Method for controlling micro-pore structure of polytetrafluoroethylene hollow fiber membrane

A polytetrafluoroethylene, microporous structure technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of hollow fiber membrane retention performance decline, unfavorable stability, reduced penetration pressure, etc. , to achieve the effect of increasing membrane efficiency, optimizing pore distribution, and improving filtration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

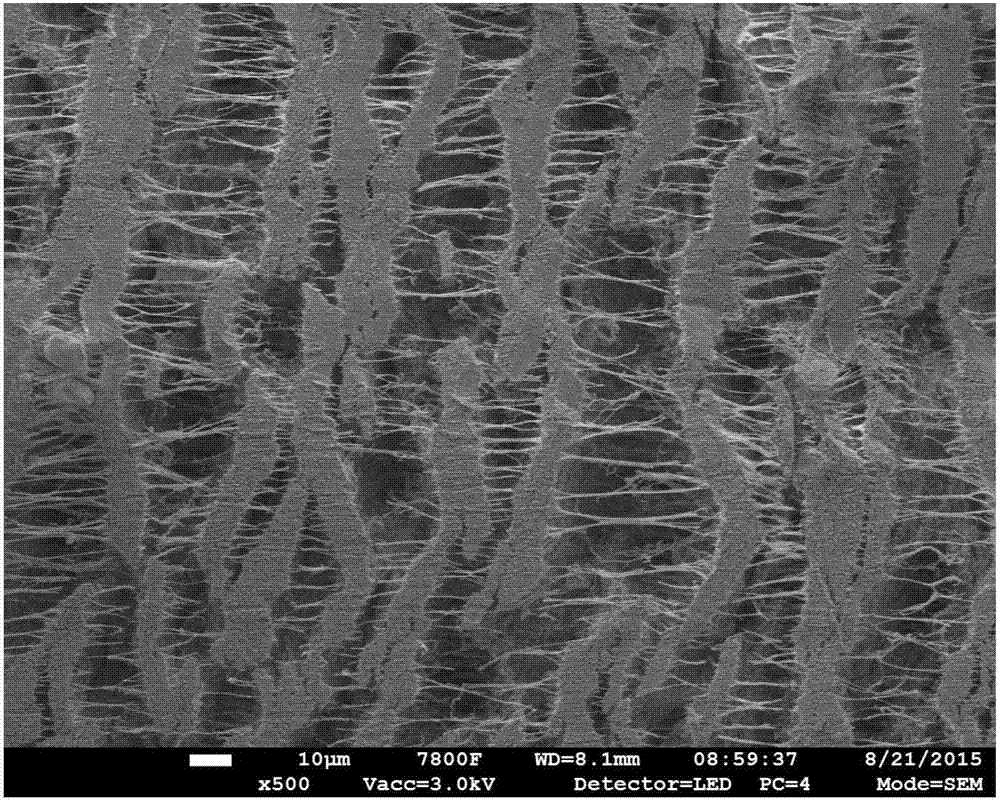

Embodiment 1

[0025] 1000g of polytetrafluoroethylene dispersion resin and 230g of lubricating aid aviation kerosene are fully mixed for later use. Then, the paste was stirred in an oscillating mixer for 15 minutes and left to mature for 24 hours. Sieve the fully matured paste and put it into the billet of the billet making machine. After the billet is extruded, the hollow primary fiber is obtained. The as-spun fiber was stretched 0.3 times at 30°C, and then stretched at 1500°C, the total stretching ratio was 3.0 times. The obtained hollow fiber membrane was heat-treated in a sintering furnace at 360° C. for 4 minutes to solidify its microstructure and obtain certain mechanical properties.

[0026] The obtained polytetrafluoroethylene hollow fiber membrane has a porosity of about 75%, an average pore diameter of about 0.3 μm, and a water contact angle of about 121°.

