Section-steel tape and manufacturing method

A type of steel and slat technology, applied in the field of electric brushes, can solve the problems of difficult precision control, high production costs, and insufficient bonding, and achieve the effects of simplifying procedures, reducing manufacturing costs, reducing investment costs and processing costs

Inactive Publication Date: 2008-07-30

成都金和工贸有限公司 +1

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] As described in Chinese patents ZL03262580.4, ZL200720036402.2 and Publication No. CN1970336A, the steel strip on the brush surface has a simple shape, and the middle part of the steel strip on the brush surface does not engage with the current-carrying substrate so that the combination is not tight enough, especially after wear and tear. , the steel strip becomes thinner, the stress is released and deformed, and the electrical conductivity between the brush surface and the current-carrying substrate becomes poor, all of which will affect the life of the power supply rail

[0006] The shape of the brush surface steel strip described in ZL99811837.0 is more reasonable, but it is produced by extrusion process, the precision control is difficult and the production cost is high

[0007] The brush surface steel strip described in Publication No. CN101058299A has a more reasonable shape, but the traditional rolling and stretching process cannot achieve high-precision industrial production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0031] The manners of three embodiments of the present invention will be described below in conjunction with the accompanying drawings.

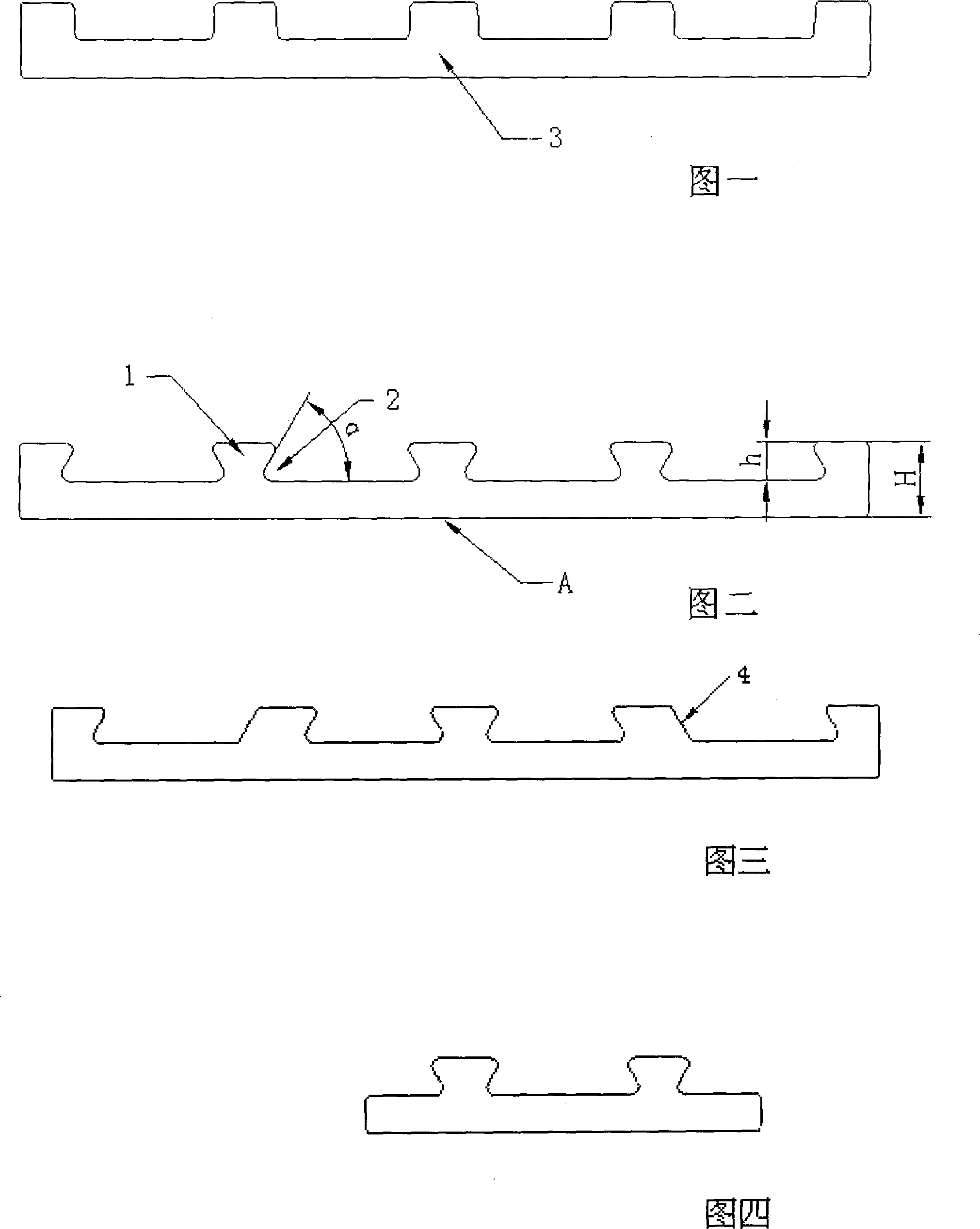

[0032] Hot rolled into strip steel billet (3) similar to that shown in Figure 1, after heat treatment and cleaning, roll drawing and milling into three implementation forms of Figure 2, Figure 3, Figure 4, and through cold drawing shaping, straightening into qualified products.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a section steel belt, one side of which is a brush surface A with protruding laths on the back. The invention has more than three pit patterns (2) formed between at least two laths and the back side of the brush surface. The invention is characterized in that the pit patterns (2) are produced firstly by rolling into billets (3) and then being pulled and milled for at least once. The section steel belt of the invention is high in precision and lower in manufacturing cost.

Description

technical field [0001] The invention relates to a brush surface of a power supply rail. Background technique [0002] The power supply rail generally consists of a brush face of a wear-resistant metal (such as stainless steel) and a current-carrying matrix of a good conductive metal (such as aluminum alloy). [0003] For the power supply rail, the smoothness of the brush surface and the tight and firm combination with the current-carrying substrate are very important. This is related to the shape and machining accuracy of the brush surface. [0004] The shape of the brush face of the supply rail and the method of combining it with the current-carrying substrate have been disclosed in various embodiments. [0005] As described in Chinese patents ZL03262580.4, ZL200720036402.2 and Publication No. CN1970336A, the steel strip on the brush surface has a simple shape, and the middle part of the steel strip on the brush surface does not engage with the current-carrying substrate ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B60M1/30

Inventor 丁元汉曾鉴韩大京

Owner 成都金和工贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com