Static elimination device and method for reducing static residue on surface of wafer

A static elimination device and static elimination technology, applied in the direction of static electricity, electrical components, etc., can solve the problem of residual static electricity on the wafer surface, achieve the effect of eliminating static electricity and improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

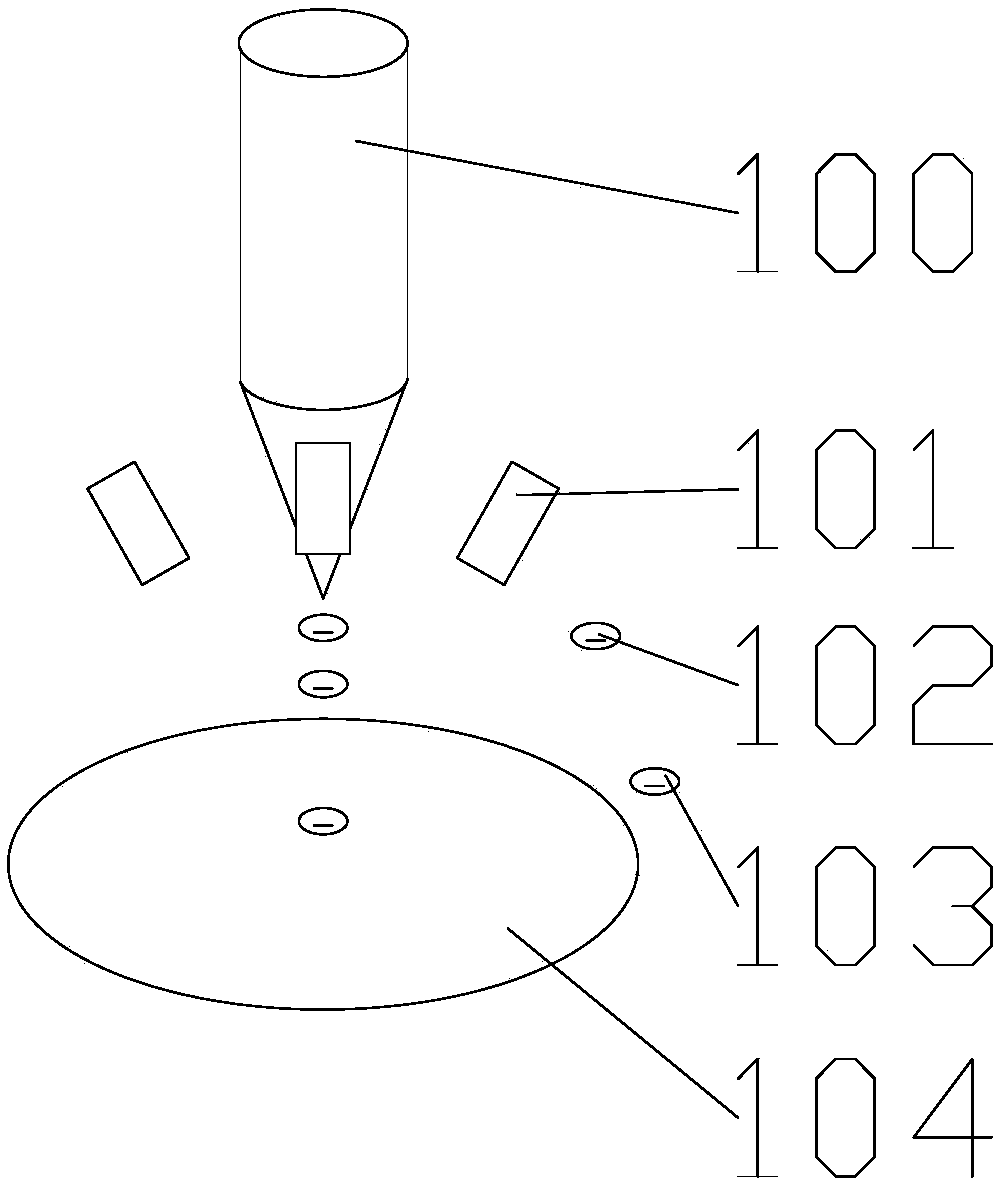

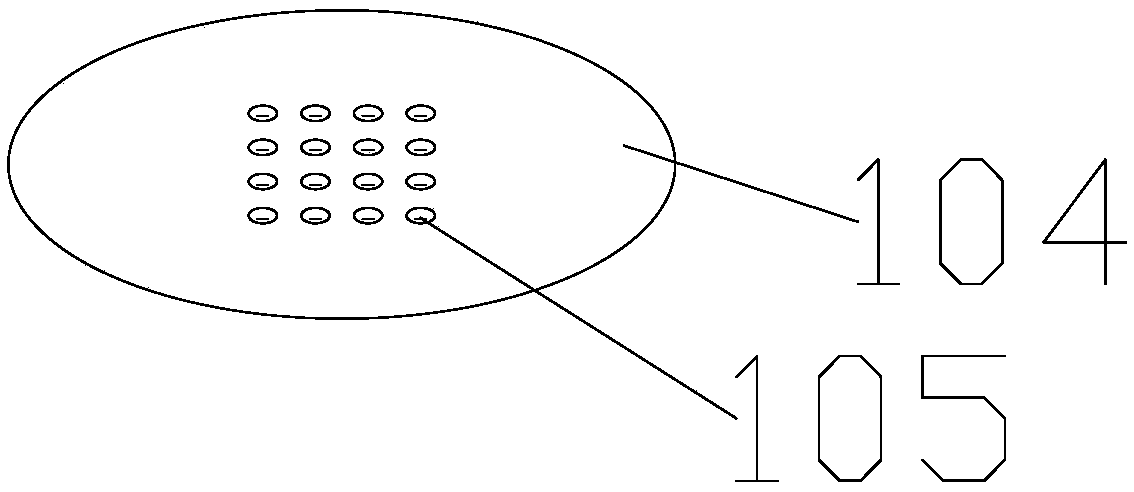

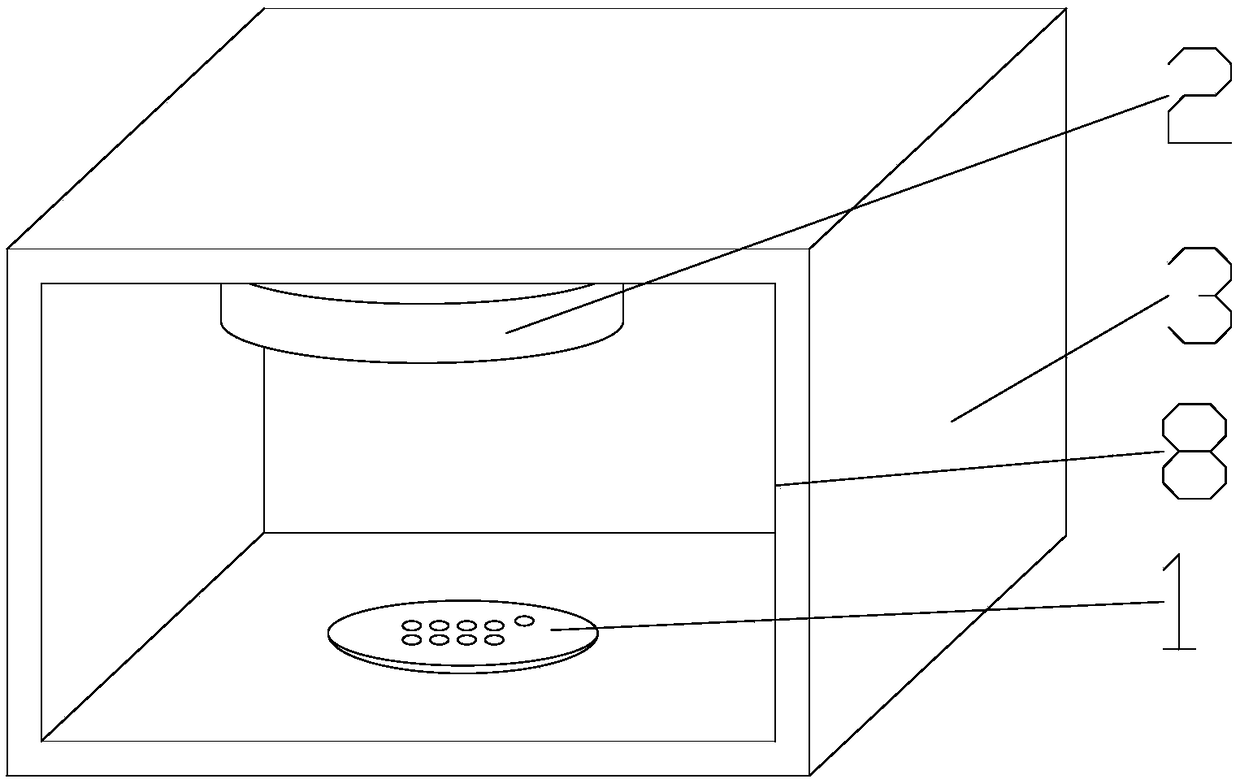

[0031] image 3 , is a schematic structural diagram of a static eliminator provided in Embodiment 1 of the present invention, please refer to image 3 . A static elimination device for eliminating static residue on the surface of a wafer 1, the static elimination device includes a static elimination unit 2 and an accommodation unit 3, and the interior of the accommodation unit 3 has a device for accommodating the wafer 1. The accommodating cavity of the circle 1, the accommodating unit 3 is provided with at least one opening 8 communicating with the accommodating cavity, the opening 8 is used to store the wafer 1, and the static elimination unit 2 is