Commutator material, method for manufacturing same, and micromotor using same

A commutator and conductivity technology, applied in the field of micro motors, can solve the problems of fast wear of commutators and brushes, short life of motors, pollution of contacts, etc., to improve life of motors, less surface pollution, and reduce usage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

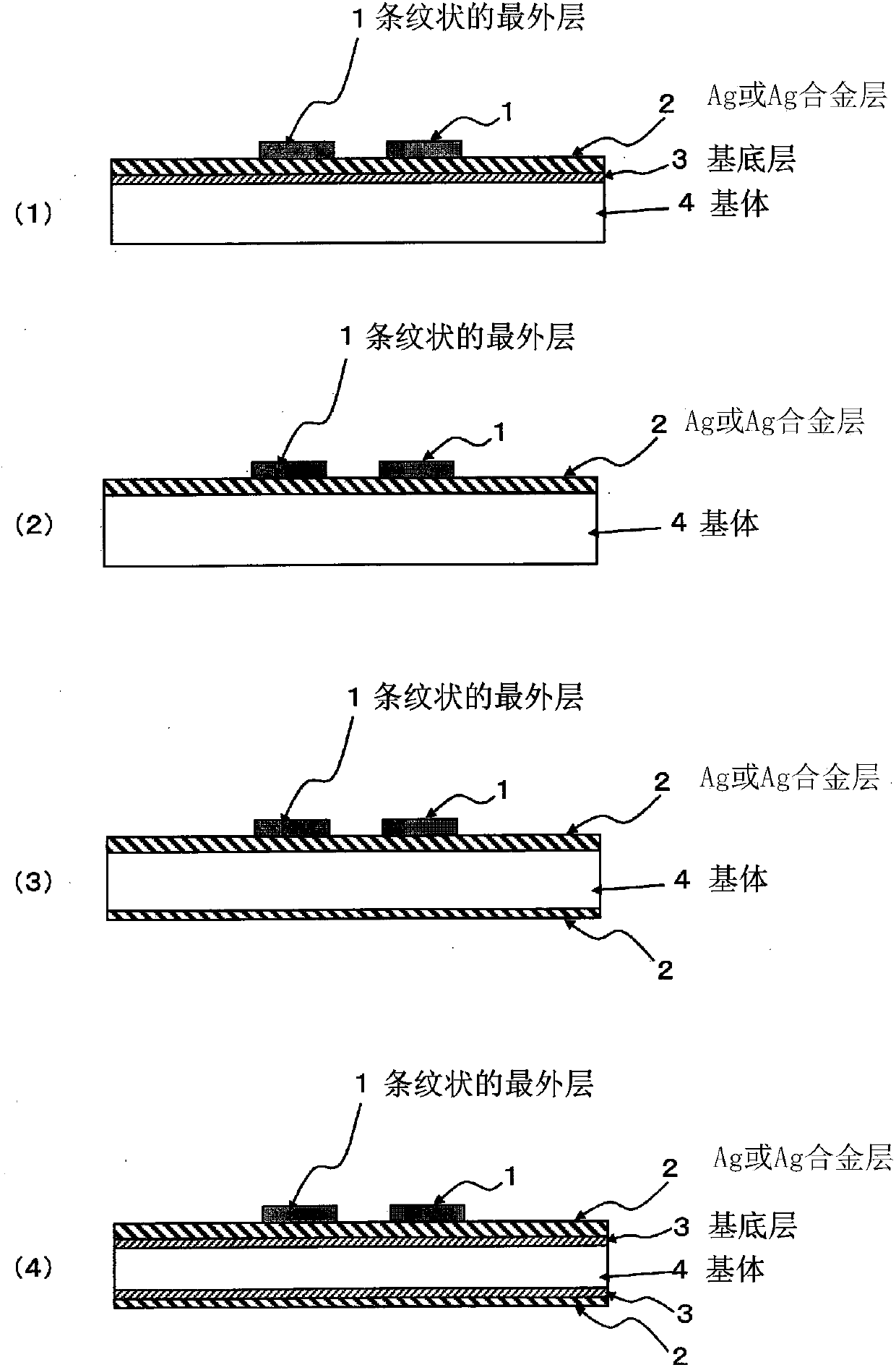

Image

Examples

Embodiment

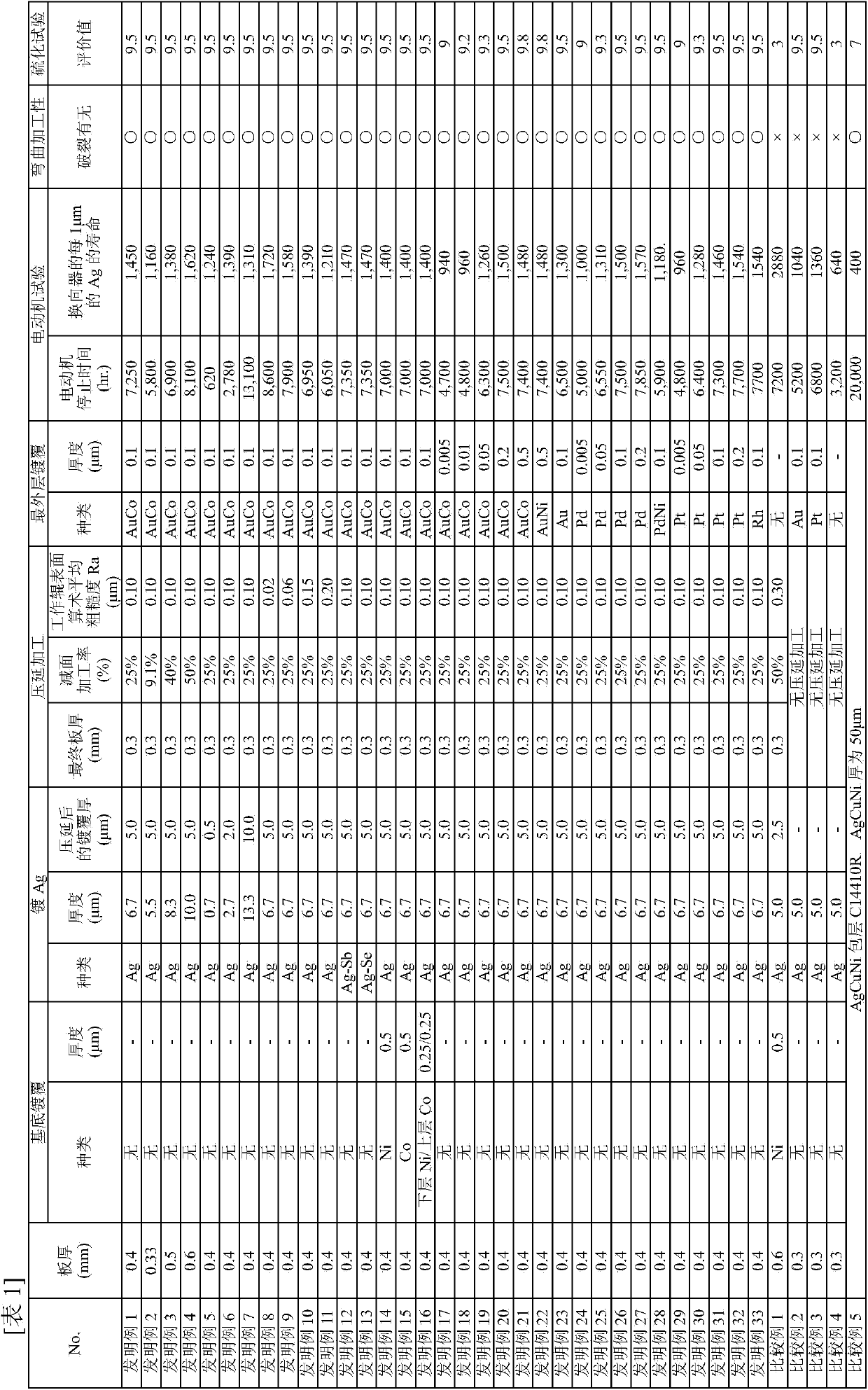

[0059] The present invention will be further described in detail based on examples.

[0060] In a production line that continuously coats strips, C14410 strips (substrates) with a width of 100 mm and a thickness of various sizes shown in Table 1 are passed through, and electrolytic degreasing and pickling are performed after pretreatment. Plating, and then rolling processing. Thereafter, it was cut to a width of 30 mm by a strip cutter, and strip plating was performed on gold, gold alloy, palladium, palladium alloy, platinum or rhodium to a width of 5 mm to obtain the commutator material of the present invention.

[0061] The above commutator material was press-processed, assembled into a micromotor, and a motor life test was performed. In addition, the 0.07-mm-thick nickel-copper strip for springs (C7701R-H material) plated with the Pd plating thickness of 1 micrometer was used for the brush material.

[0062] Table 1 shows the evaluation results.

[0063] The plating cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com