Vertical-cavity surface-emitting laser radar light source of non-periodic high-contrast grating integrated with rapid angle scanning

A vertical cavity surface emission, non-periodic technology, applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve the problems of not being able to be used as a laser radar light source, small beam deflection angle, and single realization angle, etc., to achieve beam deflection angle Effects of control and focus, large deflection angle, and reduced complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

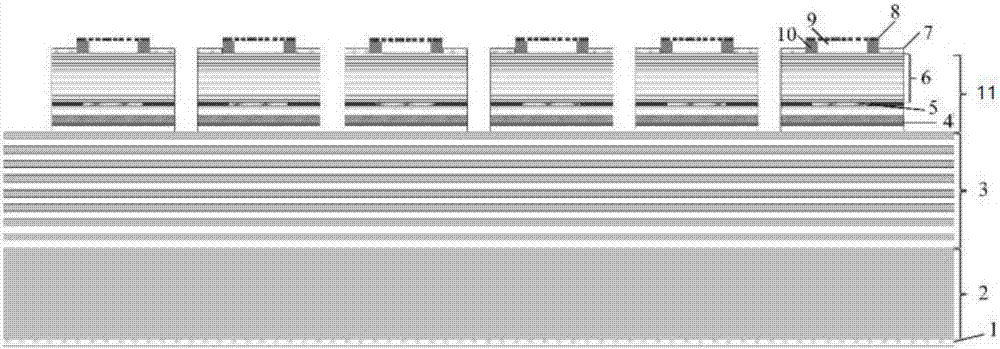

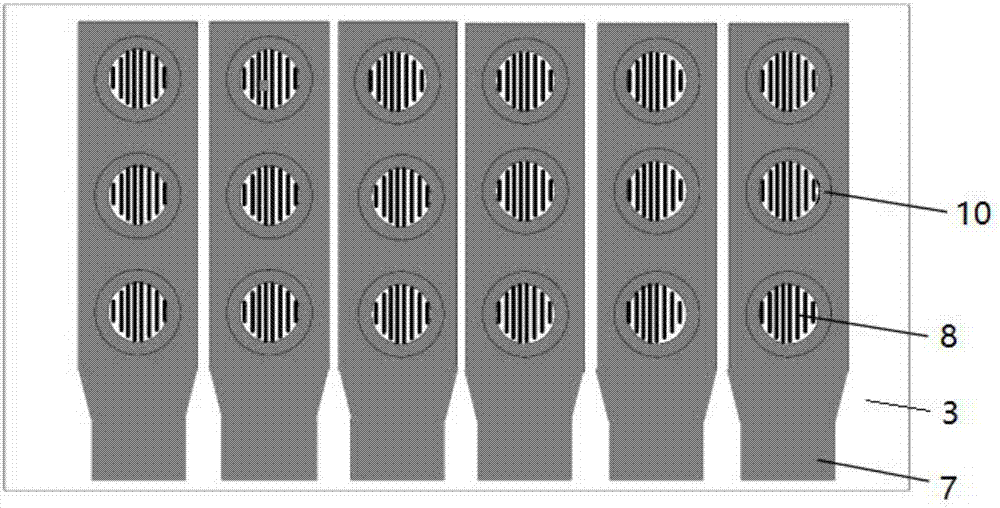

[0026] See figure 1 with figure 2 Shown

[0027] The angular fast scanning integrated non-periodic high-contrast grating vertical cavity surface emitting laser radar light source of the present invention includes: N-surface electrode 1, substrate 2, N-surface distributed Bragg reflector layer 3, multiple quantum wells, from bottom to top Active gain layer 4, oxidation current confinement hole layer 5, and P-plane distributed Bragg mirror layer 6, the multiple quantum well active gain layer 4, oxidation current confinement hole layer 5, and P-plane distributed Bragg mirror layer 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com