Preparation method of branched halogenated butyl rubber

A halogenated butyl rubber, butyl rubber technology, applied in the rubber field, can solve the problems of slow stress relaxation, poor processing performance, good damping and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

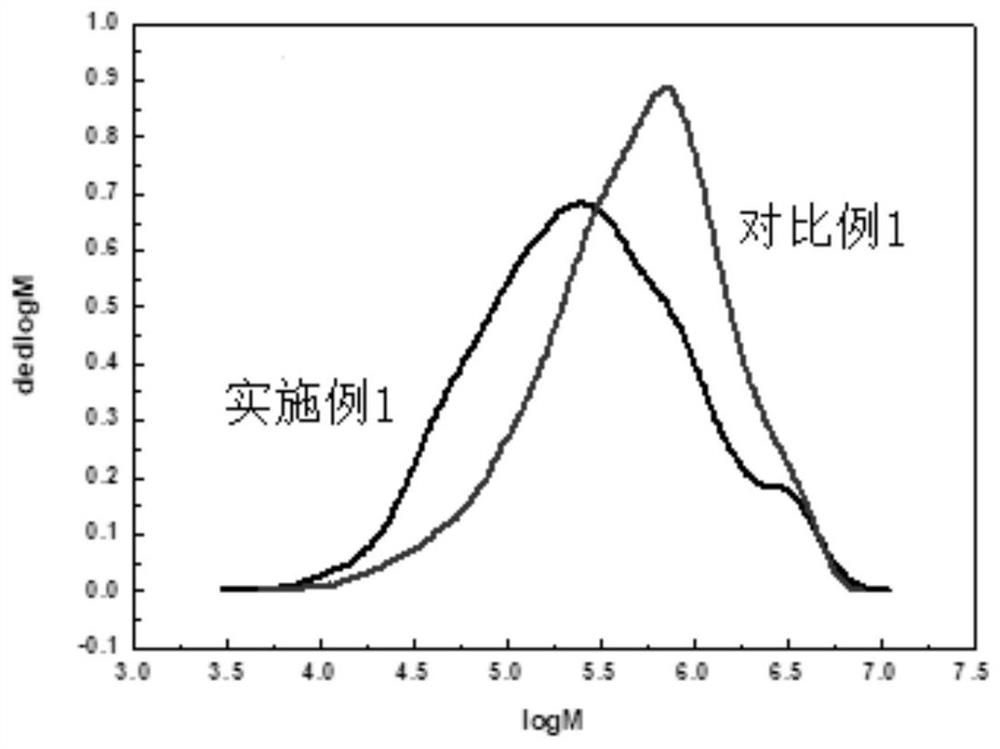

Image

Examples

preparation example Construction

[0033] The invention provides a kind of preparation method of branched halogenated butyl rubber, comprising:

[0034] S1) mixing the isomonoolefin, the conjugated diene and the first diluent to obtain a reactant solution;

[0035] Mixing the branching agent with the second diluent to obtain a branching agent solution;

[0036] S2) Mixing the reactant solution, the branching agent solution and the catalyst solution after low-temperature aging for polymerization reaction to obtain branched butyl rubber; the catalyst solution includes a Lewis acid, a cocatalyst and an aliphatic hydrocarbon;

[0037] S3) mixing branched butyl rubber with aliphatic hydrocarbons to obtain glue;

[0038] S4) mixing the glue solution and the wetting agent evenly, and then reacting it with a halogenating agent under the condition of avoiding light to obtain a reacted emulsion;

[0039] S5) mixing and reacting the reacted emulsion with the acid-binding agent to obtain a reaction solution;

[0040] S6...

Embodiment 1

[0063] 1.1 At -85°C, weigh 40g of isobutene and 1.5g of isoprene into 100g of methylene chloride to obtain a mixed material.

[0064] 1.2 Prepare 50 g of 1 wt % SBS / chloromethane solution, and pass HCl gas for 30 minutes to obtain hydrochloric acid acidified SBS / chloromethane solution.

[0065] 1.3 Add the hydrochloric acid acidified SBS / chloromethane solution obtained in step 1.2 to the mixed material obtained in 1.1, and then add 0.02 g of 1-hexene to obtain a solution to be reacted.

[0066] 1.4 Weigh 0.3g of n-hexane solution (mass fraction: 20%) of ethyl aluminum dichloride, add it to 12g HCl in dichloromethane solution (mass fraction: 0.020wt%), mix well, and age at -97.5°C After 30 min, the catalyst solution was obtained.

[0067] 1.5 Add the catalyst solution in step 1.4 to the solution to be reacted in step 1.3, and react at -97.5°C for 20 minutes. During the polymerization process, the temperature rises slowly, and the obtained slurry is uniformly dispersed in the ...

Embodiment 2

[0077] 2.1 At -85°C, weigh 40g of isobutene and 1.5g of isoprene into 100g of methylene chloride to obtain a mixed material.

[0078] 2.2 Prepare 50 g of 1 wt % SBS / chloromethane solution, and pass HCl gas for 30 minutes to obtain hydrochloric acid acidified SBS / chloromethane solution.

[0079] 2.3 Add the hydrochloric acid acidified SBS / chloromethane solution obtained in step 2.2 to the mixed material to obtain a solution to be reacted.

[0080] 2.4 Weigh 0.3g of n-hexane solution (mass fraction: 20%) of ethyl aluminum dichloride, add it to 12g HCl in dichloromethane solution (mass fraction: 0.020wt%), mix well, and age at -97.5°C After 30 min, the catalyst solution was obtained.

[0081] 2.5 Add the catalyst solution in step 2.4 to the solution to be reacted in step 2.3, and react at -97.5°C for 20 minutes. During the polymerization process, the temperature rises slowly, and the obtained slurry is uniformly dispersed in the form of particles.

[0082] 2.6 Add 2 mL of cold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com