Magnesia brick containing antioxidant C-TiN composite powder and method for preparing the same

A composite powder and anti-oxidant technology, which is applied in the field of carbon-containing refractory materials, can solve the problems of reducing the slag erosion resistance of products, achieve the effects of high hardness, prevent oxidation, and improve utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment 1

[0019] Magnesia-carbon bricks containing antioxidant "C-TiN composite powder" contain MgO 82%, C 12%, and TiN 3%.

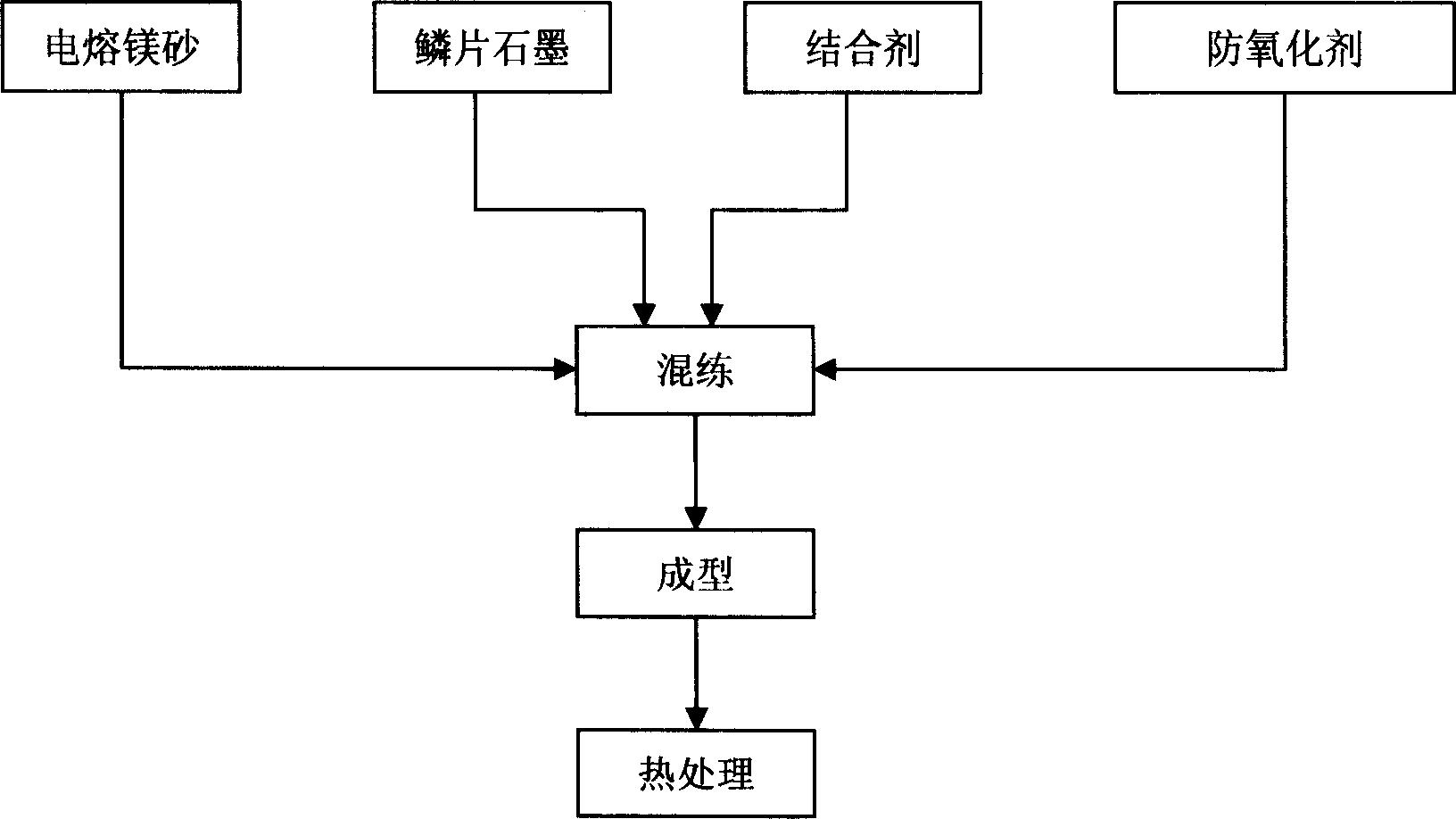

[0020] The production method of magnesia-carbon bricks containing antioxidant "C-TiN composite powder" includes raw material mixing, molding, and heat treatment. The formula of the magnesia-carbon bricks includes aggregate, matrix, binder and antioxidant. The weight percentages are as follows:

[0021] Fused magnesia 82~84%

[0022] Flake graphite 9~11%

[0023] Binder 2~4%

[0024] Antioxidant 3~5%

[0025] The MgO content of the fused magnesia mentioned therein is ≥97%, and the critical particle size is 5mm;

[0026] Wherein the flake graphite has a C content ≥ 97% and a particle size ≤ 0.15 mm;

[0027] Wherein said binding agent is a thermosetting phenolic resin with a residual carbon content ≥ 45%, which is liquid at normal temperature;

[0028] The antioxidant mentioned therein is C-TiN composite powder, in which TiN≥80%, C≤10%, TiO 2 ≤5%;

[0029] ...

Embodiment 2

[0031] The magnesia carbon brick containing antioxidant "C-TiN composite powder" contains MgO 81%, C 12%, TiN 1.5%, Al 1.5%.

[0032] The production method of magnesia-carbon bricks containing antioxidant "C-TiN composite powder" includes raw material mixing, molding, and heat treatment. The formula of the magnesia-carbon bricks includes aggregate, matrix, binder and antioxidant. The weight percentages are as follows:

[0033] Fused magnesia 82~84%

[0034] Flake graphite 9~11%

[0035] Binder 2~4%

[0036] Antioxidant 3~5%

[0037] The MgO content of the fused magnesia mentioned therein is ≥97%, and the critical particle size is 5mm;

[0038] Wherein the flake graphite has a C content ≥ 97% and a particle size ≤ 0.15 mm;

[0039] Wherein said binding agent is a thermosetting phenolic resin with a residual carbon content ≥ 45%, which is liquid at normal temperature;

[0040] Wherein the antioxidant comprises 60% of C-TiN composite powder and 40% of metal Al powder;

[0...

Embodiment 3

[0043] Magnesia-carbon bricks containing antioxidant "C-TiN composite powder" contain MgO 80-82%, C11-13%, TiN 0.5-2.5%, Al 0.5-2%, Si 0.5-2%.

[0044] The production method of magnesia-carbon bricks containing antioxidant "C-TiN composite powder" includes raw material mixing, molding, and heat treatment. The magnesia-carbon brick raw material formula includes aggregate, matrix, binder, and antioxidant. The weight percentages are as follows:

[0045] Fused magnesia 82~84%

[0046] Flake graphite 9~11%

[0047] Binder 2~4%

[0048] Antioxidant 3~5%

[0049] The MgO content of the fused magnesia mentioned therein is ≥97%, and the critical particle size is 5mm;

[0050] Wherein the flake graphite has a C content ≥ 97% and a particle size ≤ 0.15 mm;

[0051] Wherein said binding agent is a thermosetting phenolic resin, its residual carbon content is ≥ 45%, and it is liquid at normal temperature;

[0052] The antioxidant includes 30-50% of C-TiN composite powder, 20-40% of me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com