Plasma etching method and plasma etching apparatus

a plasma etching and plasma technology, applied in the direction of electrical equipment, decorative arts, electric discharge tubes, etc., can solve the problems of difficult to achieve uniform line width cd (critical dimension) and line height, and the inability to perform an etching process with high uniform line width of lines formed on the wafer, and achieve high uniformity in cross sectional shapes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

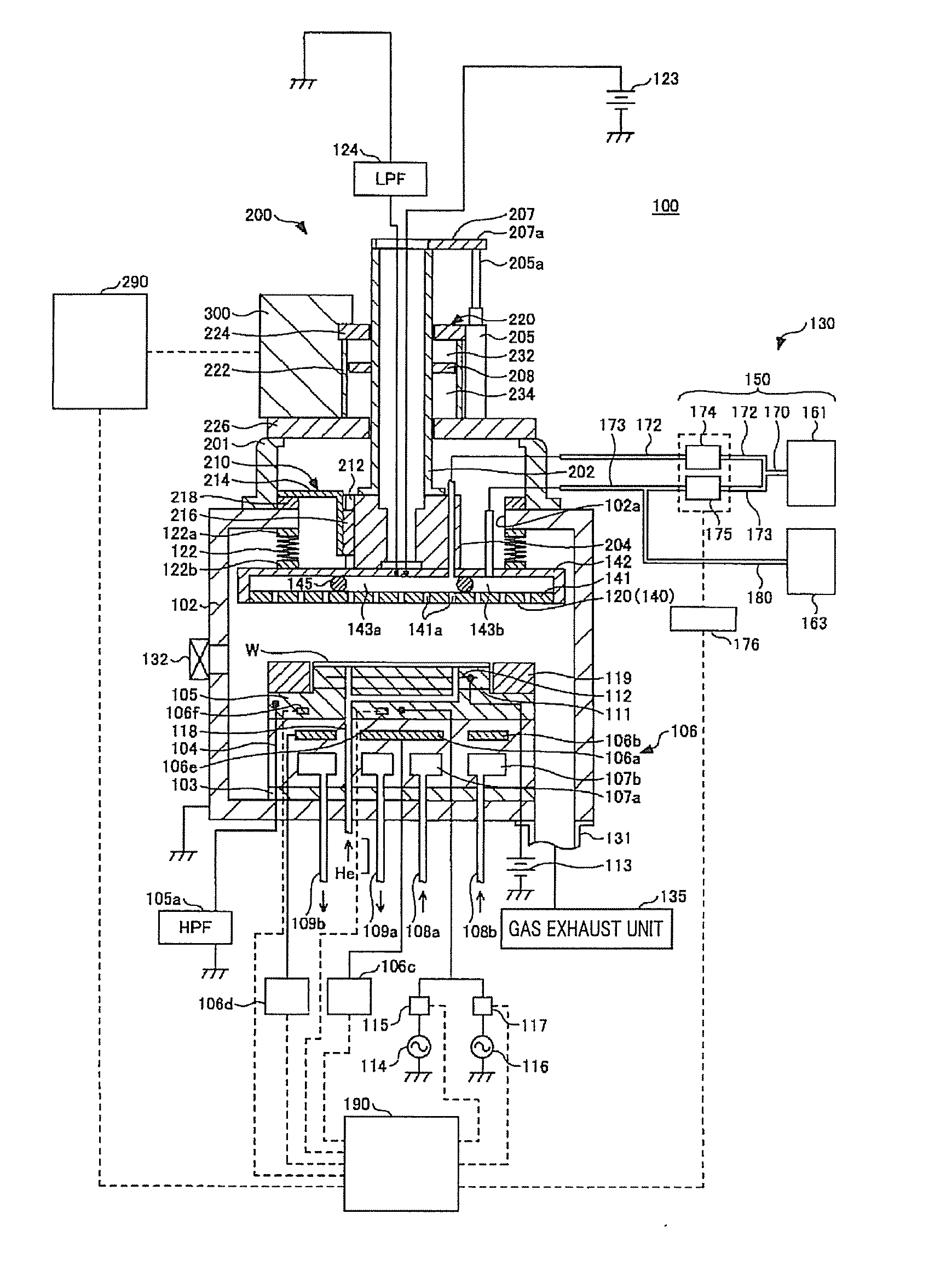

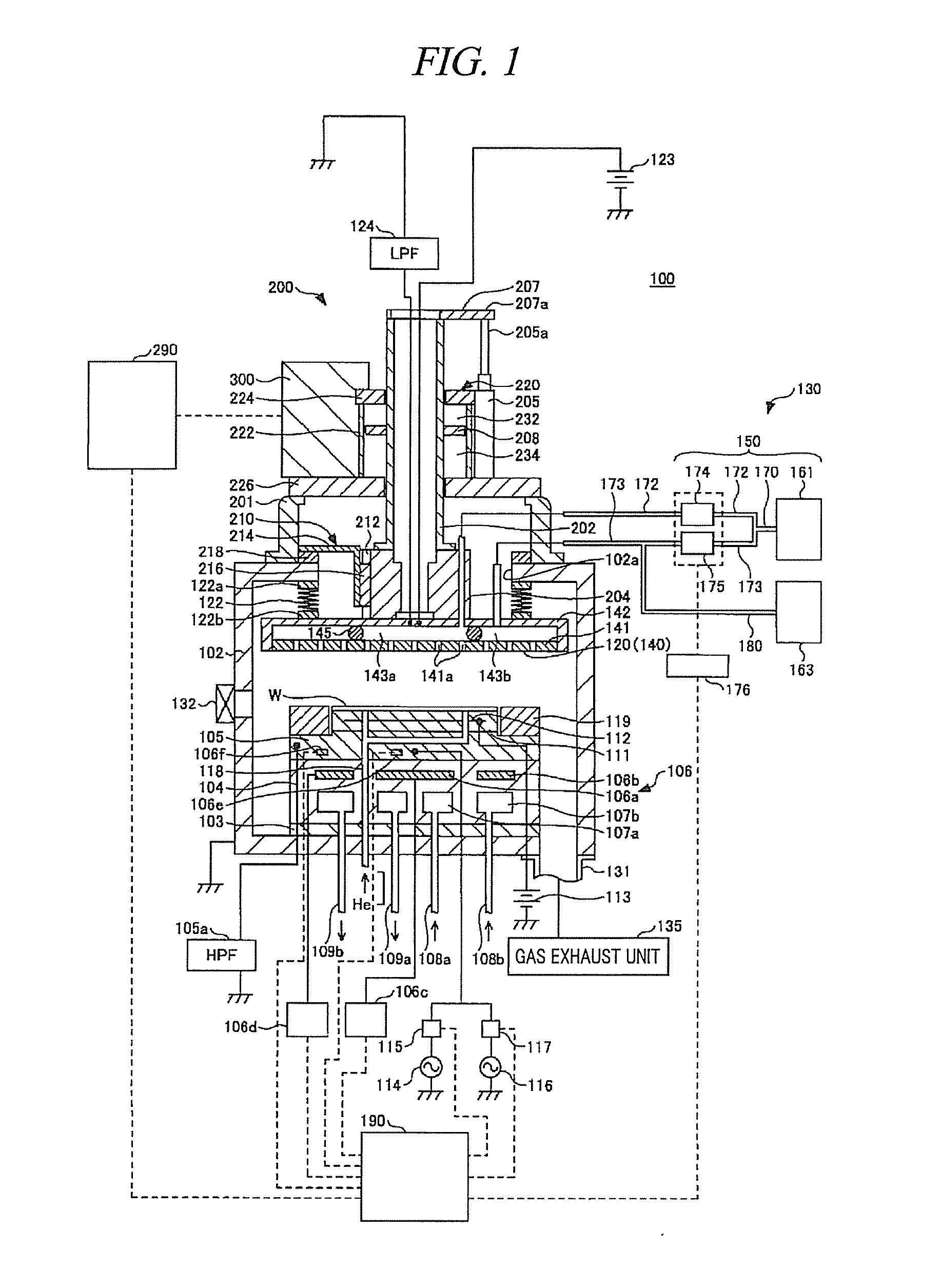

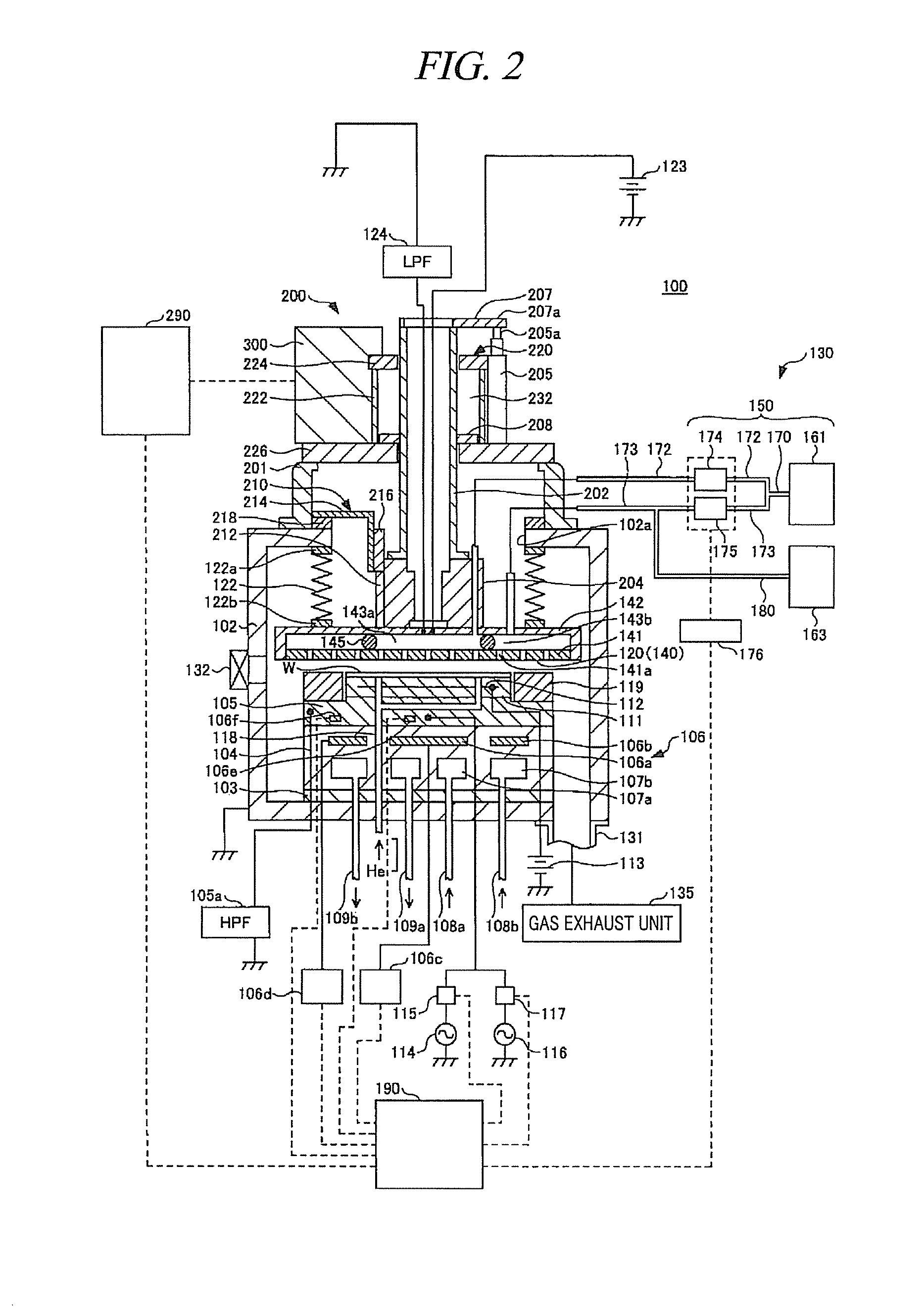

[0041]Referring to FIGS. 1 to 10D, a plasma etching method and a plasma etching apparatus in accordance with a first embodiment of the present disclosure will be explained.

[0042]First of all, referring to FIGS. 1 and 2, a plasma etching apparatus in accordance with the present embodiment will be explained. FIGS. 1 and 2 are cross sectional views showing schematic configurations of the plasma etching apparatus in accordance with the present embodiment. FIG. 1 shows a configuration in which an upper electrode is located at a retreat position, and FIG. 2 shows a configuration in which the upper electrode is located at a process position.

