Preparation method of teflon hollow fiber membrane for membrane distillation

A technology of polytetrafluoroethylene and fiber membranes, which is applied in the field of preparation of polytetrafluoroethylene hollow fiber membranes for membrane distillation, and can solve the problems of PET fiber braided tubes being easily wetted by water, the quality of water produced by membrane distillation, and high equipment requirements. problem, to achieve the effect of saving the wrapping link, reducing the cost of materials, and good hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] a. Mixing: Select polytetrafluoroethylene dispersed resin powder with a molecular weight of 2 million, mix the polytetrafluoroethylene resin powder and liquid paraffin evenly at a weight ratio of 1:0.22, and let stand at 20°C for 80 hours to make the resin powder and liquid paraffin Mix well, and sieve out larger powder particles;

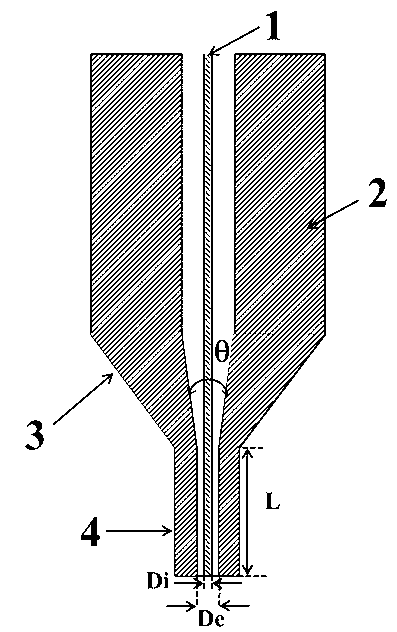

[0027] b. Compaction and extrusion: The mixed polytetrafluoroethylene material is pressed into a cylindrical blank on a compactor, and the blank is extruded at 100°C through a pusher with a cone die and a die. Hollow pipe, the cone angle θ of the cone die is 35°, the length-to-diameter ratio of the die is 11, and the extrusion speed is 100 cm / min;

[0028] c. Longitudinal stretching and sintering: stretch the treated polytetrafluoroethylene hollow tube longitudinally in an oven to form a polytetrafluoroethylene hollow fiber membrane, the stretching ratio is 0.5 times, and the oven temperature is 250°C;

[0029] d. The stretched polytetra...

Embodiment 2

[0032]a. Mixing: Select polytetrafluoroethylene dispersed resin powder with a molecular weight of 10 million, mix polytetrafluoroethylene resin powder and petroleum ether in a weight ratio of 1:0.40, and stand at 40°C for 60 hours to make the resin powder and petroleum ether Mix well, and sieve out larger powder particles;

[0033] b. Compaction and extrusion: The mixed polytetrafluoroethylene material is pressed into a cylindrical blank on a compactor, and the blank is extruded at 200°C through a pusher with a cone die and a die. Hollow tube, the extrusion speed is 300 cm / min, the cone angle θ of the cone die is 60°, and the length-to-diameter ratio of the die is 20;

[0034] c. Longitudinal stretching and sintering: longitudinally stretch the treated PTFE hollow tube in an oven to form a PTFE hollow fiber membrane, the stretching ratio is 2 times, and the oven temperature is 320°C;

[0035] d. The stretched polytetrafluoroethylene hollow fiber membrane was sintered and h...

Embodiment 3

[0038] a. Mixing: Select polytetrafluoroethylene dispersed resin powder with a molecular weight of 8 million, mix polytetrafluoroethylene resin powder and kerosene at a weight ratio of 1:0.30, and let stand at 30°C for 75 hours to fully mix the resin powder and kerosene , sieve to remove larger powder particles;

[0039] b. Compaction and extrusion: The mixed polytetrafluoroethylene material is pressed into a cylindrical blank on a compactor, and the blank is extruded at 150°C through a pusher with a cone die and a die. Hollow tube, the extrusion speed is 240 cm / min, the cone angle θ of the cone die is 45°, and the length-to-diameter ratio of the die is 15;

[0040] c. Longitudinal stretching and sintering: longitudinally stretch the treated PTFE hollow tube in an oven to form a PTFE hollow fiber membrane, the stretching ratio is 1 times, and the oven temperature is 300°C;

[0041] d. The stretched polytetrafluoroethylene hollow fiber membrane was sintered and heat-set in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com