Water guide laser processing device and processing system

A laser processing and water guide technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of uneven distribution of laser power density, expand deep processing capabilities, reduce heat accumulation effects, and ensure accurate cutting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention is described in detail below in conjunction with examples, but the present invention is not limited to these examples.

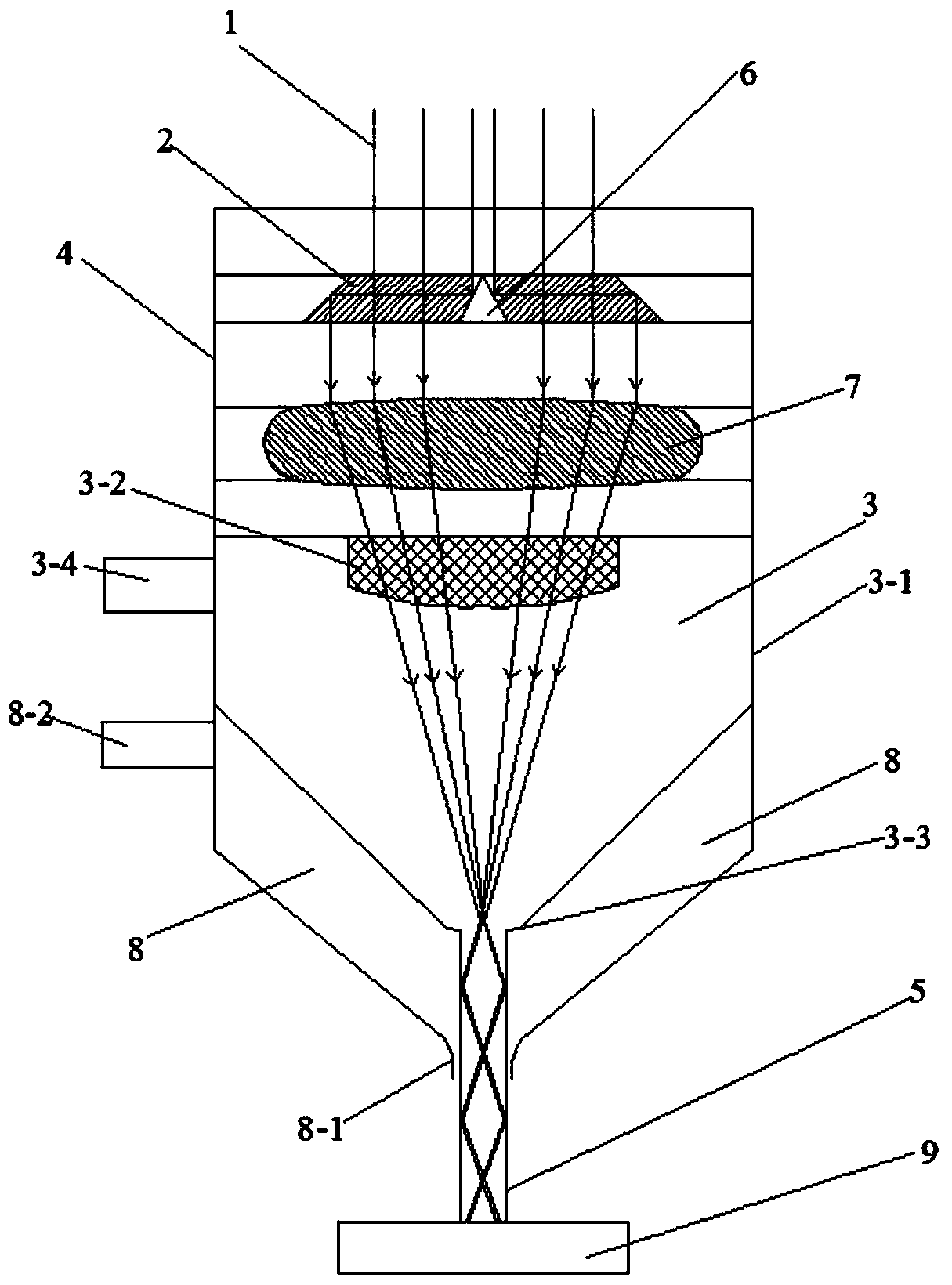

[0051] figure 1 It is a structural schematic diagram of the water-conducting laser processing device of the present invention.

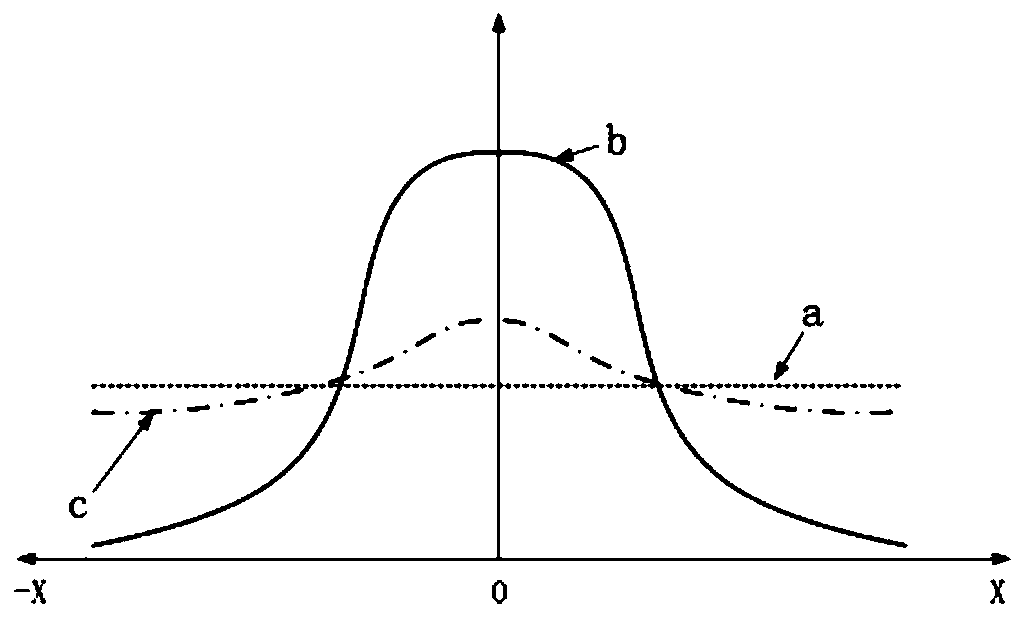

[0052]The water-conducting laser processing device of the present invention includes a table mirror 2 and a coupling water cavity 3; the table mirror and the coupling water cavity are sequentially arranged coaxially along the laser transmission direction. Wherein, the terrace reflector 2 may be in the shape of a circular truncated truncated mirror, or may be in the shape of a multi-edged (≥3) truncated prism, and is used to input the central beam of the laser 1 into the coupling water chamber after undergoing total reflection and guiding light. The central beam of 1 is transformed into an edge beam through total reflection, and together with the original edge beam of laser 1, it is input to the couplin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com