Polyvinylidene fluoride-hexafluoropropylene super-hydrophobic composite film and preparation method thereof

A technology of polyvinylidene fluoride and hexafluoropropylene, which is applied in the field of superhydrophobic composite membrane preparation, can solve the problems of high preparation cost, easy to form defects, insufficient mechanical strength of superhydrophobic membrane, etc., and achieve high mechanical strength, stable performance, Effect of good superhydrophobicity and self-cleaning function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

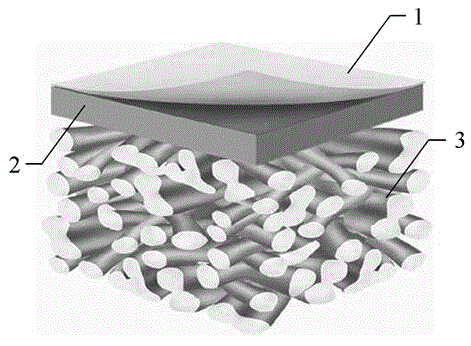

[0030] A method for preparing a polyvinylidene fluoride-hexafluoropropylene superhydrophobic composite membrane according to the present invention, the composite membrane includes a non-woven fabric layer 3, a hydrophobic support layer 2 and a superhydrophobic layer 1, and the preparation steps are as follows:

[0031] 1) Dissolve the dry organic polymer in an organic solvent, add a certain amount of small molecule additives, stir and dissolve evenly at constant temperature. Let stand at room temperature for 18-24 hours for degassing to fully ripen. The organic polymer is one or more of polyvinylidene fluoride (PVDF), polysulfone (PS), polyethersulfone (PES), polyvinyl chloride (PVC), polyetherimide (PEI) ; The organic solvent is dimethylsulfoxide (DMSo), dimethylformamide (DMF), dimethylacetamide (DMAc), triethyl phosphate (TEP), N-methylpyrrolidone (NMP) One or more of them; the content of the organic polymer in the organic solvent is 10-30% (percentage by weight and volume...

Embodiment 1

[0035] The preparation method of the superhydrophobic composite membrane of the present embodiment comprises the following steps:

[0036] a. Dissolve 25 g of dry PES in 74 ml of NMP solvent, add 1 g of PEG200, and stir in a magnetic stirrer at 50°C for 8 hours. Let it stand at room temperature for 21 hours for defoaming to fully ripen it. Use a scraper with a thickness of 300 μm to evenly scrape and coat the casting solution on the surface of the non-woven fabric, leave it in the air for 5 s, and then immerse it in pure water at 22°C. After 20 s of instantaneous phase separation, fully rinse and dry at room temperature Obtained an asymmetric organic hydrophobic ultrafiltration membrane with a contact angle of 87° and a pore size of 0.08 μm;

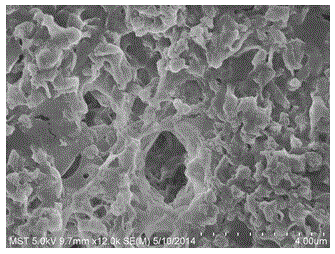

[0037] b. Dissolve 2 g of dry PVDF-HFP in 18 ml of NMP, stir and dissolve evenly at a constant temperature of 50°C, and defoam for 24 hours. Use a scraper with a thickness of 100 μm to scrape and coat the casting solution on the surface ...

Embodiment 2

[0039] a. Dissolve 16 g of dry PS in 83 ml of NMP solvent, add 1 g of PEG600, and stir in a magnetic stirrer at 50°C for 12 hours. Let it stand at room temperature for 18 hours for defoaming to fully mature. Use a scraper with a thickness of 250 μm to evenly apply the casting solution on the surface of the non-woven fabric, leave it in the air for 5 s, and then immerse it in pure water at 22°C. After 20 s of instantaneous phase separation, fully rinse and dry at room temperature Obtained an asymmetric organic hydrophobic microfiltration membrane with a contact angle of 86° and a pore size of 0.20 μm;

[0040] b. Dissolve 1 g of dry PVDF-HFP in 19 ml of DMAc, stir and dissolve evenly at a constant temperature of 50°C, and defoam for 24 hours. Use a scraper with a thickness of 100 μm to scrape and coat the casting solution on the surface of the hydrophobic base film in step a. After staying in the air for 10 s, immerse it in an ethanol solution at 22°C. After 30 s of delayed ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com