fixedly connected In the accommodating chamber, the static elimination unit 2 is used to provide ionized positive and negative ions to eliminate static electricity on the wafer 1 in a non-vacuum environment. The positive and negative charged ions formed by the ionization of the static elimination unit 2 neutralize the residual s...

Embodiment 2

[0041] Figure 7 , is a schematic structural diagram of a static eliminator provided in Embodiment 2 of the present invention, please refer to Figure 7 , the difference from Embodiment 1 is that: the number of the openings 9 is two, the accommodating unit 3 is opened along the first direction to form two through openings 9, and the static eliminator also includes a The conveyor belt 15 unit 7 for transporting the wafer 1 and the control unit for controlling the conveyor belt 15 unit 7, the conveyor belt 15 unit 7 includes a conveyor belt 15 and a motor 16, and the control unit includes a photoelectric sensor 17 and PLC controller, the conveyor belt 15 is a transparent material, the motor 16 is used to drive the conveyor belt 15 to move, and the photoelectric sensor 17 is located at the conveyor belt near the end of the journey of the conveyor belt 15 unit 7 15, the input end of the photoelectric sensor 17 is used to detect the position of the wafer 1 on the conveyor belt 15,...

Embodiment 3

[0044] The present invention also provides a method for reducing static electricity on the surface of the wafer 1, comprising the following steps: the wafer 1 passes through the above-mentioned static elimination device after being observed by the scanning electron microscope, and the positive and negative charges formed by the ionization of the static elimination unit The ions neutralize the residual static electricity on the surface of the wafer 1 to achieve the purpose of eliminating the residual static electricity on the surface of the wafer 1, and effectively prevent the residual static electricity on the surface of the wafer 1 from affecting the subsequent process, thereby improving the product yield.

[0045] In summary, the present invention provides a static elimination device and a method for reducing static electricity on the surface of a wafer. The static elimination device includes a static elimination unit and an accommodating unit, and the static elimination unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com