Treatment method of sulfuric acid method titanium dioxide acid wastewater

A technology for acid wastewater and treatment methods, which is applied in multi-stage water treatment, natural water treatment, neutralized water/sewage treatment, etc., and can solve the problem of the decline in the use efficiency of neutralization aeration tanks, restrictions on titanium dioxide production processes, and sewage treatment efficiency In order to achieve the effects of good aeration effect, efficiency improvement and cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

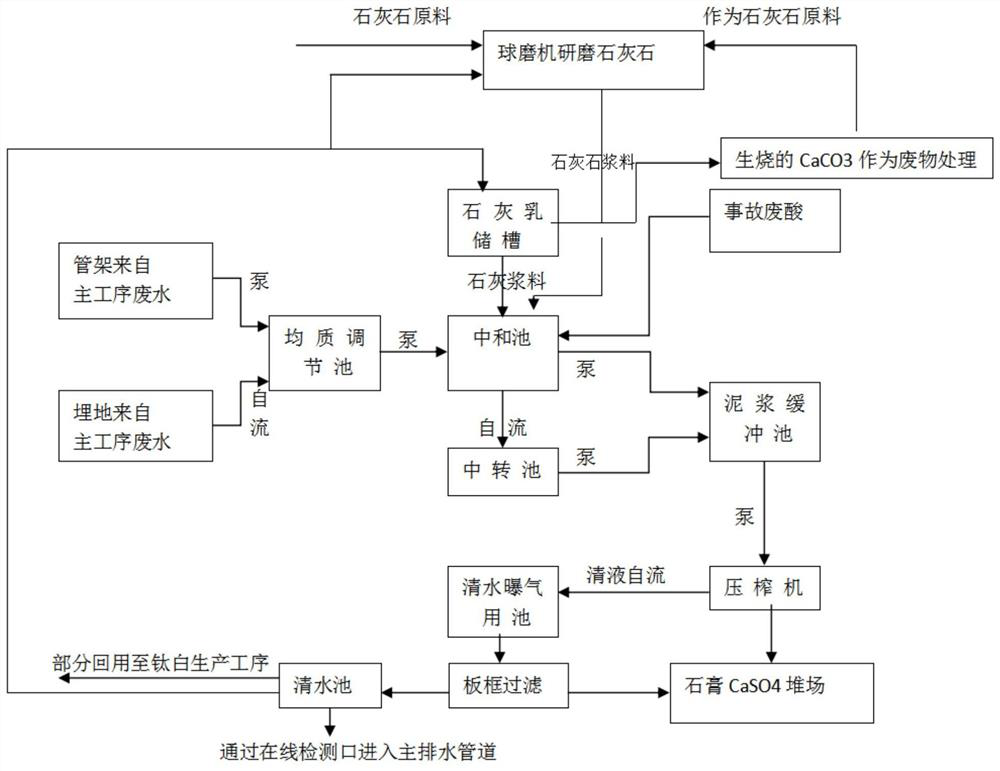

Method used

Image

Examples

Embodiment 1

[0035] A treatment method for sulfuric acid titanium dioxide acid waste water, comprising the following steps:

[0036] Under S1 stirring treatment, the mixed solution of acidic wastewater and clear water containing 3% to 8% sulfuric acid flows into the neutralization tank by gravity, and pumps limestone slurry for the first stage of neutralization. The pH of the reaction end point is 4.0 to 5.0. Among them, the ratio of acid wastewater to clean water is 1:25; the stirring speed is 40r / min.

[0037] S2 continues to stir, pumps in the digested lime slurry for the second stage of neutralization, and the pH at the end of the reaction is 7.0-8.5 to obtain a reaction slurry. Among them, the preparation method of lime slurry is as follows: after the lime is processed by a lime machine or a ball mill, it is mixed with digested water, and the water temperature is 30-40°C to obtain a lime slurry; the part of the lime that has not been digested by the digested water enters the ball mill...

Embodiment 2

[0041] A treatment method for sulfuric acid titanium dioxide acid waste water, comprising the following steps:

[0042] Under S1 stirring treatment, the mixed solution of acidic wastewater and clear water containing 3% to 8% sulfuric acid flows into the neutralization tank by gravity, and pumps limestone slurry for the first stage of neutralization. The pH of the reaction end point is 4.0 to 5.0. Among them, the ratio of acid wastewater to clean water is 1:40; the stirring speed is 45r / min.

[0043] S2 continues to stir, pumps in the digested lime slurry for the second stage of neutralization, and the pH at the end of the reaction is 7.0-8.5 to obtain a reaction slurry. Among them, the preparation method of lime slurry is as follows: after the lime is processed by a lime machine or a ball mill, it is mixed with digested water, and the water temperature is 30-40°C to obtain a lime slurry; the part of the lime that has not been digested by the digested water enters the ball mill...

Embodiment 3

[0047] A treatment method for sulfuric acid titanium dioxide acid waste water, comprising the following steps:

[0048] Under S1 stirring treatment, the mixed solution of acidic wastewater and clear water containing 3% to 8% sulfuric acid flows into the neutralization tank by gravity, and pumps limestone slurry for the first stage of neutralization. The pH of the reaction end point is 4.0 to 5.0. Among them, the ratio of acid wastewater to clean water is 1:35; the stirring speed is 60r / min.

[0049]S2 continues to stir, pumps in the digested lime slurry for the second stage of neutralization, and the pH at the end of the reaction is 7.0-8.5 to obtain a reaction slurry. Among them, the preparation method of lime slurry is as follows: after the lime is processed by a lime machine or a ball mill, it is mixed with digested water, and the water temperature is 30-40°C to obtain a lime slurry; the part of the lime that has not been digested by the digested water enters the ball mill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com