Boiler dust removing and conveying system

An ash conveying and boiler technology, which is used in external electrostatic separators, water/sludge/sewage treatment, electrode cleaning, etc. It can solve the effect of affecting anti-corrosion, and cannot accurately calculate the amount of lye added and the timing of lye addition. , The anti-corrosion effect cannot be timely feedback and other problems, so as to reduce the corrosion, improve the anti-corrosion effect, and ensure the protection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

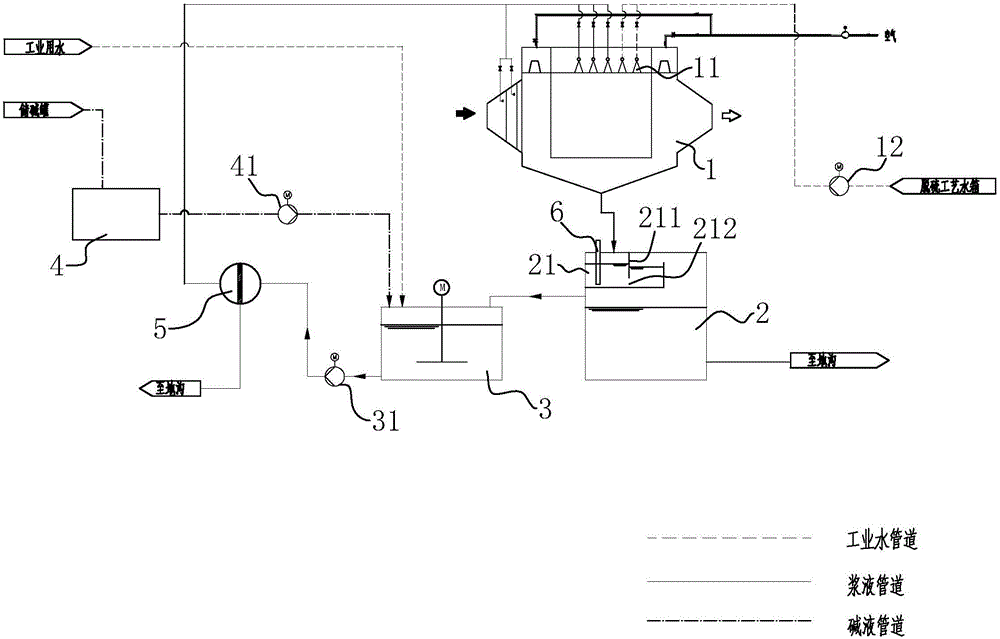

[0035] Embodiment: a kind of boiler dedusting ash conveying system, such as figure 1 As shown, it includes wet electrostatic precipitator 1, circulating water tank 3, drainage tank 2, flushing water tank and lye tank 4.

[0036] Among them, the wet electrostatic precipitator 1 is a horizontal dust collector, the air inlet and the air outlet are respectively arranged at the front and rear ends of the wet electrostatic precipitator 1, and a discharge electrode and a dust collection stage are arranged inside the wet electrostatic precipitator 1, and its working The principle is that the discharge electrode discharges to charge the dust, and the charged dust is adsorbed to the dust collection stage under the action of the electric field force, so that dust, acid mist, water droplets, aerosols, odor, PM2.5 and other harmful substances are separated from the air. For separation, an airflow distribution plate is provided at the air inlet of the wet electrostatic precipitator 1.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com