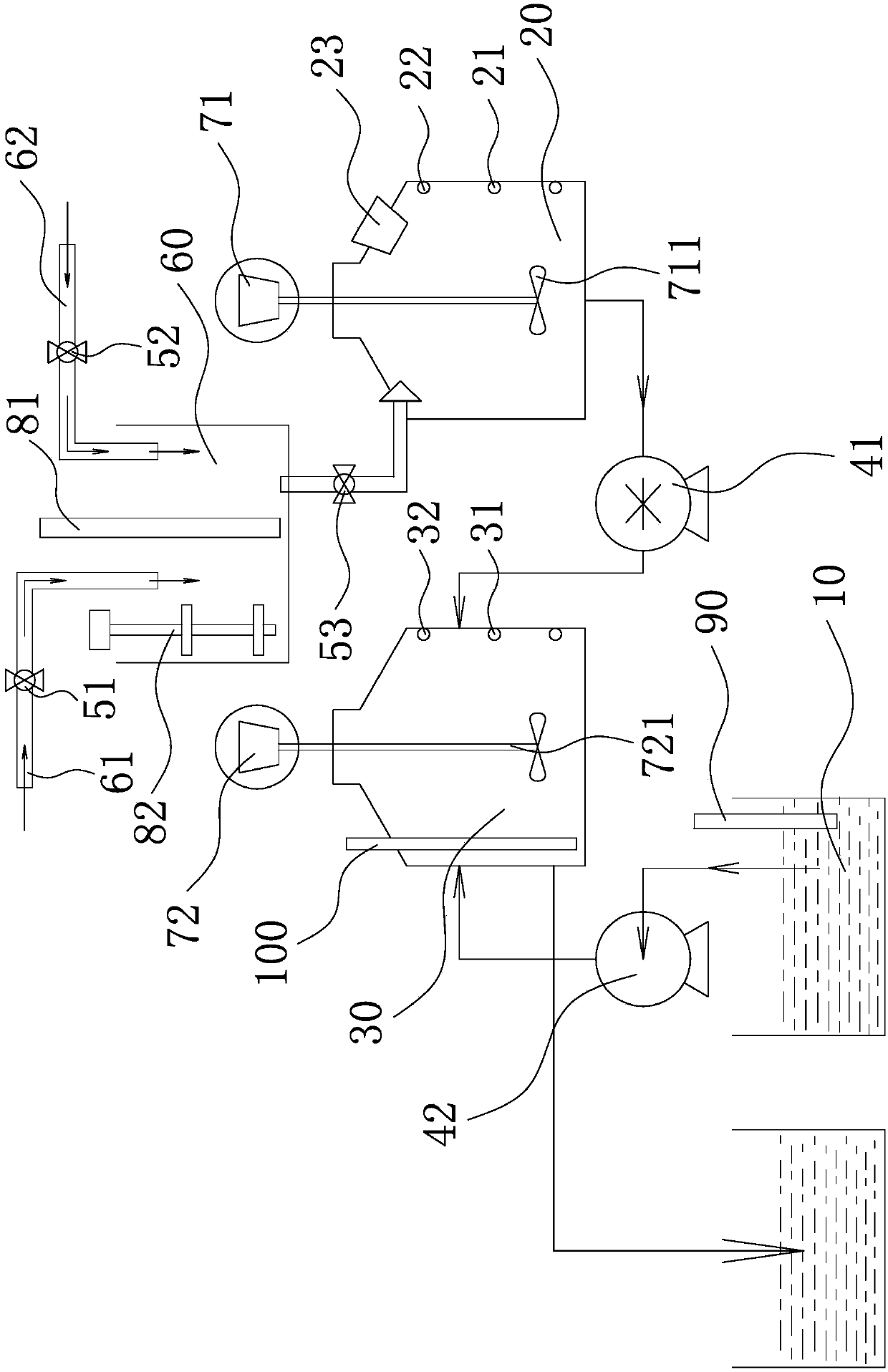

[0021] The following are specific embodiments of the present invention in conjunction with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

[0022] Such as figure 1 As shown, the casting wastewater neutralization device includes:

[0023] Wastewater tank 10, containing acidic wastewater;

[0024] The dissolving tank 20 dissolves alkaline substances to form an alkaline solution;

[0025] The neutralization tank 30 respectively sucks acidic wastewater and alkaline solution from the waste water tank 10 and the dissolution tank 20 for neutralization, and discharges the neutralized solution to the outside. The neutralization tank 30 is provided with a PH value for detecting the pH value. Detector 100;

[0026] The control unit (not shown in the figure) is connected to the PH detector 100 and can control the acid wastewater and alkaline solution to enter the neutralization tank 30....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com