Patents

Literature

82results about How to "Reduce Surface Contamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

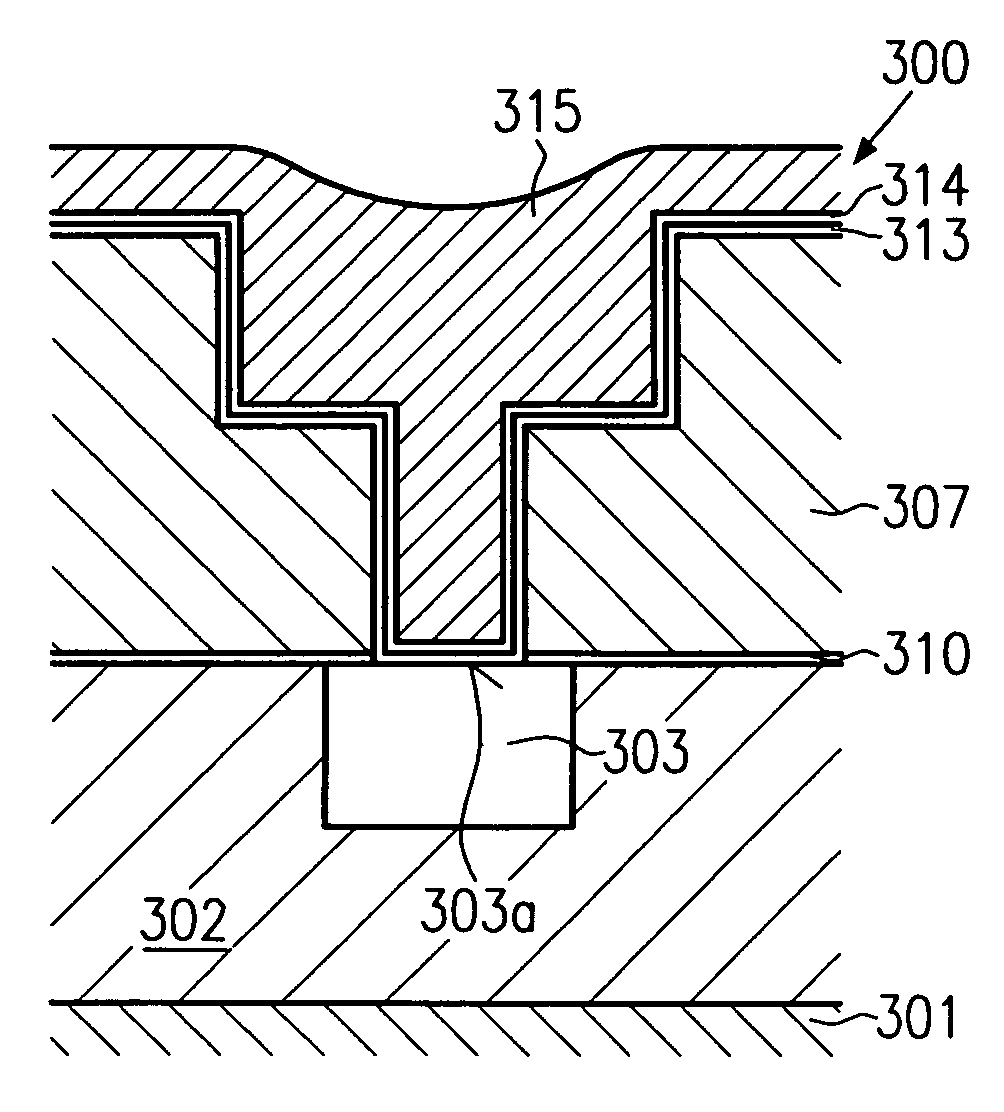

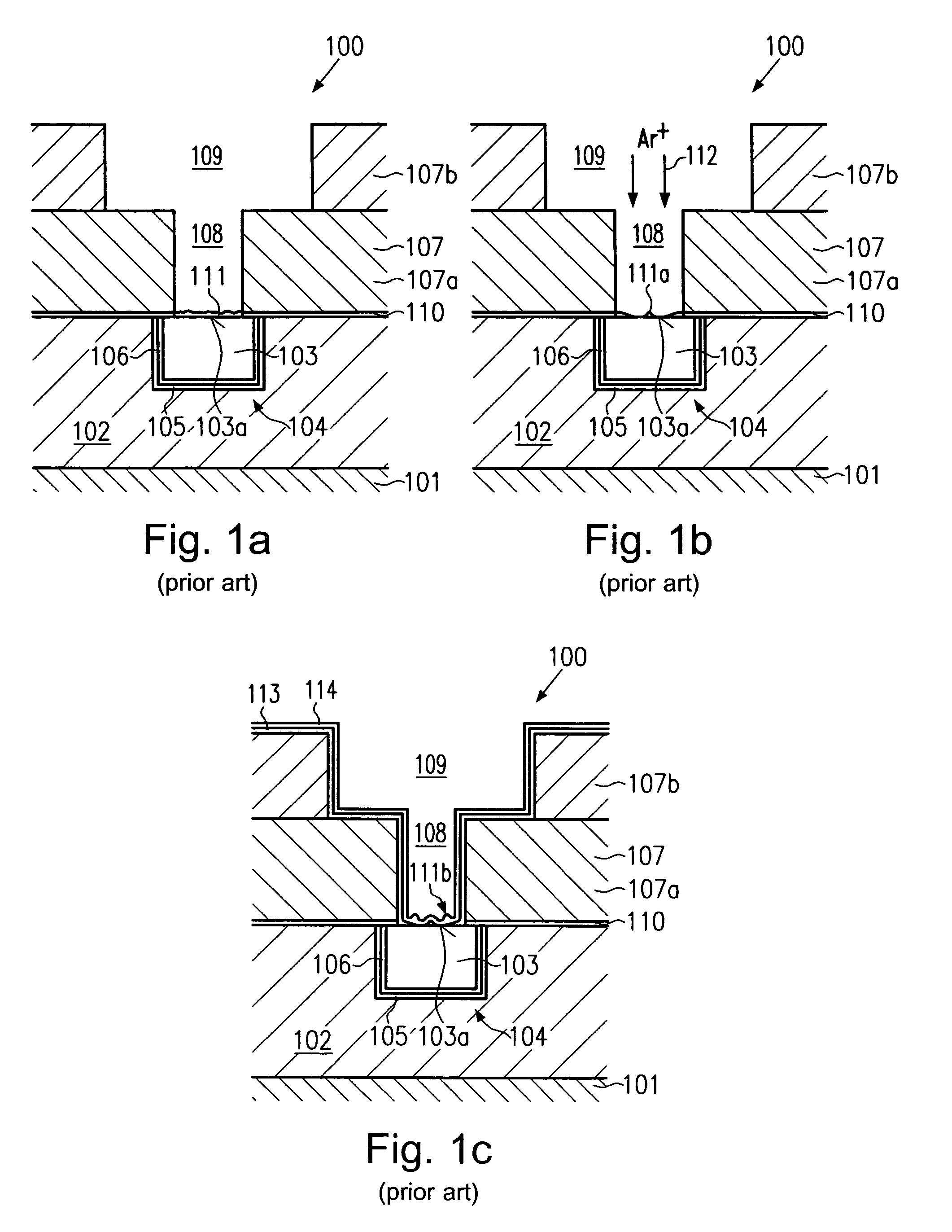

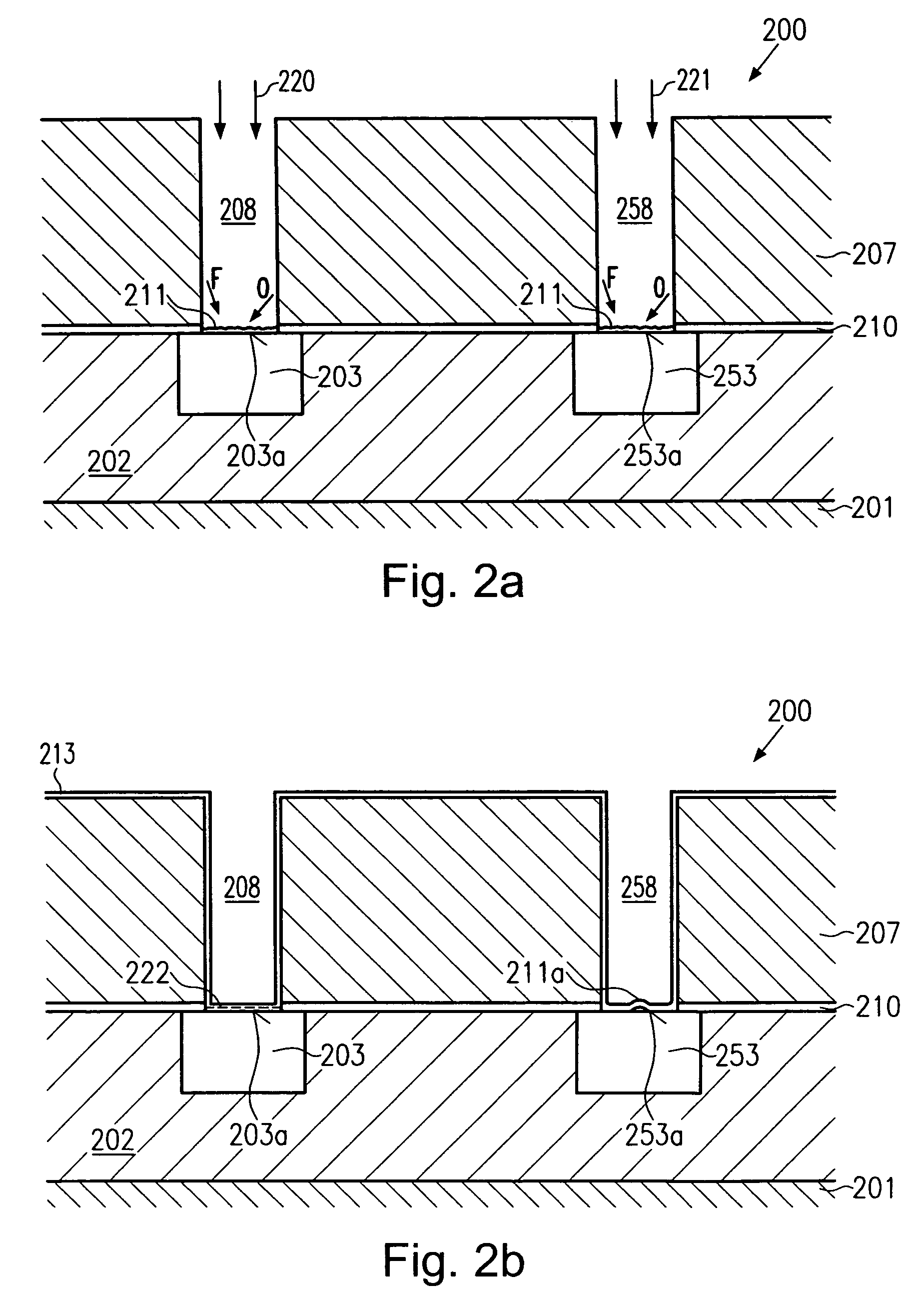

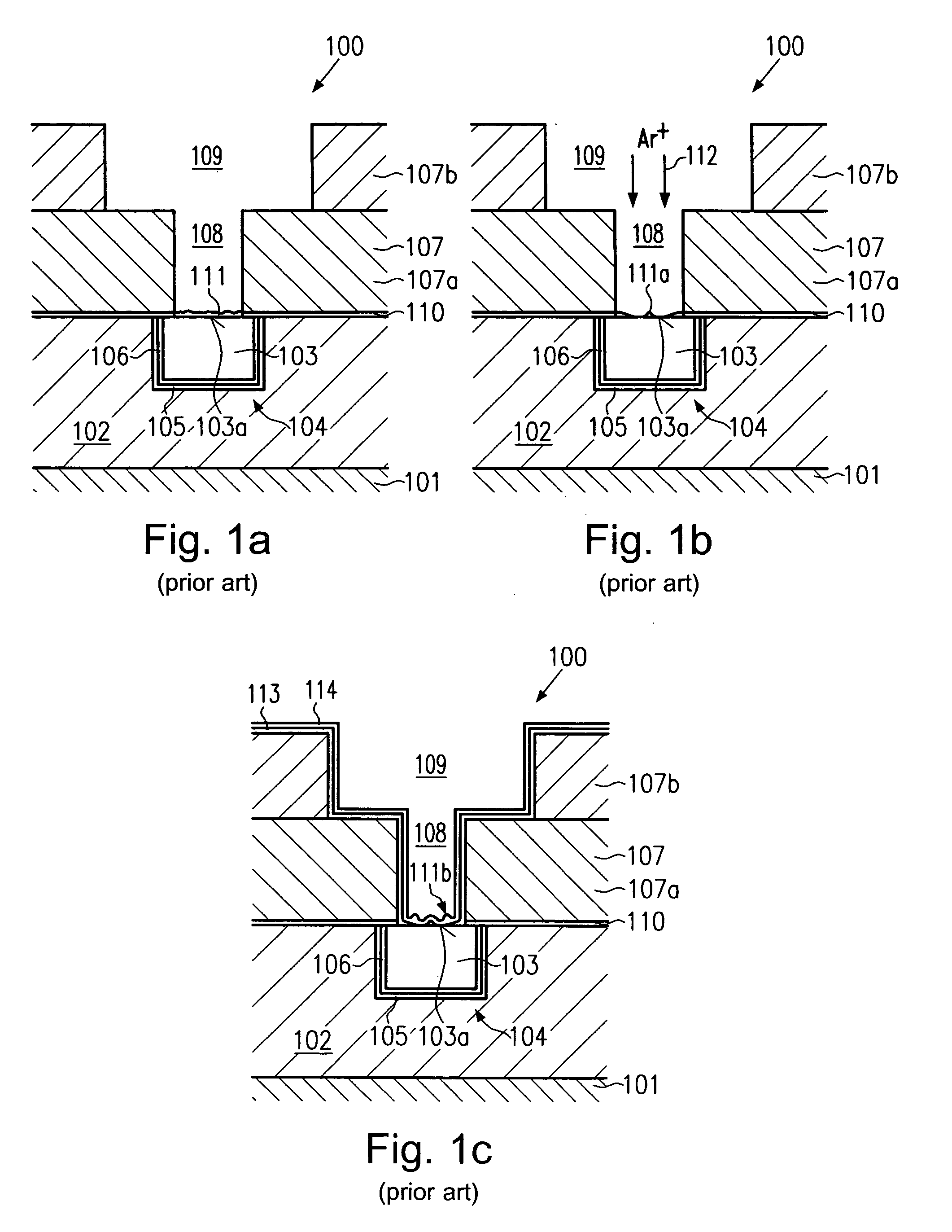

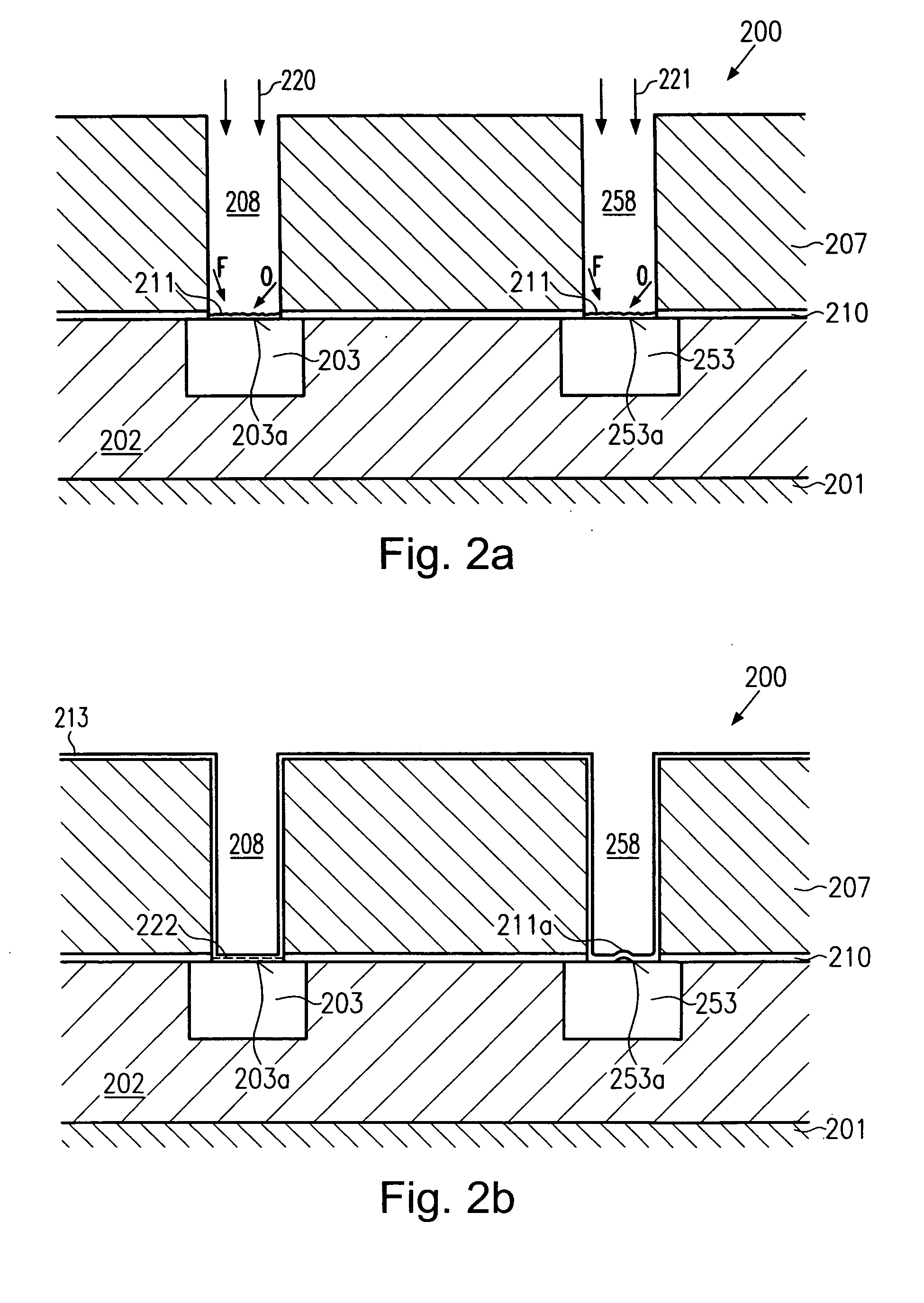

Technique for forming a passivation layer prior to depositing a barrier layer in a copper metallization layer

ActiveUS7259091B2Reduce violationsSimple structureSemiconductor/solid-state device manufacturingCopperContamination

Owner:ADVANCED MICRO DEVICES INC

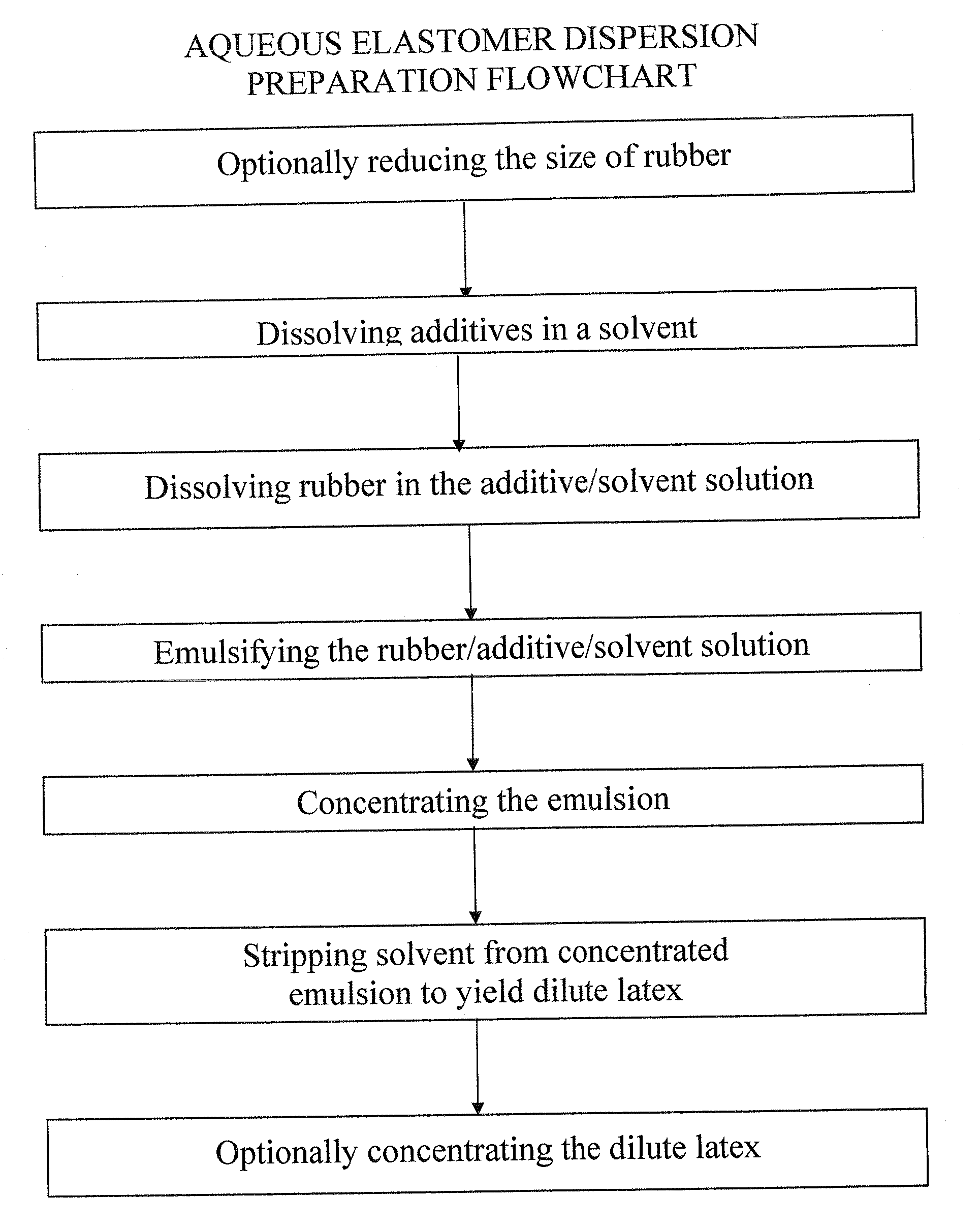

Water-based resin composition and articles made therefrom

InactiveUS20090234064A1Well formedLess surfactant/emulsifierGroup 4/14 element organic compoundsSpecial tyresElastomerWater based

