Apparatus and method for generating a beam of neutral particles

A particle beam and neutral technology, applied in the direction of discharge tubes, accelerators, electrical components, etc., can solve the problems that cannot meet the etching process, and achieve the effect of improving the neutralization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

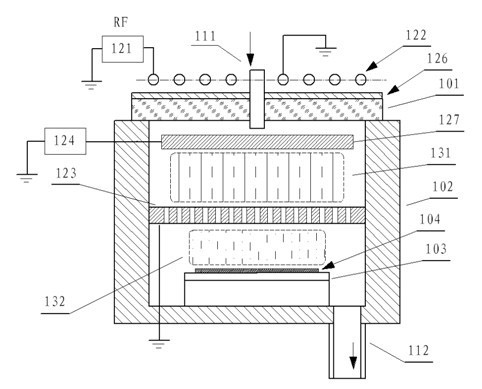

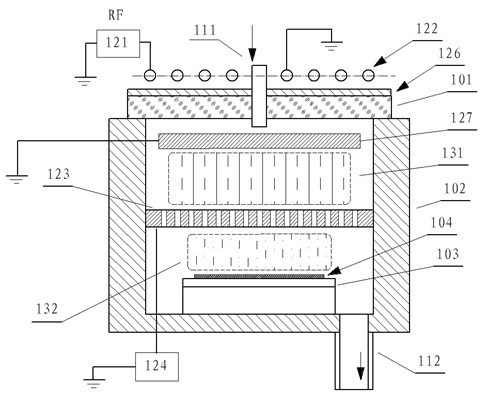

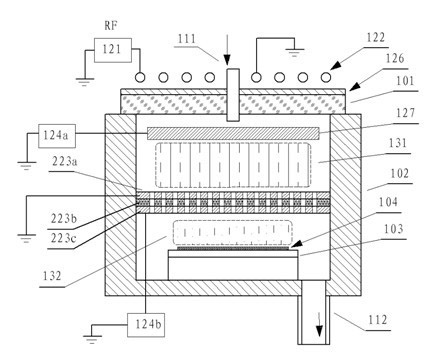

[0027] Such as image 3 As shown, the device for generating a neutral particle beam provided by the embodiment of the present invention includes a reaction chamber 102, an air inlet 111, a radio frequency power supply 121, a planar helical radio frequency coil 122, a Faraday shielding grid 126, a plasma source 131, and an exhaust port 112. The slide table 103, the chip 104, the upper plate 127, the middle plate 223a, the insulating plate 223b and the lower plate 223c. The upper board 127 is disposed above the plasma source 131 . Between the plasma source 131 and the slide stage 103, a middle grid plate 223a, an insulating plate 223b and a lower grid plate 223c are sequentially arranged. The upper board 127 is connected with a DC bias voltage DC1. The mid-screen board 223a is grounded. The lower screen plate 223c is supplied with a DC bias voltage DC2. Cylindrical, hexagonal, rhombic or other shaped holes run through the middle mesh plate 223a, the insulating plate 223b and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com