Multi-component water-coal-slurry additive

A coal-water slurry and additive technology, applied in the field of coal-water slurry additives, can solve problems such as narrow range, low stability, and poor adaptability of coal types, and achieve the effects of improving fluidity, improving wettability, and preventing coalescence

Inactive Publication Date: 2015-07-29

XIAN BAYER COMPOSITE MATERIAL CO LTD

View PDF2 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, there are still problems of narrow applicable coal types and high cost

[0012] Therefore, for the above-mentioned problems that most additives cannot solve, such as high price, poor adaptability to coal types, low stability, etc., the development of CWS additives with high cost performance and wide adaptability to coal types can promote the development of CWS. Improve the economic efficiency of the enterprise

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

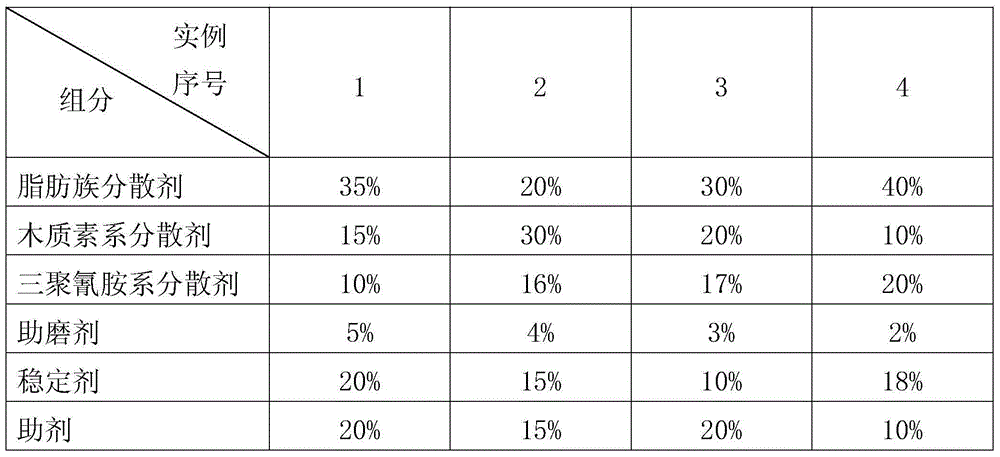

Embodiment 1-4

[0026] The distribution ratio of each group is as follows (by weight percentage)

[0027]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the technical field of additives, and particularly discloses a multi-component water-coal-slurry additive. The additive comprises the following components in percentage by weight: 30 to 50 percent of an aliphatic dispersant, 10 to 30 percent of a lignin-based dispersant, 10 to 20 percent of a melamine dispersant, 2 to 5 percent of a grinding aid, 10 to 20 percent of a stabilizing agent, and 5 to 10 percent of an auxiliary agent. The additive is low in dosage and high in efficiency, and the prepared water coal slurry is low in surface viscosity, high in concentration and good in stability; as the additive can be applied to coals with different metamorphic grades, the additive has wide applicability.

Description

technical field [0001] The invention relates to the technical field of additives, in particular to a coal water slurry additive. Background technique [0002] As one of the clean coal technologies, coal-water slurry gasification has been widely used in China after years of continuous scientific and technological research and production practice since its research and development in the early 1980s, and its production and application scale rank first in the world. High-concentration coal-water slurry not only maintains the original physical and chemical properties of coal, but also has good fluidity and stability like petroleum, and its safety is better than petroleum. Coal-water slurry, as an ideal fuel-saving fuel substitute, has received widespread attention from all over the world as soon as it appeared. With the rapid expansion of the coal chemical industry led by coal-water slurry gasification, the application scale of gasified coal-water slurry will maintain a strong ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10L1/24C10L1/188C10L1/196C10L1/195C10L1/12C10L1/10C10L1/32

Inventor 高德华

Owner XIAN BAYER COMPOSITE MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com