Focused ion beam four-stage grid mesh system achieving fixed point removal and method thereof

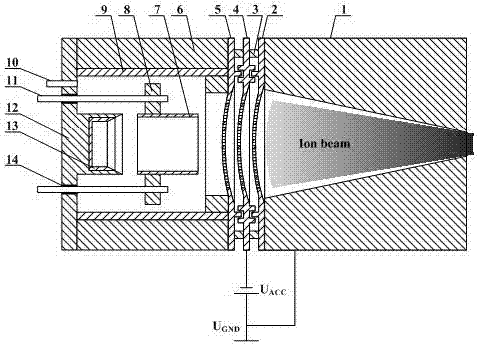

A focused ion beam and grid technology, which is applied in the field of focused ion beam four-level grid system, can solve the problems of inability to eliminate fixed-point machining to eliminate surface shape errors, low efficiency of ion source polishing, and equipment introduction, etc., to improve energy density and work efficiency, reduce surface pollution, reduce the effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1, using isostatic graphite grid; screen grid, acceleration grid and grounding grid spherical radius is 80mm; grid spacing 0.25mm; grid aperture diameter 0.5mm, aperture center distance 2 times the diameter, i.e. 1mm ;Parallel opening method, the small holes are arranged in a regular hexagon, and the diagonal length of the figure is 40mm; the grids are insulated by ceramic balls; the measured focus position of the ion beam is 80mm away from the ground grid plane, and the beam spot diameter is 15mm. It is determined that the inlet diameter of the confinement grid is 40mm, the outlet diameter is 15mm, and the length is 70mm; the accelerating voltage is -100V; the ion source operating parameters are: anode voltage 1000V, gas flow rate 15SCCM, working pressure 5×10 -2 Pa; the measured beam current size is 32.7mA.

Embodiment 2

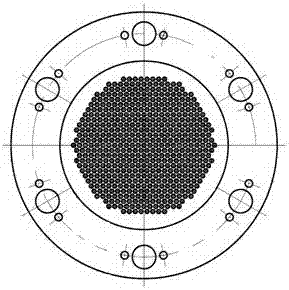

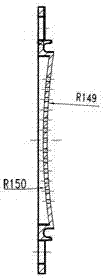

[0039] Example 2 (see figure 2 with image 3 ), using pyrolytic graphite grid; the spherical radius of the screen grid is 150mm, the spherical radius of the accelerating grid and the grounding grid are both 100mm; the grid spacing is 0.5mm; the grid hole diameter is 1mm, and the hole center distance is 1.5 times the diameter, that is, 1.5mm ;Parallel opening method, the small holes are arranged in a regular hexagon, and the diagonal length of the pattern is 40mm; the grids are insulated by ceramic columns; the measured focus position of the ion beam is 85mm away from the ground grid plane, and the beam spot diameter is 20mm. It is determined that the entrance diameter of the confinement grid is 40mm, the exit diameter is 20mm, and the length is 75mm; the accelerating voltage is -200V; the working parameters of the ion source are: anode voltage 1000V, gas flow rate 15SCCM, working pressure 5×10 -2 Pa; the measured beam current size is 31.4mA.

Embodiment 3

[0040] Embodiment 3 (see Figure 4 with Figure 5 ), using metal molybdenum grid; the spherical radius of the screen grid, acceleration grid and grounding grid is 250mm; the grid spacing is 0.5mm; the grid hole diameter is 1mm, and the center distance of the hole is 2 times the diameter, that is, 2mm; parallel opening method (see Image 6 ), the small holes are arranged in a regular hexagon, and the diagonal length of the pattern is 20mm; the grids are insulated by ceramic tubes; the measured focus position of the ion beam is 25mm away from the ground grid plane, and the beam spot diameter is 8mm, so it is determined that the constraint The grid inlet diameter is 20mm, the outlet diameter is 10mm, and the length is 20mm; the accelerating voltage is -1000V; the working parameters of the ion source are: anode voltage 1000V, gas flow rate 15SCCM, working pressure 5×10 -2 Pa; the measured beam current size is 9.8mA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com