Open aluminium sheet without transverse frames

An open, aluminum plate technology, used in building components, walls, buildings, etc., can solve the problems that aluminum plates are difficult to eliminate, affect the flatness of the curtain wall, and easily form bulges, achieve good thermal insulation and sound absorption effects, reduce surface area. Pollution, the effect of reducing cooling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

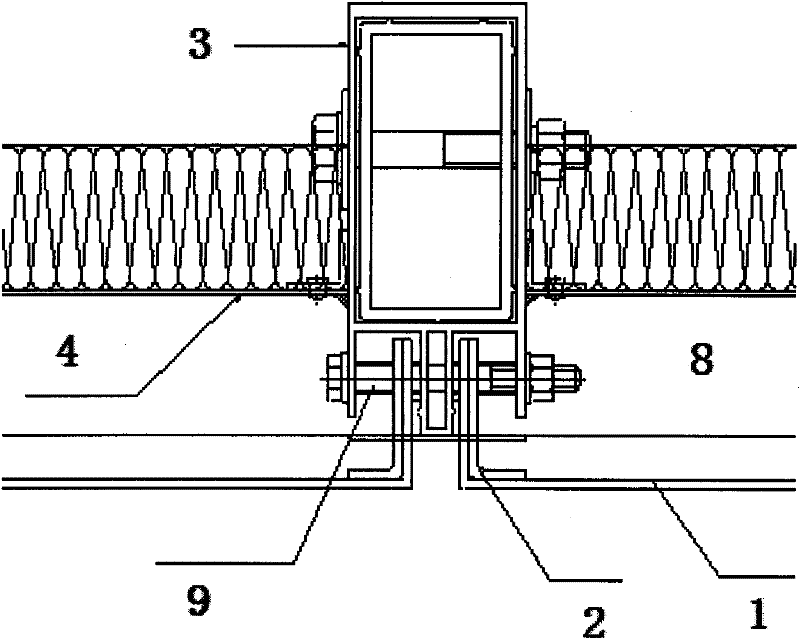

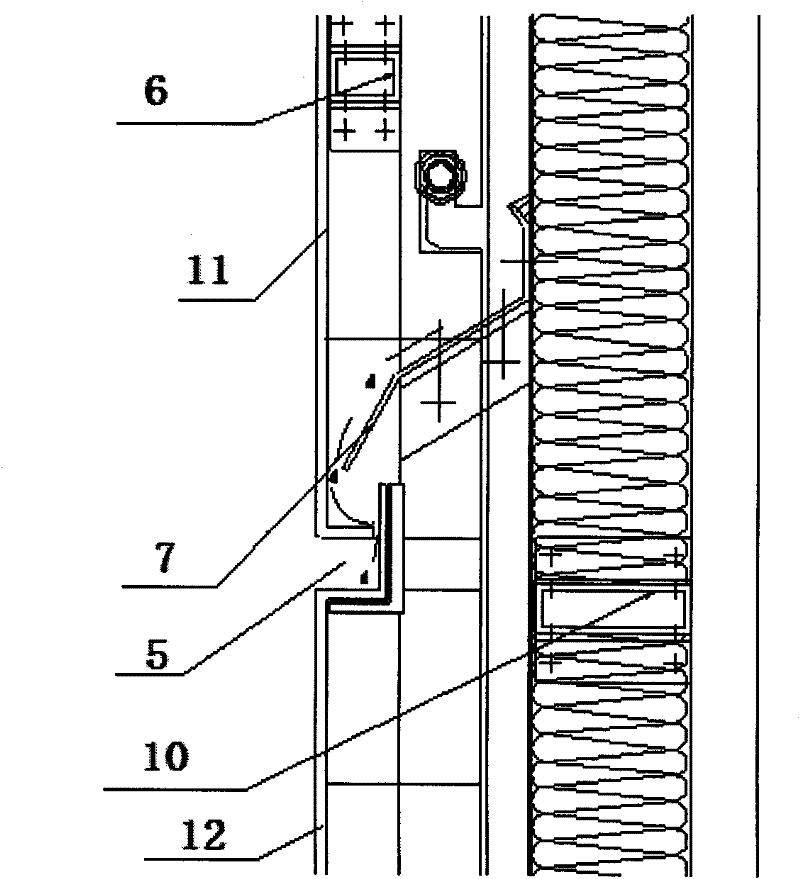

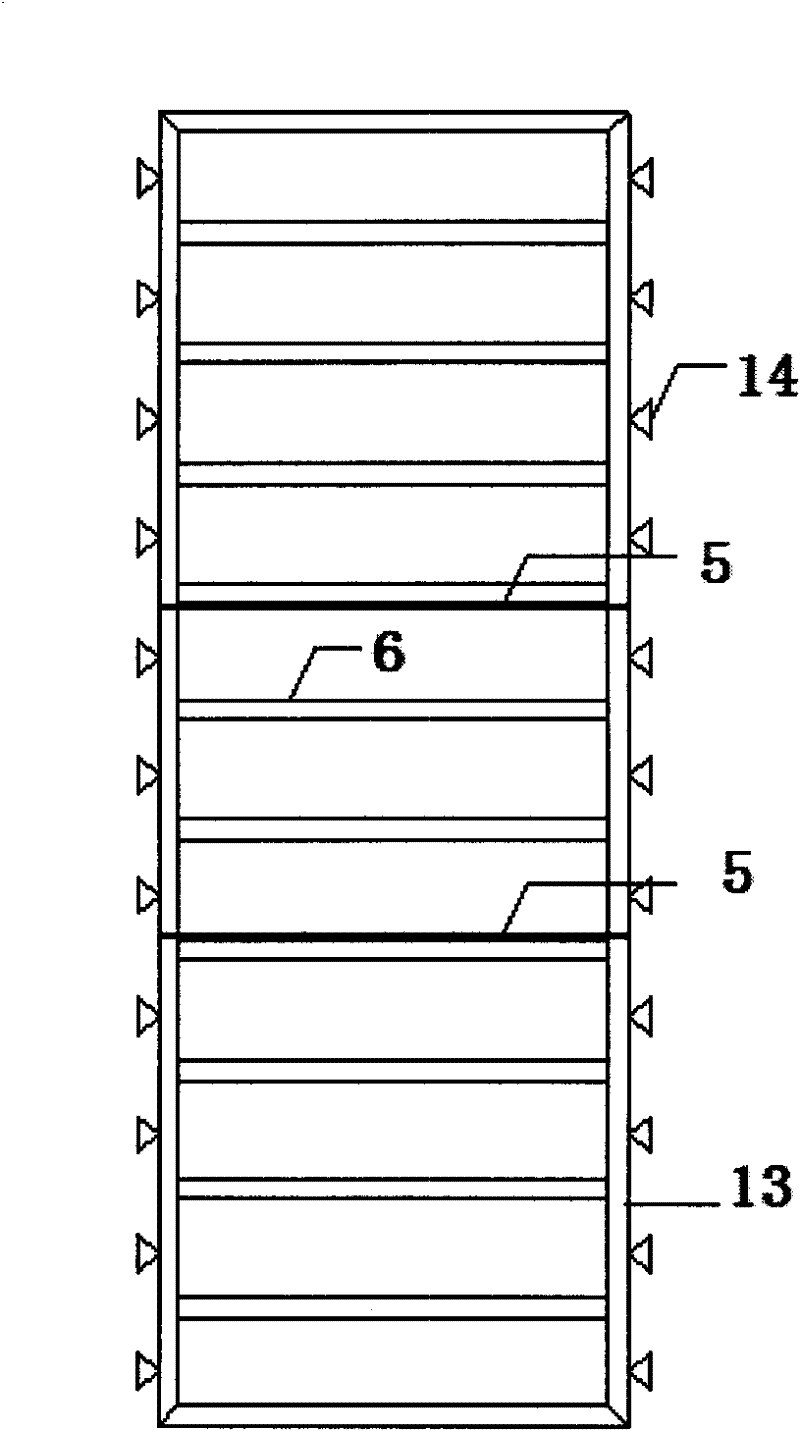

[0019] Such as Figure 1~3 As shown, an open aluminum plate without a horizontal frame, including an aluminum veneer 1, a hook 2, a column 3 and a waterproof plate 4, the top of the aluminum veneer 1 is stepped, the bottom is L-shaped, and the aluminum veneers arranged up and down There is an aluminum plate separation gap 5 between the plates, and the top of the lower aluminum veneer 11 among the upper and lower aluminum veneers is inserted into the upper aluminum veneer 12, and there is a gap between the upper aluminum veneer and the bottom of the upper aluminum veneer as a fluid channel (Such as figure 2 shown). Aluminum sub-frame 13 is arranged around aluminum veneer 1, and described hook 2 is arranged on the aluminum sub-frame 13, and U-shaped aluminum is used as reinforcing bar 6 on the back side of aluminum veneer 1.

[0020] The column 3 is U-shaped (U-shaped aluminum alloy column), and its opening is provided with a connecting bolt 9, and a 2mm thick anti-shock and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com