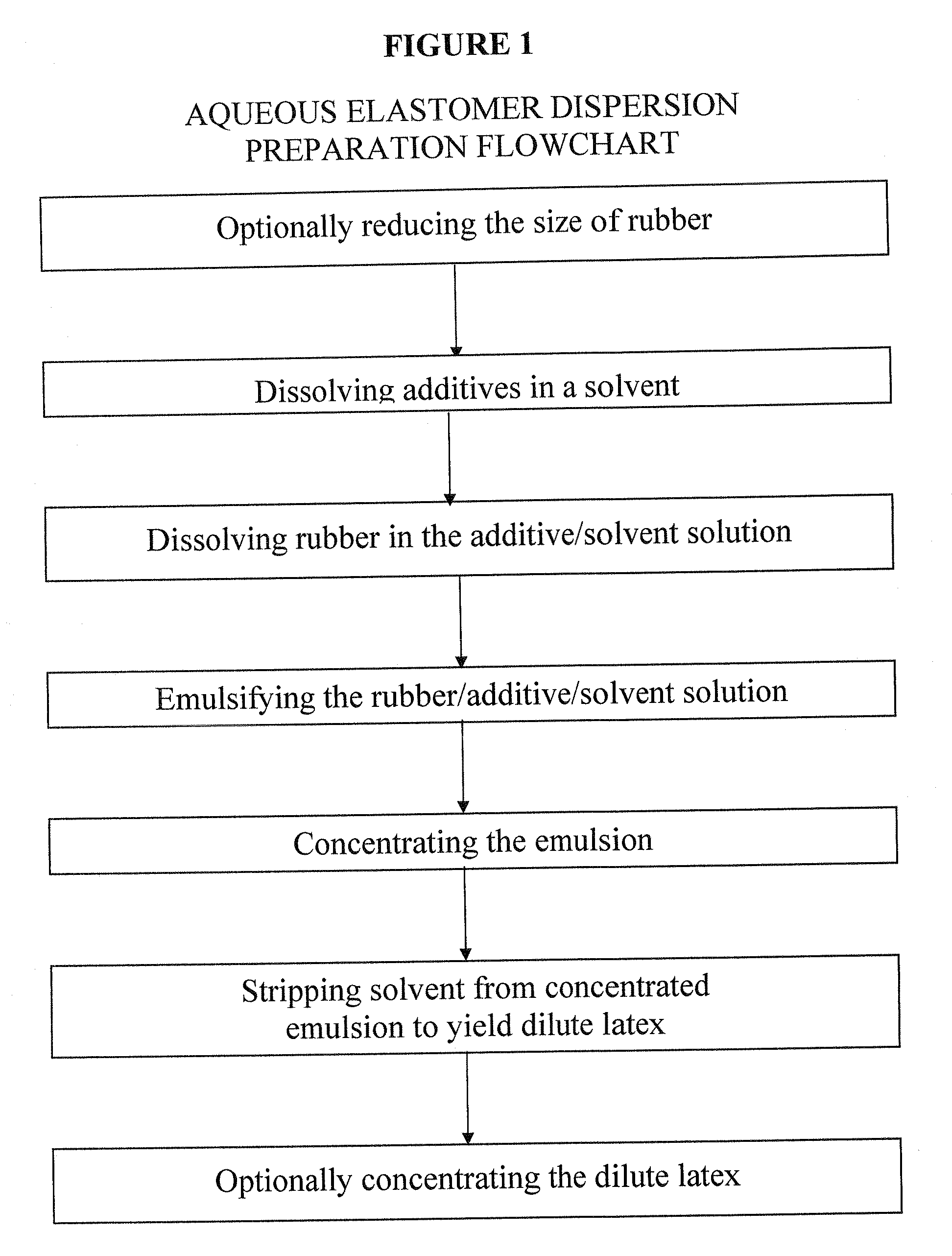

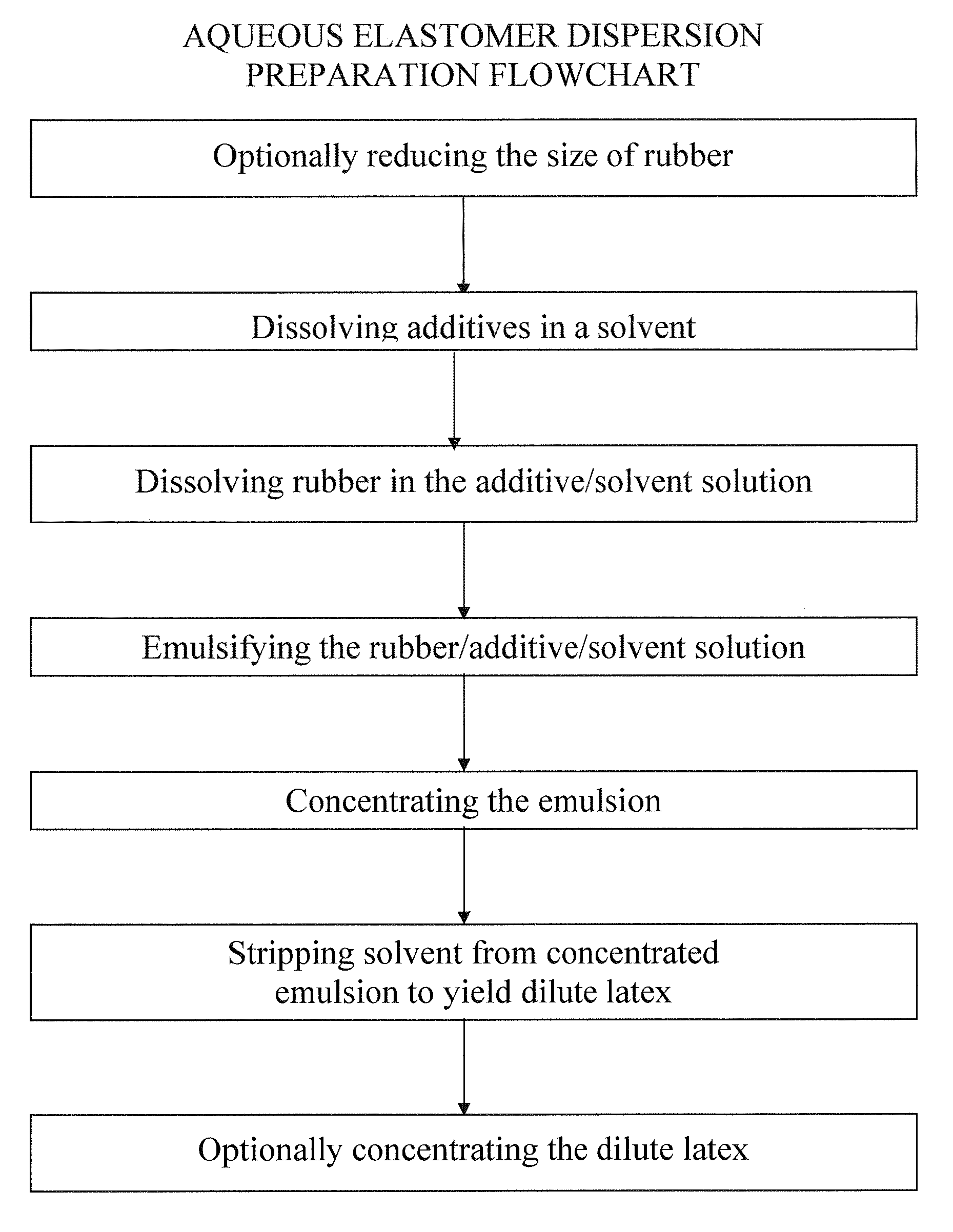

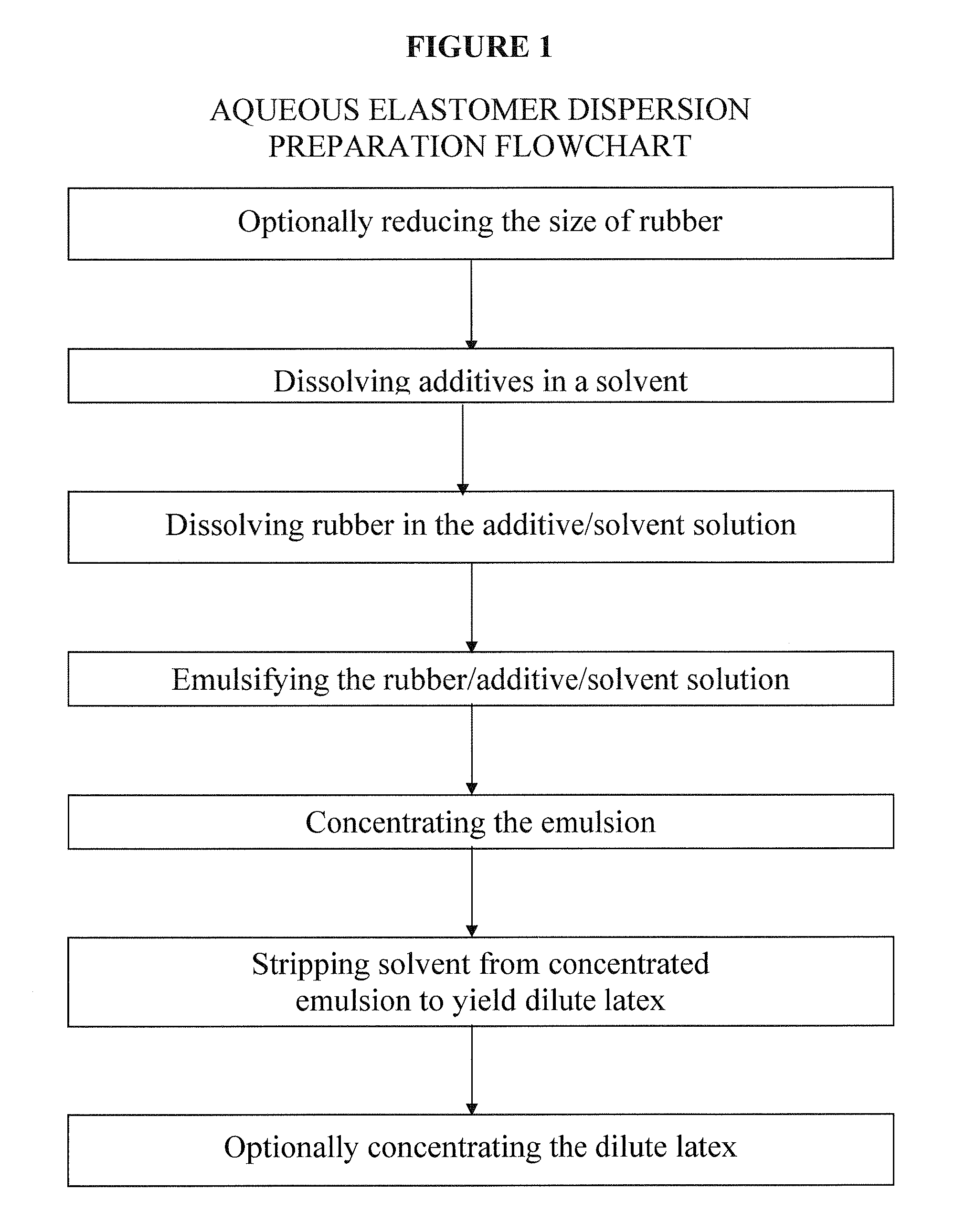

An aqueous elastomer dispersion includes a dispersed phase and an aqueous phase. The dispersed phase includes an elastomer including curable aliphatic conjugated-diene elastomers, such as polyisoprene, and a minor amount of at least one additive. The aqueous phase includes water and other optional components in either a soluble state or a dispersion state. The aqueous elastomer dispersion may be prepared by dissolving an elastomer, such as rubber, and additives in a solvent mixture and then converting the resulting solution into an aqueous emulsion. The aqueous emulsion is concentrated and the solvent is stripped from it to yield a dilute latex. The dilute latex that is obtained is concentrated again. Articles made from the aqueous elastomer dispersion include medical gloves, condoms, probe covers, dental dams, finger cots, catheters and the like.

Owner:ALLEGIANCE CORP

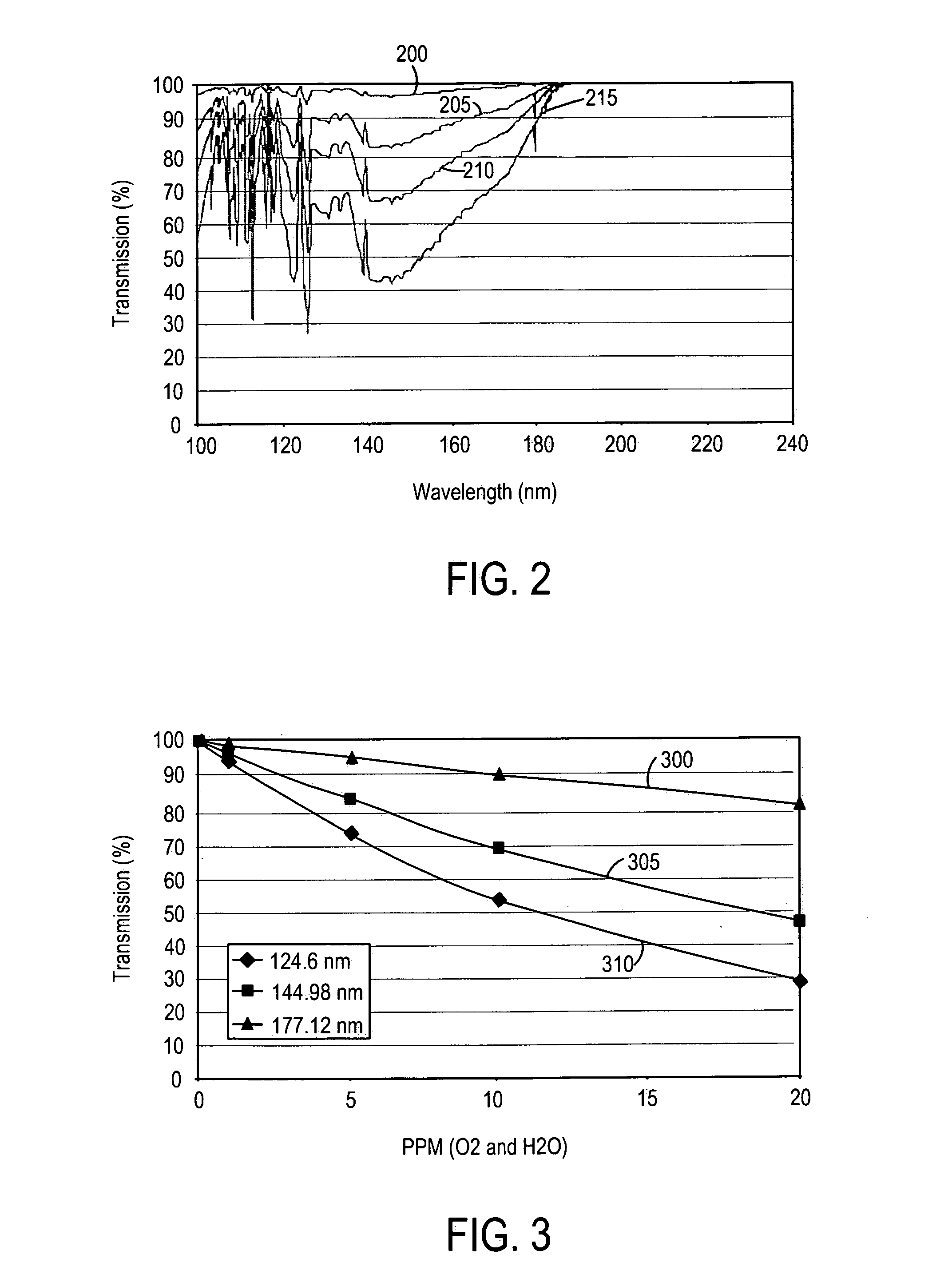

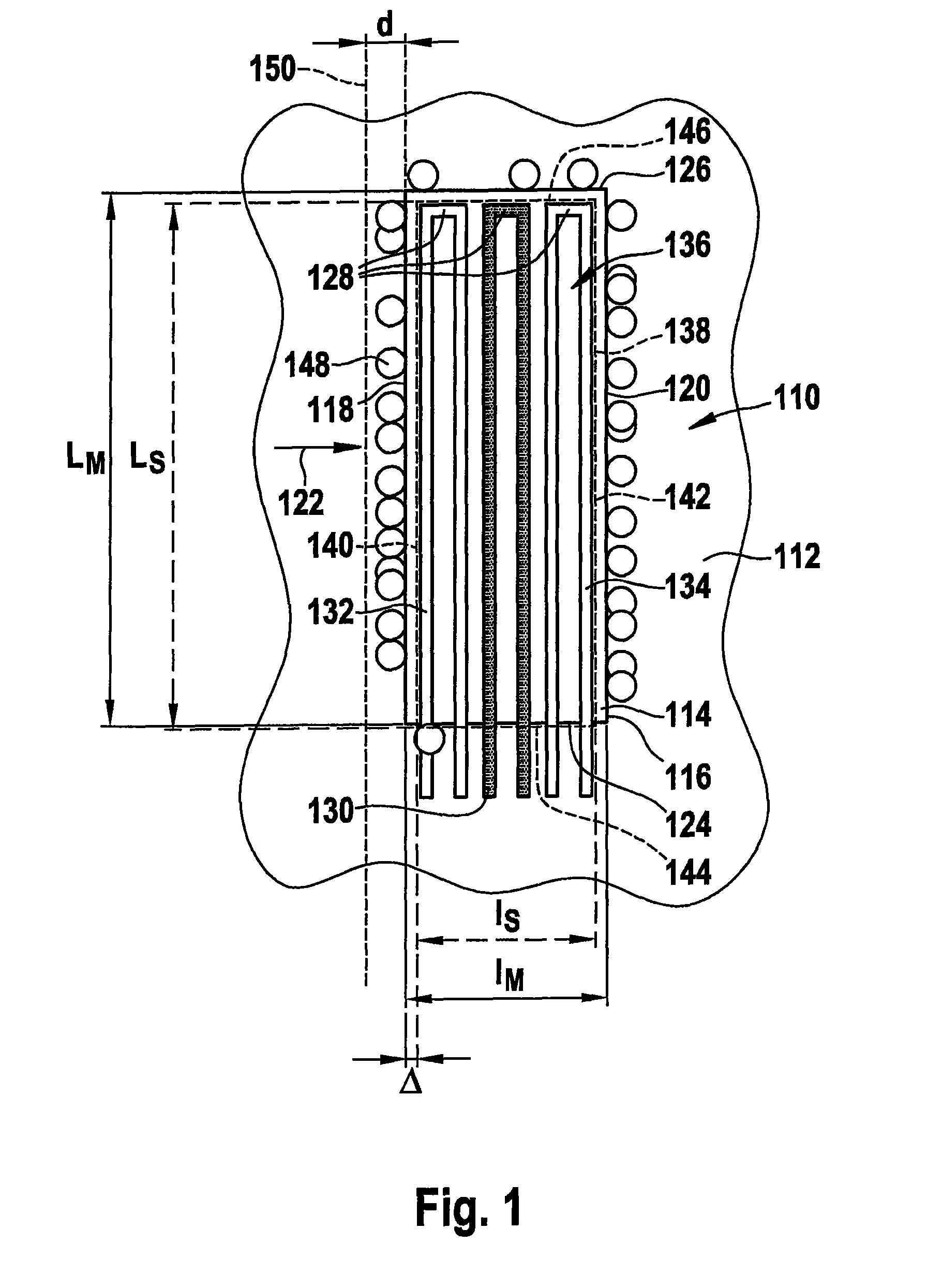

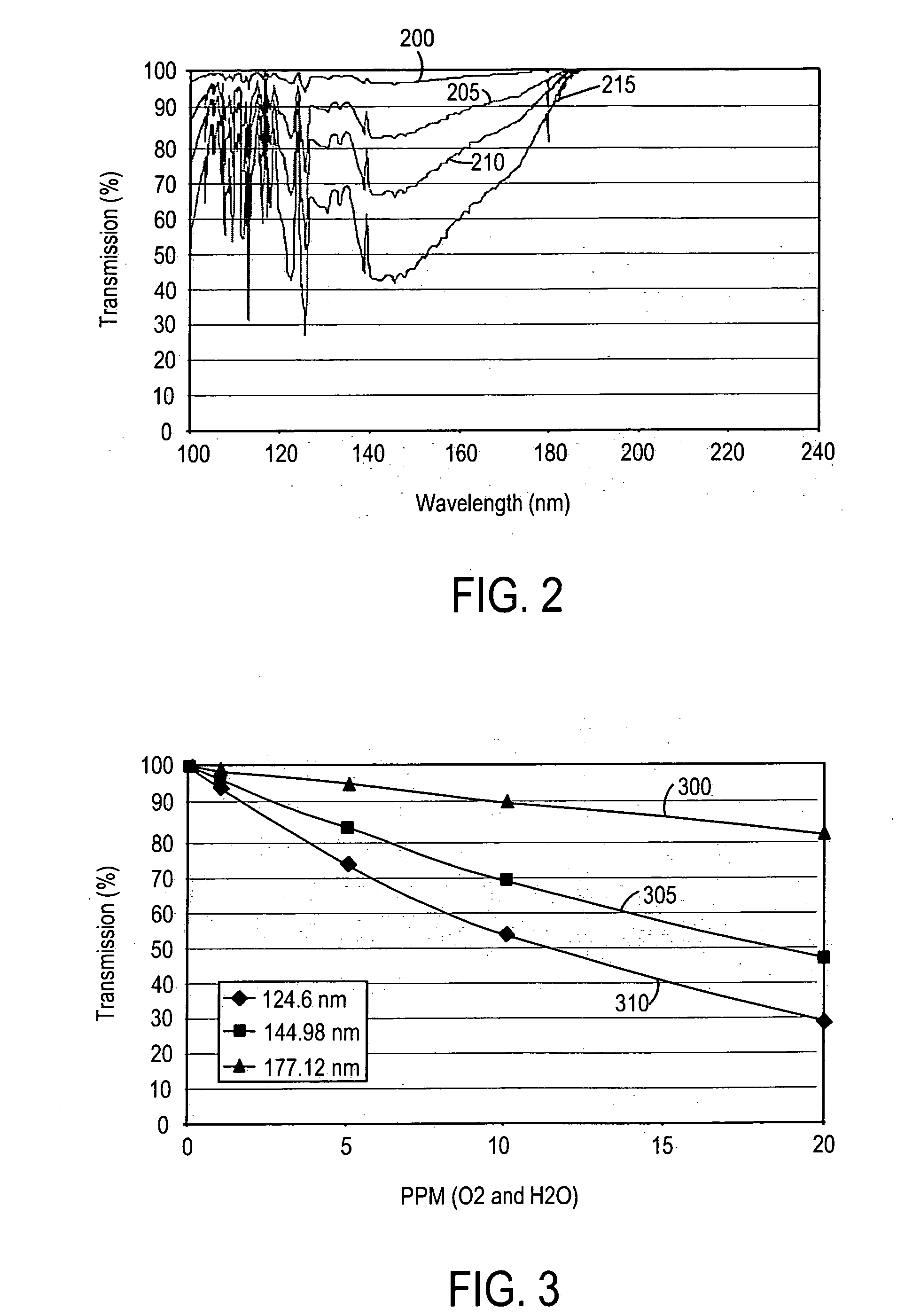

Contamination monitoring and control techniques for use with an optical metrology instrument

ActiveUS7342235B1Eliminate, the build-up of contaminantsReduce Surface ContaminationSpectrum investigationScattering properties measurementsOptical radiationUltraviolet

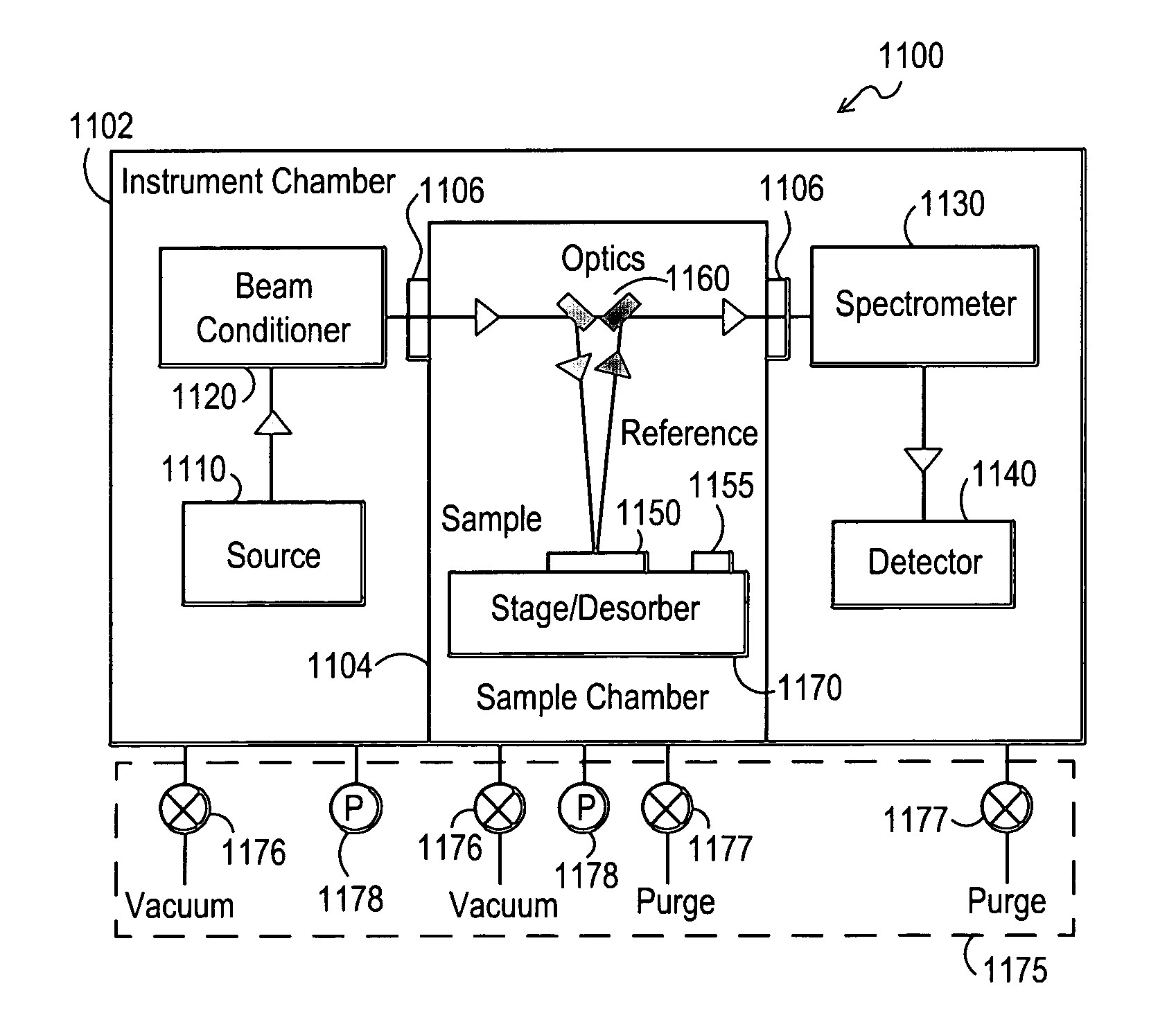

A technique is provided monitoring and removing contaminants from the surface of a sample that is being measured with an optical metrology tool. The monitoring and removing contaminants from the surface of a sample may occur prior to recording an optical response from said sample in order to ensure that accurate results are obtained. Contaminant layers may be quantified so that other measurements may be accurately obtained without requiring the removal of the contaminant layer. The contaminant layers may be removed through the exposure to optical radiation. Alternatively, properties of non-contaminant layers may be characterized by analyzing changes that occur in such layers by exposure to optical radiation. The optical metrology instrument may be an instrument which operates at wavelengths that include vacuum ultra-violet (VUV) wavelengths.

Owner:BRUKER TECH LTD

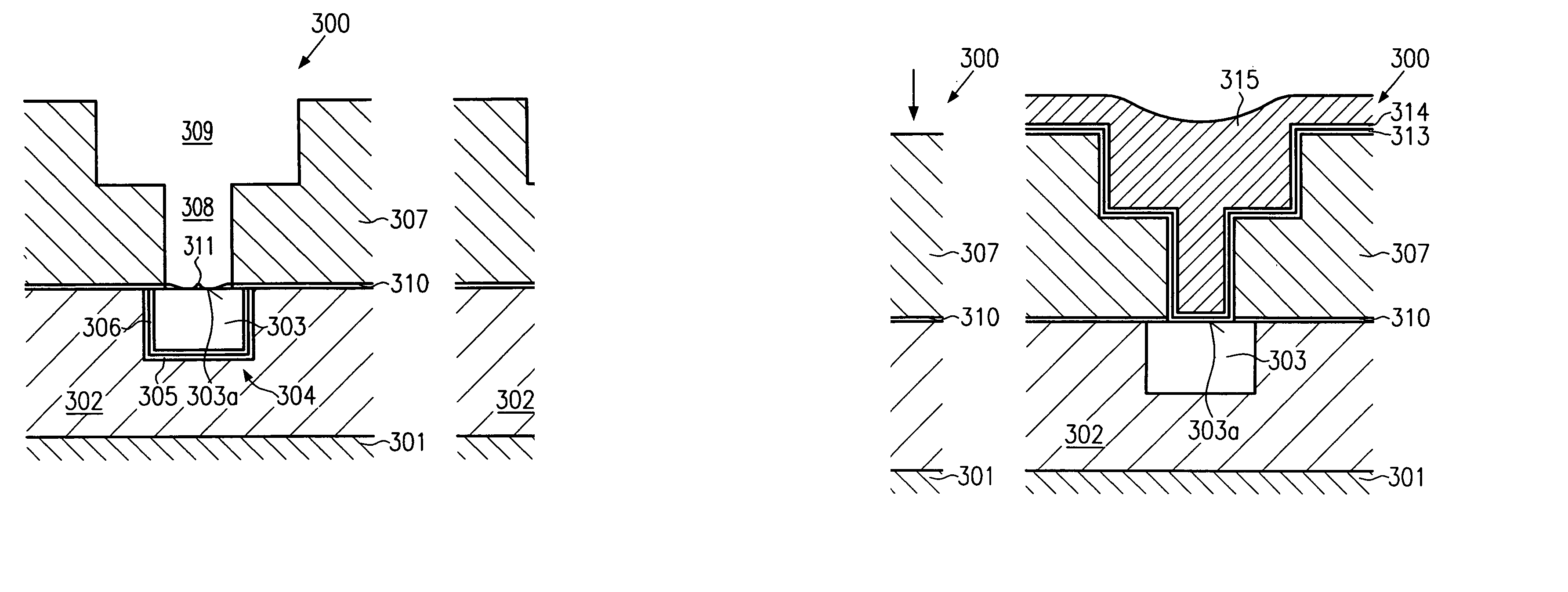

Technique for forming a passivation layer prior to depositing a barrier layer in a copper metallization layer

ActiveUS20060024951A1Reduction of structural irregularityReducing inhomogeneously distributed surface contaminationSemiconductor/solid-state device manufacturingChemical processCompound (substance)

By performing a wet chemical process after etching a via, contaminations may be removed and a thin passivation layer may be formed that may then be readily removed in a subsequent sputter etch process for forming a barrier / adhesion layer. In a particular embodiment, the wet chemical process may be performed on the basis of fluoric acid and triazole or a compound thereof.

