Electric catalysis reactor capable of reducing side reaction for wastewater treatment

A wastewater treatment and reactor technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of recycling of unfavorable particles, reduction of effective area between electrodes and wastewater, and large local current of electrodes To achieve the effect of reducing the occurrence of oxygen evolution side reactions, reducing the ohmic thermal resistance effect, and slowing down surface pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

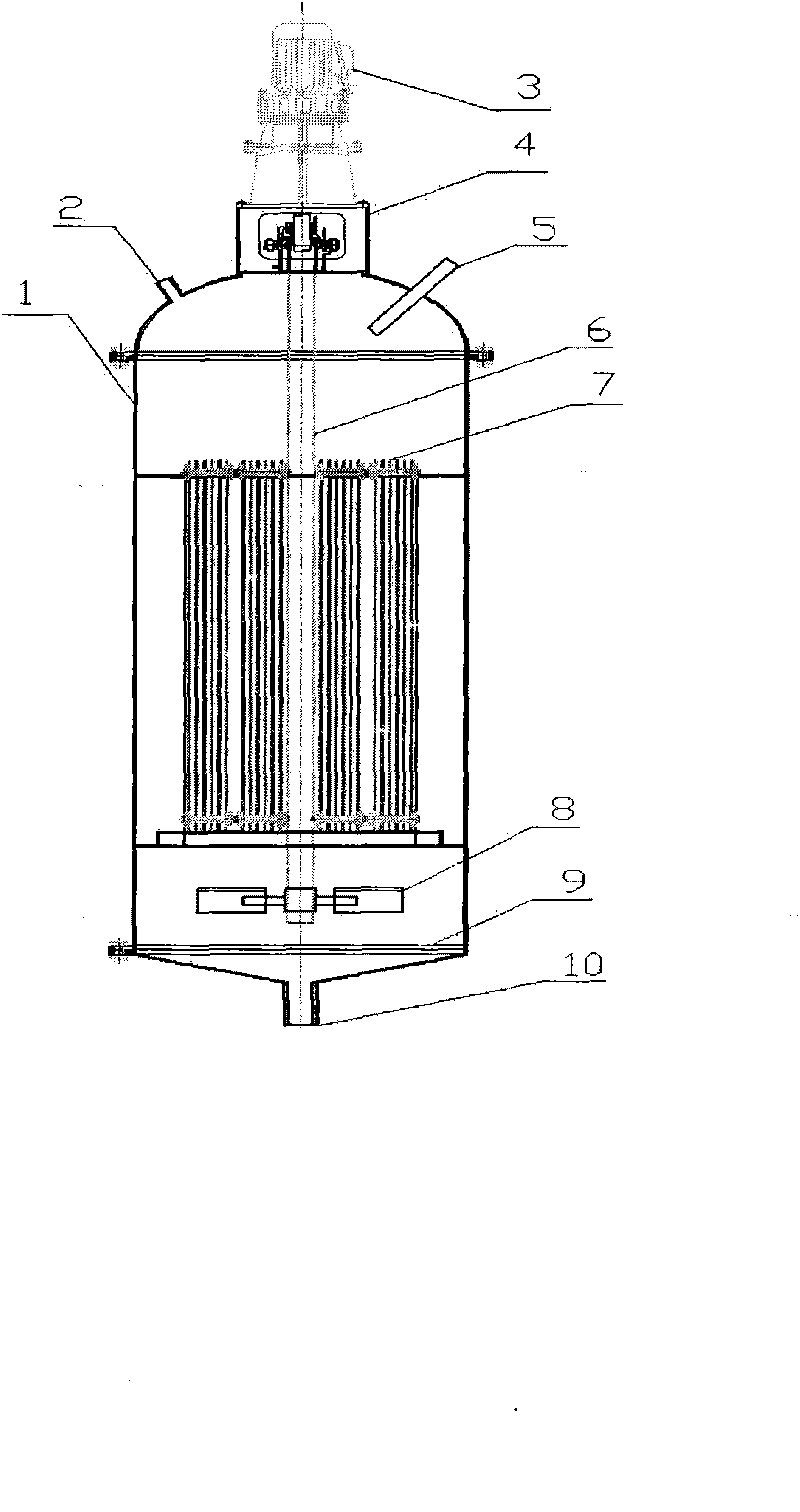

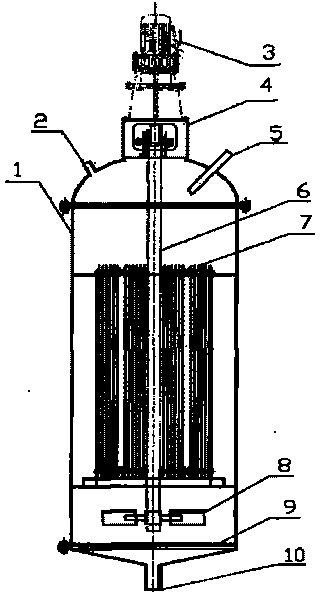

[0021] Referring to the accompanying drawings, a special multi-dimensional electrocatalytic water treatment reactor with a straight part diameter of 500mm, a straight height of 1200mm and a single treatment capacity of 200L was fabricated. The reactor tank includes upper and lower heads and a straight part, the straight part is cylindrical; the upper head is elliptical; the lower head is cone. Legs are welded to the lower part of the tank to place the reactor and keep it vertical. The water inlet is set at the upper head; the water outlet is set at the bottom of the reactor; a filter plate is set above the water outlet to prevent catalytic particles from flowing out of the reactor when the water is discharged. The electrode group inside the reactor is composed of negative and positive plate electrodes arranged alternately. The electrode material is a titanium-based tin dioxide coating material. The electrode group is powered by an external DC stabilized power supply to reali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com