Embodiment 2

[0028] 1000g of polytetrafluoroethylene dispersion resin and 180g of petroleum ether, a lubricating aid, are fully mixed and set aside. Then, the paste was stirred in an oscillating mixer for 10 min and then left to mature for 36 h. Sieve the fully matured paste and put it into the billet of the billet making machine. After the billet is extruded, the hollow primary fiber is obtained. The as-spun fiber was stretched 0.6 times at 80°C, and then stretched at 280°C, the total stretching ratio was 2.5 times. The obtained hollow fiber membrane was heat-treated in a sintering furnace at 370° C. for 2 minutes to solidify its microstructure and obtain certain mechanical properties.

[0029] The obtained polytetrafluoroethylene hollow fiber membrane has a porosity of about 70%, an average pore diameter of about 0.25 μm, and a water contact angle of about 125°.

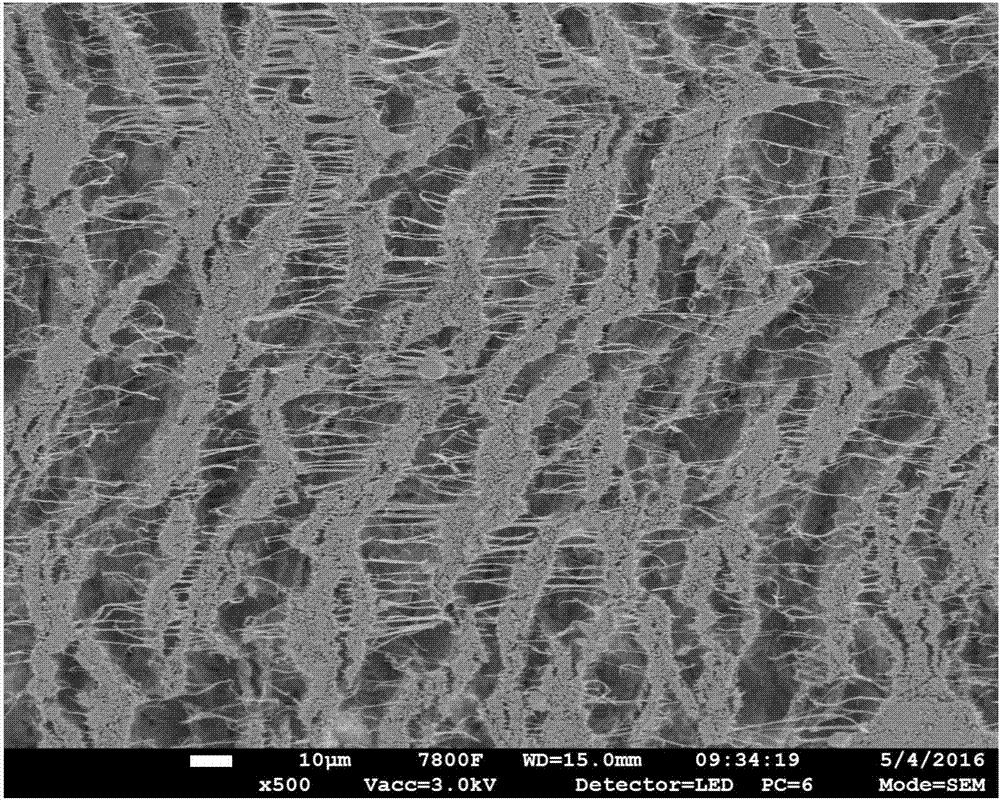

Embodiment 3

[0031] 1000g of polytetrafluoroethylene dispersion resin and 200g of lubricating aid isoparaffin are fully mixed for later use. Then, the paste was stirred in an oscillating mixer for 10 min and then left to mature for 48 h. Sieve the fully matured paste and put it into the billet of the billet making machine. After the billet is extruded, the hollow primary fiber is obtained. The as-spun fiber was stretched 0.5 times at 50°C, and then stretched at 200°C, the total stretching ratio was 2.0 times. The obtained hollow fiber membrane was heat-treated in a sintering furnace at 380° C. for 3 minutes to solidify its microstructure and obtain certain mechanical properties. The obtained polytetrafluoroethylene hollow fiber membrane has a porosity of about 65%, an average pore diameter of about 0.18 μm, and a water contact angle of about 118°. In addition, the as-spun fiber was stretched 2.0 times "one-stage" at 200°C, and other preparation parameters were the same as above, as a com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Static water contact angle | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com