[0043]A plasma etching apparatus 100 in accordance with the present embodiment is configured as a parallel plate type plasma etching apparatus, for example.

[0044]The plasma etching apparatus 100 includes a cylindrical chamber (processing vessel) 102 made of, for example, aluminum of which surface is anodically oxidized (alumite treated). The chamber 102...

modification example of first embodiment

[0191]Hereinafter, a plasma etching method and a plasma etching apparatus in accordance with a modification example of the first embodiment will be explained.

[0192]The present modification example is different from the first embodiment in that when an organic film is etched, a processing gas having a high adhesion coefficient and having radicals of a high reaction rate is used in a second mask film etching process.

[0193]In the present modification example, the plasma etching apparatus explained with reference to FIGS. 1 to 5 may be used, as in the first embodiment. Further, as the first embodiment, a plasma etching method in accordance with the present modification example also includes a resist pattern forming process (step S11), an anti-reflective coating etching process (step S12), a second mask film etching process (step S13), a first mask film etching process (step S14), and an etching target film etching process (step S15) explained with reference to FIG. 6. Furthermore, a waf...

second embodiment

[0206]Hereinafter, referring to FIGS. 11 to 15, a plasma etching method and a plasma etching apparatus in accordance with a second embodiment of the present disclosure will be explained.

[0207]The present embodiment is different from the first embodiment in that a distribution of a gas supply amount in a wafer surface is not adjusted and a pattern to be formed does not have a sparse area but only has a dense area.

[0208]Referring to FIGS. 11 to 15, the plasma etching apparatus in accordance with the present embodiment will be elaborated. FIGS. 11 and 12 are cross sectional views showing a schematic configuration of the plasma etching apparatus in accordance with the present embodiment. To be specific, FIG. 11 shows a configuration in which an upper electrode is located at a retreat position, and FIG. 12 shows a configuration in which the upper electrode is located at a process position. FIGS. 13a and 13b provide explanatory diagrams simply showing an upper electrode driving unit. To b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| DC voltage | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com