Refractory castable for producing air blowing assisted slagging-off spray gun

A technology for refractory castable and slag removal is applied in the field of refractory materials for molten iron pretreatment before converter steelmaking, which can solve the problems of reducing the production efficiency of molten iron pretreatment process, increasing labor intensity of workers, frequent maintenance and replacement, etc. Mechanical properties and slag resistance, the effect of improving mechanical properties and slag resistance, improving high temperature performance and thermal shock stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

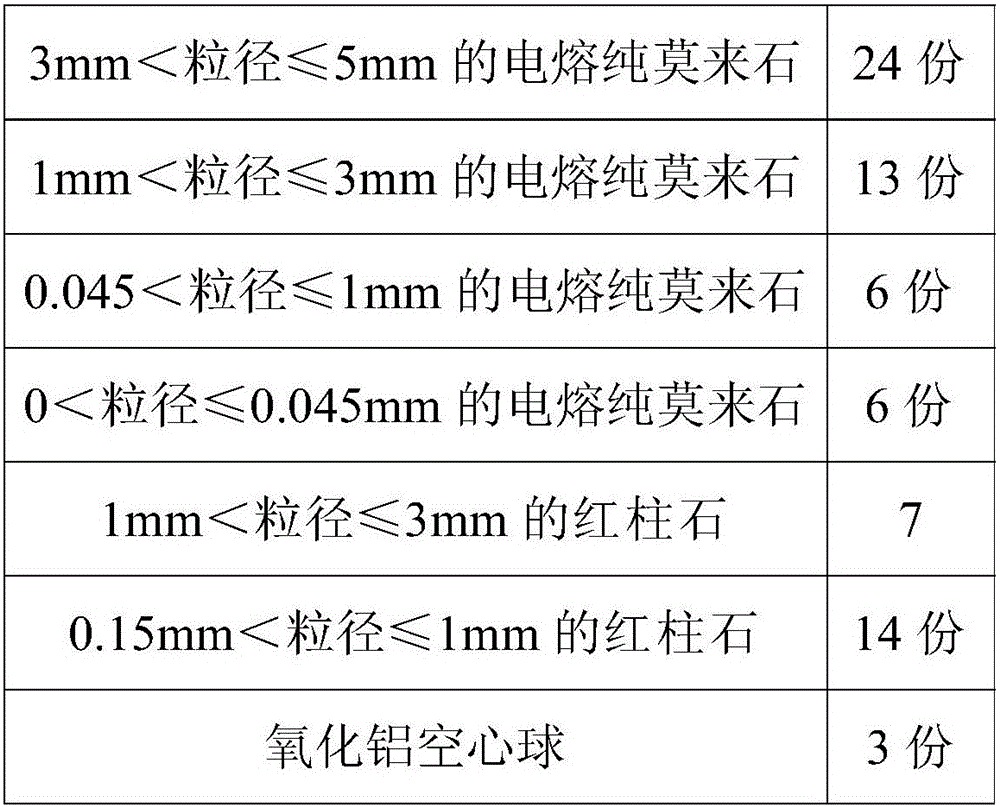

[0031] The components of the refractory castable 1 for the molten iron blowing auxiliary slag removal top blowing spray gun are as follows in parts by weight:

[0032]

[0033]

[0034] A batch of air blowing auxiliary slag removal spray guns were prepared by casting, and a comparative test was carried out in a steelmaking plant. The test results showed that the average service life of the auxiliary slag removal spray guns prepared with refractory castable 1 was 15 times longer than that of conventional spray guns.

Embodiment 2

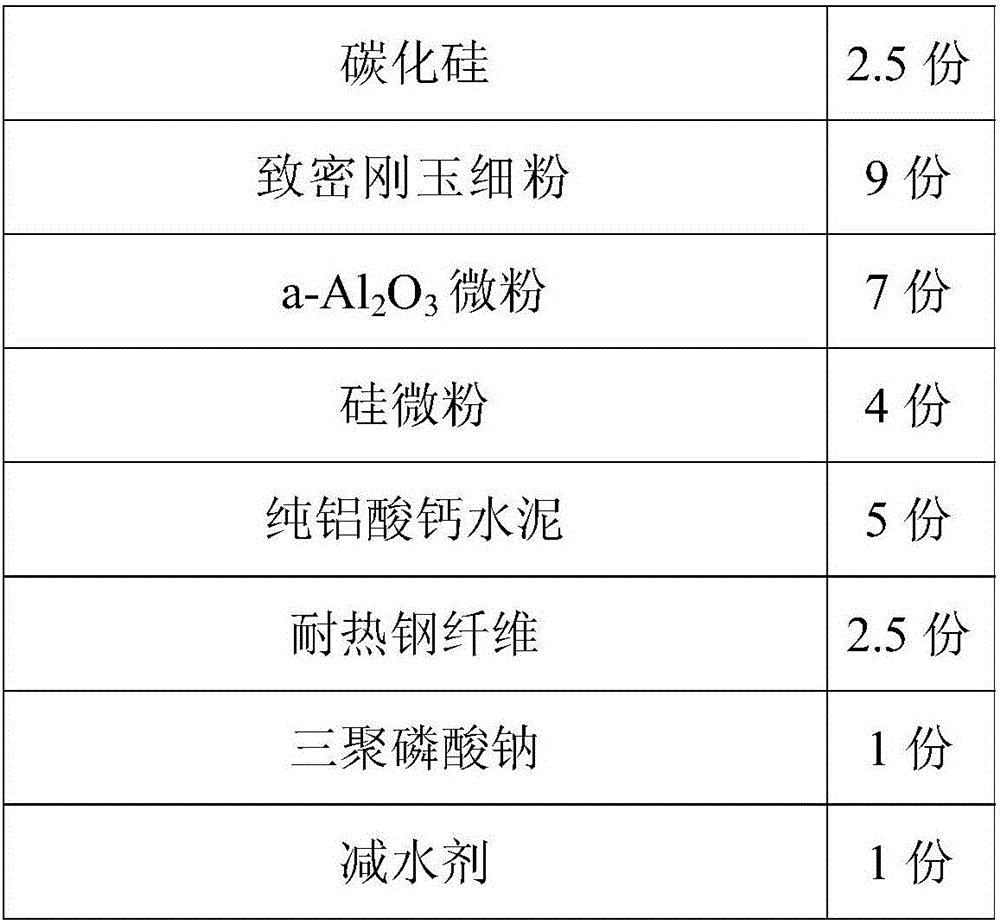

[0036] The parts by weight of the two components of the refractory castable for the molten iron blowing assisted slag removal top blowing spray gun are:

[0037]

[0038]

[0039]A batch of air blowing auxiliary slag removal spray guns were prepared by casting, and a comparative test was carried out in a steelmaking plant. The test results showed that the average service life of the auxiliary slag removal spray guns prepared with refractory castable 2 was 10 times longer than that of conventional spray guns.

Embodiment 3

[0041] The percentage by weight of the refractory castable component 3 for the molten iron blowing auxiliary slag removal top blowing spray gun is:

[0042]

[0043]

[0044] A batch of air blowing auxiliary slag removal spray guns were prepared by casting, and a comparative test was carried out in a steelmaking plant. The test results showed that the average service life of the auxiliary slag removal spray guns prepared with refractory castable 3 was 5 times longer than that of conventional spray guns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com