Corundum wearing-resistant plastic refractory and preparation method thereof

A technology that can be plasticized and corundum is applied in the field of refractory materials, which can solve the problems of poor wear resistance and high temperature stability, and achieve the effects of improving slag resistance, increasing service life and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A corundum wear-resistant and refractory plastic, which is composed of the following raw materials in mass percentage:

[0021] Corundum: 70.48%; Chrome corundum: 15%; Zircon: 8%; Alumina fine powder: 2%; Zirconium powder: 0.5%; Lanthanum and lanthanide metal oxide fine powder: 0.01%; Agent: 2%; Binder: 2%. The production steps are as follows:

[0022] (1) Fine grinding: send the corundum, chrome corundum and zircon into the pulverizer and fine grinder respectively, and pulverize until the particle diameter is less than 1mm;

[0023] (2) Premixing: send the finely ground corundum, chrome corundum and zircon and alumina micropowder in step (1) into a sand mixer in proportion to premix for 8 minutes;

[0024] (3) Mixing: add the dispersant to the premixed raw materials in step (2), mix in the sand mixer for 20 minutes; add zirconium powder, lanthanum and lanthanide metal oxide micropowder and yttrium powder, Mix within 20 minutes; add binder and mix for 20 minutes to m...

Embodiment 2

[0028] A corundum wear-resistant and refractory plastic, which is composed of the following raw materials in mass percentage:

[0029] Corundum: 70.4%; Chrome corundum: 15%; Zircon: 8%; Alumina fine powder: 2%; Zirconium powder: 0.5%; Lanthanum and lanthanide metal oxide fine powder: 0.05%; Agent: 2%; Binder: 2%.

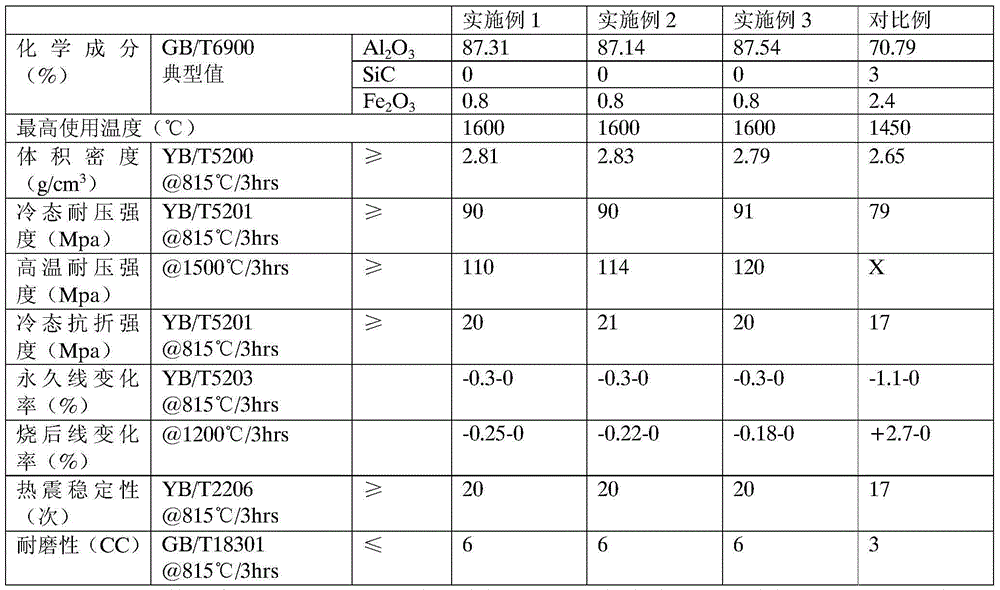

[0030] The production steps are substantially the same as in Example 1. After completion, 10 samples were randomly sampled for high-temperature performance test, and the results are shown in Table 1.

Embodiment 3

[0032] A corundum wear-resistant and refractory plastic, which is composed of the following raw materials in mass percentage:

[0033] Corundum: 70.3%; Chrome corundum: 15%; Zircon: 8%; Alumina fine powder: 2%; Zirconium powder: 0.5%; Lanthanum and lanthanide metal oxide fine powder: 0.1%; Agent: 2%; Binder: 2%.

[0034] The production steps are substantially the same as in Example 1. After completion, 10 samples were randomly sampled for high-temperature performance test, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com