Optical disk having pattern for tilt detection

A technology of tilt detection and optical disc, which is applied in the direction of optical recording/reproduction, digital signal error detection/correction, optical record carrier, etc., and can solve the problem of signal detection degradation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

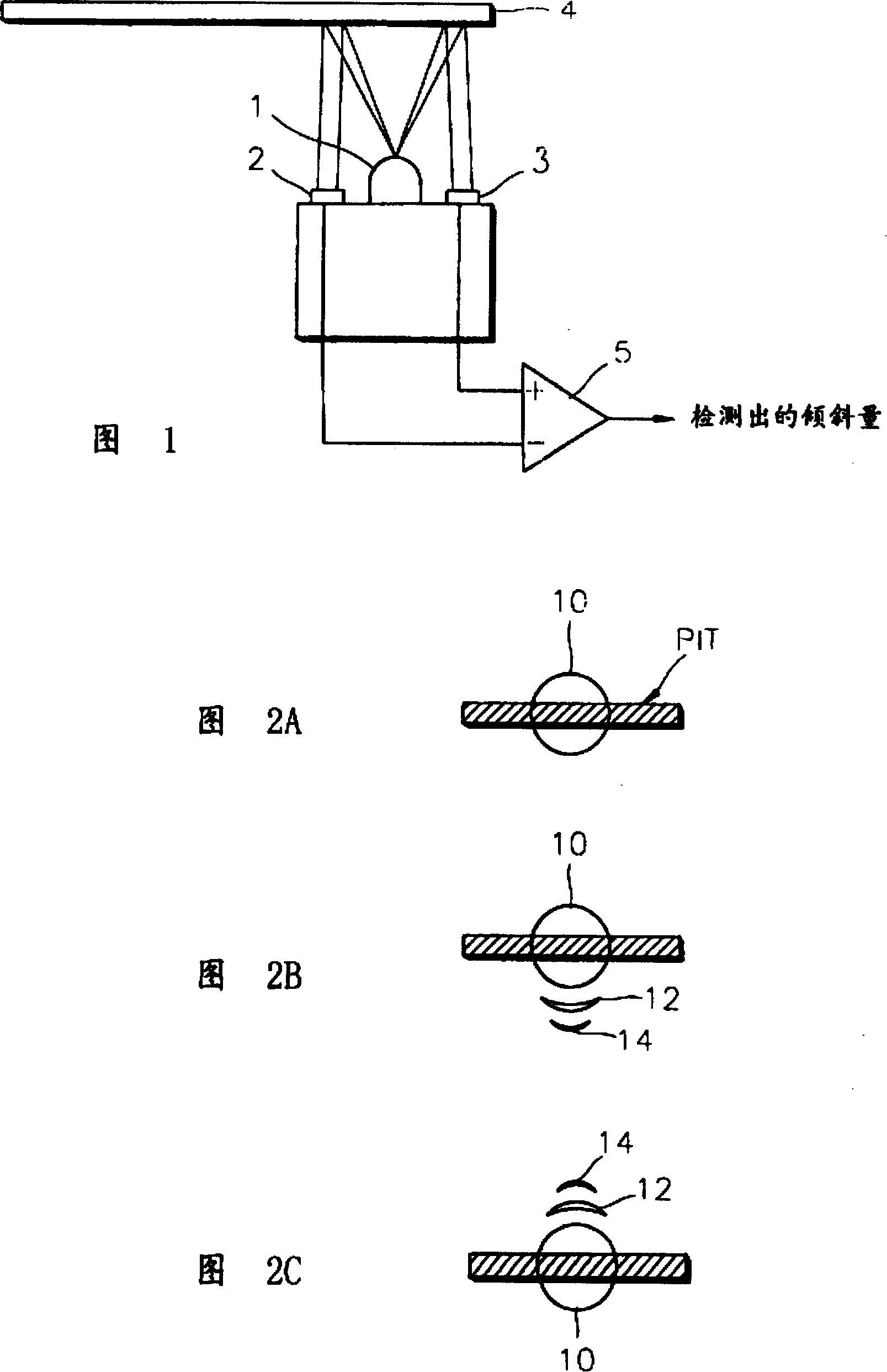

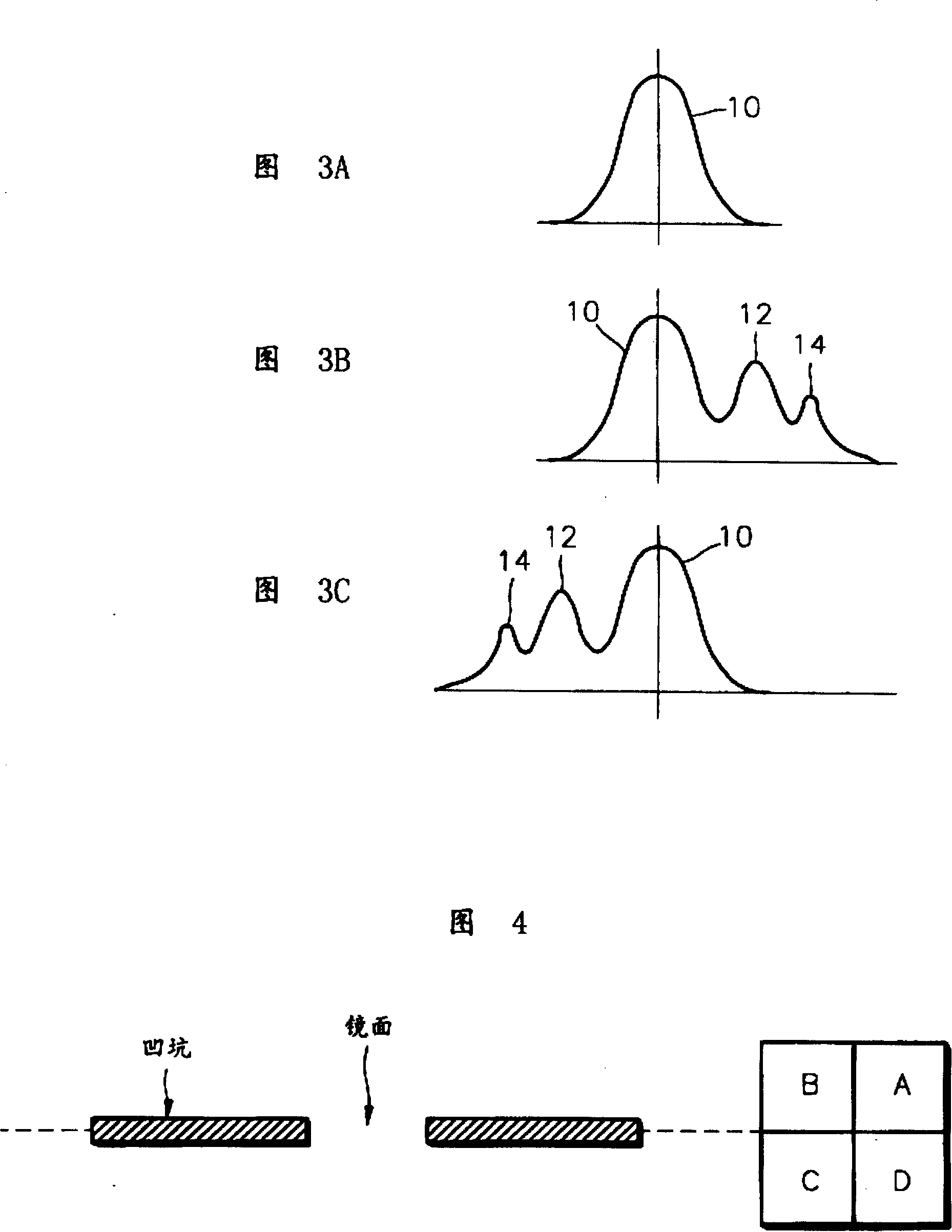

[0058] 2A and FIG. 2C are views showing the distribution of laser beams radiated onto the surface of an optical disc, wherein FIG. 2A shows a situation where no tilt occurs, FIG. 2B shows a situation where there is a downward tilt, and FIG. 2C shows a situation where there is an upward tilt. Case.

[0059] When no tilt occurs, the distribution of the laser beam forms a small circle, and the energy of the laser beam is concentrated to the center of the circle. The energy distribution in this case is shown in Figure 3A. In the absence of tilt, the distribution of the laser beam resembles a Gaussian distribution.

[0060] When the disc is tilted, the distribution of the laser beam expands, as opposed to the case where the disc is not tilted, as shown in Figures 2B and 2C, where the energy of the laser beam is diffused centrally and peripherally. That is, a main lobe 10 with maximum energy is created in the middle of the circle, while first side lobes 12 and second side lobes 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com