Owner:ADVANCED MICRO DEVICES INC

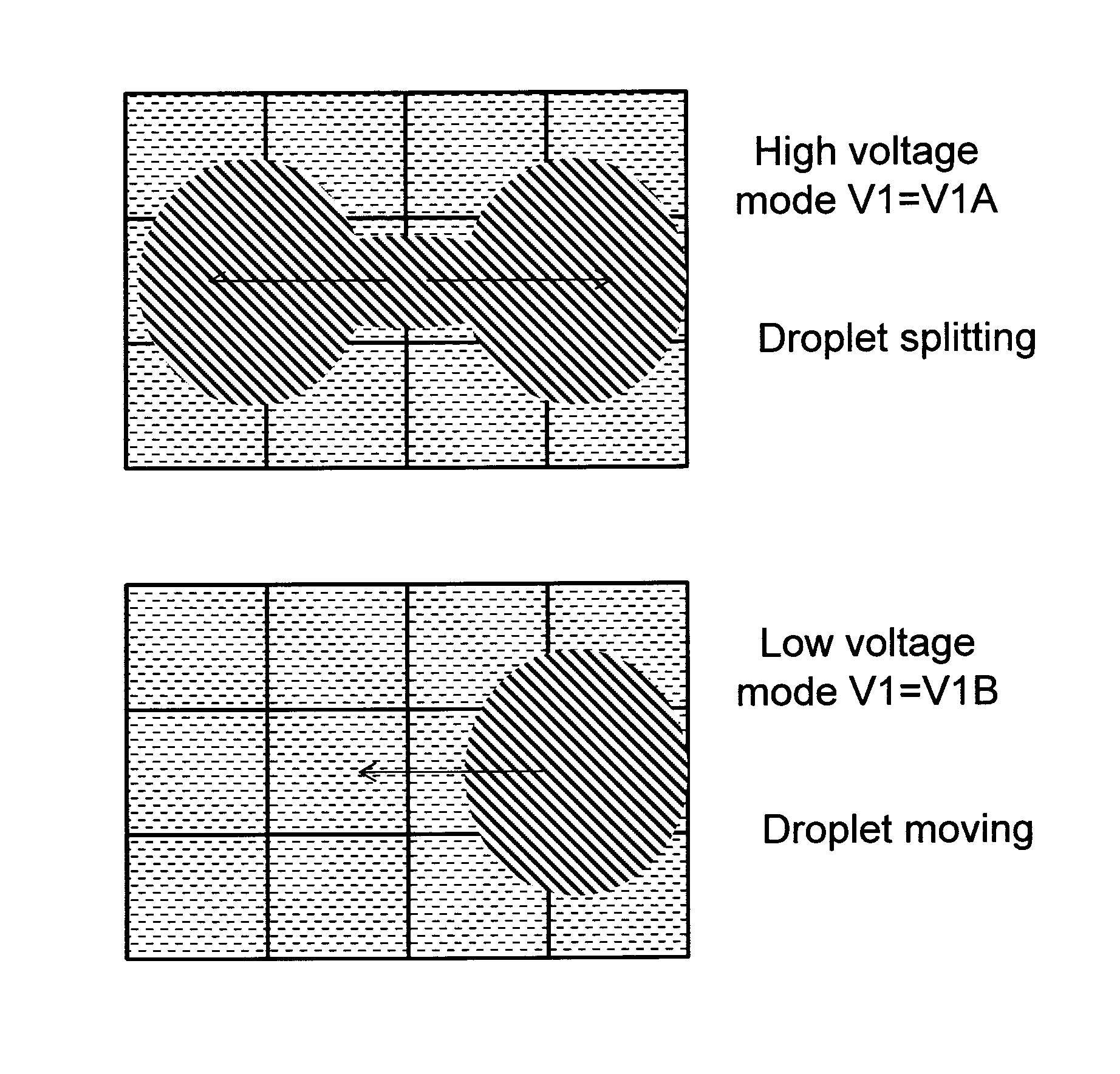

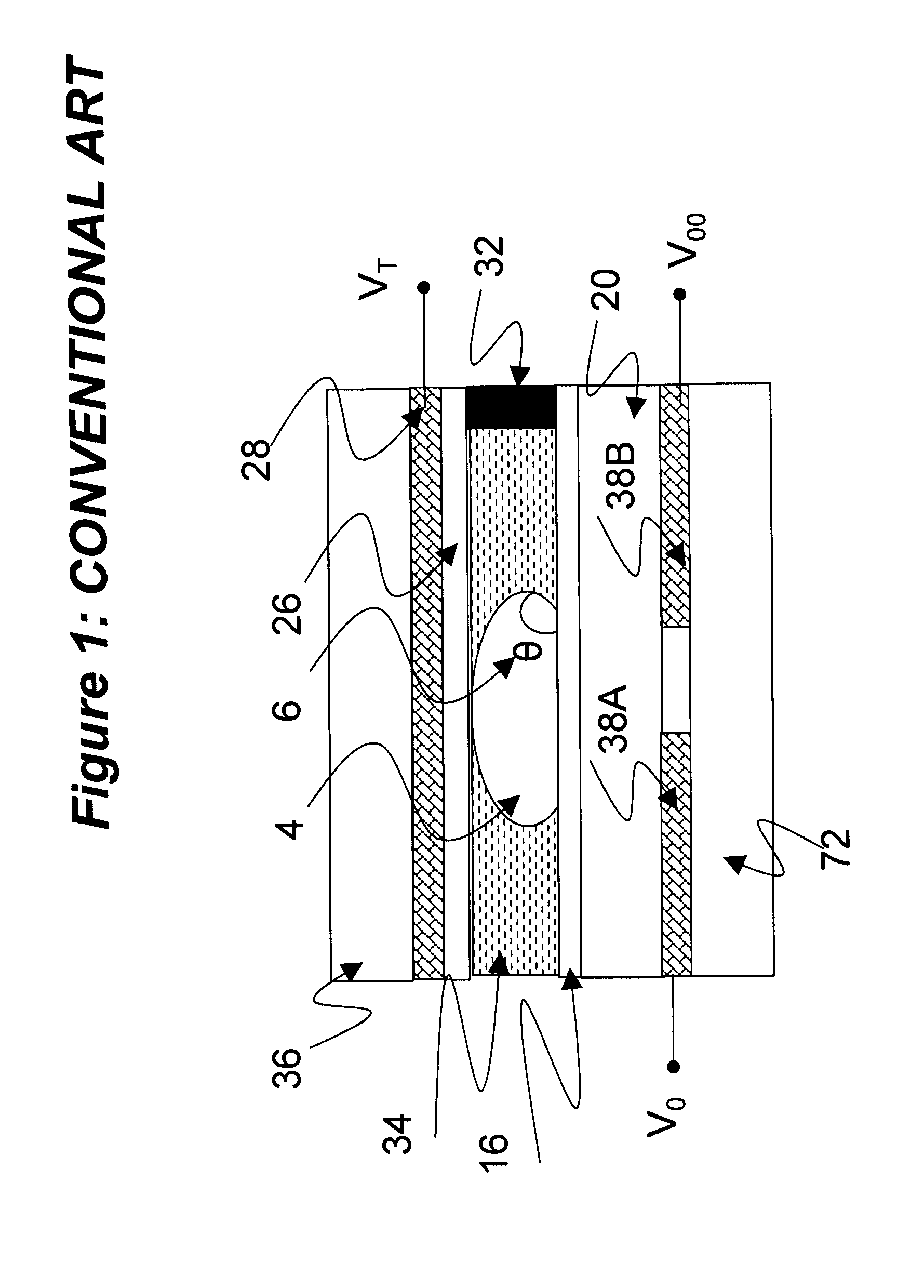

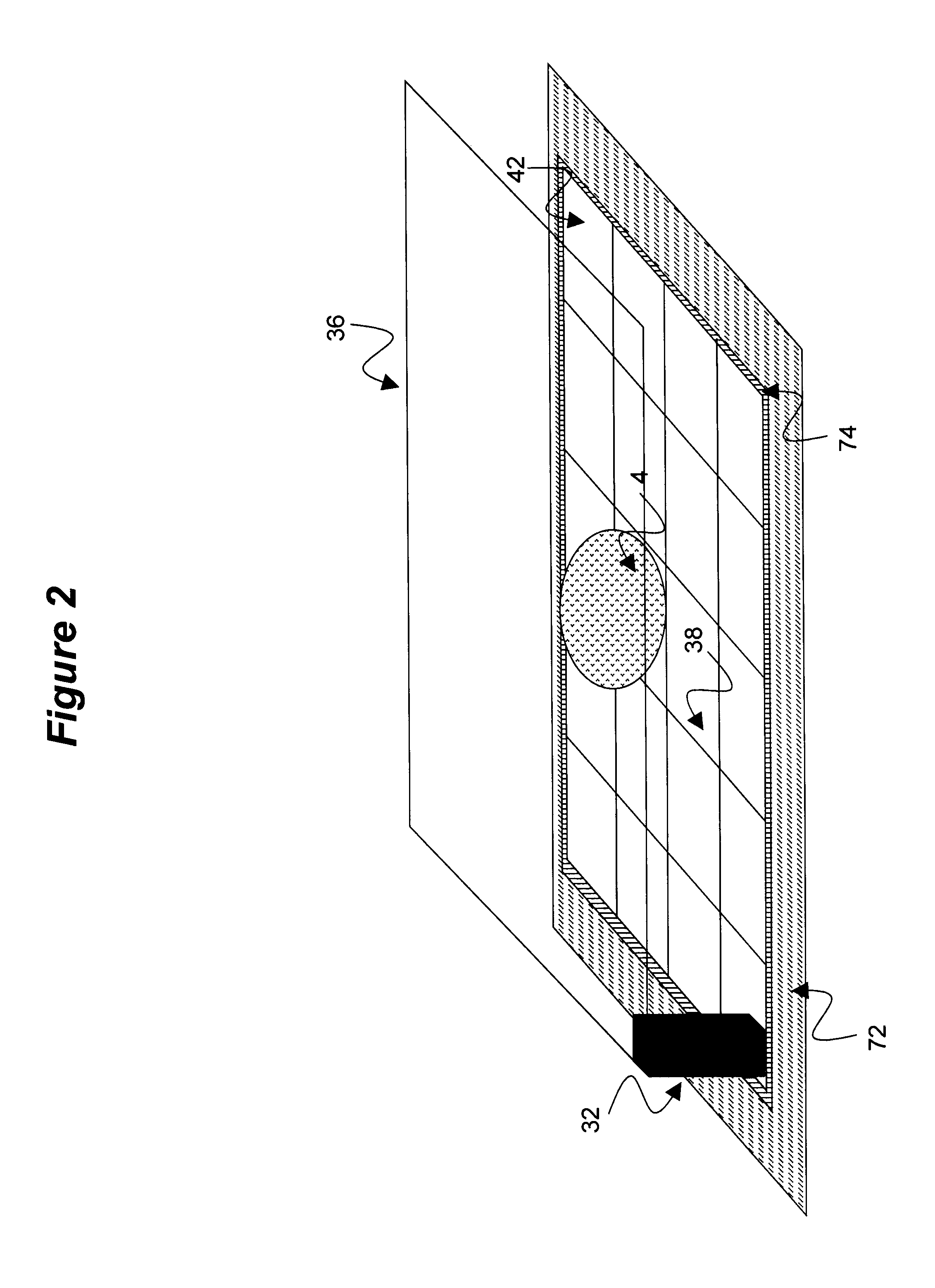

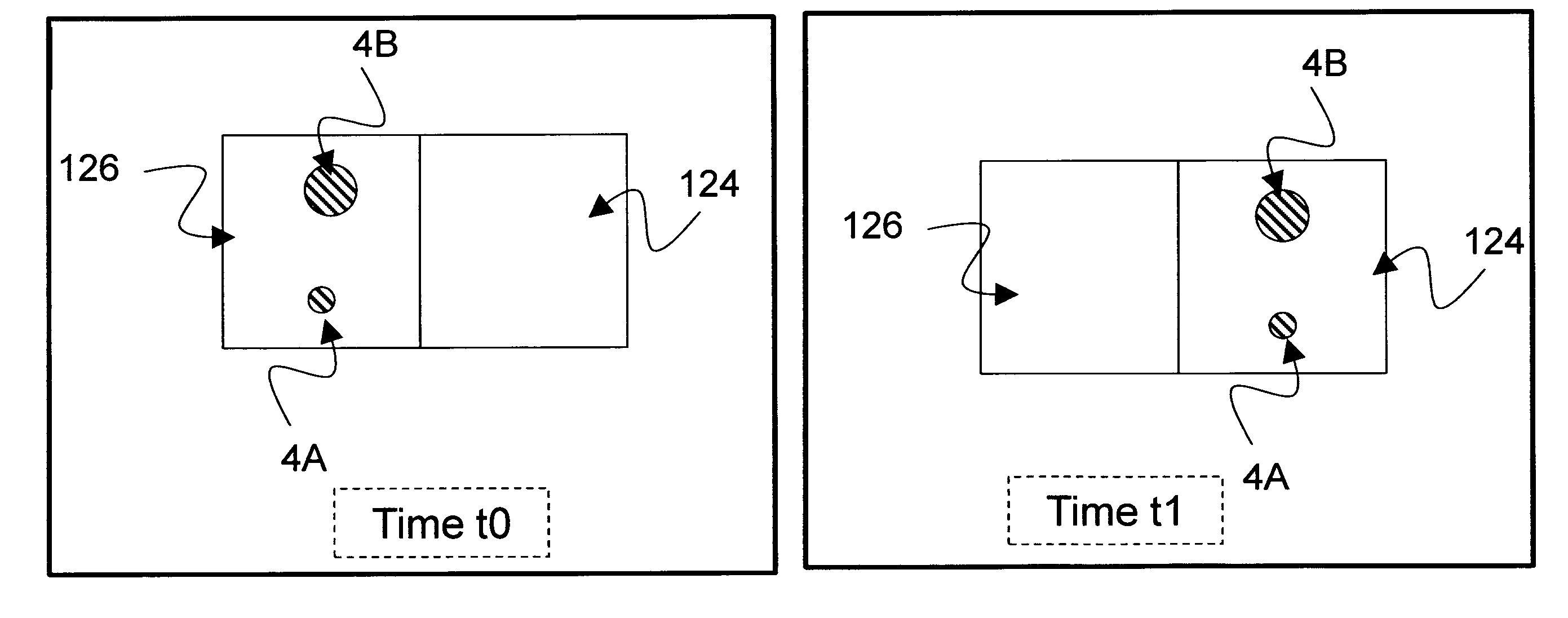

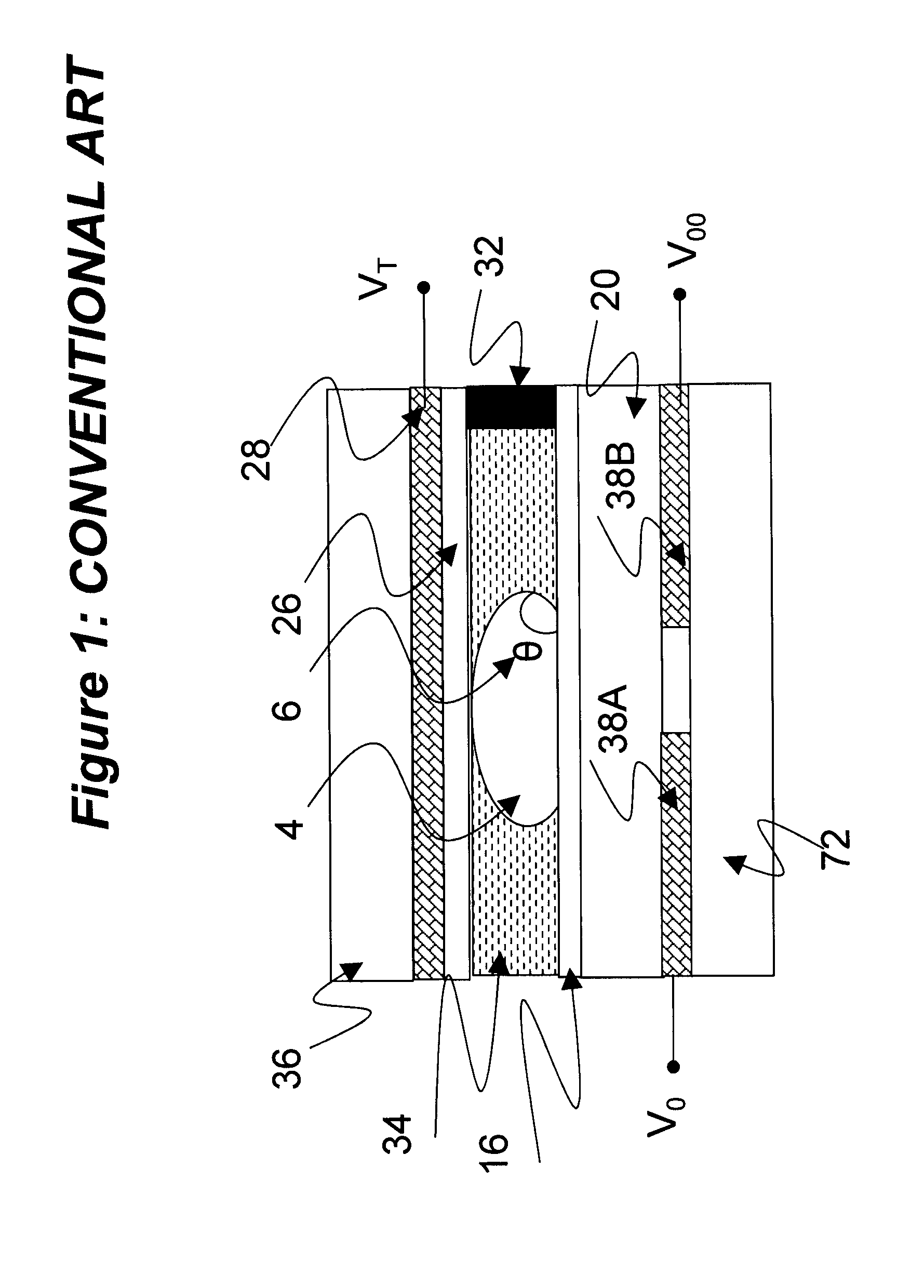

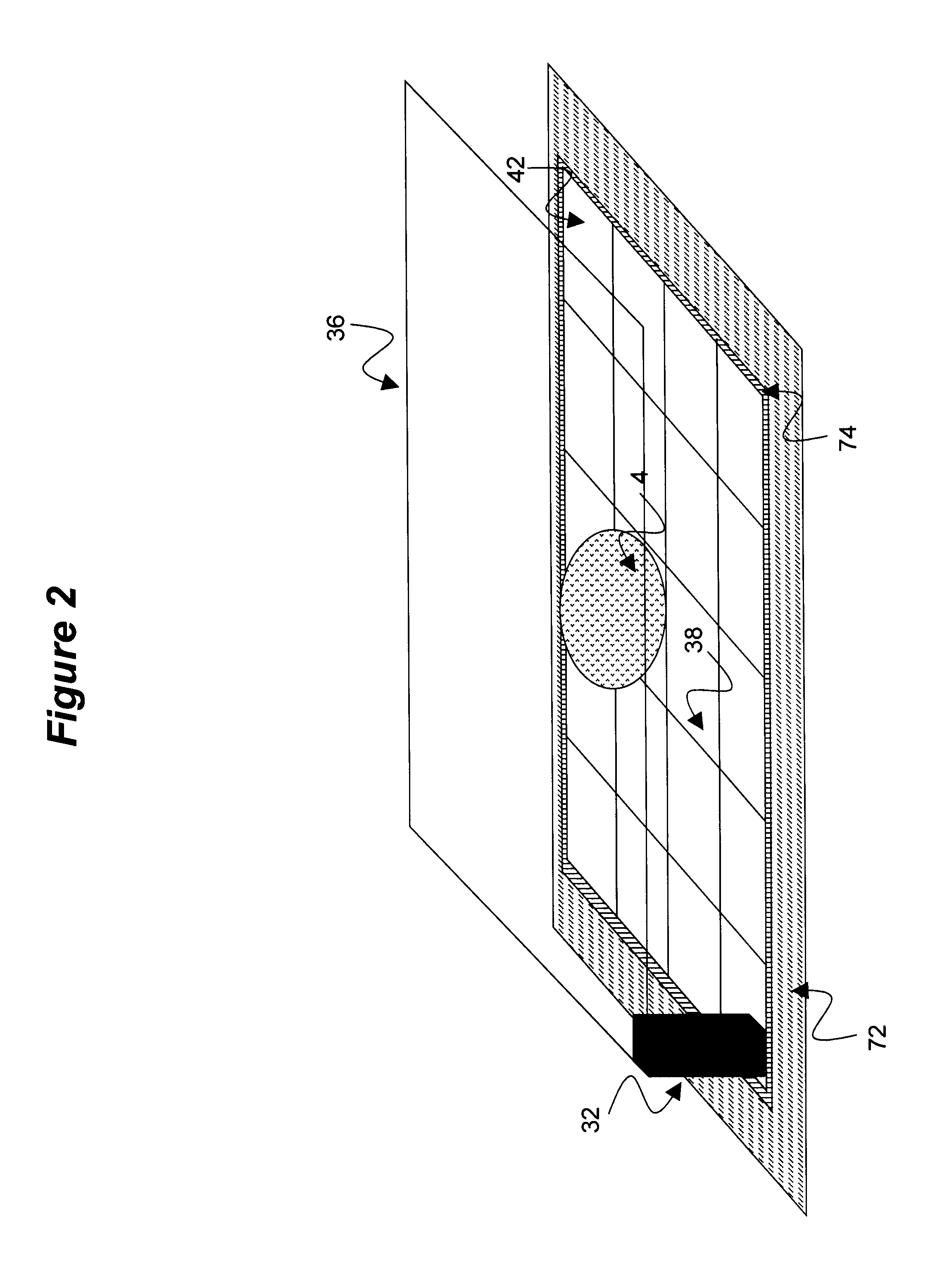

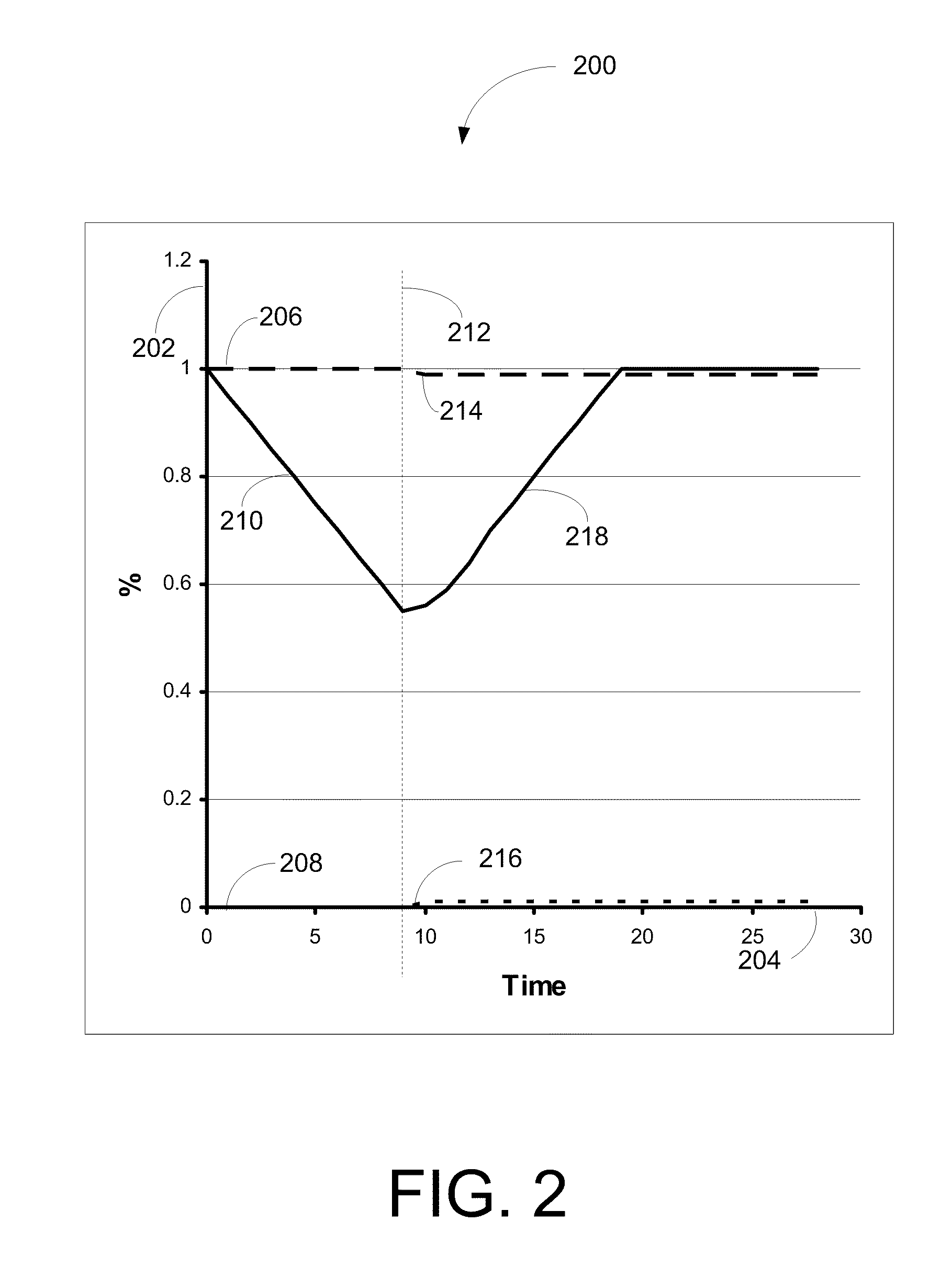

Am-ewod device and method of driving with variable voltage ac driving

ActiveUS20140202863A1Improve equipment reliabilityReduce Surface ContaminationElectrostatic separatorsSludge treatmentDielectricActive matrix

An active matrix electrowetting on dielectric (AM-EWOD) device includes a substrate electrode and a plurality of array elements, each array element including an array element electrode. The AM-EWOD device further includes thin film electronics disposed on a substrate. The thin film electronics includes first circuitry configured to supply a first time varying signal V1 to the array element electrodes, and second circuitry configured to supply a second time varying signal V2 to the substrate electrode. An actuation voltage is defined by a potential difference between V2 and V1, and the first circuitry further is configured to adjust the amplitude of V1 to adjust the actuation voltage. V1 may be adjusted to adjust the actuation voltage while V2 remains unchanged. The actuation voltage may be controlled to operate the AM-EWOD device between high and low voltage modes of operation in accordance with different droplet manipulation operations to be performed.

