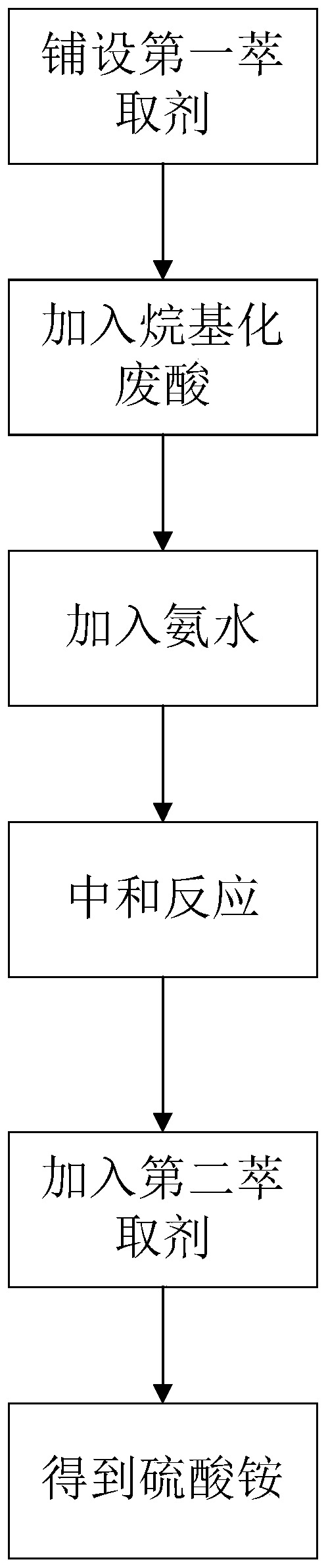

One-step impurity removal method for preparing ammonium sulfate from alkylated waste acid through

A technology of alkylating waste acid and ammonium sulfate, which is applied in the direction of ammonium sulfate, etc., can solve the problems of unable to adsorb and remove the color and odor of ammonium sulfate, easy to block pipes and valves, and reduce product purity, so as to avoid frequent shutdowns The effect of cleaning the pipeline, realizing continuous production and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation of embodiment 1 ammonium sulfate sample 1

[0044] 1) add carbon tetrachloride in the neutralization reaction vessel, submerge the bottom of reaction vessel to carbon tetrachloride solution and form the carbon tetrachloride solution layer that thickness is 20mm;

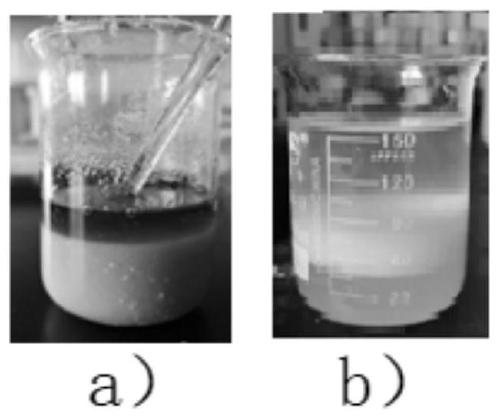

[0045]2) Dilute the alkylated waste acid with an organic content of 10% and add water until the mass concentration of the alkylated waste acid is 30%, to obtain a diluted solution of the spent acid, add the diluted solution of the spent acid to the reaction vessel, and then add 25% of the mass concentration Ammonia, carry out the neutralization reaction at normal temperature and pressure for 15 minutes.

[0046] 3) After the neutralization reaction is completed, add anhydrous methanol solution to the reaction vessel, and add according to the volume ratio of anhydrous methanol solution and waste acid dilution solution at 10:1; after standing for 10 minutes, flow into the centrifuge through the p...

Embodiment 2

[0048] The preparation of embodiment 2 ammonium sulfate sample 2

[0049] 1) Add tetrachlorethylene in the neutralization reaction vessel until the tetrachlorethylene solution submerges the bottom of the reaction vessel and forms a tetrachlorethylene solution layer with a thickness of 30 mm;

[0050] 2) Add water to dilute the alkylated waste acid with an organic content of 13% until the mass concentration of the alkylated waste acid is 30%, to obtain a diluted solution of the spent acid, add the diluted solution of the spent acid to the reaction vessel, and then add 25% of the mass concentration Ammonia, neutralization reaction was carried out at normal temperature and pressure for 10 minutes.

[0051] 3) After the neutralization reaction is completed, add the second extractant solution (mixture of acetone and ethanol in a volume ratio of 1:1) to the reaction vessel, and add it according to the volume ratio of the second extractant solution to the waste acid dilution solution...

Embodiment 3

[0052] The preparation of embodiment 3 ammonium sulfate sample 3

[0053] 1) Add and mix the first extractant (carbon trichloride and chloroform in a volume ratio of 1:1) in the neutralization reaction vessel until the first extractant solution submerges the bottom of the reaction vessel and forms a solution with a thickness of 20-30mm The first extractant solution layer;

[0054] 2) Dilute the alkylation waste acid with an organic content of 10% to 13% with water until the mass concentration of the alkylation waste acid is 30%, to obtain a diluted solution of the spent acid, add the diluted solution of the spent acid to the reaction vessel, and then add the diluted solution with a mass concentration of 25% % ammonia water, carry out the neutralization reaction at normal temperature and pressure for 10 to 15 minutes.

[0055] 3) After the neutralization reaction is completed, add absolute ethanol solution to the reaction vessel, and add according to the volume ratio of absolu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com