Anti-fingerprint antibacterial glass

An antibacterial glass and anti-fingerprint technology, applied in antifouling/underwater coatings, paints containing biocides, coatings, etc., can solve the problems of scratching and abrasion of the antibacterial film layer, reducing the strength of the glass, reducing the antibacterial effect, etc. Achieve the effect of improving antibacterial effect, reducing yellowing and strong antibacterial ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

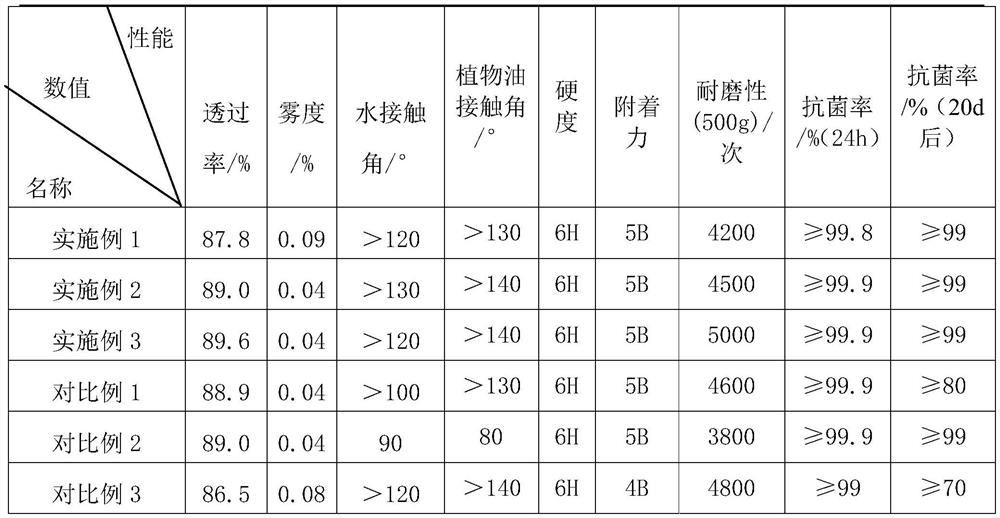

Examples

Embodiment 1

[0033] An anti-fingerprint antibacterial glass and a preparation method thereof, comprising an original glass sheet and an anti-fingerprint antibacterial film covering the upper surface of the original glass sheet. 8% permanent acrylic resin, 60% toluene, 25% dichloromethane, 7% ethanol dispersion of 0.5wt% fluorinated silver-loaded carbon nanohorn.

[0034] A preparation method of fluorinated silver-loaded carbon nanohorn ethanol dispersion comprises the following steps:

[0035] 1) Carboxylation modification of single-walled carbon nanohorns (SWNHs), disperse 100 mg of SWNHs into 150 ml of nitric acid solution and reflux at 120 °C for 24 h to obtain carboxylated SWNHs, wash with deionized water several times and then vacuum dry at 90 °C .

[0036] 2) Disperse 0.2g of carboxylated carbon nanohorns in 40ml of methanol solution and mix evenly, add 2ml of perfluorooctyltrimethylsilane, stir at room temperature for 16h, heat to 120°C and continue stirring for 1h to obtain fluori...

Embodiment 2

[0044]An anti-fingerprint antibacterial glass and a preparation method thereof, comprising an original glass sheet and an anti-fingerprint antibacterial film covering the upper surface of the original glass sheet. 5% permanent acrylic resin, 68% toluene, 22.5% dichloromethane, 4.5% ethanol dispersion of 0.5wt% fluorinated silver-loaded carbon nanohorn.

[0045] A preparation method of fluorinated silver-loaded carbon nanohorn ethanol dispersion comprises the following steps:

[0046] 1) Carboxylation modification of single-walled carbon nanohorns (SWNHs), disperse 100 mg of SWNHs into 150 ml of nitric acid solution and reflux at 120 °C for 24 h to obtain carboxylated SWNHs, wash with deionized water several times and then vacuum dry.

[0047] 2) Disperse 0.2g of carboxylated carbon nanohorns in 40ml of methanol solution and mix evenly, add 2ml of perfluorooctyltrimethylsilane, stir at room temperature for 18h, heat to 140°C and continue stirring for 1h to obtain fluorinated mo...

Embodiment 3

[0054] An anti-fingerprint antibacterial glass and a preparation method thereof, comprising an original glass sheet and an anti-fingerprint antibacterial film covering the upper surface of the original glass sheet. 5.5% permanent acrylic resin, 72% toluene, 17.7% dichloromethane, 4.8% ethanol dispersion of 0.5wt% fluorinated silver-loaded carbon nanohorn.

[0055] A preparation method of fluorinated silver-loaded carbon nanohorn ethanol dispersion comprises the following steps:

[0056] 1) Carboxylation modification of single-walled carbon nanohorns (SWNHs), disperse 100 mg of SWNHs into 150 ml of nitric acid solution and reflux at 120 °C for 24 h to obtain carboxylated SWNHs, wash with deionized water several times and then vacuum dry.

[0057] 2) Disperse 0.2g of carboxylated carbon nanohorns in 40ml of methanol solution and mix evenly, add 2ml of perfluorooctyltrimethylsilane, stir at room temperature for 24h, heat to 130°C and continue stirring for 1h to obtain fluorinated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com