Owner:SHARP LIFE SCI EU LTD

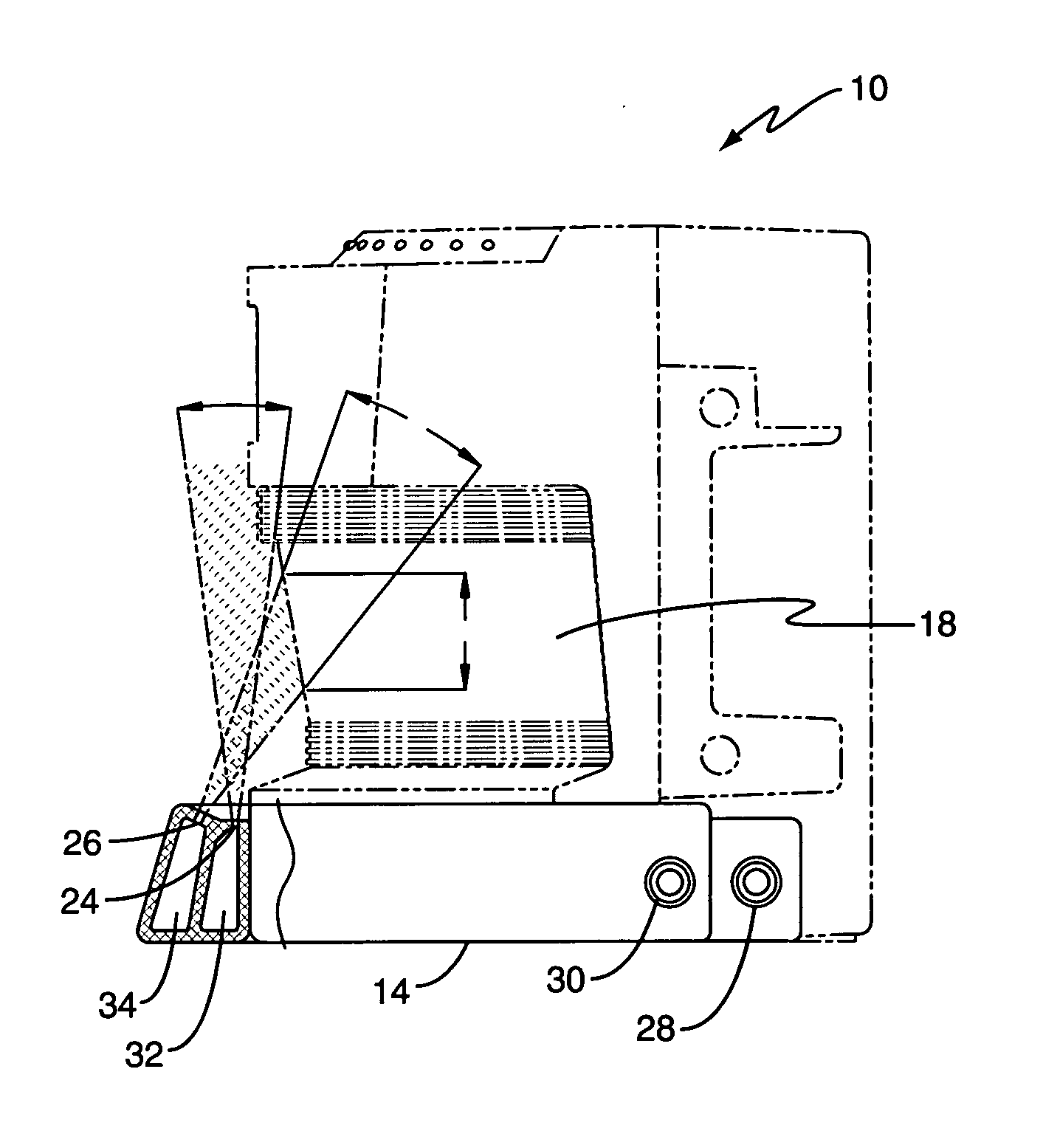

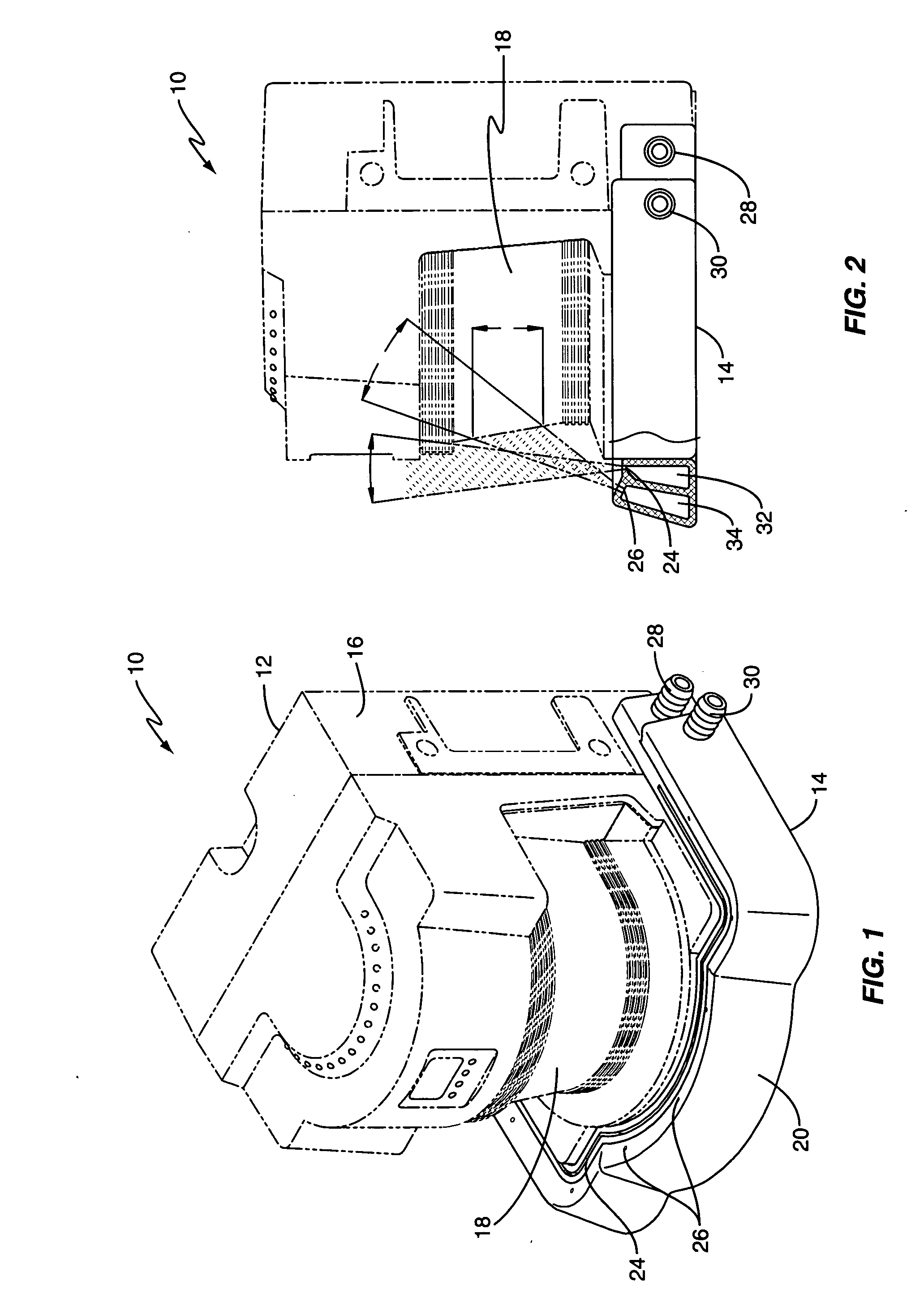

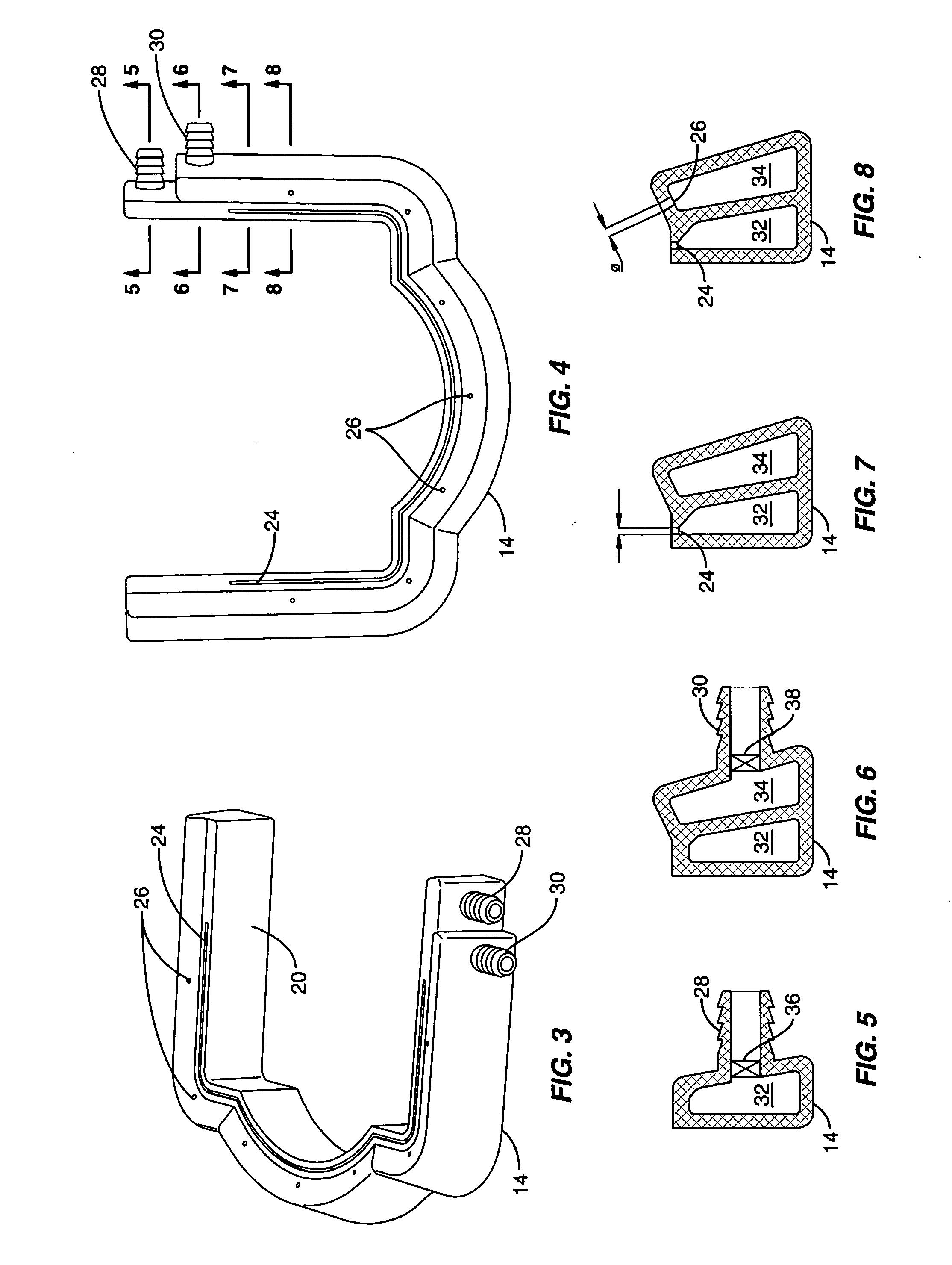

Apparatus and method for laser scanner cleaning and protection

InactiveUS20060068696A1Reduce Surface ContaminationPrevent subsidenceLighting and heating apparatusAir currents for screeningMode controlLaser scanning

An air guard directs air toward a viewing window of an optoelectronic presence sensing device to reduce surface contamination thereon. The air guard may include a control valve, and possibly control circuits, to enable selective activation of the air guard. In one embodiment, the air guard includes one or more slits configured to vent pressurized air in a generally laminar (curtain like) flow in front of the window to prevent the deposition of airborne contaminants thereon. Alternatively, or additionally, the air guard may include one or more nozzles configured to vent pressurized air in directed air streams toward the window to remove surface contaminants thereon, and may include a control valve enabling selective operation in preventive, cleaning, or standby modes. Mode control may be effected by an external control system, by the presence sensing device, or by the air guard itself, which may include a timer or other control circuit.

Owner:SCI TECH INC

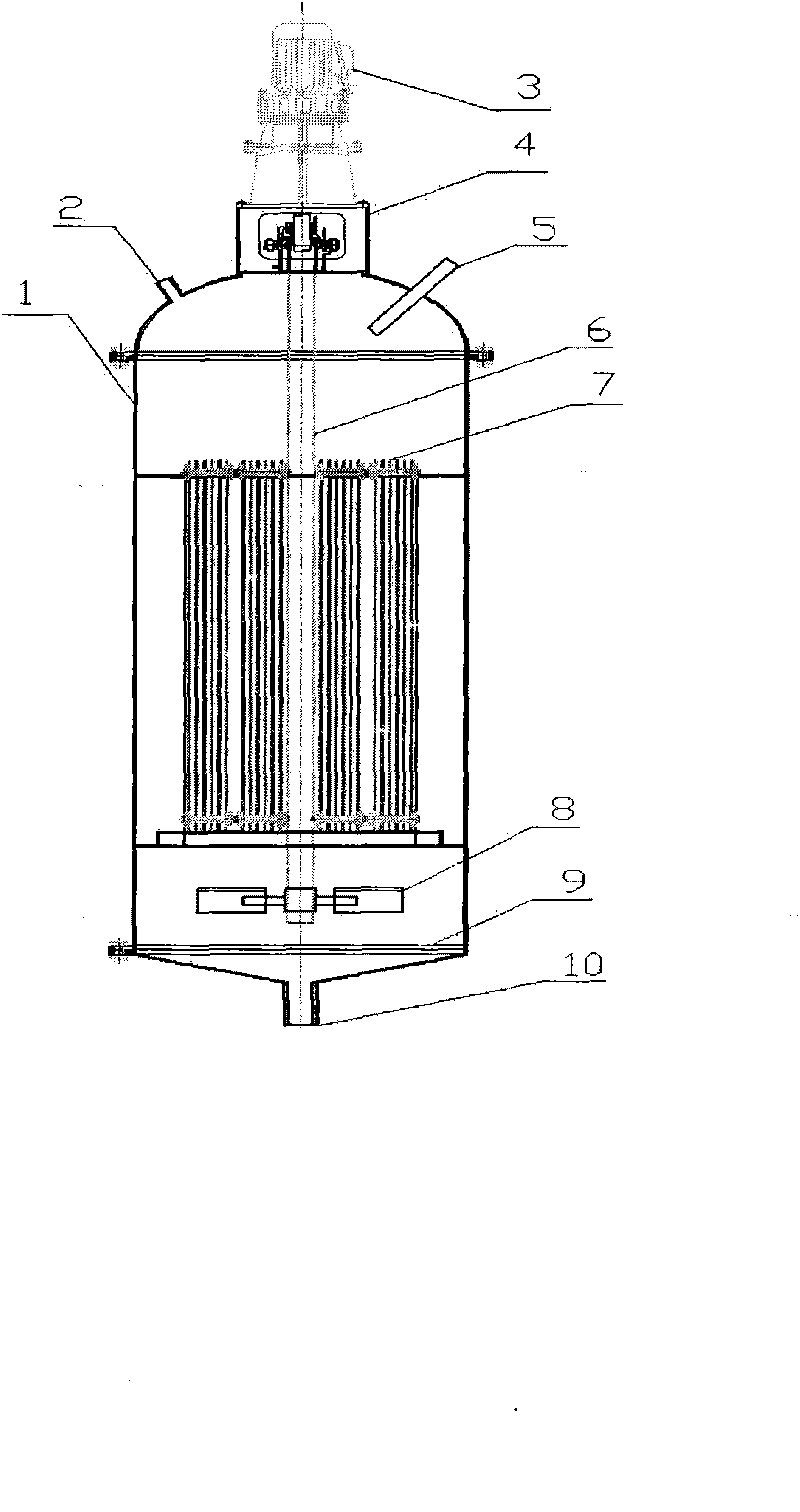

Electric catalysis reactor capable of reducing side reaction for wastewater treatment

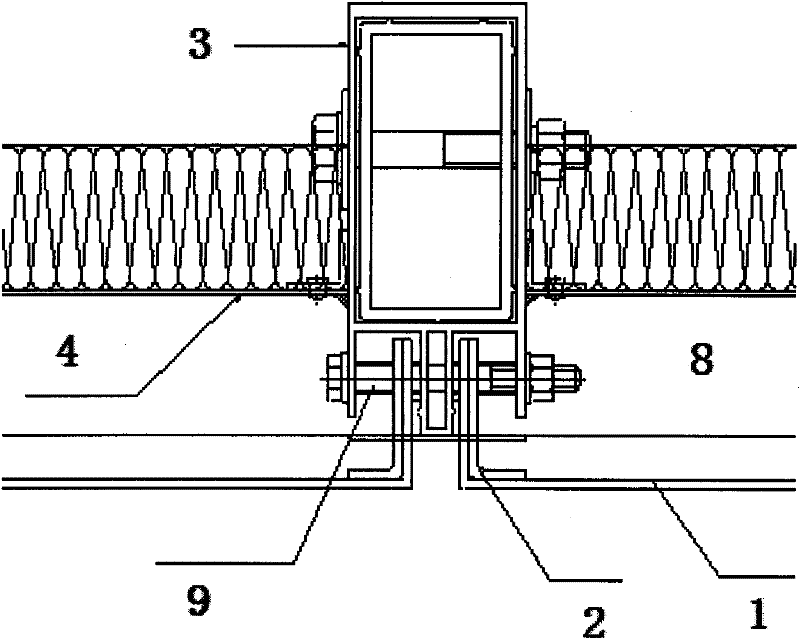

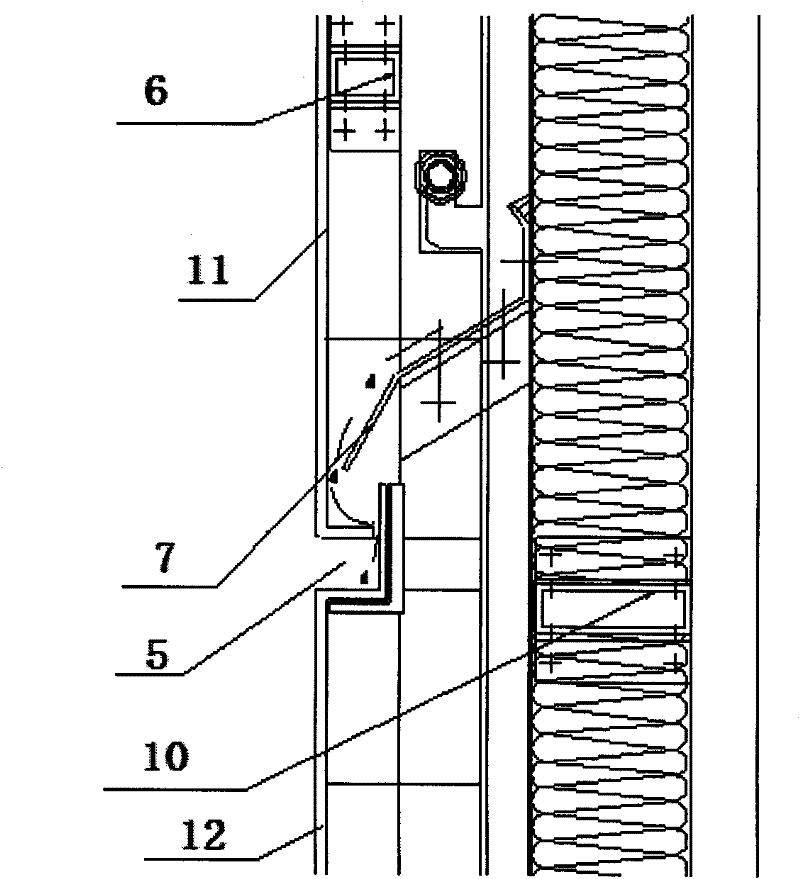

InactiveCN101691251AReduce Surface ContaminationImprove mass transfer efficiencyWater contaminantsWater/sewage treatmentHigh concentrationExhaust valve

The invention discloses an electric catalysis reactor capable of reducing side reaction for wastewater treatment. The reactor consists of a pot body (1), an exhaust valve (2), a stirring mechanism (comprising a motor (3), a speed adjustor (4), a stirring shaft (5) and a stirring paddle (8)), a water inlet (5), a cathode / anode sheet group (7), a filter plate (9), a water outlet (10) and the like. A three-dimensional particle electrode is filled inside the reactor, and three-dimensional particles can be suspended between flat electrodes in a controllable stirring mode so as to effectively play a role in catalysis of the particle electrode, improve the generation rate of hydroxyl free radicals and reduce the occurrence of side reaction. Meanwhile, the controllable stirring mode improves the mass transfer effect of the solution, prevents dirt from being accumulated on the flat electrodes, and reduces the ohmic thermal resistance effect of electrodes. The electric catalysis reactor is applicable to degradation and purification treatment of high-concentration organic wastewater difficult to be biochemically degraded, high-chroma and high-ammonia nitrogen wastewater and oily wastewater, overcomes the defects that the prior equipment for treating the high-concentration organic wastewater has poor effect, high cost and the like, and has the advantages of simple and convenient operation, cleanness, thorough oxidation, stable treatment effect and the like.

Owner:BEIJING UNIV OF CHEM TECH

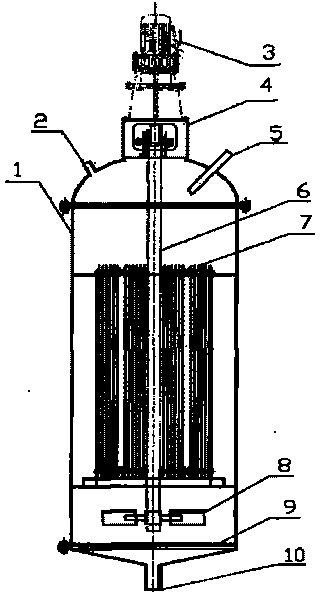

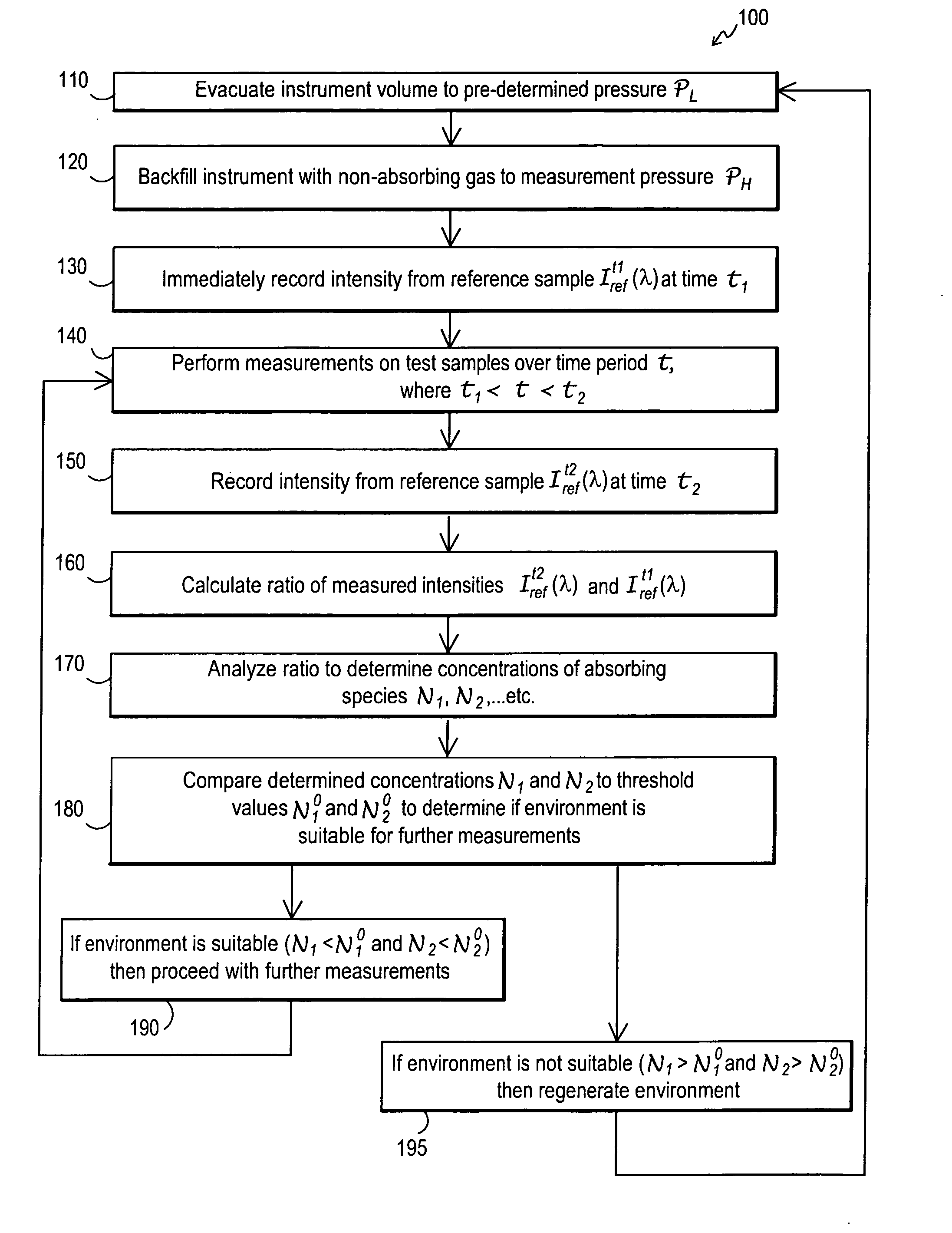

Contamination monitoring and control techniques for use with an optical metrology instrument

