Apparatus and method for laser scanner cleaning and protection

a technology of laser scanners and apparatuses, applied in lighting and heating apparatus, instruments, heating types, etc., can solve the problems of reducing the sensitivity of the device, triggering the detection of a device fault, and reducing the cost of the device, so as to reduce the surface contamination of the viewing window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

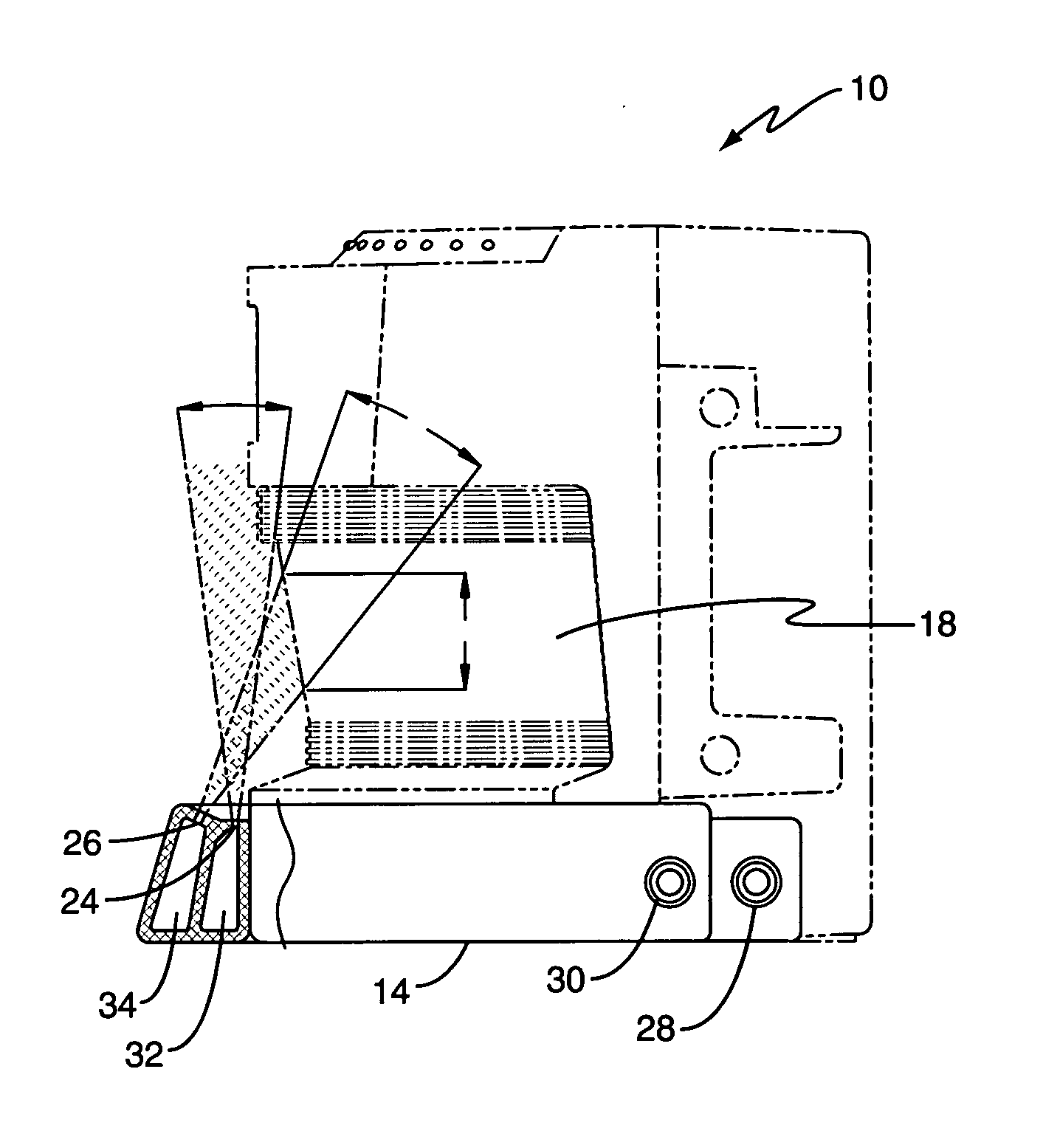

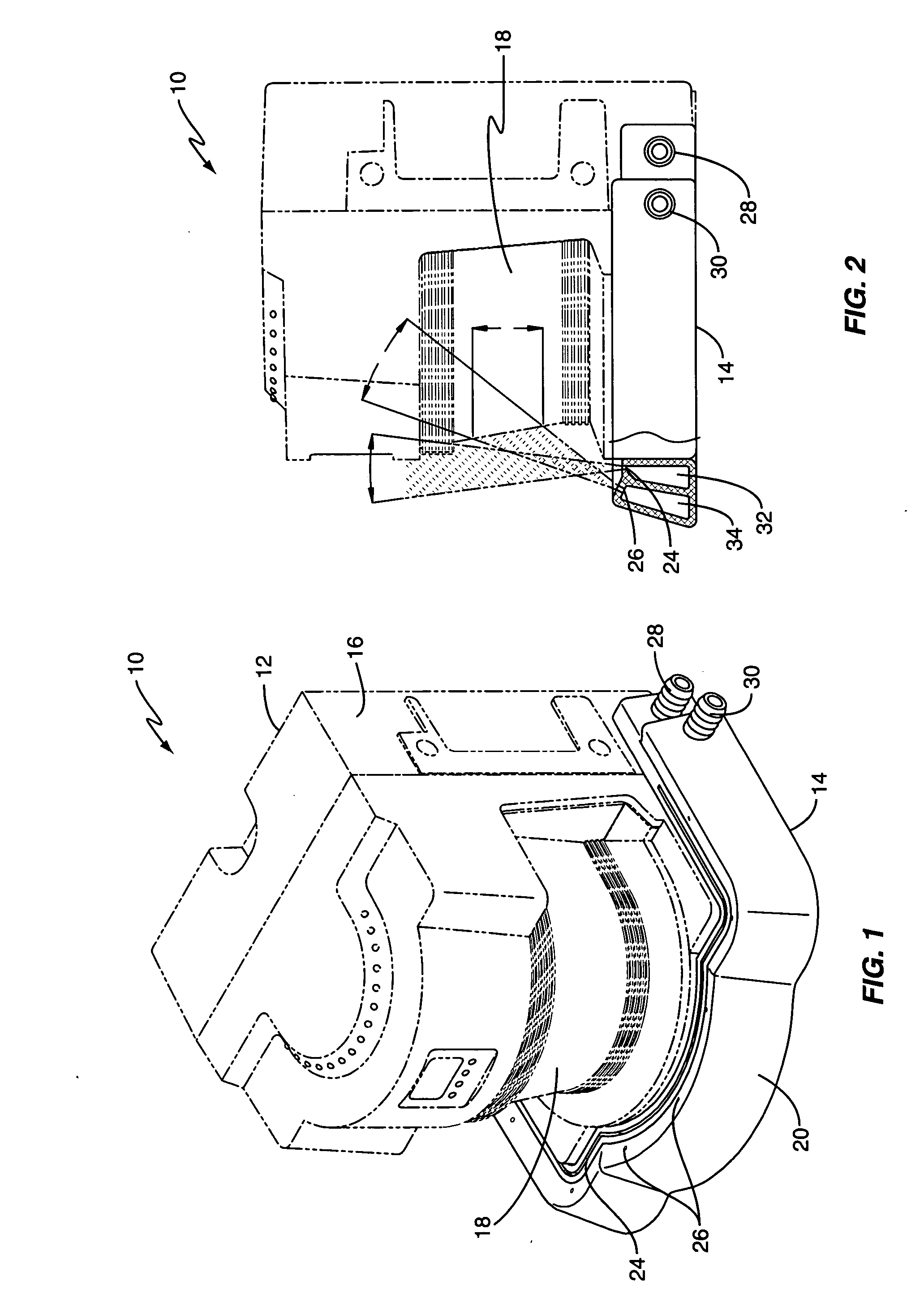

