Iron and steel enterprise wastewater advanced treatment and recycling process

A technology for advanced treatment and waste water, which is applied in metallurgical waste water treatment, water/sewage treatment, biological water/sewage treatment, etc. It can solve the problems of substandard discharge indicators and insufficient consumption, so as to reduce the processing load, achieve high cleanliness, and save energy. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

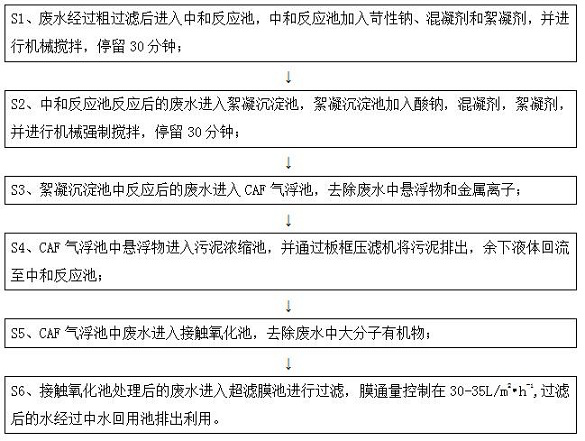

[0025] refer to figure 1 As shown, the present invention provides a kind of iron and steel enterprise wastewater advanced treatment reuse process, comprises the following steps:

[0026] Due to the high content of Fe ions in the wastewater produced by iron and steel plants, the traditional neutralization reaction adopts the method of lime neutralization, which will produce a large amount of residue, so the lime is replaced by caustic soda, and the wastewater enters the neutralization reaction tank after coarse filtration. Add caustic soda, coagulant and flocculant to the reaction tank, and carry out mechanical stirring, and stay for 30 minutes. When the pH value is high, caustic soda is used as a neutralizing agent, which can reduce the amount of residue and improve neutralization efficiency. It can be compared with Fe and Cu ions quickly form hydroxide precipitates, thereby improving the removal rate of the metal ions;

[0027] The wastewater after the reaction in the neutra...

Embodiment 2

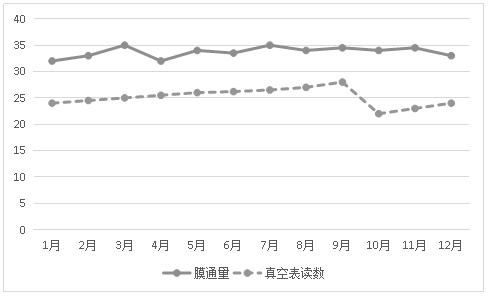

[0035] The difference between this embodiment and other embodiments is that the wastewater treated in the contact oxidation tank enters the ultrafiltration membrane tank for filtration, and the membrane flux is controlled at 31L / m 2 •h -1 , the filtered water is discharged and utilized through the reclaimed water reuse pool;

[0036] Set 10 separate membrane pools in the ultrafiltration membrane pool, the ultrafiltration membrane is immersed in the membrane pool, and the water pump sucks from the water outlet of each membrane pool to make the ultrafiltration membrane generate a vacuum, and push the water in the membrane pool under the vacuum pressure to enter In the membrane, the large particles of pollutants in the sewage are intercepted by the micropores on the surface of the membrane, and the filtered water enters the reclaimed water reuse tank for discharge and utilization;

[0037] The membrane area of the ultrafiltration membrane is 6000m2, the aperture is 0.06um, and...

Embodiment 3

[0041] The difference between this embodiment and other embodiments is that the wastewater treated in the contact oxidation tank enters the ultrafiltration membrane tank for filtration, and the membrane flux is controlled at 33L / m 2 • h -1 , the filtered water is discharged and utilized through the reclaimed water reuse pool;

[0042] Set 10 separate membrane pools in the ultrafiltration membrane pool, the ultrafiltration membrane is immersed in the membrane pool, and the water pump sucks from the water outlet of each membrane pool to make the ultrafiltration membrane generate a vacuum, and push the water in the membrane pool under the vacuum pressure to enter In the membrane, the large particles of pollutants in the sewage are intercepted by the micropores on the surface of the membrane, and the filtered water enters the reclaimed water reuse tank for discharge and utilization;

[0043] The membrane area of the ultrafiltration membrane is 6500m2, the aperture is 0.07um, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com