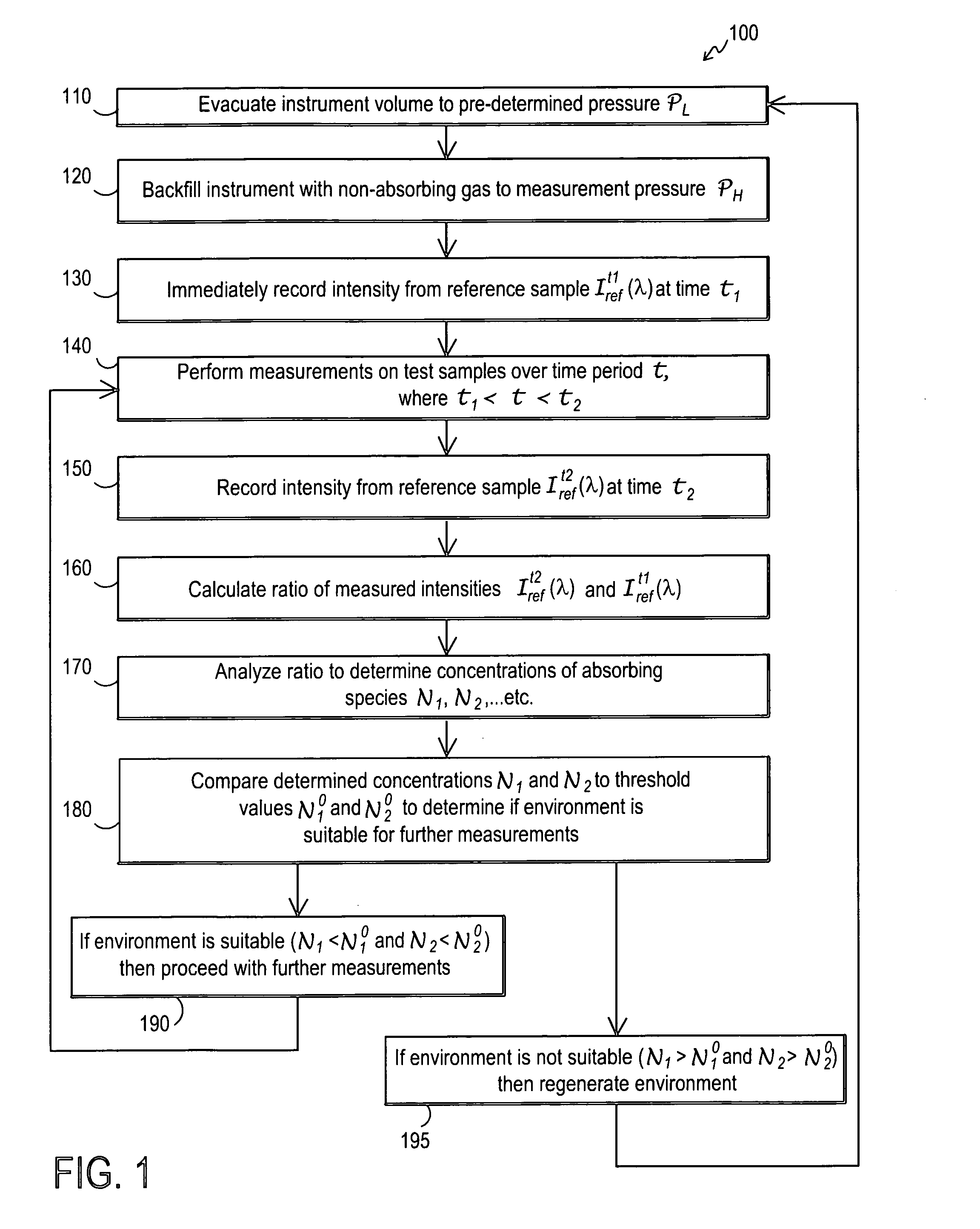

ActiveUS20080073560A1Eliminate, the build-up of contaminantsReduce Surface ContaminationRadiation pyrometrySemiconductor/solid-state device testing/measurementUltravioletEngineering

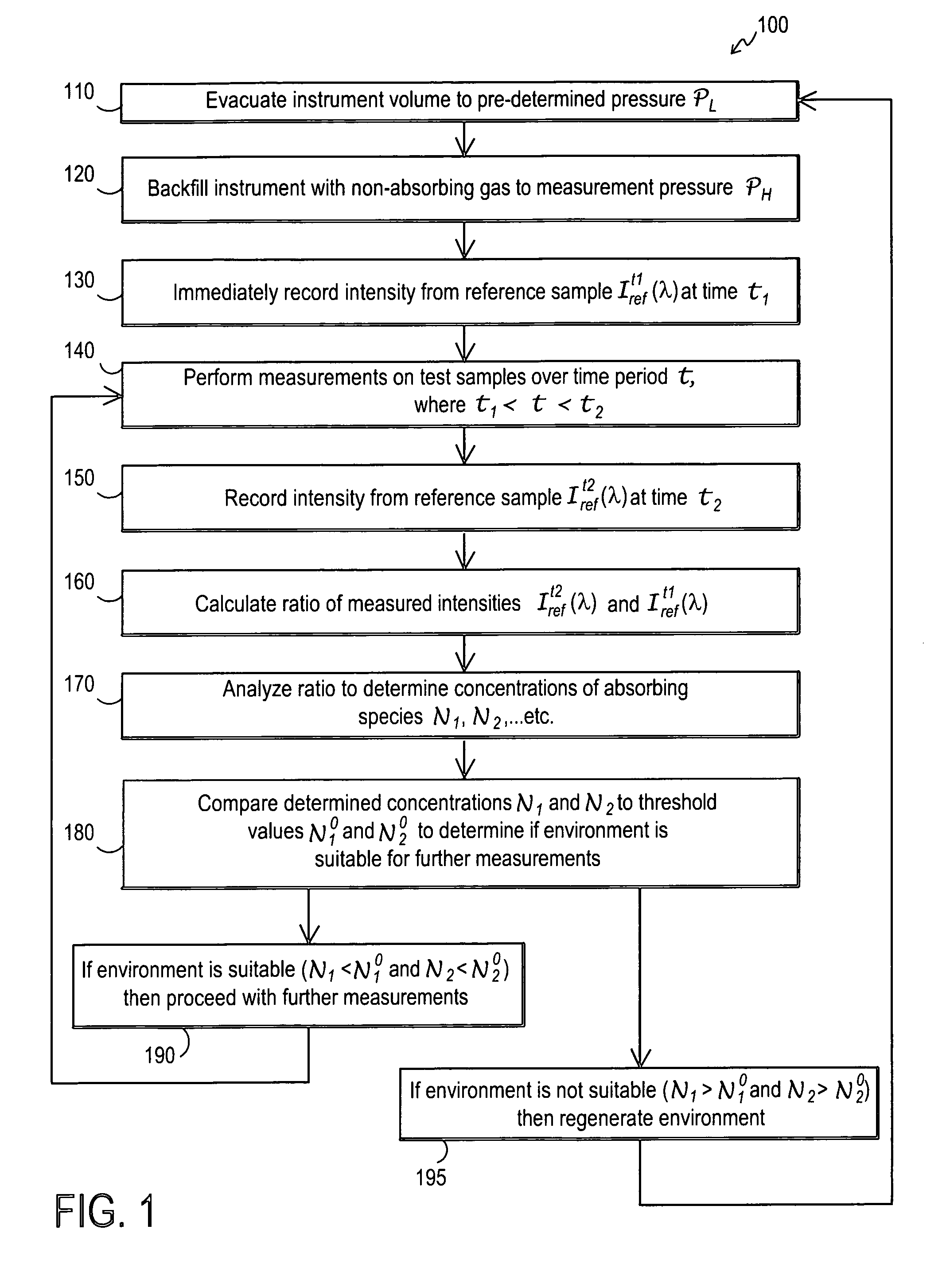

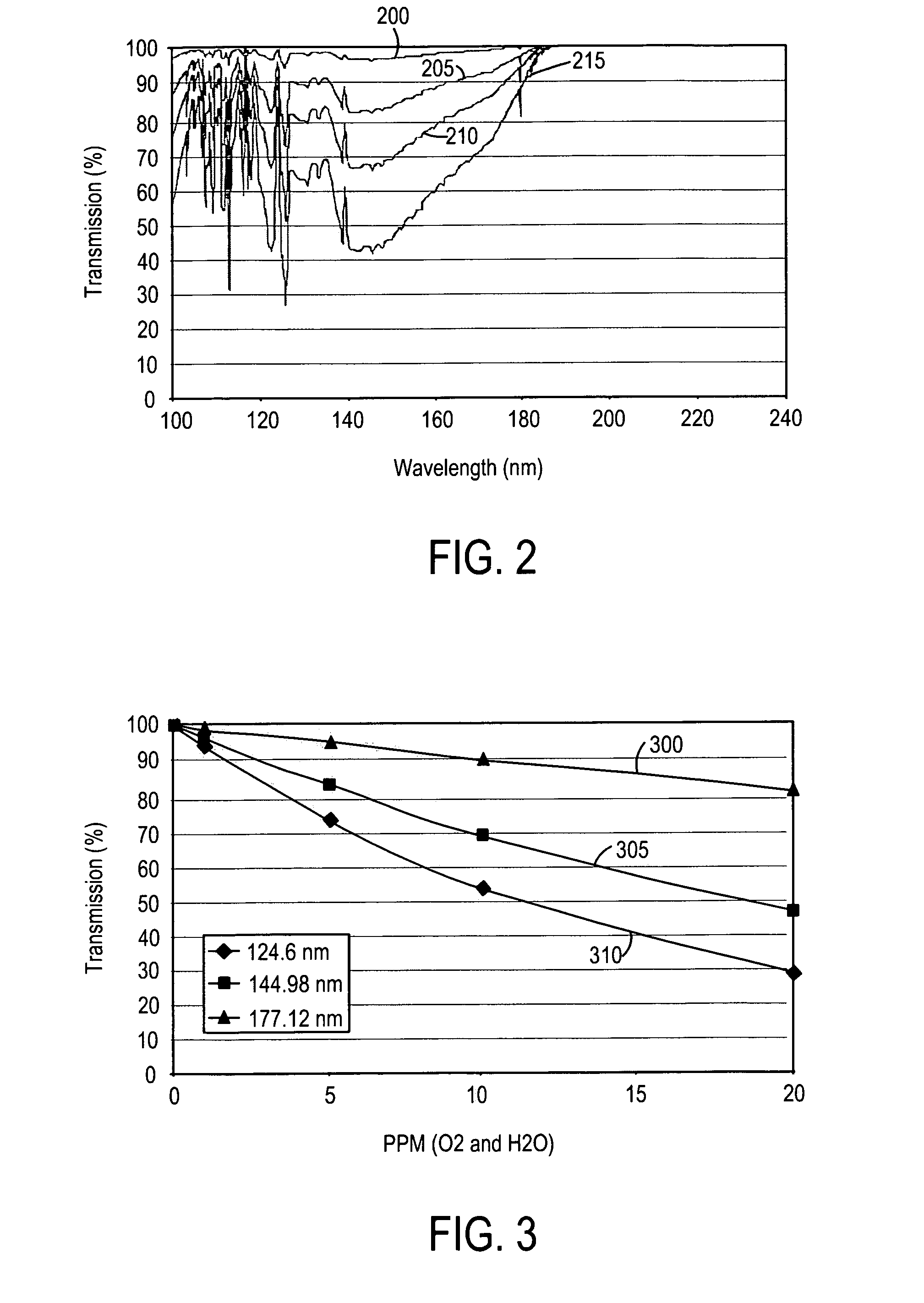

A technique is provided for generating and subsequently monitoring the controlled environment(s) within an optical metrology instrument in such a manner as to minimize absorbing species within the light path of the metrology instrument and to minimize the build-up of contaminants on the surfaces of optical elements that may result in performance degradation. Both evacuation and backfill techniques may be utilized together along with a monitoring technique to determine if the environmental is suitable for measurements or if the environment should be regenerated. The optical metrology instrument may be an instrument which operates at wavelengths that include vacuum ultra-violet (VUV) wavelengths.

Owner:BRUKER TECH LTD

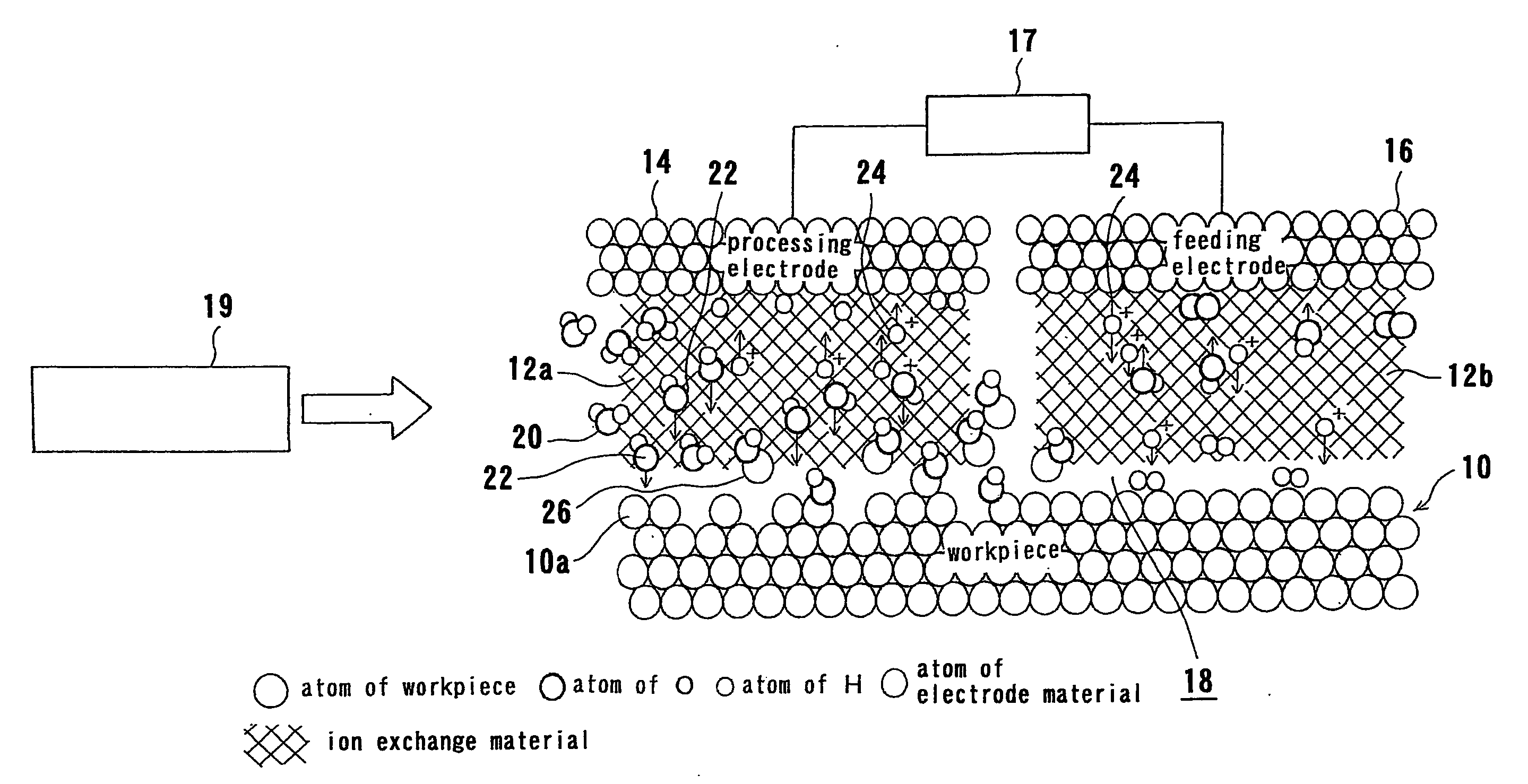

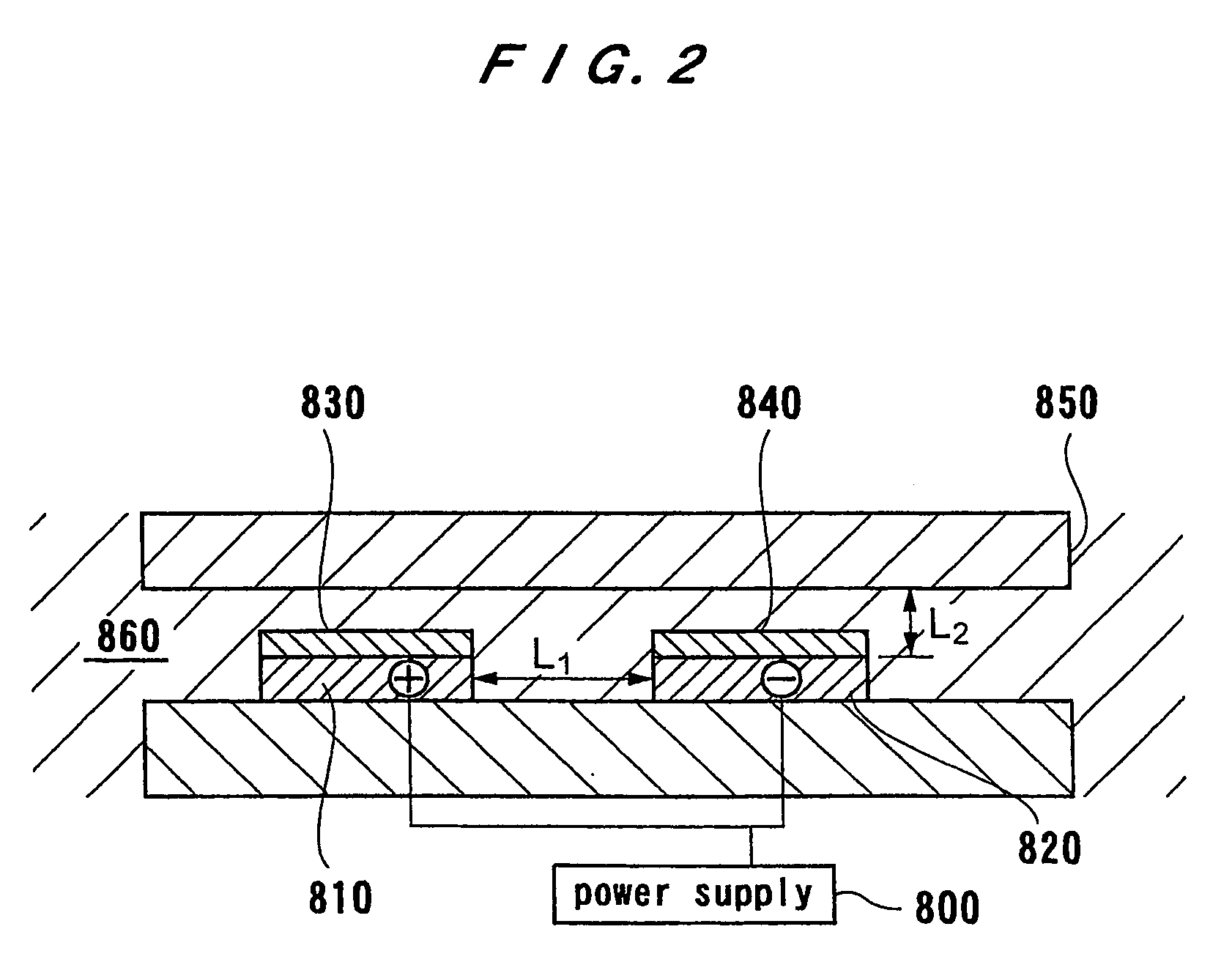

Electolytic processing apparatus

InactiveUS20060091005A1Easy to processFlexiblyMachining electrodesMachining electric circuitsChemical LinkagePhysical chemistry

An electrolytic processing apparatus has at least one processing electrode (86) and at least feeding electrode (86) disposed on the same side as the processing electrode (86) with respect to a substrate (W). An organic compound having an ion exchange group is chemically bonded to at least one of a surface of the processing electrode (86) and a surface of the feeding electrode (86b) to form an ion exchanger (90). The electrolytic processing apparatus also has a substrate holder (42) for holding the substrate (W) and bringing the substrate (W) into contact with or close to the processing electrode (86). The electrolytic processing apparatus includes a power supply (48) for applying a voltage between the processing electrode (86) and the feeding electrode (86), and a fluid supply unit (92, 94) for supplying a fluid between the substrate (W) and the processing electrode (86).

Owner:EBARA CORP

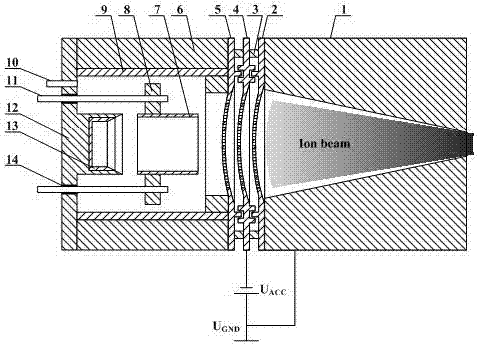

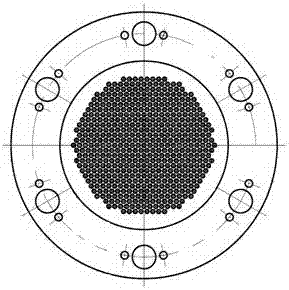

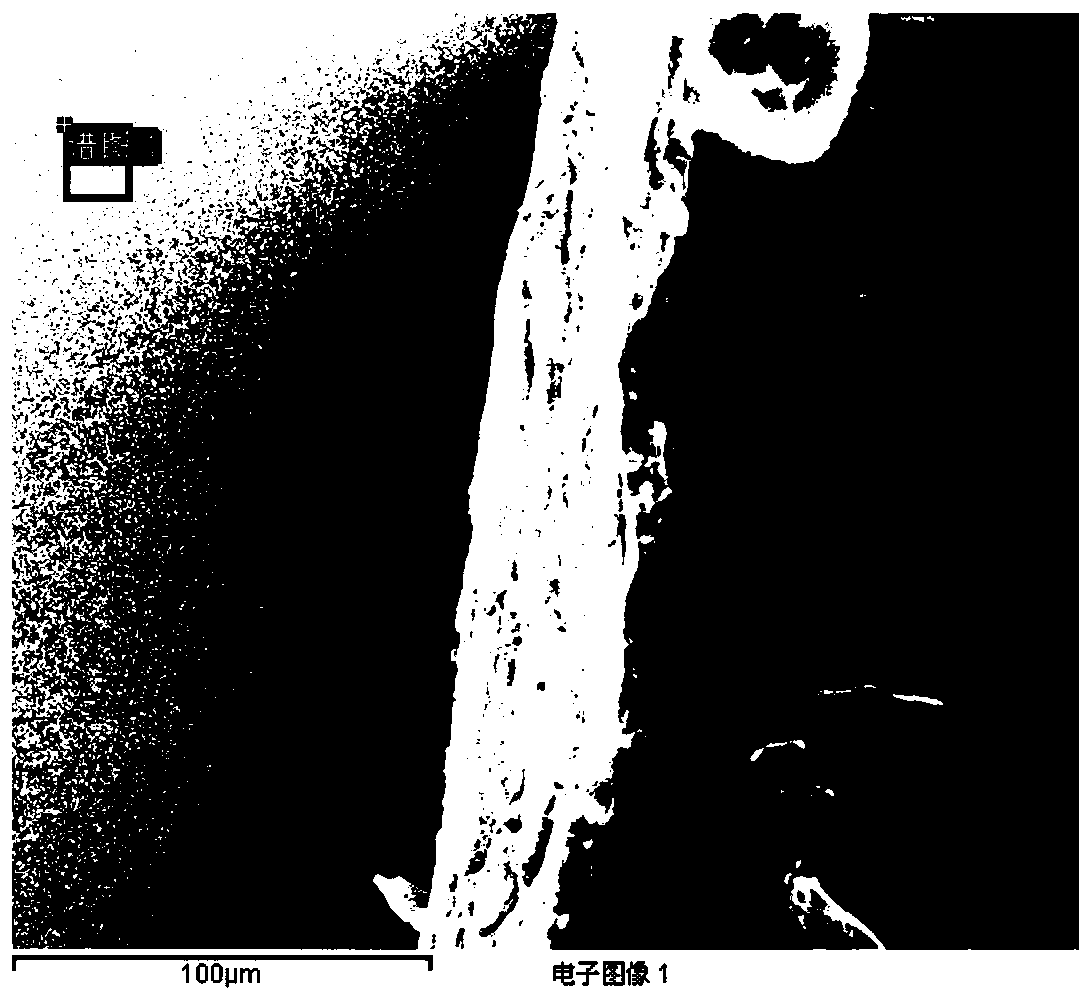

Focused ion beam four-stage grid mesh system achieving fixed point removal and method thereof

ActiveCN107020549AAchieve focusImplement spot removalOptical surface grinding machinesThree stageIon beam

The invention relates to a focused ion beam four-stage grid mesh system achieving fixed point removal and a method thereof. With the adoption of a three-stage spherical grid mesh, extraction, shaping and focusing of an ion beam of a wide-beam cold cathode ion source are realized, and a position of an ion beam focus can be adjusted according to the size of the spherical radius of the grid mesh; by changing a distribution map of small holes and the sizes of the small holes in the grid mesh, the size of a beam spot and the size of a beam current are adjusted; and through adjustment on electric potential of an accelerating grid, an ion motion trace can be controlled effectively, and loss and grid mesh loss in an ion motion process can be reduced. The fixed point removal on a processing surface can be realized, and the engineering application of an ion beam technology in China shall be pushed.

Owner:XIAN TECHNOLOGICAL UNIV

Water-based resin compositon and articles made therefrom

An aqueous elastomer dispersion includes a dispersed phase and an aqueous phase. The dispersed phase includes an elastomer including curable aliphatic conjugated-diene elastomers, such as polyisoprene, and a minor amount of at least one additive. The aqueous phase includes water and other optional components in either a soluble state or a dispersion state. The aqueous elastomer dispersion may be prepared by dissolving an elastomer, such as rubber, and additives in a solvent mixture and then converting the resulting solution into an aqueous emulsion. The aqueous emulsion is concentrated and the solvent is stripped from it to yield a dilute latex. The dilute latex that is obtained is concentrated again. Articles made from the aqueous elastomer dispersion include medical gloves, condoms, probe covers, dental dams, finger cots, catheters and the like.

Owner:ALLEGIANCE CORP

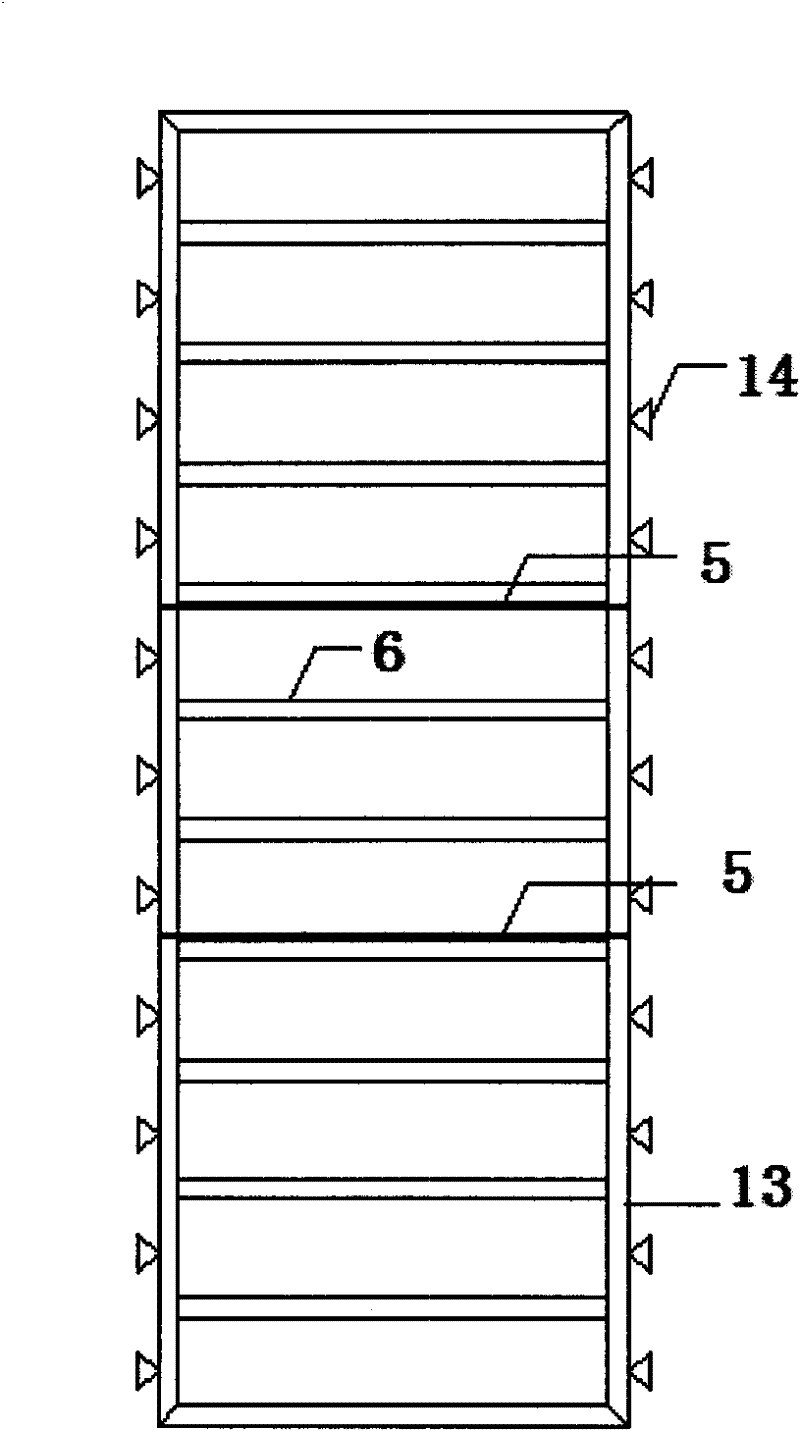

Open aluminium sheet without transverse frames

ActiveCN102220793AReduce Surface ContaminationSmooth circulationWallsAtmospheric pressureAbsorption effect

The invention relates to an open aluminium sheet without transverse frames. The aluminium sheet comprises aluminium veneers, hooks, a vertical column and waterproof sheets, wherein the aluminium veneers are hung on the vertical column by the hooks; aluminium sheet separating gaps are arranged among the aluminium veneers arranged up and down; the waterproof sheets are arranged behind the aluminium veneers and form air chambers with the aluminium veneers; and the pressure in the air chambers behind the aluminium veneers is equal to the external atmospheric pressure by using the aluminium sheet separating gaps. Compared with the prior art, the open aluminium sheet has the following advantages: the open aluminium sheet has good heat insulation and sound absorption effects and can volatilize the condensed water in the air layer circulation process; and surface pollution of the aluminium sheet is reduced so that the surface of the aluminium sheet is kept clean for a long time.