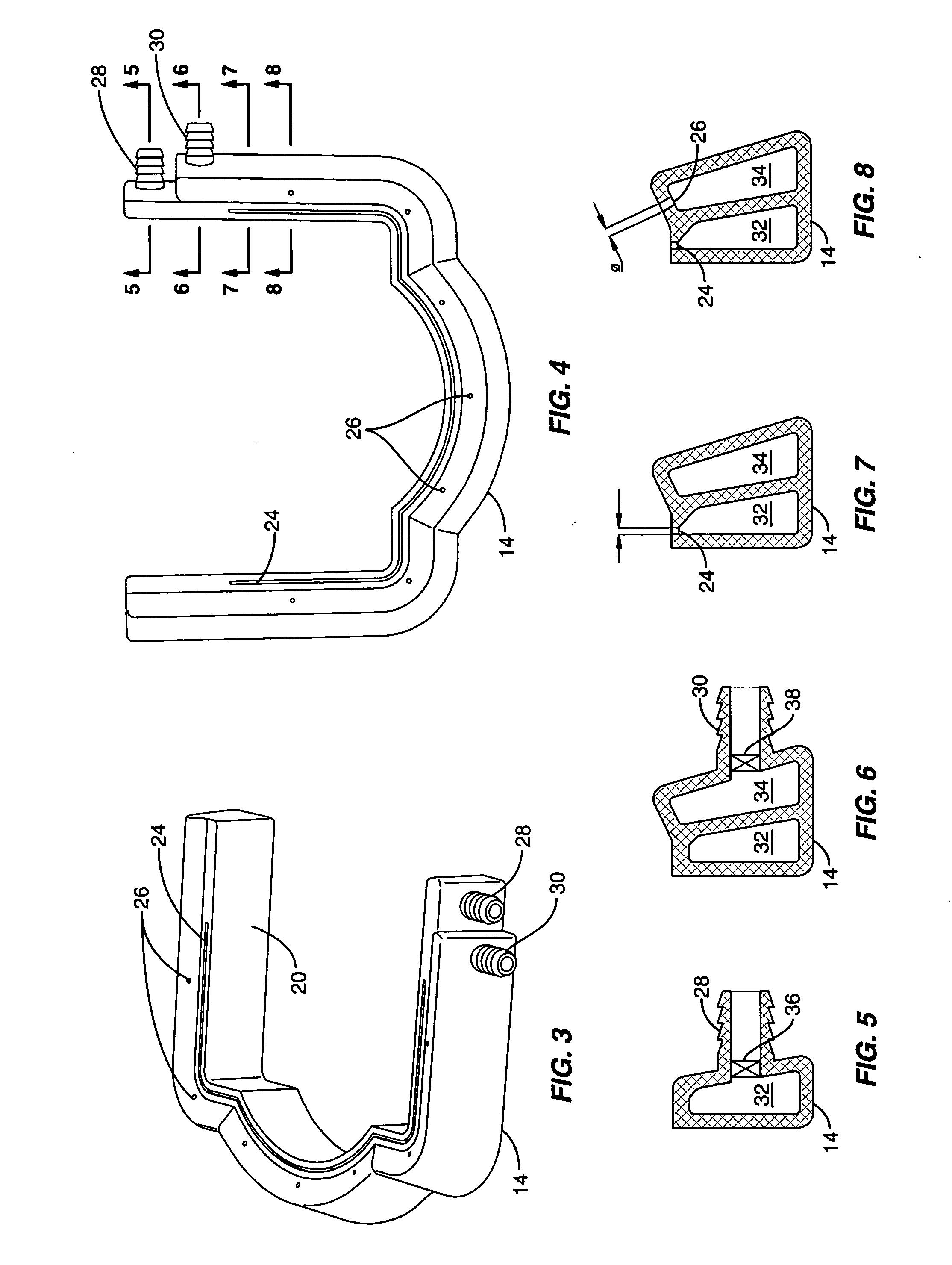

[0025]FIG. 1 is a diagram of an exemplary optoelectronic presence sensing system 10 that is configured according to one or more embodiments of the present invention. In the illustrated embodiment, system 10 comprises an optoelectronic presence sensing unit or device 12 and an associated air guard unit 14 that is integrated with or affixed to a housing 16 of the presence sensing device 12.

[0026] In operation, the air guard 14 prevents the deposition of airborne contaminants (dust, oil, etc.) on an exterior surface of a viewing window 18 of the presence sensing device 12 by creating a laminar air flow in front of window 18 and / or cleans the exterior of window 18 by directing one or more streams of air at the window 18. By preventing contamination of window18 and / or by at least partially removing surface contaminants from window 18, air guard 14 improves the operation of presence sensing device 10. That is, use of air guard 18 can reduce the frequency at which maintenance personal mus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com