Method for manufacturing AlGaN/GaN-HEMT employing selective regrowth

A manufacturing method and structure technology, which are applied in the field of manufacturing AlGaN/GaN-HEMT using selective regrowth, can solve the problems of AlGaN/GaN-HEMT device characteristic deviation, device reliability deterioration, etching damage and etching end, etc. The effect of maximum drain current and mutual conductance, shortened manufacturing process, and no etching damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

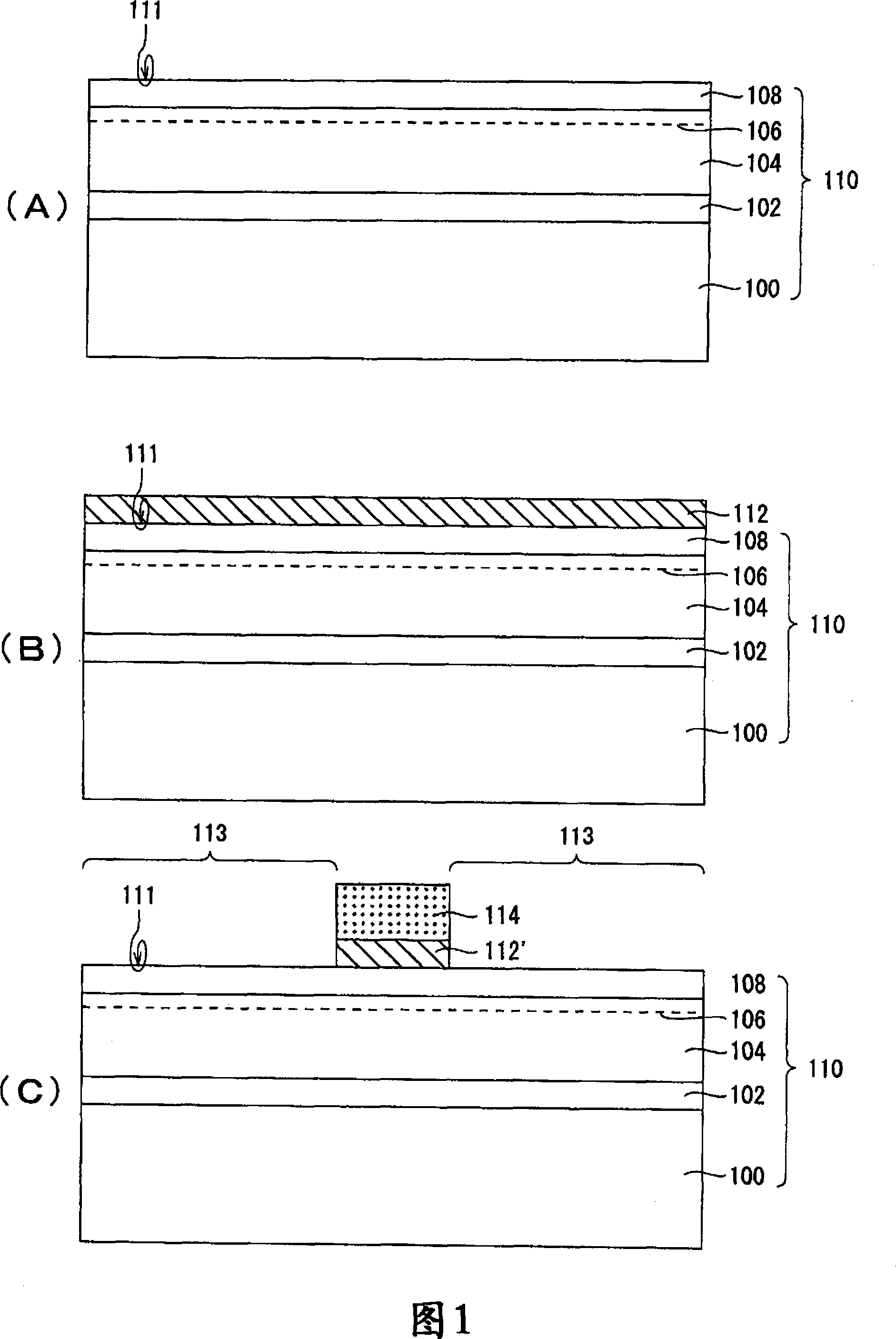

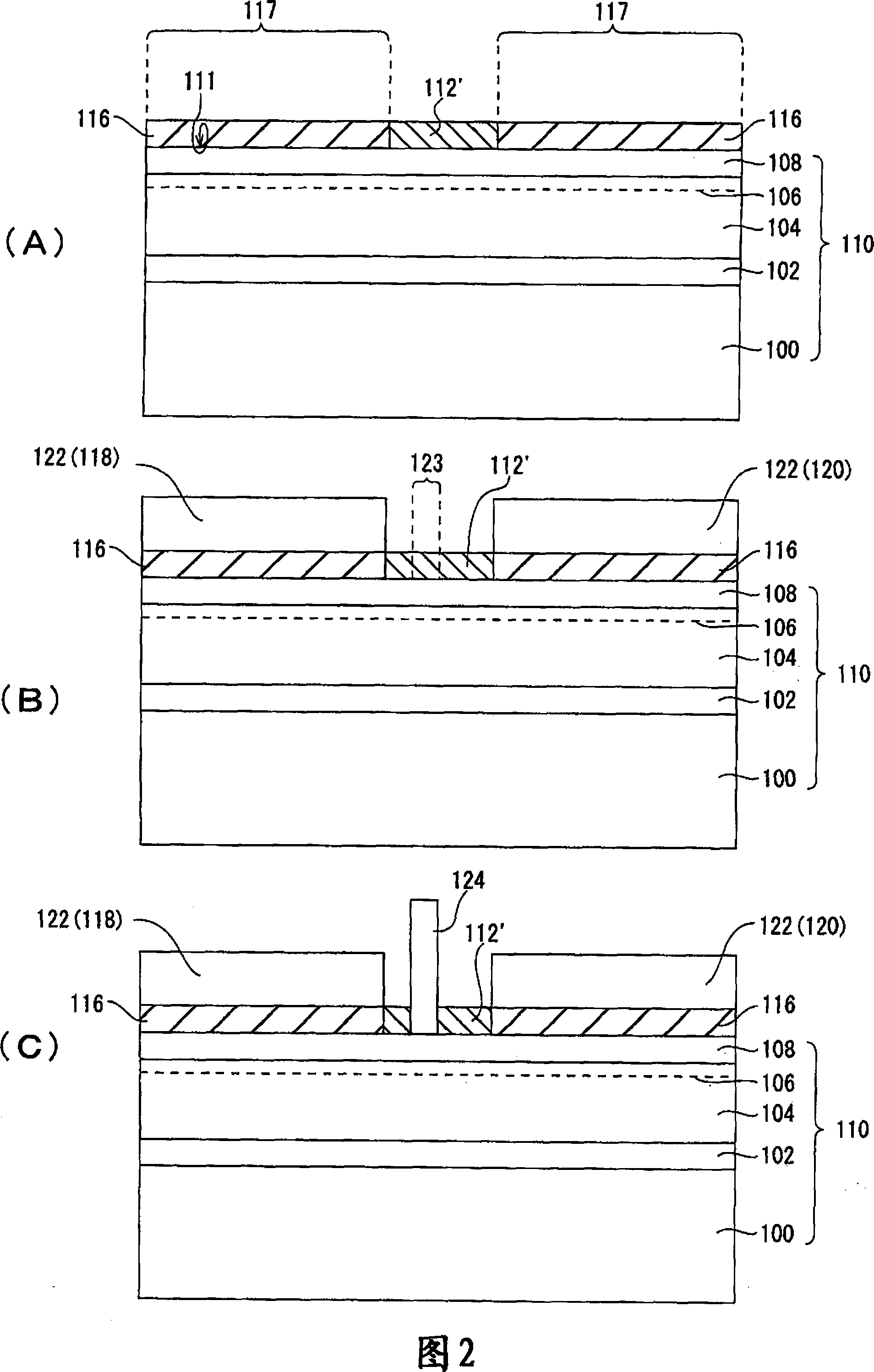

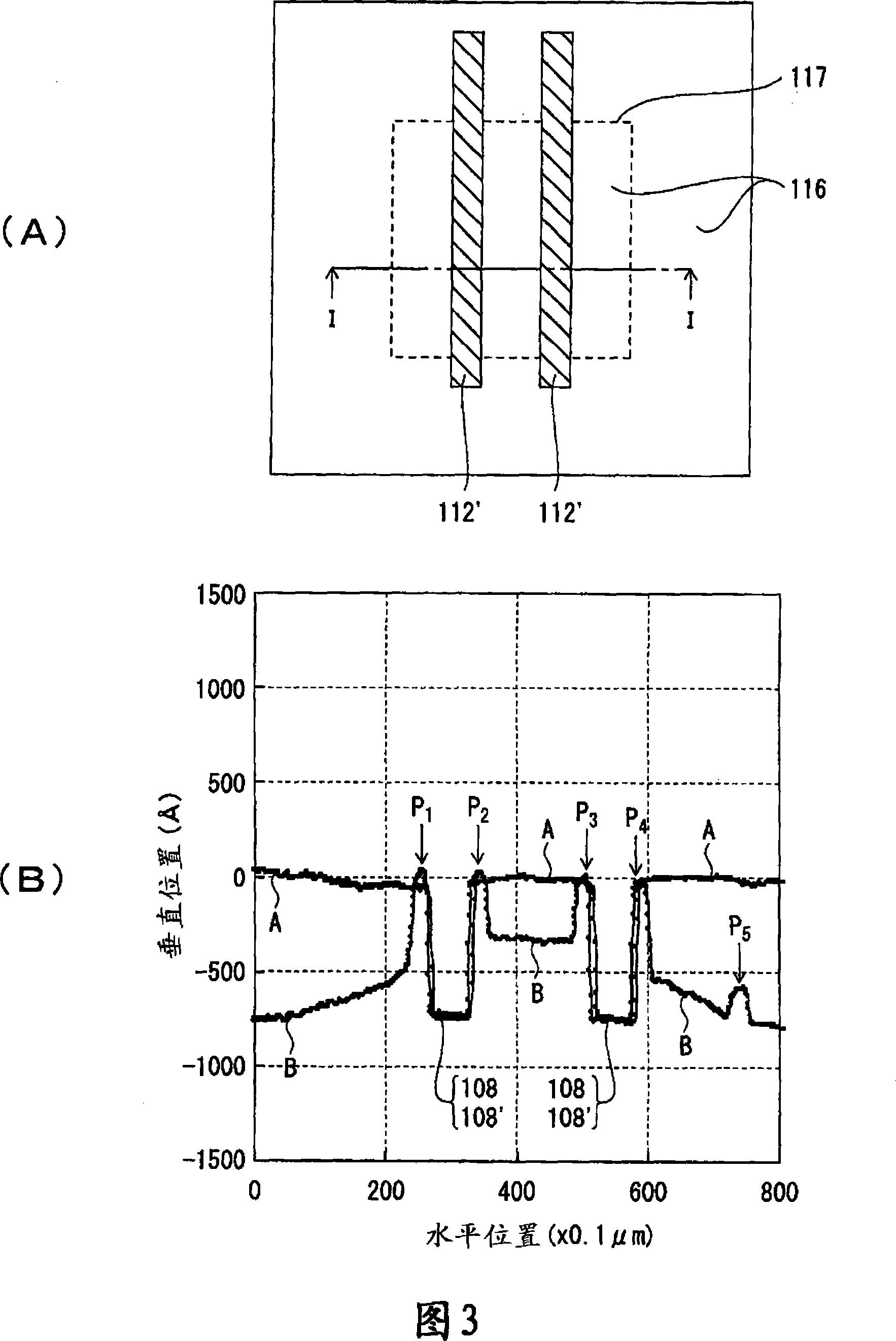

[0049] Fig. 1(A) to Fig. 1(C) and Fig. 2(A) to Fig. 2(C) show the production process flow of AlGaN / GaN-HEMT using selective regrowth for explaining the first embodiment of the present invention summary of . Each figure shows the cross section of the main