Owner:墙管家建筑科技(上海)有限公司

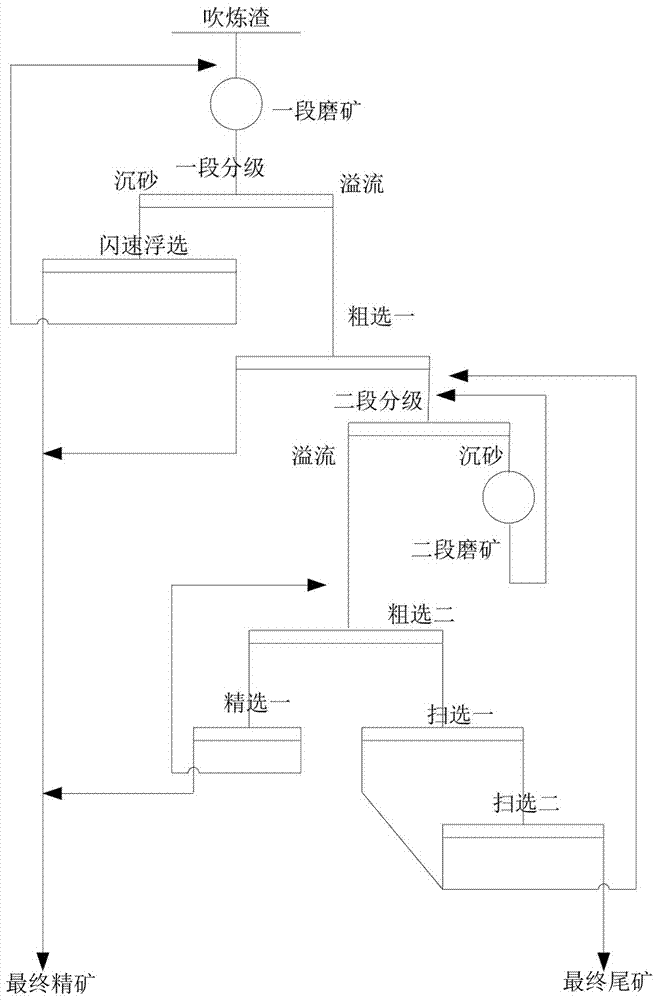

Beneficiation method for recovering copper from converting slag

InactiveCN107377202AHigh recovery rateReduces chances of returning to the mill for regrindingSolid separationCycloneSlag

The invention discloses a beneficiation method for recovering copper from converting slag. The beneficiation method comprises the following steps that (1) the converting slag subjected to grinding by a first-section ball grinding mill enters a first-section cyclone for classification, and first concentrates and first tailings are obtained by flash flotation of first-section classified set sand obtained by classification; (2) second concentrates and primary coarsely-selected tailings are obtained by primary coarse selection of first-section cyclone overflow products, second-section classified set sand is obtained after the primary coarsely-selected tailings are classified by a second-section cyclone, and the second-section classified set sand subjected to grinding by a second-section ball grinding mill returns to the second-section cyclone for classification; (3) first coarse concentrates and secondary coarsely-selected tailings are obtained by secondary coarse selection of second-section cyclone overflow products, and third concentrates and second tailings are obtained by selection of first coarse concentrates; (4) final tailings are obtained by primary scavenging and secondary scavenging of the secondary coarsely-selected tailings, and dehydrated tailings are obtained after the final tailings are concentrated and filtered; and (5) the first concentrates, the second concentrates and the third concentrates are combined into final concentrates, and copper concentrate products are obtained after the final concentrates are concentrated and filtered.

Owner:HENAN YUGUANG GOLD & LEAD

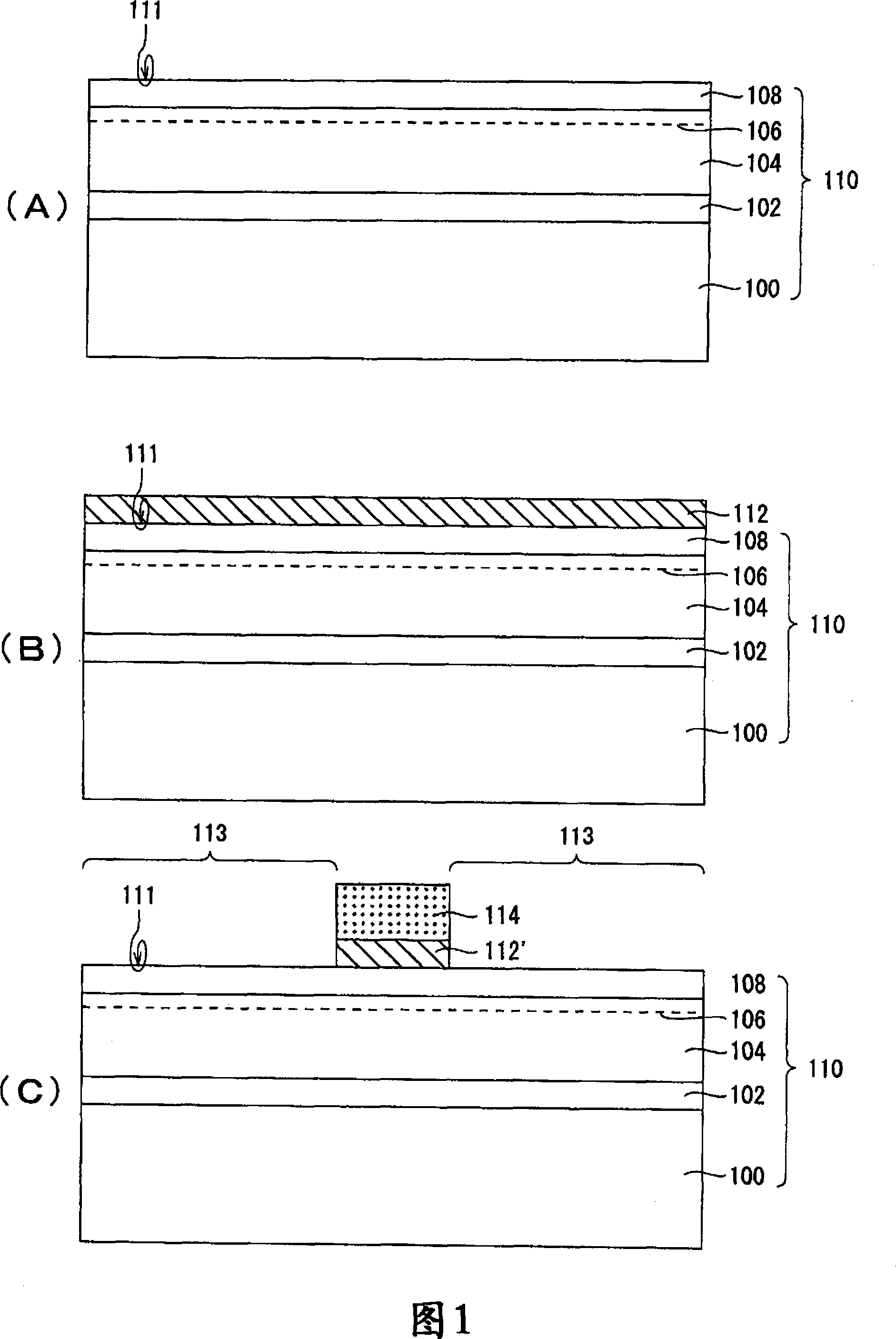

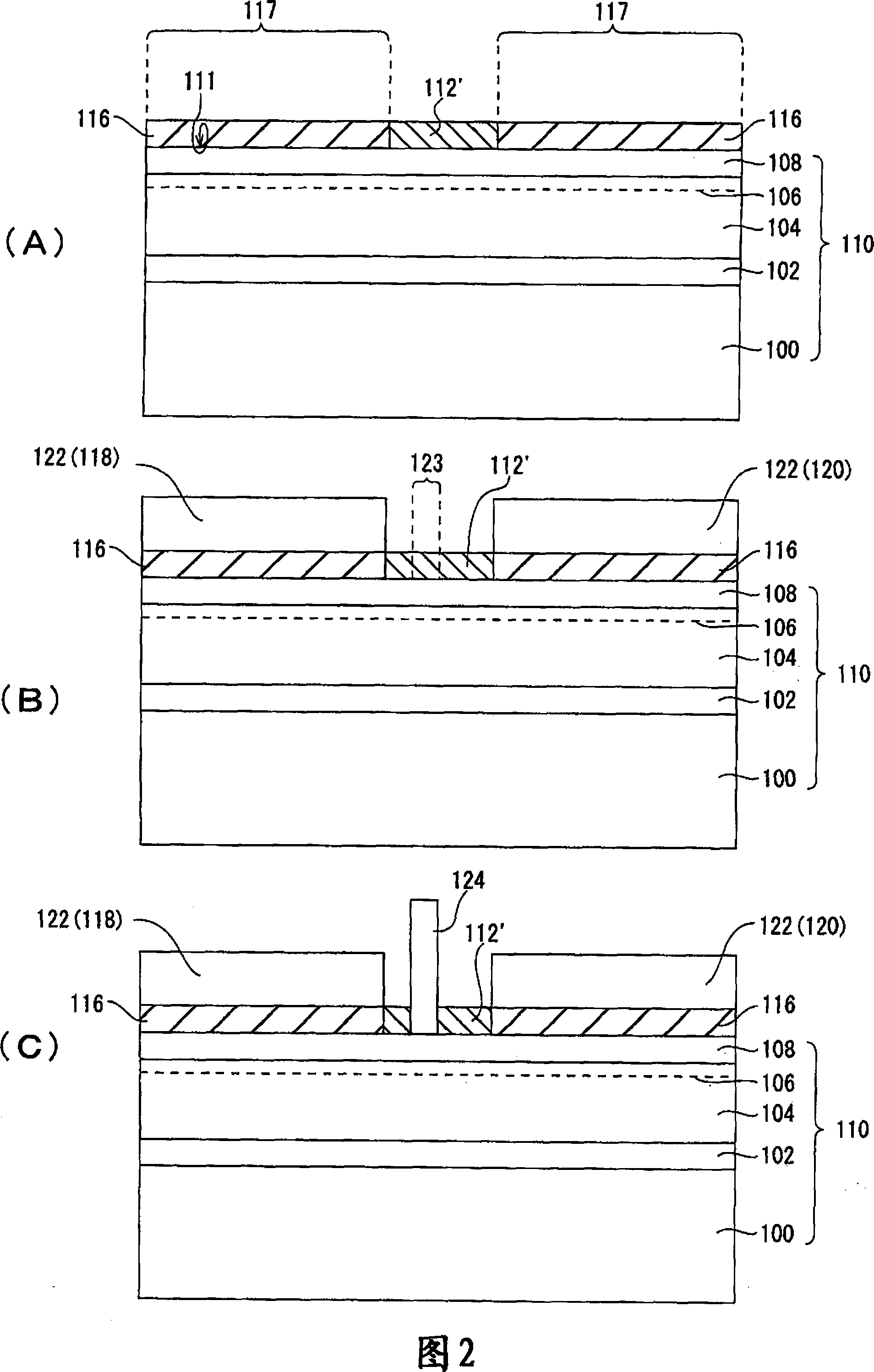

Method for manufacturing AlGaN/GaN-HEMT employing selective regrowth

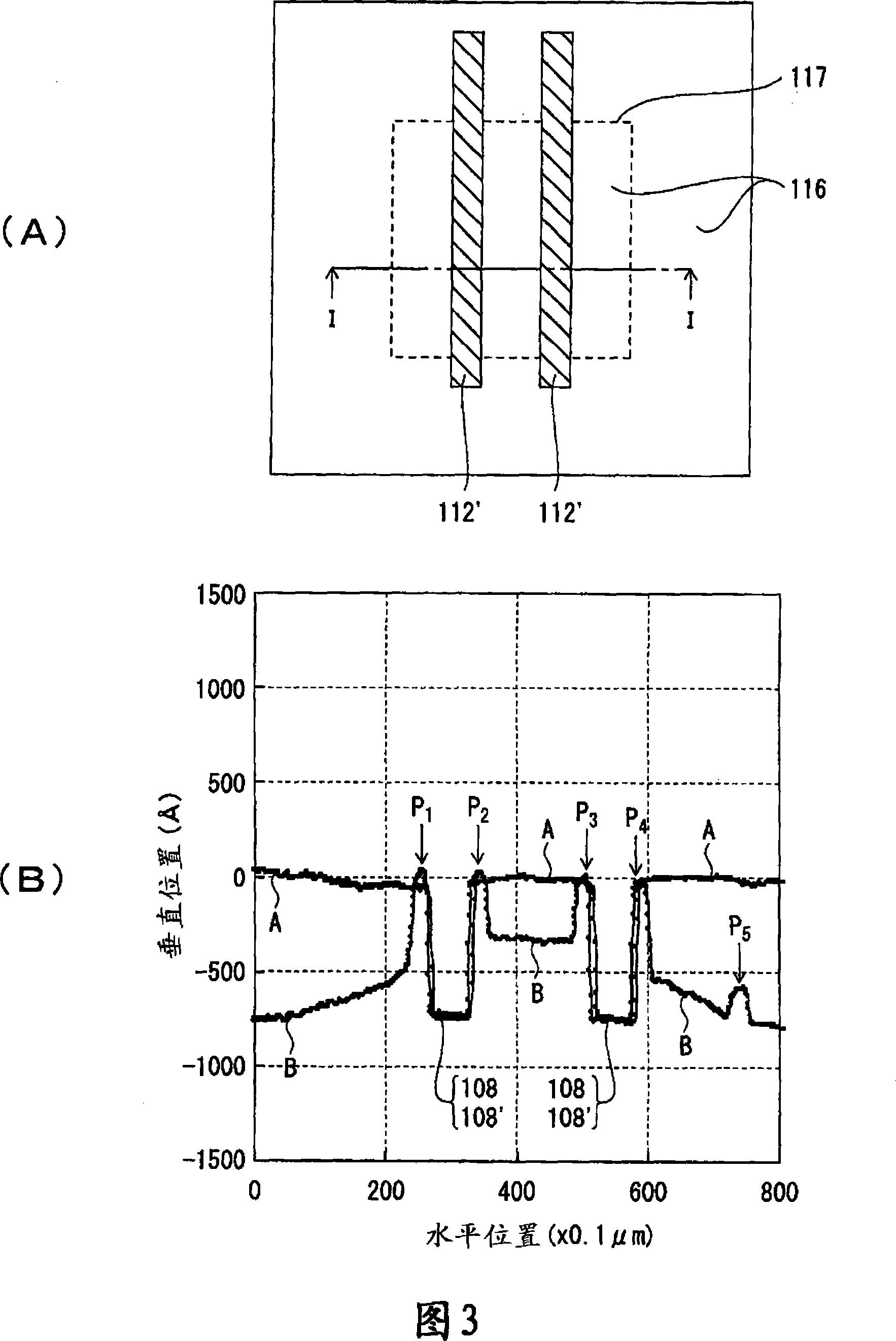

InactiveCN101183647ANo shape problemNo etch damageSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorOhm

The invention relates to a manufacturing method using AlGaN / GaN-HEMT which can selectively revegetate. The method includes preparing a semiconductor main body (110) formed with a laminated structure, which cascades a cushion breaker (102) on a substrate (100), a UID-GaN layer on the cushion breaker, and a UID-AlGaN layer on the UID-GaN layer. The pattern of an insulating film (112) is formed on the first major face (111) of the surface of the semiconductor main body used as the UID-AlGaN layer in order to form a mask of an insulating film (112'). An etching process is not processed on the surface of the semiconductor main body,therefore an nSUP and / SUP-GaN layer selectively revegetates on the surface of the major face (111) of the semiconductor main body apart from the area of the insulating film. An ohm electrode is divided, a preconcerted area (117) is formed and the ohm electrode (122) is formed in the area of the selectively revegetated nSUP and / SUP-GaN layer. Then a preconcerted area (123) is formed and an opening is formed by dividing a gate electrode, and the gate electrode (124) is formed.

Owner:OKI ELECTRIC IND CO LTD

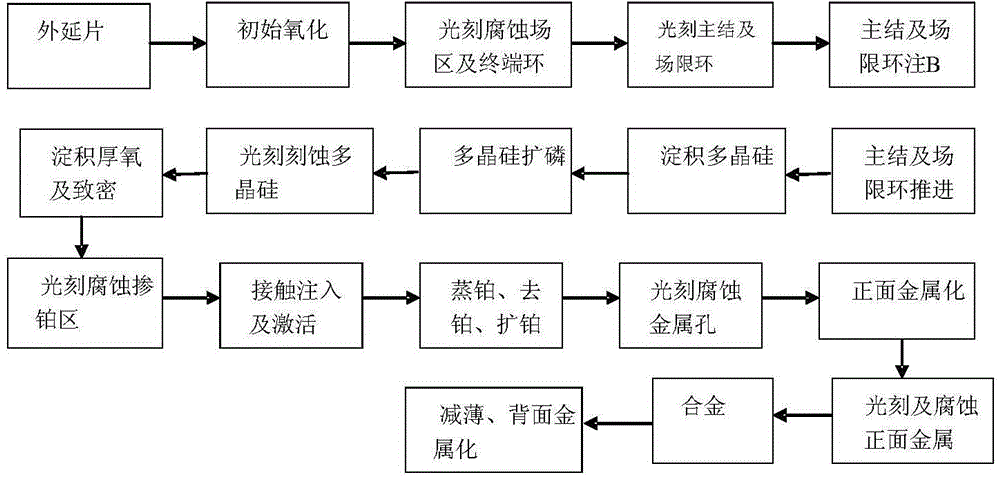

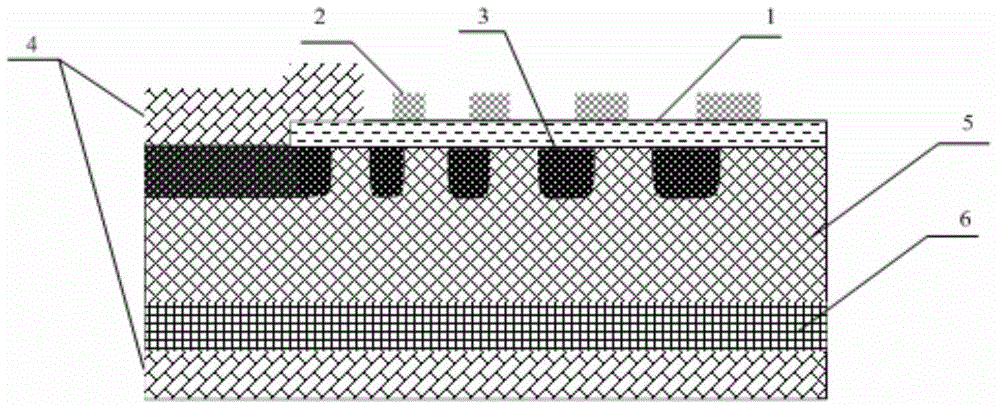

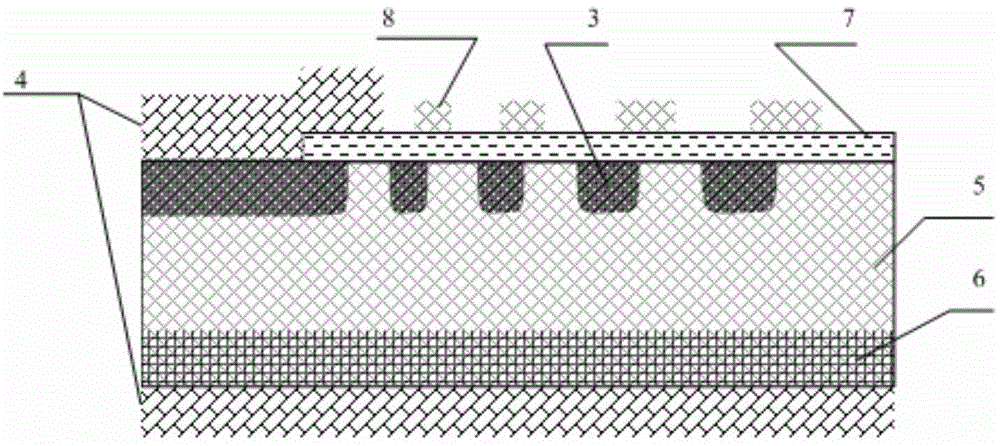

Preparation method of fast recovery diode

ActiveCN104616986AMass productionSuitable for military needsSemiconductor/solid-state device manufacturingSemiconductor devicesManufacturing technologySilicon dioxide

The invention provides a preparation method of a fast recovery diode; the method employs a SOI substrate to replace the conventional epitaxial wafer, and employs a planar manufacturing technology; the preparation method is compatible to the conventional fast recovery diode, and the method utilizes the silicon dioxide and the upper silicon in the SOI substrate as the field oxide and the field plate; due to the fact that the silicon dioxide in the SOI substrate is formed by absolutely pure oxygen atom injection, the silicon dioxide purity is high and in good contact with the lower silicon crystal, thus well reducing the surface pollution of the fast recovery diode, reducing the formation of surface charge, thereby reducing electric leakage on the surface, increasing the electric property and rate of finished product of the fast recovery diode; the preparation method of the fast recovery diode employs the SOI substrate to replace the conventional epitaxial wafer, thus reducing the manufacturing steps of the fast recovery diode, improving the quality of the field oxide and the polycrystalline silicon field plate, greatly reducing the charge of oxide layer interface, and increasing the consistency of the technology.

