Beneficiation method for recovering copper from converting slag

A beneficiation method and a technology of blowing slag, applied in the direction of solid separation, etc., can solve the problems of difficult processing of intermediate products, poor separation effect of slag with high metal copper content, and long process flow, so as to reduce surface pollution and reduce wear and tear. The burden of ore classification and the effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

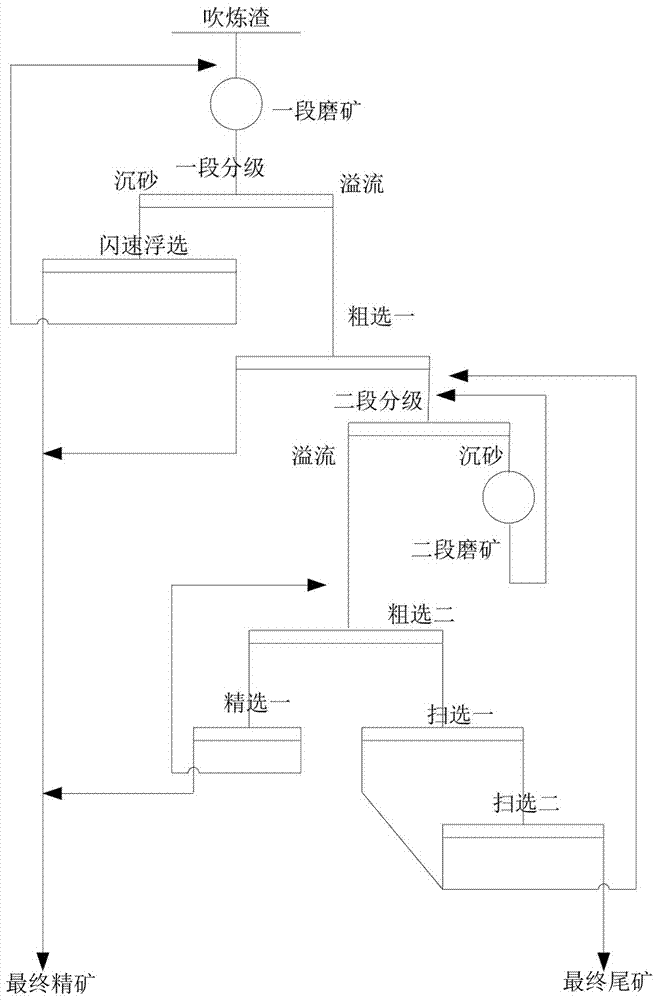

[0032] A mineral processing method for recovering copper from blowing slag, comprising the following steps:

[0033] (1) Transport the blowing slag crushed to -12mm to the first-stage ball mill for grinding, and the first-stage ball mill discharges ore and enters the first-stage cyclone for classification, and the first-stage graded sand settling obtained after classification is subjected to flash flotation to obtain the first concentrate and the first tailings, the first tailings are returned to the first stage of ball mill grinding; wherein, the mass concentration of the first stage of graded grit settling is 70%, and the occupancy rate of -0.074mm fineness in the first stage of graded grit settling is 15%;

[0034] (2) The overflow product of the first-stage cyclone enters the primary roughing to obtain the second concentrate and the tailings of the primary roughing, and the tailings of the primary roughing enter the secondary cyclone for classification. The first-stage gra...

Embodiment 2

[0045] The content of embodiment 2 is basically the same as embodiment 1, and its difference is:

[0046] The mass concentration of one section of graded grit settling described in step (1) is 65%, and the occupancy rate of fineness of -0.074mm in one segment of graded grit settling is 10%; the time of described flash flotation is 1.5min, and described The adjusting agent of flash flotation is sodium sulfide, and collector is thiocarbamate, and foaming agent is terpineol oil, and the consumption of described sodium sulfide is 100g / t, and the consumption of described thiocarbamate is 20g / t. t, the amount of pine alcohol oil is 25g / t, and the addition point of the regulator, collector, and foaming agent used in flash flotation is the pipe mouth of the first-stage cyclone for sand settling and collection.

[0047] The mass concentration of one section cyclone overflow product described in step (2) is 40%, and fineness is 65% in the one section cyclone overflow product that finene...

Embodiment 3

[0053] The content of embodiment 3 is basically the same as embodiment 1, and its difference is:

[0054] The mass concentration of one section of graded sand settling described in step (1) is 75%, and the occupancy rate of fineness in one section of graded sand settling is-0.074mm is 20%; The time of described flash flotation is 3min, and described flash flotation The regulator of fast flotation is sodium sulfide, the collector is thiocarbamate, and the foaming agent is terpineol oil, the consumption of described sodium sulfide is 200g / t, and the consumption of described thiocarbamate is 40g / t , the consumption of pine alcohol oil is 40g / t, and the addition point of the regulator, collector and foaming agent used in flash flotation is the pipe mouth of a section of cyclone sand settling and collection.

[0055] The mass concentration of one section cyclone overflow product described in step (2) is 45%, and fineness is 70% in the one section cyclone overflow product that finen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com