Degradable biaxially stretching polylactic acid cigarette film and preparation method thereof

A technology of biaxial stretching and polylactic acid, applied in the field of degradable biaxially stretched polylactic acid cigarette film and its preparation, can solve the problems of waste of resources, environmental pollution, and non-degradable polypropylene materials, etc., to reduce pollution and reduce surface pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a method for preparing the degradable biaxially oriented polylactic acid cigarette film, comprising the following steps:

[0046] 1) extruding and melting the raw material mixture of each layer respectively to obtain the melt of each layer;

[0047] 2) extruding the melts of each layer to obtain a sheet;

[0048] 3) longitudinally stretching and transversely stretching the sheet to obtain a film;

[0049] 4) Stretching, winding, and aging treatment are performed on the film in sequence to obtain a degradable biaxially oriented polylactic acid cigarette film.

[0050] The extrusion melting temperature of the raw material mixture of the first functional layer in step 1) of the present invention is preferably 140-200°C, more preferably 150-180°C, more preferably 160-170°C; the raw material mixture of the second functional layer and the second functional layer The extrusion melting temperature of the raw material mixture of the three fu...

Embodiment 1

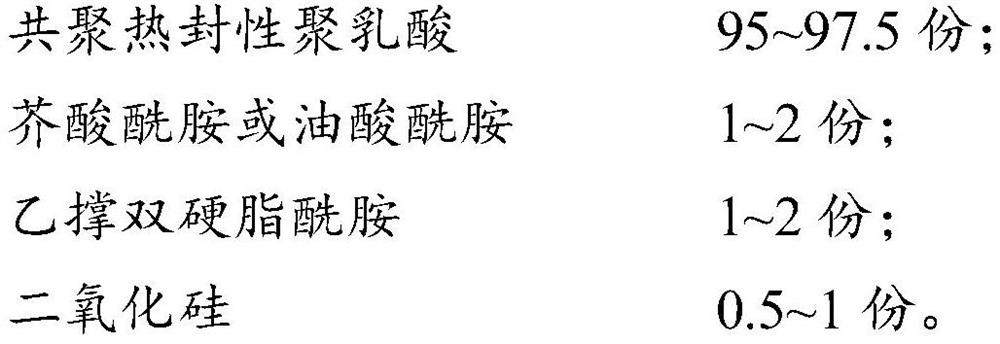

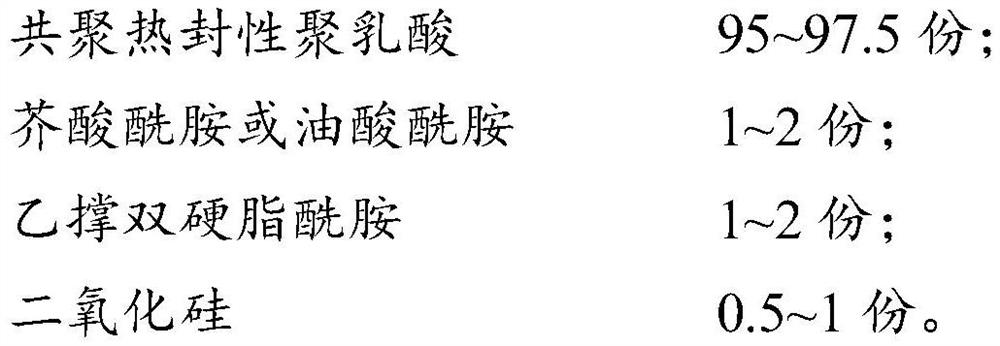

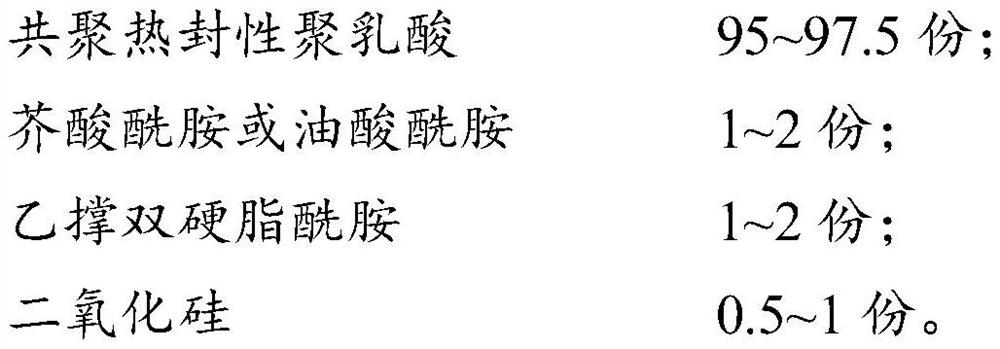

[0064] In the raw material mixture of the first functional layer, the weight ratio of copolymerized heat-sealable polylactic acid, erucamide, ethylene bisstearamide and silicon dioxide is 95:2:2:1; in the raw material mixture of the second functional layer , the weight ratio of polylactic acid and alkyl betaine is 97:3; in the raw material mixture of the third functional layer, the weight ratio of polylactic acid and alkyl betaine is 97:3; in the raw material mixture of core layer, polylactic acid, The weight ratio of oxazoline, nano-calcium carbonate and talc is preferably 91.5:3:5:0.5; in the raw material mixture of the fourth functional layer, the weight ratio of copolymerized heat-sealable polylactic acid and silicon dioxide is preferably 98:2 .

[0065] Extrude and melt 6kg of the raw material mixture of the first functional layer in the auxiliary machine No. 1 twin-screw extruder, the extrusion melting temperature is 150°C, 6kg of the raw material mixture of the second f...

Embodiment 2

[0067] In the raw material mixture of the first functional layer, the weight ratio of copolymerized heat-sealable polylactic acid, oleic acid amide, ethylene bisstearamide and silicon dioxide is 97.5:1:1:0.5; in the raw material mixture of the second functional layer The weight ratio of polylactic acid and sodium alkylsulfonate is 99:1; in the raw material mixture of the third functional layer, the weight ratio of polylactic acid and sodium alkylsulfonate is 99:1; in the raw material mixture of the core layer, poly The weight ratio of lactic acid, oxazoline, nano-calcium carbonate and layered sodium silicate is preferably 97.2:0.5:2:0.3; in the raw material mixture of the fourth functional layer, the weight ratio of copolymerized heat-sealable polylactic acid and talcum powder is preferably It is 99.5:0.5.

[0068] Extrude and melt 9kg of the raw material mixture of the first functional layer in auxiliary machine No. 1 twin-screw extruder, the temperature of extrusion melting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com