Exhausting structure of papermaking workshop

A workshop and exhaust pipe technology, applied in the field of papermaking, can solve problems such as incompatibility, and achieve the effects of improving neutralization effect, low cost and ingenious conception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments.

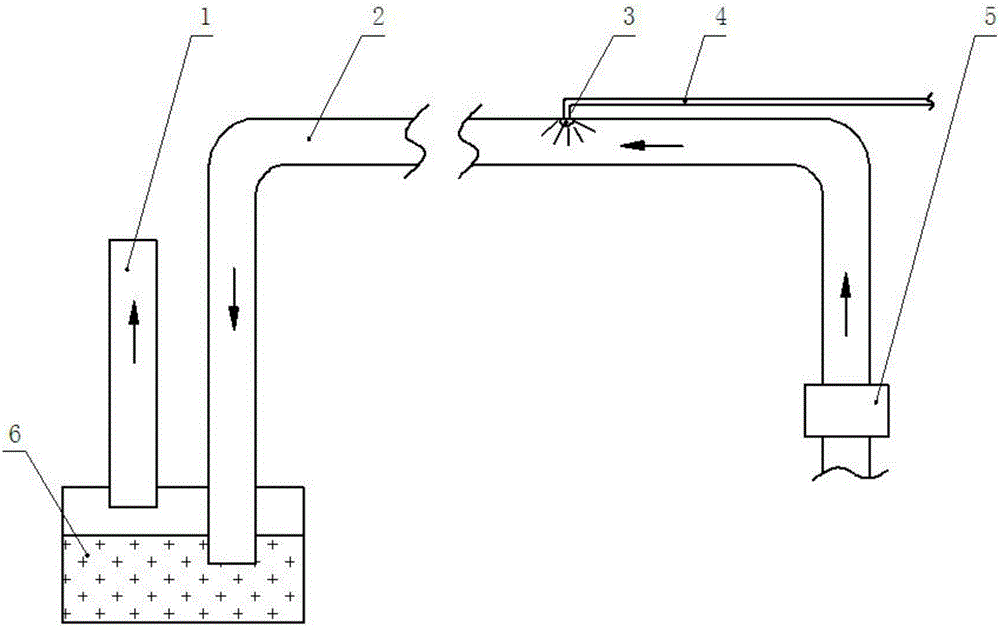

[0015] An exhaust structure of a paper mill, such as figure 1 Shown, comprise lye tank 6, the first exhaust pipeline 2, the second exhaust pipeline 1 and exhaust fan 5, the input end of described first exhaust pipeline connects workshop, the output end connects lye tank, is positioned at the input end An exhaust fan is installed on the first exhaust pipe, and the sour and smelly gas in the workshop is discharged into the lye tank through the exhaust fan. Neutralize, and then the gas is discharged through the second exhaust pipe that is sealed and communicated at the top of the lye tank, figure 1 The middle arrow is the gas flow direction. The structure effectively neutralizes the sour smell in the workshop gas through the lye, and is low in cost and easy to implement, so that people can breathe fresh air.

[0016] In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com