Alginate dentifrice composition and preparation method thereof

A technology of dentifrice and composition, which is applied in the field of alginate dentifrice composition and its preparation, can solve problems such as astringent taste of oral care products, interfere with foaming and cleaning, and reduce the beneficial effect of zinc, and achieve protection against Oxidation and antibacterial effect, prevention of pulp damage, effect of prevention of tooth decay and periodontal disease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

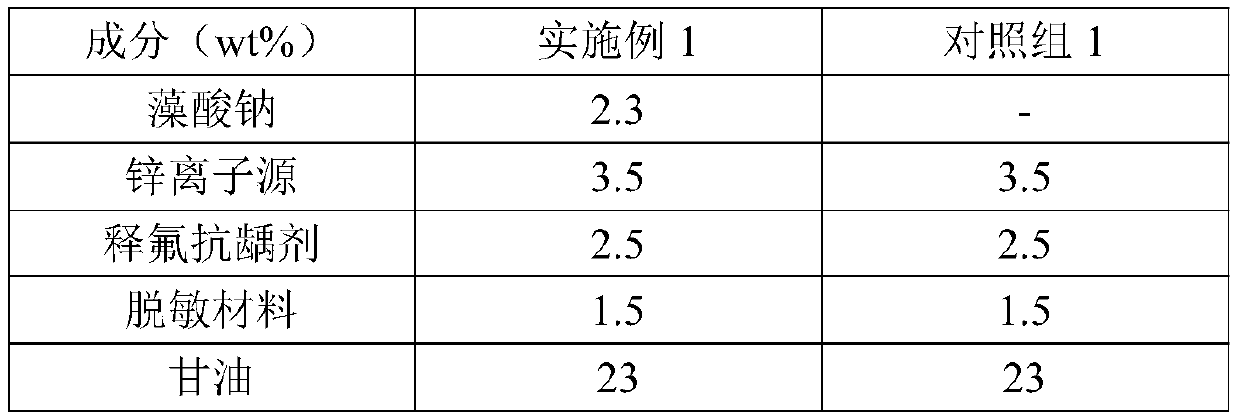

Embodiment 1

[0074] The alginate dentifrice composition, based on the total weight of the composition, comprises: 2.3wt% of sodium alginate, 3.5wt% of zinc ion source, 2.5wt% of fluorine-releasing and anti-caries agent, 1.5wt% of sensitive material, 23wt% glycerin, 18wt% calcium carbonate, 10wt% sodium lauryl isethionate, 4.5wt% tea saponin, 15wt% carboxymethyl cellulose, 8wt% dipotassium glycyrrhizinate, 0.8wt% ethanol and 11.9wt% water, the zinc ion source is a mixture of zinc citrate and zinc lactate with a mixing weight ratio of 4:6.

[0075] The preparation method of above-mentioned alginate dentifrice composition, comprises the following steps:

[0076] 1) Using zirconium oxychloride octahydrate as the zirconium source, using yttrium nitrate hexahydrate as the stabilizer, using sodium metasilicate and glycerophosphate as the precipitating agent, using ammonium fluorozirconate as the fluorine source, adding ammonia water to adjust the pH to 10, After stirring and mixing for 35 minute...

Embodiment 2

[0084] The alginate dentifrice composition, based on the total weight of the composition, includes: 2.55wt% calcium alginate, 3.55wt% zinc ion source, 2wt% fluorine releasing anti-caries agent, 2.5wt% desensitization Material, 18wt% glycerin, 13wt% calcium carbonate, 13wt% sodium lauryl isethionate, 4wt% tea saponin, 18wt% carboxymethyl cellulose, 10wt% dipotassium glycyrrhizinate, 1.5wt % ethanol and 11.9wt% water, the zinc ion source is a mixture of zinc citrate and zinc chloride with a mixing weight ratio of 1.5:1.

[0085] The difference between the preparation method of composition and Example 1 in this embodiment is:

[0086]Step 2) Dissolving dodecylamine in an ethanol solution with a volume concentration of 80%, then adding tetraethyl orthosilicate, calcium nitrate tetrahydrate and triethyl phosphate, bathing in water at 45°C for 165min to form an emulsion, and then aging After melting for 16 hours, wash the obtained precipitate twice with deionized water, freeze-dry ...

Embodiment 3

[0089] The alginate dentifrice composition, based on the total weight of the composition, comprises: 2.3wt% of sodium alginate, 3.5wt% of zinc ion source, 2.5wt% of fluorine-releasing and anti-caries agent, 1.5wt% of sensitive material, 13wt% glycerin, 10wt% calcium carbonate, 10wt% sodium lauryl isethionate, 2.5wt% tea saponin, 10wt% carboxymethyl cellulose, 5wt% dipotassium glycyrrhizinate, The ethanol of 0.8wt%, the calcium chlorite of 2.5wt%, the betaine of 1.5wt%, the menthol of 1.5wt% and the water of 33.4wt%, the above-mentioned zinc ion source is the citric acid that mixing weight ratio is 4:6 A mixture of zinc and zinc lactate.

[0090] The difference between the preparation method of composition in the present embodiment and embodiment 1 is:

[0091] Step 5): taking sodium alginate, zinc citrate and zinc lactate, fluorine-releasing anti-caries agent, desensitizing material, calcium carbonate, calcium chlorite, betaine and menthol in proportion by weight and mixing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com