Owner:BEIJING MXTRONICS CORP +1

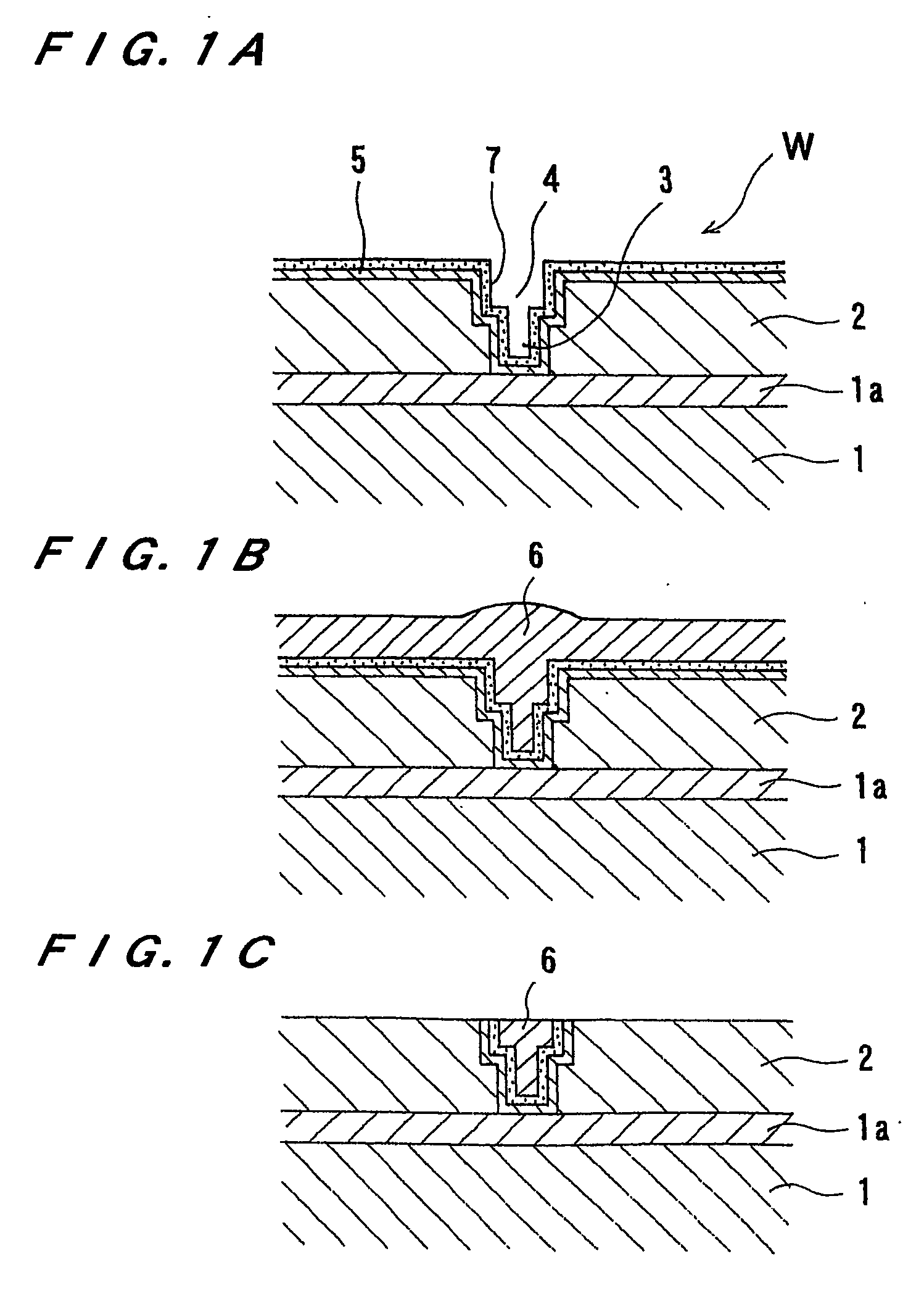

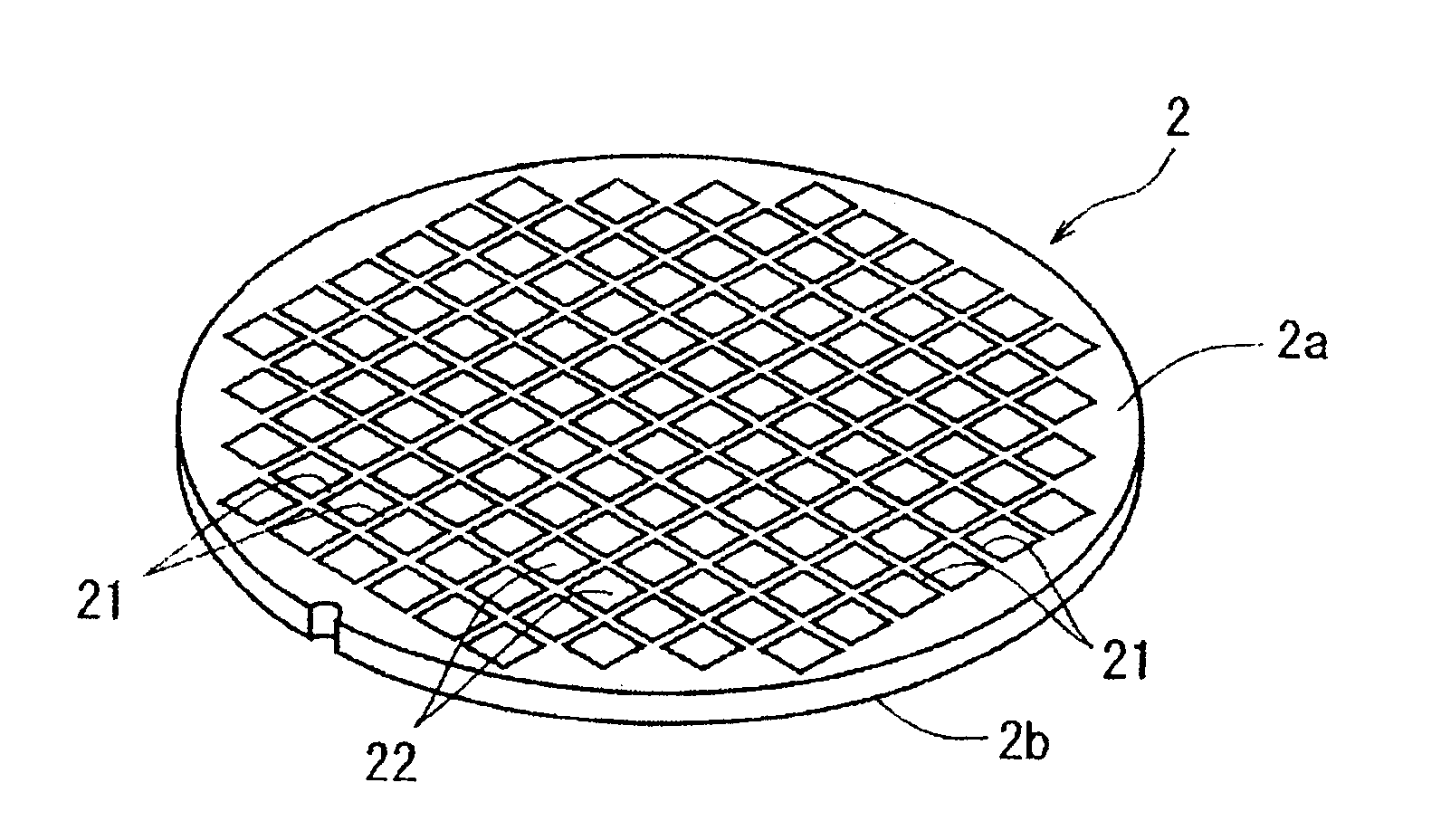

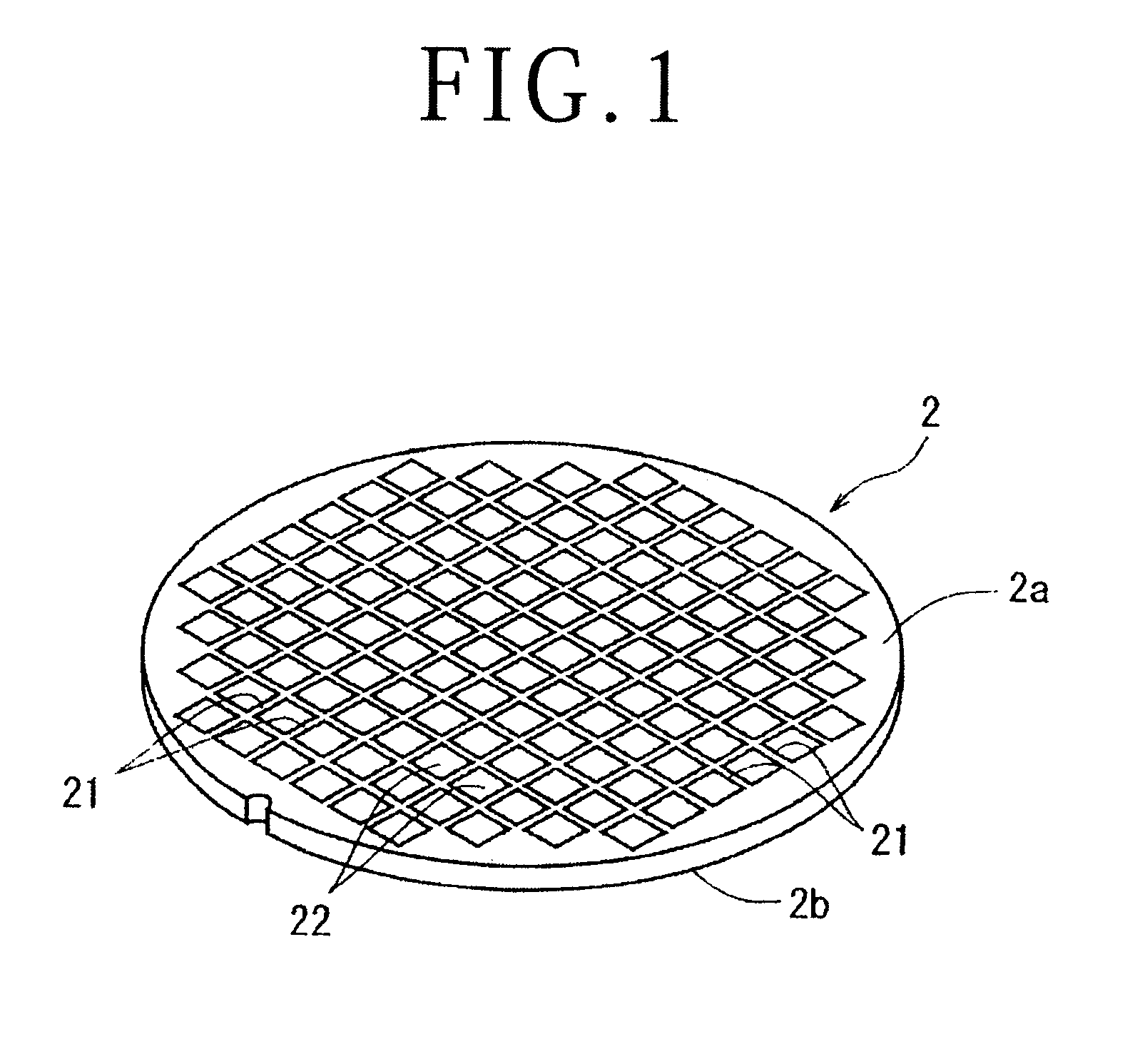

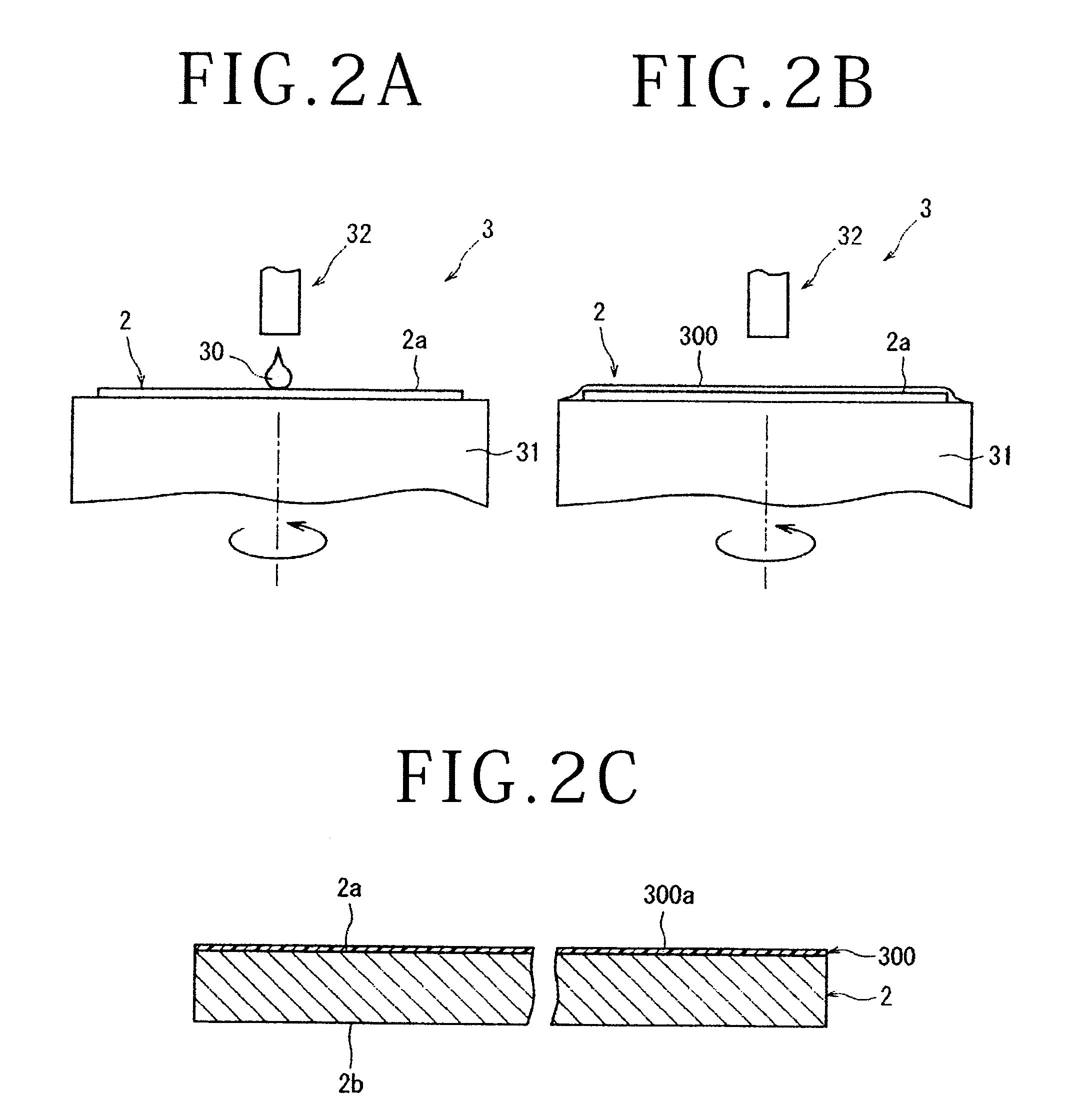

Wafer processing method

ActiveUS20150357224A1Quality improvementThin waferSolid-state devicesSemiconductor/solid-state device manufacturingTectorial membraneSplit lines

In a wafer processing method, a protective film is formed by applying a liquid resin to the front side of a wafer. A protective tape is adhered to a surface of the protective film. A modified layer is formed by applying a laser beam having such a wavelength as to be transmitted through the wafer along each of division lines, with a focal point positioned inside the wafer. The modified layer is formed inside the wafer along each of the division lines. The back side of the wafer is ground while supplying grinding water to thin the wafer to a predetermined thickness and to crack the wafer along the division lines using the modified layers as crack starting points so as to divide the wafer into individual device chips, after the protective film is formed, the protective tape is adhered, and the modified layer is formed.

Owner:DISCO CORP

Chemical mechanical polishing liquid and preparation method thereof

InactiveCN105623526AAvoid harmImprove polishing effectPolishing compositions with abrasivesSodium bicarbonateSemiconductor chip

The invention discloses a chemical mechanical polishing liquid and a preparation method thereof. The chemical mechanical polishing liquid is prepared from, by weight, 15-30 parts of phosphoric acid, 10-20 parts of sodium tetraborate, 10-20 parts of sodium silicate, 10-20 parts of sodium bicarbonate, 10-20 parts of sodium citrate, 25-45 parts of deionized water, 10-15 parts of talcum powder, 8-10 parts of calcium carbonate, 1-10 parts of oxidizing agent, 5-10 parts of liquid paraffin, 2-10 parts of corrosion inhibitor, 1-10 parts of surfactant, 1-9 parts of pH regulator, 1-3 parts of kaolin, 1-2 parts of diatomite, 1-2 parts of lamellar mica powder and 1-2 parts of hollow glass beads. The raw materials are stirred, heated and mixed to obtain the chemical mechanical polishing liquid. The chemical mechanical polishing liquid is effective in polishing, harmless to surfaces of semiconductor chips, safe, nontoxic, free of harmful gases and capable of increasing polishing speed and reducing surface contaminants of polishes materials.

Owner:章建群

Non-corrosive polishing solution of mechanical equipment

InactiveCN103468150AInhibition of polishing rateThe removal rate has little effectPolishing compositionsSodium acetateMechanical equipment

The invention discloses a non-corrosive polishing solution of mechanical equipment, which comprises the following substances in parts by weight: 21-30 parts of sodium salicylate, 9-12 parts of sodium acetate, 8-10 parts of sodium oxalate, 2-8 parts of sodium benzoate, 3-6 parts of monopotassium phosphate, 1-2 parts of antistatic agent, 4-9 parts of methyl silicone oil, 8-13 parts of liquid halloysit, 3-8 parts of stearic acid, 7-10 parts of purifier, 11-18 parts of treatment agent, 3-5 parts of titanium dioxide, 2-4 parts of monopotassium phosphate, 1-2 parts of molecular sieve, 1 part of kieselguhr, 2-4 parts of sodium borate, 1 part of mica powder in a laminated structure and 1-2 parts of hollow glass microsphere. The chemical machinery polishing solution can inhibit the polishing velocity of a low dielectric material, has a small influence on the removal velocity of copper and silicon dioxide, and can reduce pollutants on the surface of a polished material.

Owner:QINGDAO CHENGTIAN WEIYE MACHINERY MFG

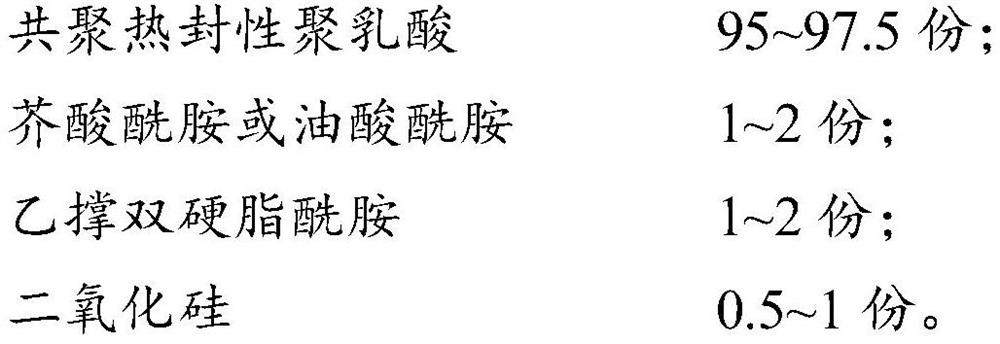

Degradable biaxially stretching polylactic acid cigarette film and preparation method thereof

PendingCN112848599AReduce pollutionTransparency makes no differenceLamination ancillary operationsSynthetic resin layered productsPolymer scienceBoPET

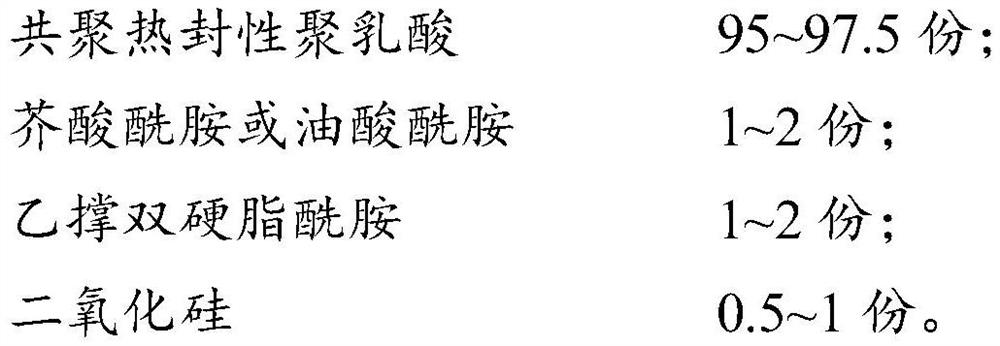

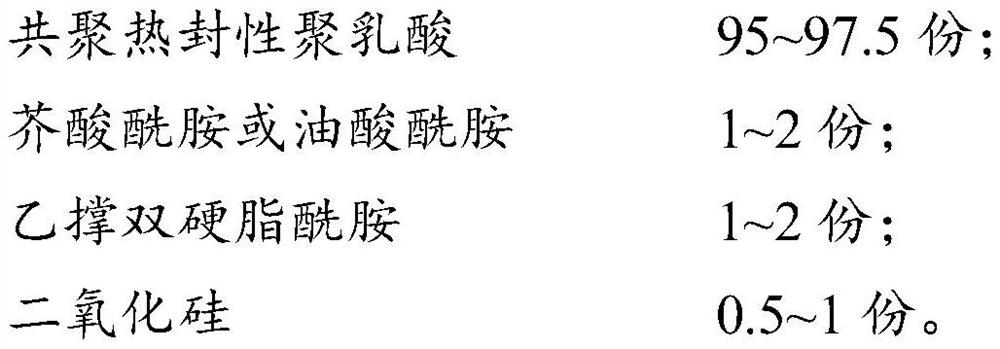

The invention belongs to the technical field of cigarette films. The invention provides a degradable biaxially stretching polylactic acid cigarette film. The degradablebiaxially stretching polylactic acid cigarette film comprises a first functional layer, a second functional layer, a core layer, a third functional layer and a fourth functional layer which are sequentially arranged in a contact manner, the weight ratio of the first functional layer to the second functional layer to the core layer to the third functional layer to the fourth functional layer is (5-10): (5-10): (60-80): (5-10): (5-10); the first functional layer comprises the following components in parts by weight: 95 to 97.5 parts of copolymerized heat-sealable polylactic acid; 1 to 2 parts of erucyl amide or oleamide; 1 to 2 parts of ethylene bis stearamide; and 0.5 to 1 part of silicon dioxide. The invention also provides a preparation method of the degradable biaxially stretching polylactic acid cigarette film. The polylactic acid smoke film can be completely degraded and has an antibacterial function; and the transparency, the heat sealing strength, the elastic modulus and the shrinkage rate are the same as those of a polypropylene smoke film.

Owner:HUBEI FIRSTA MATERIALS SCI & TECH GRP

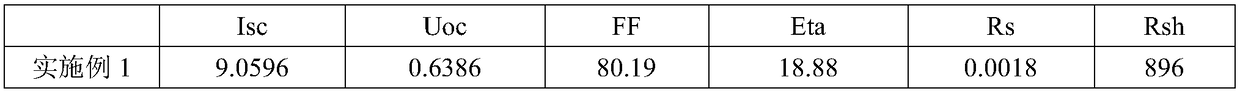

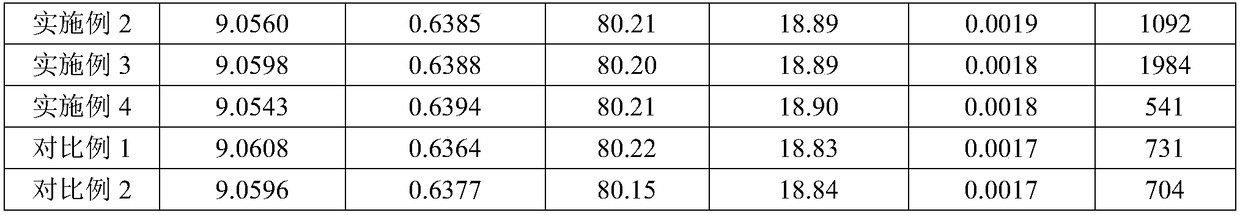

A cleaning process before preparing black silicon by solar polycrystalline RIE

InactiveCN109148265AReduce Surface ContaminationReduce body recombinationFinal product manufactureSemiconductor/solid-state device manufacturingChemistryOxide

The invention belongs to the technical field of solar polycrystalline battery pieces. The invention discloses a cleaning process before preparing black silicon by solar polycrystalline RIE, which comprises the steps of pre-cleaning, cleaning, removing oxide layer and drying, wherein the pre-cleaning stage adopts a mixed solution of sodium hydroxide and hydrogen peroxide for cleaning, and the cleaning stage adopts a high-concentration alkaline solution for impregnating, wherein the pre-cleaning stage adopts a high-concentration alkaline solution for impregnating. The method of the invention canuse simple groove-type equipment to pre-clean the RIE black silicon of mortar / diamond wire silicon wafer, not only removing the damage layer generated in the silicon wafer cutting process, but also removing the impurities on the silicon wafer surface, such as grease, metal particles and other organic matter; For the original silicon wafer surface impurities treatment can reduce surface contamination reduce internal recombination in the subsequent diffusion, and hydrogen passivation can get a good passivation effect, thus improving the conversion efficiency of black silicon battery.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

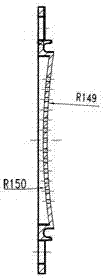

Method for reducing surface pollution generated when ion beams polish optical element

ActiveCN110712094APrevent sputtering outCleanliness effectOptical surface grinding machinesIon beam processingAdhesive belt

The invention relates to a method for reducing the surface pollution generated when ion beams polish an optical element. The method comprises the steps that 1), high-temperature adhesive tape is usedfor carrying out sealing treatment on the outer side of a clamp used for clamping the optical element in ion beam polishing equipment; 2), after the optical element is mounted on the clamp, the surfaces of the optical element and the clamp are cleaned, then the optical element and the clamp are placed in a secondary chamber of the ion beam polishing equipment, and finally the optical element is sent to a main chamber of the ion beam polishing equipment; 3), an ion source is mounted, and a grid network of the ion source adopts a grid network with the sputtering rate being lower than the metal silver sputtering rate; and 4), the ion beam polishing equipment is started, the ion source is started, an ion beam current emitted by the ion source is measured by using the Faraday cup, and after theion source runs for a certain set time t, the optical element is subjected to ion beam polishing. By adopting the method, the surface of the optical element after ion beam processing is clean, the pollution is effectively inhibited, and the processing quality is improved.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

High-compactness anti-fouling marking paint

InactiveCN110079138AReduce porosityImprove compactnessFireproof paintsAntifouling/underwater paintsPorosityCoated surface

The invention discloses a high-compactness anti-fouling marking paint. The high-compactness anti-fouling marking paint comprises primer and finish paint, and is characterized in that the primer and the finish paint are dual-component paints; the primer is colored paint, and the finish paint is varnish; during use, the primer and a curing agent are sprayed to the pavement after being mixed in the volume ratio of 98:2, and then a layer of finish paint is immediately coated and sprayed on the wet primer surface; the finish paint and the primer are in chemical crosslinking reaction to form anti-fouling marking. The paint film is small in porosity and high in compactness; the paint film is covered on the surface of the coating, the adhesion and corrosion to the coating by the dust, the oil contamination and fine particulate matters and like pollutants is prevented and reduced, and the coating anti-fouling performance is greatly improved; the finish paint and the primer are bounded through the chemical crosslinking reaction, two coatings are firmly adhered to form the marking coating heat resistance stability; the coating cannot become tacky and soft after encountering the heat, therebyeffectively preventing the pollutant from adhering or embedding into the coating to form the pollution. The high-compactness anti-fouling marking paint disclosed by the invention is suitable for the urban road marking and the lane edge marking of the highway.

Owner:南宁华之邦交通设施材料有限公司

AM-EWOD device and method of driving with variable voltage AC driving

ActiveUS9169573B2Reduce the starting voltageImprove equipment reliabilityElectrolysis componentsStatic indicating devicesDielectricLow voltage

An active matrix electrowetting on dielectric (AM-EWOD) device includes a substrate electrode and a plurality of array elements, each array element including an array element electrode. The AM-EWOD device further includes thin film electronics disposed on a substrate. The thin film electronics includes first circuitry configured to supply a first time varying signal V1 to the array element electrodes, and second circuitry configured to supply a second time varying signal V2 to the substrate electrode. An actuation voltage is defined by a potential difference between V2 and V1, and the first circuitry further is configured to adjust the amplitude of V1 to adjust the actuation voltage. V1 may be adjusted to adjust the actuation voltage while V2 remains unchanged. The actuation voltage may be controlled to operate the AM-EWOD device between high and low voltage modes of operation in accordance with different droplet manipulation operations to be performed.