part of the AlGaN / GaN-HEMT in the main process. Also, in these FIGS. 1 and 2, the same symbols as those in FIGS. 7 and 8 are used for the same elements as those in FIGS. express.

[0050] FIG. 1(A) is a diagram showing a cross-sectional structure of a semiconductor body 110 used in the first embodiment of the present invention.

[0051] First, in the first step, the semiconductor body 110 is prepared. The semiconductor body 110 has a stacked structure in which a HT-AlN buffer layer 102 is stacked on a SI-SiC substrate 100, a UID-GaN layer 104 is stacked on the HT-AlN buffer layer 102, and the UID - formed by laminating a UID-AlGaN layer 108 on the GaN layer 104 . The semiconductor body 110 can be fabricated as follows.

...

no. 2 Embodiment approach

[0080] Next, a MIS-type AlGaN / GaN-HEMT employing selective regrowth according to a second embodiment of the present invention will be described.

[0081] 5 is a view showing a cross section of a main part of an MIS-type AlGaN / GaN-HEMT structure employing selective regrowth for explaining a second embodiment of the present invention. Since the production process and structure are basically the same as those described in the first embodiment of the present invention, they will be briefly described, and in particular, only differences between the second embodiment and the first embodiment will be described. In addition, the same symbols as those in the first embodiment are attached to the symbols of the constituent elements.

[0082] The structures of the Si-SiC substrate 100 and the semiconductor body 110 used are the same as those of the first embodiment.

[0083] Then, on the first main surface 111 of the semiconductor body 110, a 50 nm-thick SiO 2 Layer 112. The SiO 2 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com