Preparation of superefficient carbon fiber electromagnetic shielding paper

A technology of electromagnetic shielding and effective carbon fiber, which is applied in the direction of magnetic field/electric field shielding, synthetic cellulose/non-cellulose material pulp/paper, and non-fiber pulp addition, which can solve the problem of not meeting the application requirements of carbon fiber electromagnetic shielding paper and electromagnetic shielding effectiveness , poor mechanical strength and heat resistance, easy cracking of the coating on the fiber surface, etc., to achieve good messy effect, improved fiber network isotropy, and low reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

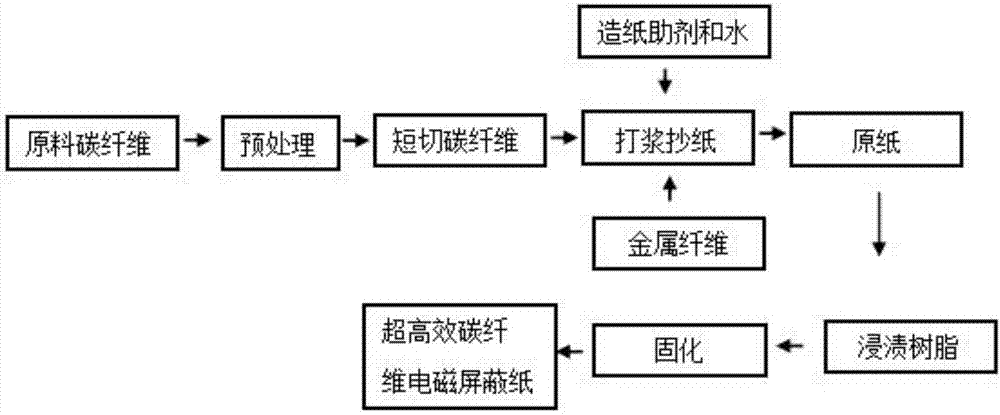

[0034] A preparation of ultra-efficient carbon fiber electromagnetic shielding paper, comprising the following steps:

[0035](1) Activation: pretreat the carbon fibers in 2mol / L NaOH for 2 hours, and use ultrasonic-assisted treatment; the ultrasonic treatment conditions are as follows: temperature is 40°C, ultrasonic frequency is 50kHz, and time is 30min; the treated carbon fibers are taken out and used to Wash with deionized water until neutral, remove the organic coating on the carbon fiber surface, dry and set aside;

[0036] (2) Compounding and additive addition: mix the carbon fiber treated in step (1) with stainless steel fiber, the mixed ingredients are by weight, carbon fiber: stainless steel fiber is 7:3; add the fiber slurry mass to the mixed slurry 0.12% APAM, 1% PVA in fiber slurry mass, stir for 30s;

[0037] (3) wet forming: a certain amount of slurry concentration obtained in step (2) is taken to be 0.09% and carried out in a sheet machine for wet forming, deh...

Embodiment 2

[0040] A preparation of ultra-efficient carbon fiber electromagnetic shielding paper, comprising the following steps:

[0041] (1) Activation: pretreat the carbon fibers in 1mol / L NaOH for 4 hours, and use ultrasonic-assisted treatment; the ultrasonic treatment conditions are as follows: the temperature is 60°C, the ultrasonic frequency is 100kHz, and the time is 10min; the treated carbon fibers are taken out and used to Wash with deionized water until neutral, remove the organic coating on the carbon fiber surface, dry and set aside;

[0042] (2) Compounding and additive addition: mix the carbon fiber treated in step (1) with stainless steel fiber, the mixed ingredients are by weight, carbon fiber: stainless steel fiber is 7:3; add the fiber slurry mass to the mixed slurry 0.5% APAM, 2% PVA of fiber slurry mass, stir for 30s;

[0043] (3) wet forming: a certain amount of slurry concentration obtained in step (2) is taken to be 0.09% and carried out in a sheet machine for wet...

Embodiment 3

[0046] A preparation of ultra-efficient carbon fiber electromagnetic shielding paper, comprising the following steps:

[0047] (1) Activation: pretreat the carbon fibers in 3mol / L NaOH for 1 hour, and use ultrasonic-assisted treatment; the conditions of ultrasonic treatment are as follows: the temperature is 20°C, the ultrasonic frequency is 20kHz, and the time is 60min; the treated carbon fibers are taken out and used to Wash with deionized water until neutral, remove the organic coating on the carbon fiber surface, dry and set aside;

[0048] (2) Compounding and additive addition: mix the carbon fiber treated in step (1) with stainless steel fiber, the mixed ingredients are by weight, carbon fiber: stainless steel fiber is 7:3; add the fiber slurry mass to the mixed slurry 0.6% APAM, 3% PVA of fiber slurry mass, stirring for 30s;

[0049] (3) wet forming: a certain amount of slurry concentration obtained in step (2) is taken to be 0.09% and carried out in a sheet machine fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com