Owner:SHARP LIFE SCI EU LTD

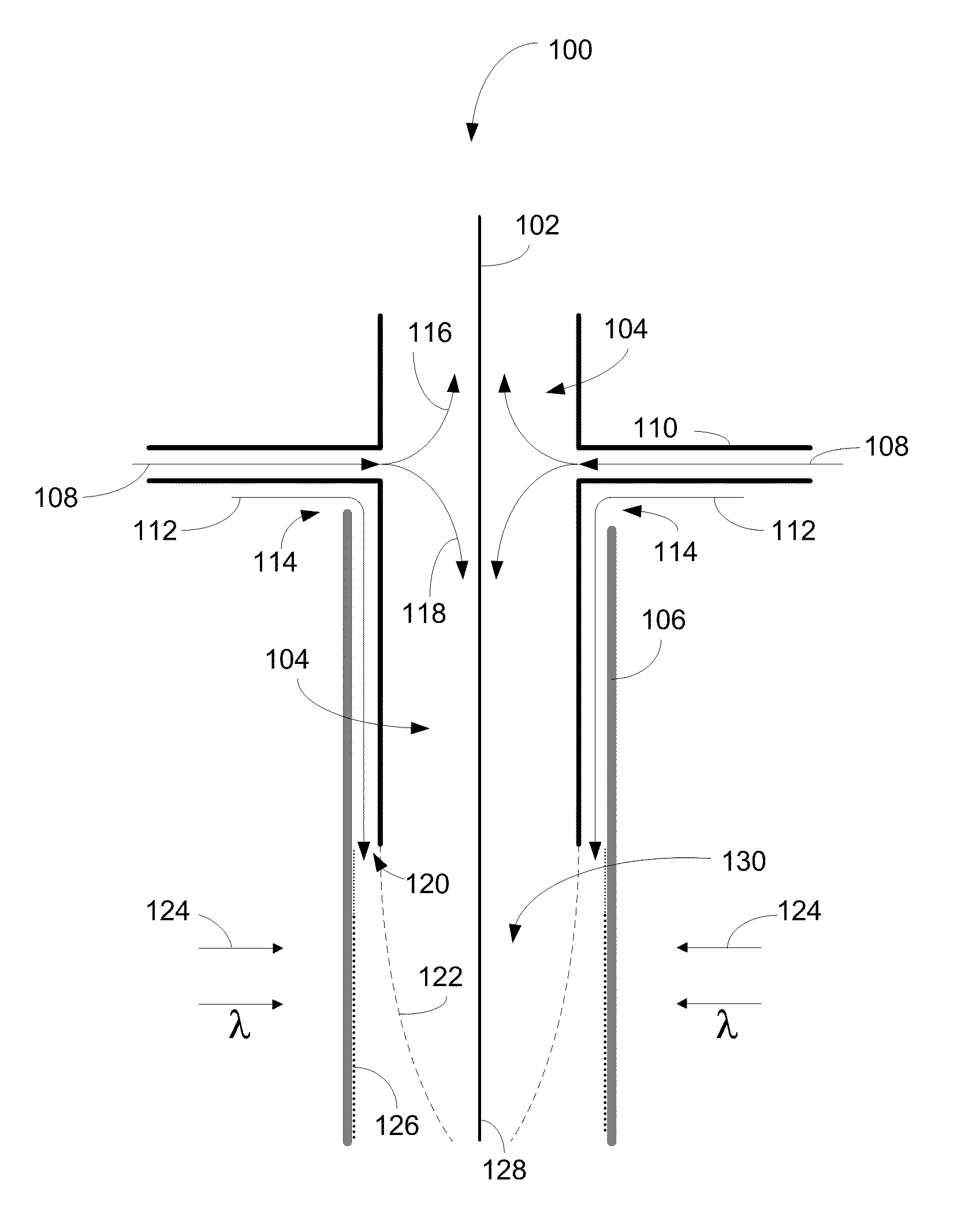

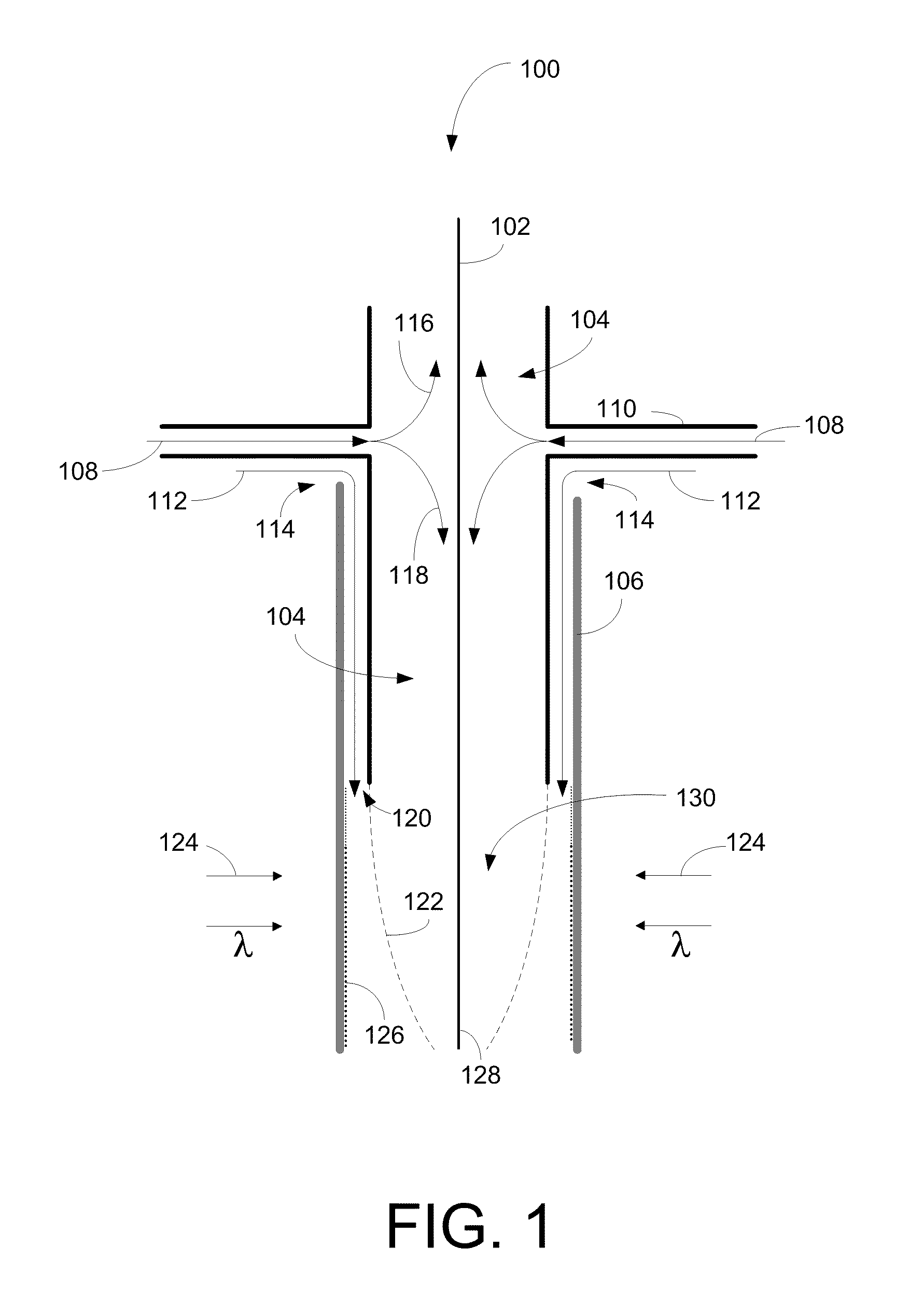

Systems and methods for purging UV curing tubes

ActiveUS20110159178A1Reduce decreaseReduce Surface ContaminationDrying solid materials with heatDrying gas arrangementsFiberUV curing

Certain embodiments of the invention may include systems and methods curing a coated optical fiber. The method includes drawing the coated optical fiber through a gas chamber filled with a predetermined gas, drawing the fiber through a cure tube coupled to the gas chamber, and purging at least a portion of an inner surface of the cure tube with a purge gas as the coated optical fiber is drawn through the cure tube.

Owner:OFS FITEL LLC

Chemical mechanical equipment polishing solution

InactiveCN103468147AInhibition of polishing rateThe removal rate has little effectPolishing compositions with abrasivesMonopotassium phosphateMechanical equipment

The invention discloses a chemical mechanical equipment polishing solution which comprises the following substances in parts by weight: 15-35 parts of sulfocyanate, 15-25 parts of salicylate, 7-16 parts of ethylene bis stearamide, 9-13 parts of glycerol monostearate, 9-14 parts of glycerol tristearate, 1-3 parts of reducing agent, 5-8 parts of softening agent, 7-10 parts of decontamination agent, 11-18 parts of treatment agent, 3-5 parts of titanium dioxide, 2-4 parts of monopotassium phosphate, 1-2 parts of molecular sieve, 1 part of kieselguhr, 2-4 parts of sosium borate, 1 part of mica powder with a lamellar structure, and 1-2 parts of hollow glass bead. The chemical mechanical polishing solution can restrain a polishing rate of a low-dielectric material, has a small influence on a removal rate of copper and silicon dioxide, and can reduce surface contaminants of a polished material.

Owner:QINGDAO CHENGTIAN WEIYE MACHINERY MFG

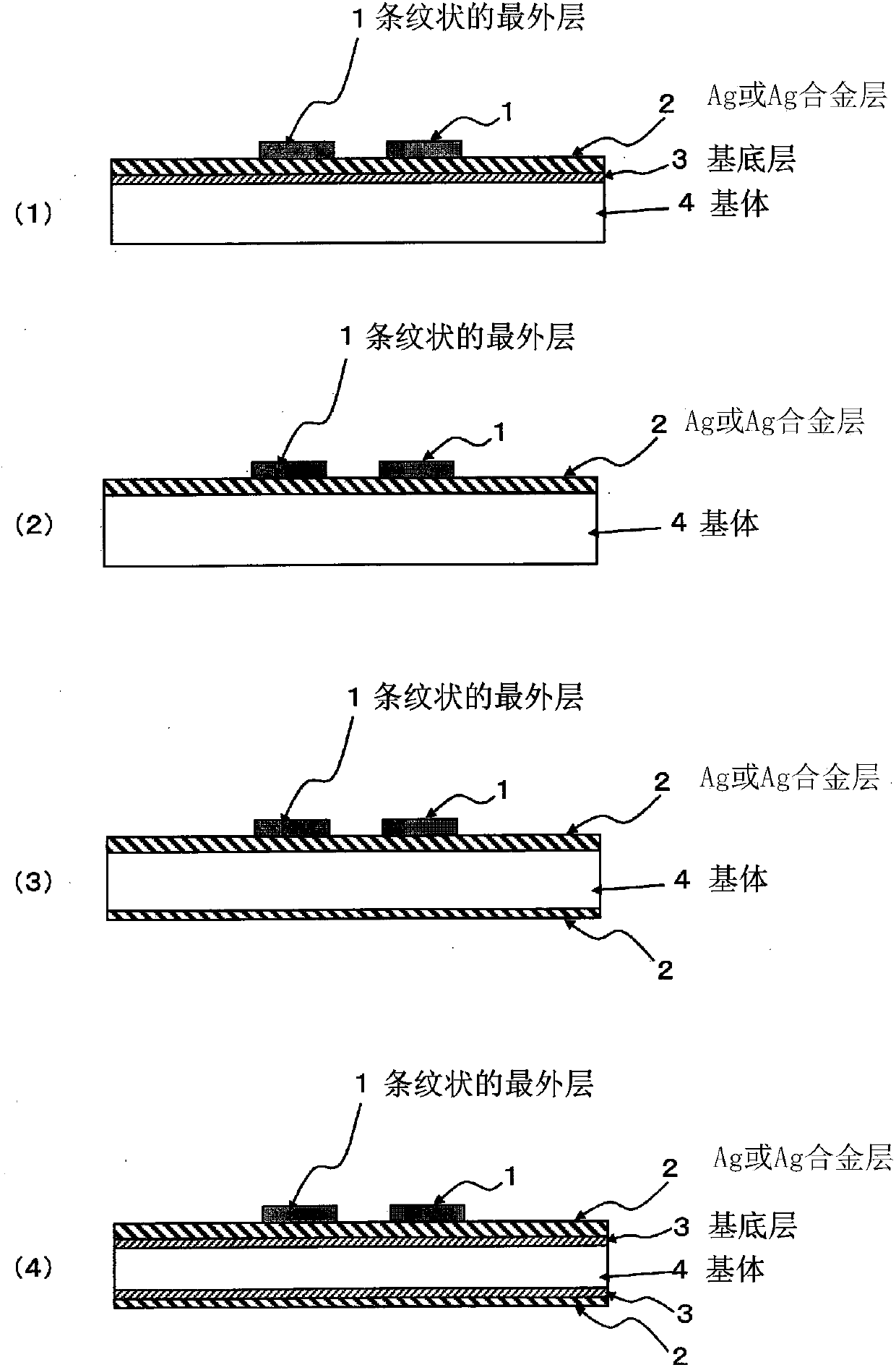

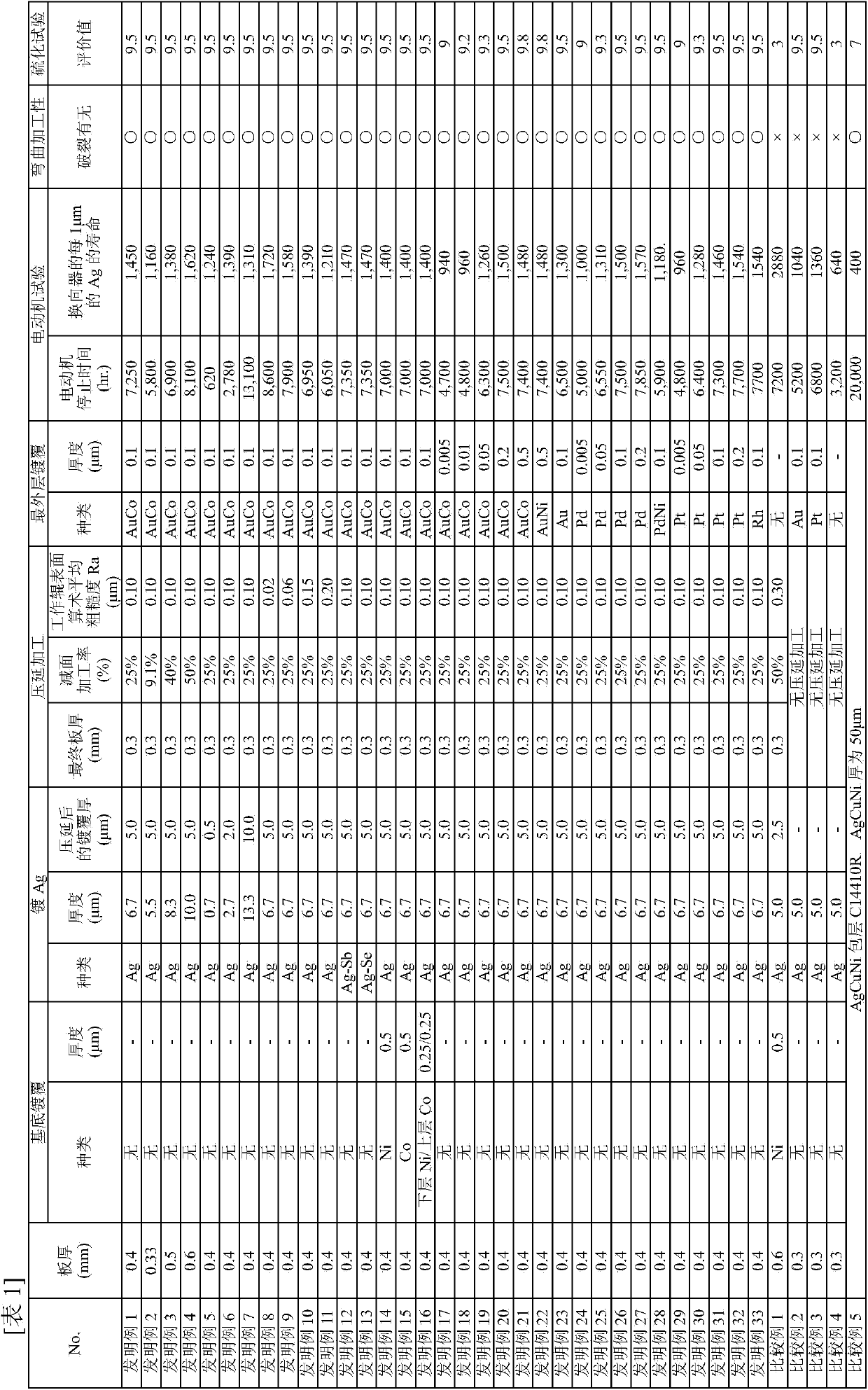

Commutator material, method for manufacturing same, and micromotor using same

InactiveCN103857522AReduce usageImprove overall lifespanRotary current collectorPiezoelectric/electrostriction/magnetostriction machinesGold alloysMicromotor

A commutator material such that all or part of a conductive substrate is plated with silver or a silver alloy, and the silver or silver-alloy surface is further plated with gold or a gold alloy, the commutator material being characterized in that after the conductive substrate is plated with the silver or silver alloy, surface-reduction processing is performed and then the gold or gold alloy is applied in stripes.

Owner:FURUKAWA ELECTRIC CO LTD

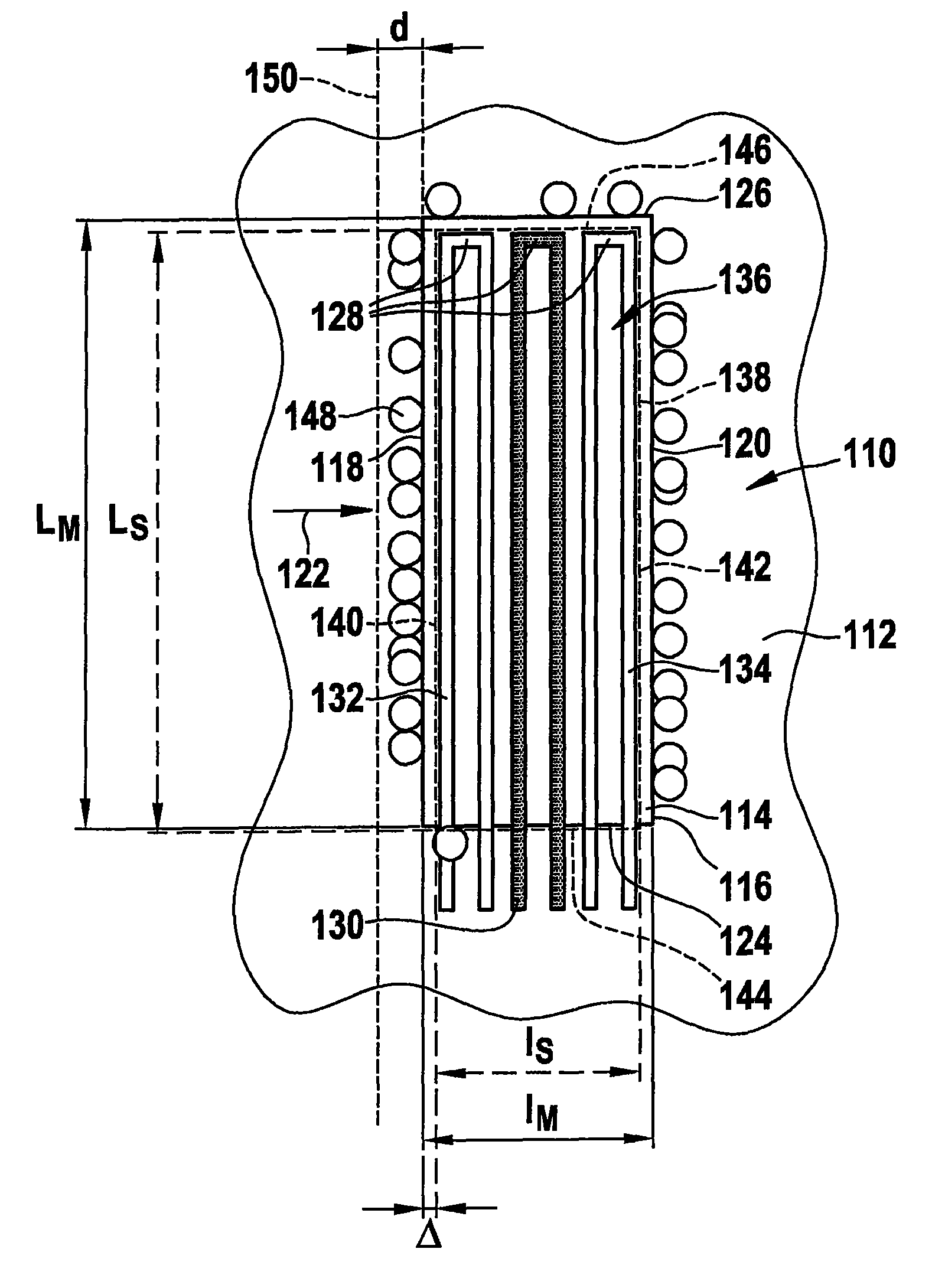

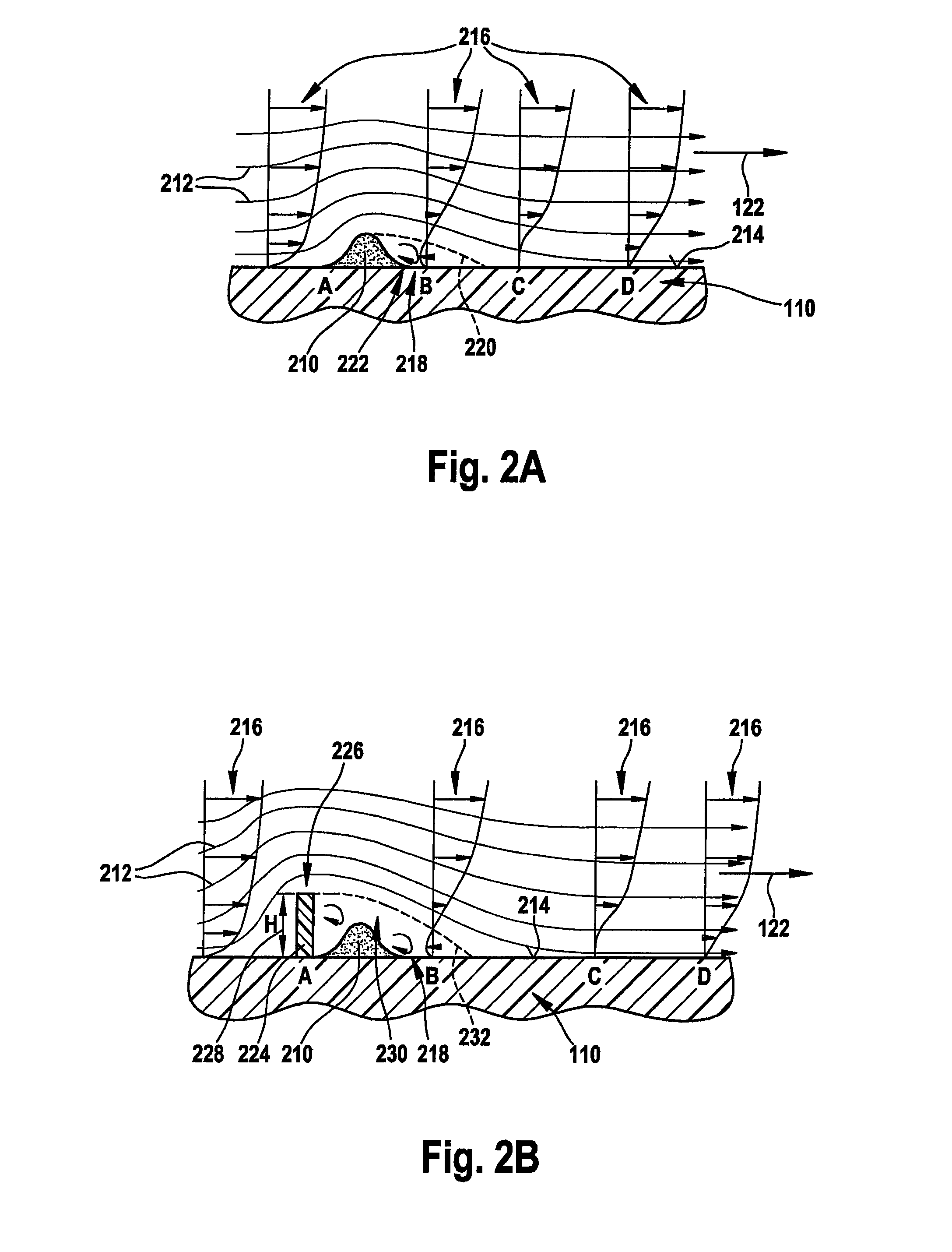

Hot-film air-mass meter having a flow separating element

InactiveUS8448503B2Reduce Surface ContaminationReduce instabilityInternal-combustion engine testingVolume/mass flow by thermal effectsEngineeringInternal combustion engine

A hot-film air-mass meter for measuring an air-mass flow which flows in the main direction of the flow, which can be used, in particular, in the intake tract of an internal combustion engine. The hot-film air-mass meter comprises a sensor chip having a measuring surface. The air-mass flow flows essentially parallel over one surface of the sensor chip. A flow separating element is mounted upstream from the measuring surface with respect to the main flow direction. The at least one flow separating element is designed in such a way that the air-mass flow is separated from the measuring surface of the sensor chip in at least one separation zone prior to reaching the measuring surface.

Owner:ROBERT BOSCH GMBH

Anticorrosive equipment polishing solution

InactiveCN104059540AInhibition of polishing rateThe removal rate has little effectPolishing compositions with abrasivesPolyvinyl alcoholStearic acid

The invention discloses an anticorrosive equipment polishing solution, which is characterized by including the following materials by weight: 4-13 parts of sodium chloride, 9-17 parts of fatty alcohol sodium sulfate, 4-10 parts of nano-organic montmorillonite, 1-7 parts of a stearic acid salt, 10-15 parts of polyvinyl alcohol, 9-10 parts of mica powder, 14-23 parts of sodium salicylate, 1-3 parts of paraformaldehyde, 1-2 parts of silver sulfate, 1-2 parts of copper sulfate, 9-13 parts of a molecular sieve, 8-10 parts of diatomite, 3-10 parts of sodium borate, 4-9 parts of methyl silicone oil, and 1-2 parts of hollow glass beads. The chemical mechanical polishing solution provided by the invention can restrain the polishing rate of low dielectric materials, has little influence on the removal rate of copper and silica, and also can reduce the surface pollutants of polished materials.

Owner:QINGDAO XIANGHAI ELECTRONICS

Contamination monitoring and control techniques for use with an optical metrology instrument

ActiveUS20100000569A1Eliminate, the build-up of contaminantsReduce Surface ContaminationElectrostatic cleaningOptically investigating flaws/contaminationOptical radiationUltraviolet

A technique is provided for monitoring and controlling surface contaminants on optical elements contained within the optical path (or sub-path) of an optical metrology instrument. The technique may be utilized in one embodiment in such a manner as to not require that additional components and / or instrumentation be coupled to, or integrated into, existing metrology equipment. Surface contaminants on optical elements within an optical metrology instrument are monitored so that cleaning procedures can be performed as deemed necessary. The cleaning procedures may include the use of exposing the optical elements to optical radiation. The optical metrology instrument may be an instrument which operates at wavelengths that include vacuum ultra-violet (VUV) wavelengths.

Owner:BRUKER TECH LTD

Ultrathin transparent nano/micron structure self-assembly film and green preparation method thereof

ActiveCN110240117ASimple processEasy to implementMaterial nanotechnologySemi-permeable membranesHigh volume manufacturingElectrical devices

The invention discloses an ultrathin transparent nano / micron structure self-assembly film and a green preparation method thereof. The green preparation method comprises the following steps: dispersing a nano / micron structure and / or a modifier thereof into a first liquid phase system to form a nano / micron structure dispersion liquid; spraying the nano / micron structure dispersion liquid to the surface of a second liquid phase system in a spraying manner, and removing the second liquid phase system to obtain a nano / micron structure film; and carrying out extrusion treatment on the nano / micron-structure film, so that the nano / micron-structure film is self-assembled on a gas-liquid interface to form a compact and stable thickness-controllable nano / micron-structure self-assembled film. The nano / micron particles and the modified film thereof have good comprehensive performance and can be widely applied to optical and electrical devices and nano coatings; and meanwhile, the preparation method is simple in preparation process flow, convenient to operate and low in requirement on environmental factors, does not cause any influence, and meets the requirements of industrial large-area and large-batch production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com